In the world of crafting, maintaining your stitching device is crucial for achieving the best results. Whether you’re a novice or an experienced enthusiast, familiarizing yourself with the inner workings of your equipment can enhance your creativity and efficiency. A well-functioning machine not only saves time but also elevates the quality of your projects.

Comprehending the nuances of your specific model empowers you to tackle minor issues independently, transforming potential setbacks into learning experiences. This knowledge allows for a deeper connection with your tool, ensuring it remains a reliable partner in your sewing endeavors.

Through this guide, you will explore essential techniques and tips for preserving your machine’s performance. From routine maintenance to troubleshooting common challenges, each section is designed to equip you with the insights needed to keep your creative journey uninterrupted and enjoyable.

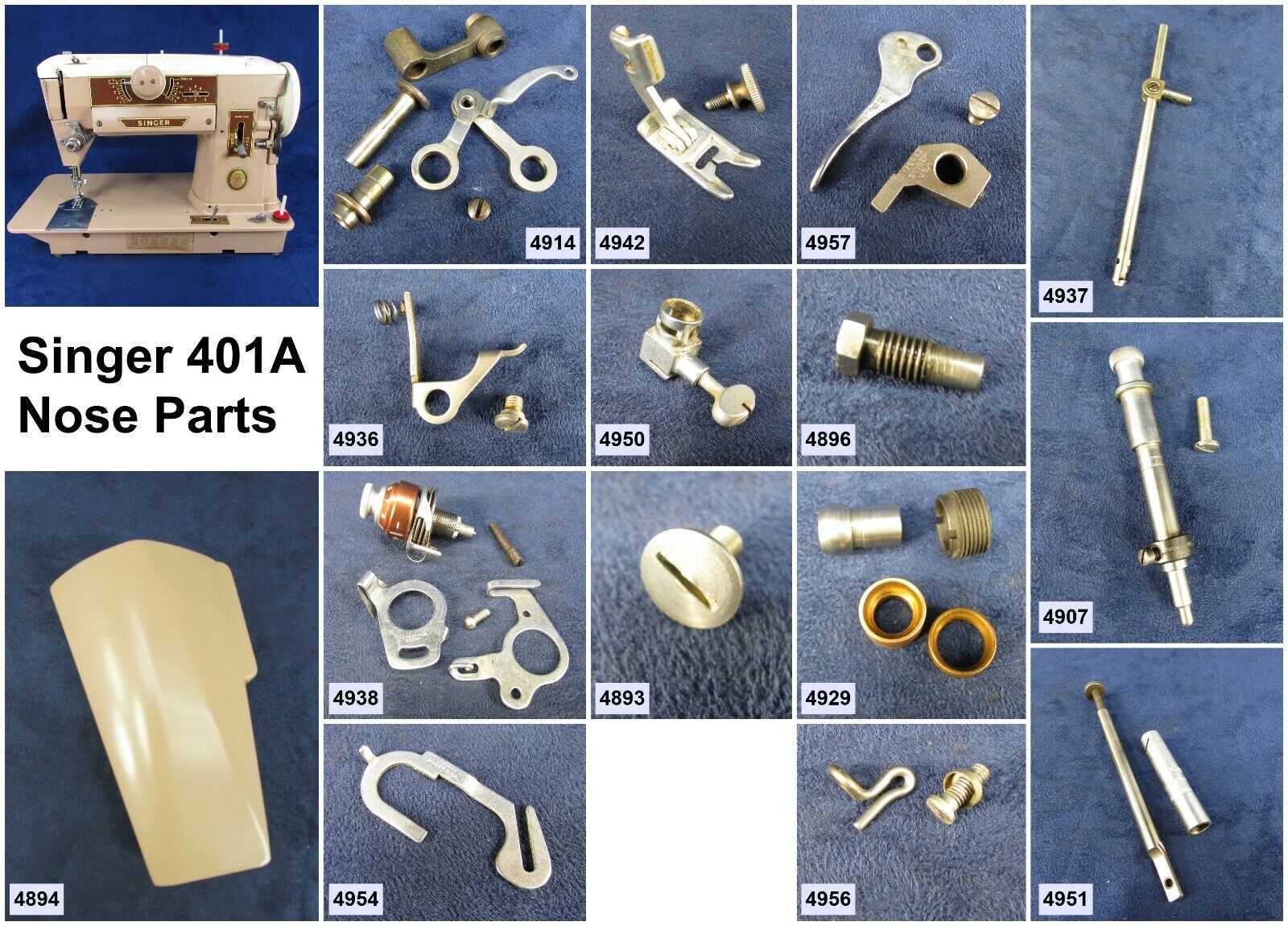

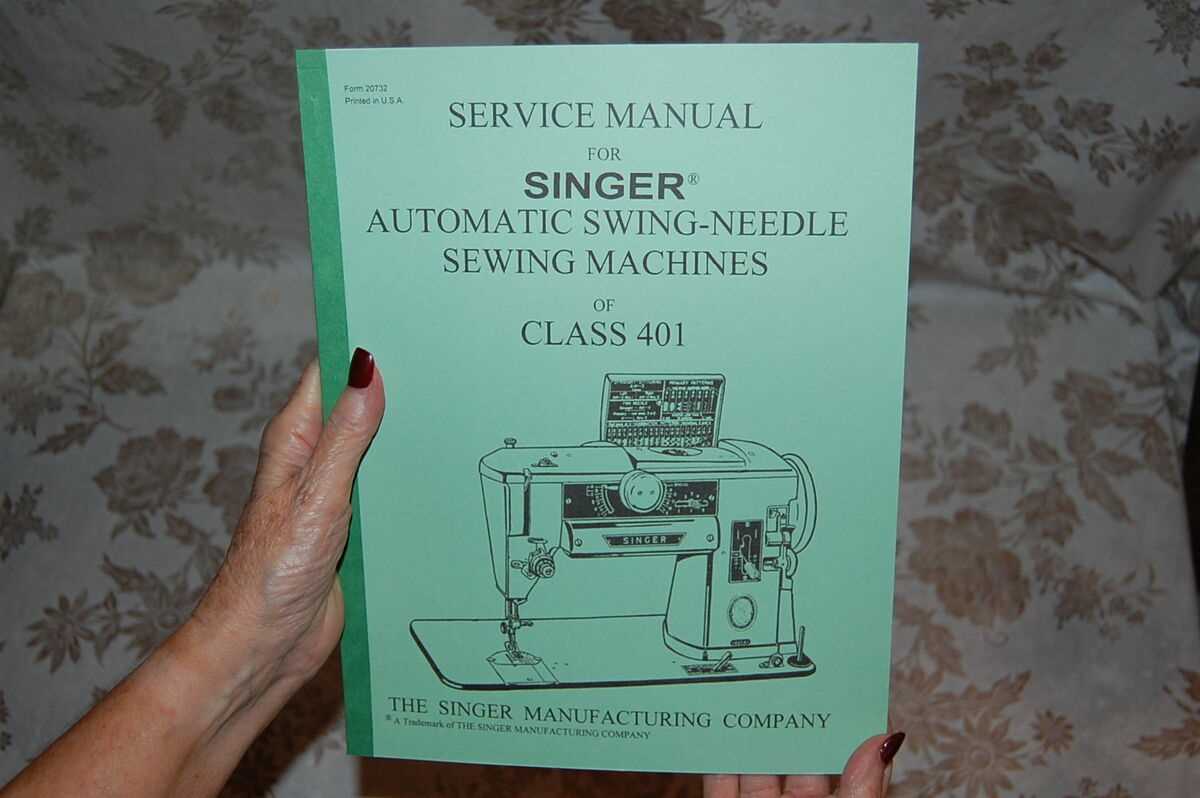

Singer 401A Overview

This section provides an insightful examination of a notable sewing machine that has garnered attention for its performance and versatility. Designed with both amateur and experienced crafters in mind, this model stands out due to its robust features and user-friendly interface.

Key characteristics include:

- Stitch Variety: Offers a wide range of stitch options, allowing for creative expression in various projects.

- Durability: Built with high-quality materials that ensure longevity and reliability in use.

- Ease of Use: Simple controls and mechanisms make it accessible for users of all skill levels.

- Powerful Motor: Equipped with a strong motor that handles multiple fabric types with ease.

Additionally, this machine is recognized for:

- Design: Classic aesthetic that appeals to both vintage enthusiasts and modern users.

- Maintenance: Designed for straightforward upkeep, contributing to its lasting performance.

- Community: A vibrant community of users who share tips, techniques, and support.

Overall, this machine represents a blend of tradition and innovation, making it a beloved choice among sewing enthusiasts around the world.

Common Issues with Singer 401A

When it comes to vintage sewing machines, several recurring problems can arise, impacting their performance and usability. Understanding these common challenges can help users maintain and troubleshoot their devices effectively.

- Thread Jamming: One of the most frequent issues is thread jams, often caused by incorrect threading or using incompatible thread types.

- Needle Breakage: This can occur due to improper installation, using the wrong needle type, or sewing through thick materials without the right settings.

- Skipping Stitches: Skipped stitches can result from dull needles, incorrect tension settings, or issues with the feed mechanism.

- Tension Problems: Uneven tension can lead to puckering or loose stitches, often necessitating adjustments to the tension settings.

- Motor Malfunctions: Electrical issues or worn-out parts may cause the machine to stop functioning, requiring thorough inspection of the motor and connections.

Addressing these common problems promptly can enhance the longevity and efficiency of your sewing equipment, ensuring a smooth and enjoyable sewing experience.

Tools Required for Repairs

When undertaking maintenance tasks on your sewing device, having the right equipment is crucial for achieving optimal results. The following tools will assist you in diagnosing issues and performing necessary adjustments effectively.

Essential Equipment

- Screwdrivers: A set of both flat-head and Phillips screwdrivers is necessary for accessing internal components.

- Wrenches: Various sizes will help in loosening and tightening bolts.

- Needle-nose pliers: Ideal for gripping small parts and reaching tight spaces.

- Scissors: Sharp fabric scissors are essential for cutting threads and fabrics cleanly.

- Cleaning brushes: Small brushes help remove lint and debris from hard-to-reach areas.

Additional Tools

- Lubricants: High-quality sewing machine oil keeps moving parts functioning smoothly.

- Multimeter: Useful for checking electrical components and diagnosing electrical issues.

- Measuring tape: Ensures accurate measurements for adjustments or replacements.

- Flashlight: A bright light can illuminate dark spaces within the machine.

- Magnifying glass: Helpful for examining small parts and intricate mechanisms closely.

Equipping yourself with these tools will enhance your ability to maintain and fine-tune your sewing apparatus effectively.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your sewing machine remains in optimal condition. Regular upkeep can enhance performance and longevity, allowing you to enjoy sewing without interruptions.

- Gather Tools:

- Screwdriver

- Cleaning brush

- Oiling lubricant

- Soft cloth

- Unplug the Machine:

Always ensure the machine is disconnected from power before starting any maintenance work.

- Clean the Exterior:

Wipe down the surface using a soft cloth to remove dust and debris.

- Remove and Clean the Bobbin Area:

Take out the bobbin and casing, and use a brush to clear out lint and dust.

- Check the Needle:

Inspect the needle for any signs of damage or dullness and replace it if necessary.

- Oil the Machine:

Apply lubricant to the designated areas as per the manufacturer’s guidelines.

- Reassemble and Test:

Put everything back together, plug in the machine, and run a test stitch to ensure everything operates smoothly.

Cleaning the Machine Components

Maintaining the internal parts of your sewing device is essential for optimal performance and longevity. Regular cleaning helps prevent dust and debris from accumulating, which can interfere with functionality and lead to more significant issues down the line.

To effectively clean the machine components, follow these steps:

- Gather necessary tools and materials:

- Soft brush or lint brush

- Microfiber cloth

- Screwdriver set

- Vacuum cleaner with a small nozzle attachment

- Lubricant appropriate for sewing machines

cssCopy code

By routinely cleaning your sewing machine’s components, you enhance its efficiency and extend its lifespan. Make this a regular part of your maintenance routine to ensure smooth operation and reliable results in your sewing projects.

Threading the Singer 401A Correctly

Properly threading your sewing machine is essential for achieving smooth and flawless stitches. A well-threaded machine not only enhances the quality of your sewing but also minimizes the risk of jams and thread breaks. This section will guide you through the correct process of threading to ensure optimal performance.

Step-by-Step Threading Guide

- Start with the spool of thread positioned on the spool pin.

- Guide the thread through the thread guide above the needle.

- Wrap the thread around the tension disc, ensuring it fits snugly.

- Pull the thread down through the take-up lever.

- Continue to thread down towards the needle area, following the designated path.

- Finally, thread the needle from front to back, making sure the thread is secure.

Troubleshooting Common Issues

- Skipped Stitches: Check if the thread is properly seated in the tension disc.

- Jamming: Ensure that the thread path is clear and free of tangles.

- Uneven Tension: Adjust the tension dial for better control.

Following these steps will help you achieve optimal threading for your machine, leading to a more enjoyable sewing experience.

Replacing the Needle Properly

Ensuring optimal performance of your sewing device often begins with a simple yet crucial task: changing the needle. This component plays a vital role in achieving clean and precise stitches, making it essential to know the correct method for replacement. Following the right steps can prevent issues such as skipped stitches or fabric damage.

Tools Needed

- New sewing needle

- Screwdriver (if required)

- Fabric or thread for testing

Step-by-Step Instructions

- Turn off the machine to ensure safety during the process.

- Remove the presser foot to gain better access to the needle area.

- Loosen the needle clamp by turning it counterclockwise.

- Carefully pull the old needle out and discard it properly.

- Take the new needle and insert it with the flat side facing the back of the machine.

- Secure the needle by tightening the clamp screw until snug.

- Reattach the presser foot and ensure it is locked in place.

- Turn on the machine and perform a test stitch to confirm proper installation.

Regularly changing the needle can greatly enhance the quality of your sewing projects. Always ensure that the needle is compatible with your fabric type and thickness to achieve the best results.

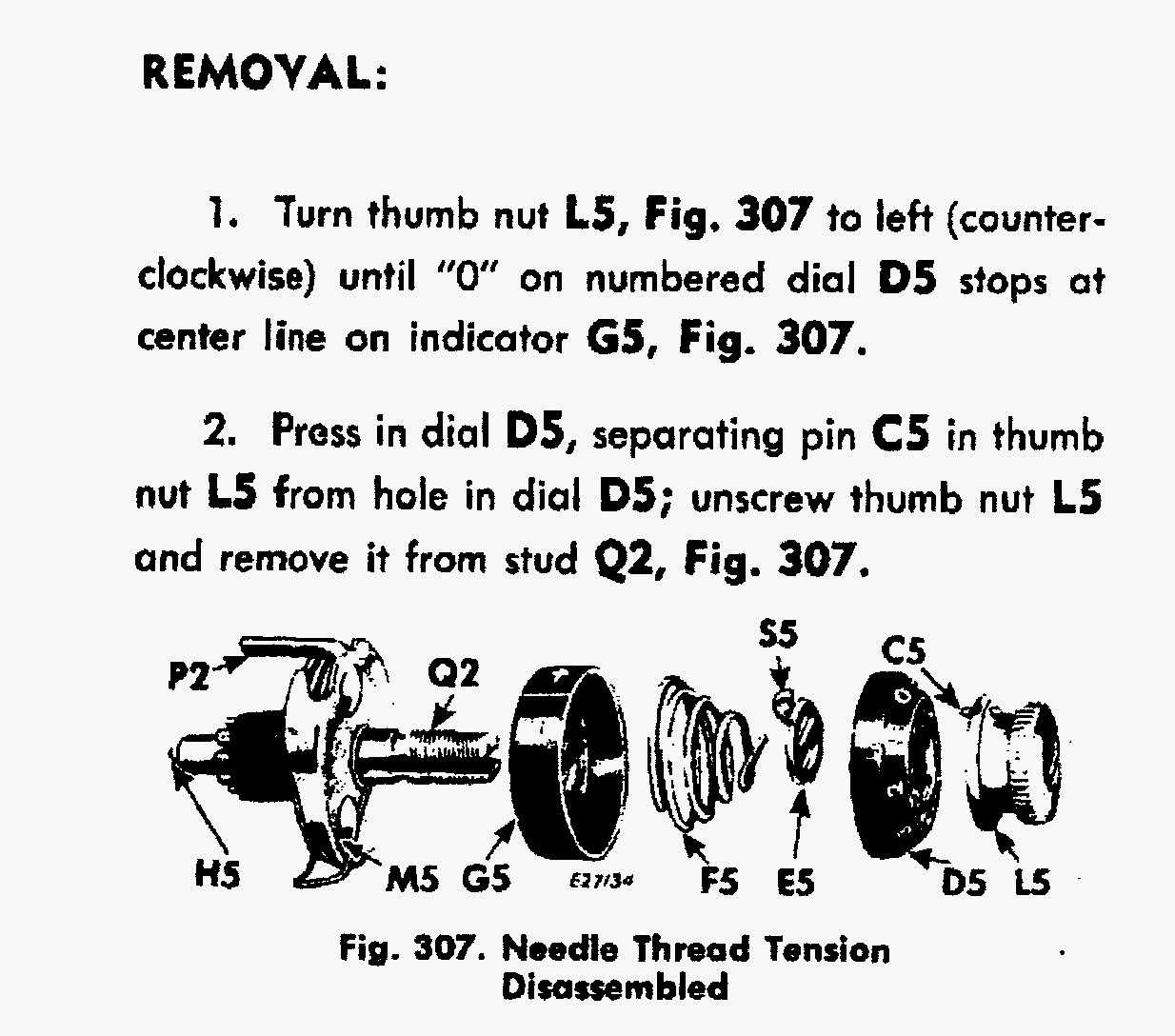

Adjusting Tension Settings Effectively

Achieving optimal stitch quality is crucial for any sewing project. One of the key factors that influence the final result is the balance of tension in your sewing machine. Proper adjustments can help prevent issues such as puckering, thread breakage, and uneven stitches, ensuring that your fabric is sewn together smoothly and evenly.

To effectively adjust tension settings, follow these essential steps:

- Understand the Components: Familiarize yourself with the tension mechanisms on your machine. Knowing which dial or lever controls the upper and lower threads will help you make precise adjustments.

- Check Thread Type: Use the appropriate thread for your fabric. Different materials may require varying tension settings. Always consult the thread manufacturer’s recommendations.

- Test Stitches: Before starting your main project, sew a few test stitches on a scrap piece of the same fabric. This will allow you to observe how the tension settings affect the stitch quality.

When adjusting the tension, consider the following tips:

- Upper Thread: If the upper thread is too loose, you may notice loops on the underside of your fabric. Conversely, if it’s too tight, the top stitches will pull the fabric, creating puckers.

- Lower Thread: A loose lower thread will create visible knots on the top, while a tight lower thread can lead to thread breakage or uneven tension.

- Incremental Changes: Make small adjustments to the tension settings, and always test sew after each change to observe the impact.

Finally, keep in mind that different projects may require different settings. Regularly revisiting and fine-tuning your tension will help maintain the quality of your sewing endeavors, allowing you to achieve professional-looking results every time.

Oil and Lubrication Tips

Maintaining the longevity and efficiency of your sewing machine hinges on proper oiling and lubrication. Regularly applying the right type of lubricant not only ensures smooth operation but also helps prevent wear and tear on crucial components.

Choose the Right Oil: Select a high-quality sewing machine oil specifically designed for delicate mechanisms. Avoid using general-purpose oils, as they can attract dust and debris, leading to potential damage.

Know Where to Apply: Focus on key areas such as the needle bar, presser foot, and any moving parts that experience friction. A few drops in these locations can significantly enhance performance.

Frequency Matters: Establish a routine for lubrication based on usage. Machines that see regular action may require more frequent oiling, while those used sporadically can be maintained with less regularity.

Wipe Away Excess: After applying oil, it’s crucial to wipe away any excess. This prevents buildup that can impede function and create a sticky residue over time.

Stay Informed: Refer to your device’s guidelines for specific lubrication recommendations. Understanding the needs of your equipment will help maintain its efficiency and reliability.

Fixing Motor and Electrical Problems

Addressing issues related to motors and electrical systems is crucial for ensuring optimal performance and longevity of your device. Common symptoms such as unusual noises, inconsistent operation, or complete failure can often be traced back to specific components within the electrical framework. Understanding how to diagnose and resolve these concerns will enhance your troubleshooting skills and minimize downtime.

Identifying Electrical Issues

Begin by inspecting the power source. Ensure that the device is properly plugged in and that the outlet is functional. A multimeter can be invaluable for checking voltage levels and continuity in the electrical circuit. Look for any signs of wear or damage to wires and connectors, as these can disrupt the flow of electricity.

Motor Troubleshooting

If the motor is not operating correctly, it may be due to a lack of lubrication or accumulated debris. Clean the motor components thoroughly and apply appropriate lubricant to reduce friction. Additionally, check the motor brushes; worn or damaged brushes can prevent the motor from running smoothly. Replacing them when necessary can restore functionality.

Overheating Concerns

Overheating can indicate that the motor is under strain or that ventilation is inadequate. Ensure that any vents are clear of obstructions and consider using a cooling fan if the device operates in a high-temperature environment. If overheating persists, further investigation into the motor’s load and efficiency may be warranted.

By systematically diagnosing electrical and motor-related issues, you can effectively restore functionality and extend the lifespan of your equipment. Regular maintenance and awareness of potential problems will lead to a more reliable operation and greater satisfaction in usage.

Understanding Stitch Options Available

When exploring the variety of stitching techniques offered by modern sewing machines, it becomes evident that each option serves a unique purpose and contributes to the overall aesthetic and functionality of the final project. The ability to select different stitch patterns not only enhances creativity but also allows for precision in crafting various fabrics and designs.

Basic Stitches are the foundation of sewing, typically including straight and zigzag stitches. These options are essential for constructing seams and finishing edges. They provide durability and versatility, making them suitable for a wide range of materials.

Decorative Stitches elevate projects by adding visual interest. These can include intricate patterns such as scallops, flowers, or waves, allowing for customization and personal expression. Utilizing these stitches can transform a simple piece into a work of art.

Stretch Stitches are specifically designed for knit fabrics. They maintain the elasticity of the material, ensuring that the seams can stretch without breaking. This is particularly important for garments that require movement and comfort.

Utility Stitches encompass a variety of specialized options such as blind hems or overlock stitches, each serving specific functions in finishing and securing edges. These stitches are vital for achieving professional-looking results and enhancing the durability of garments.

Understanding the range of stitching options available empowers creators to make informed choices that suit their sewing projects. Experimenting with these various techniques can lead to innovative designs and improved sewing skills.

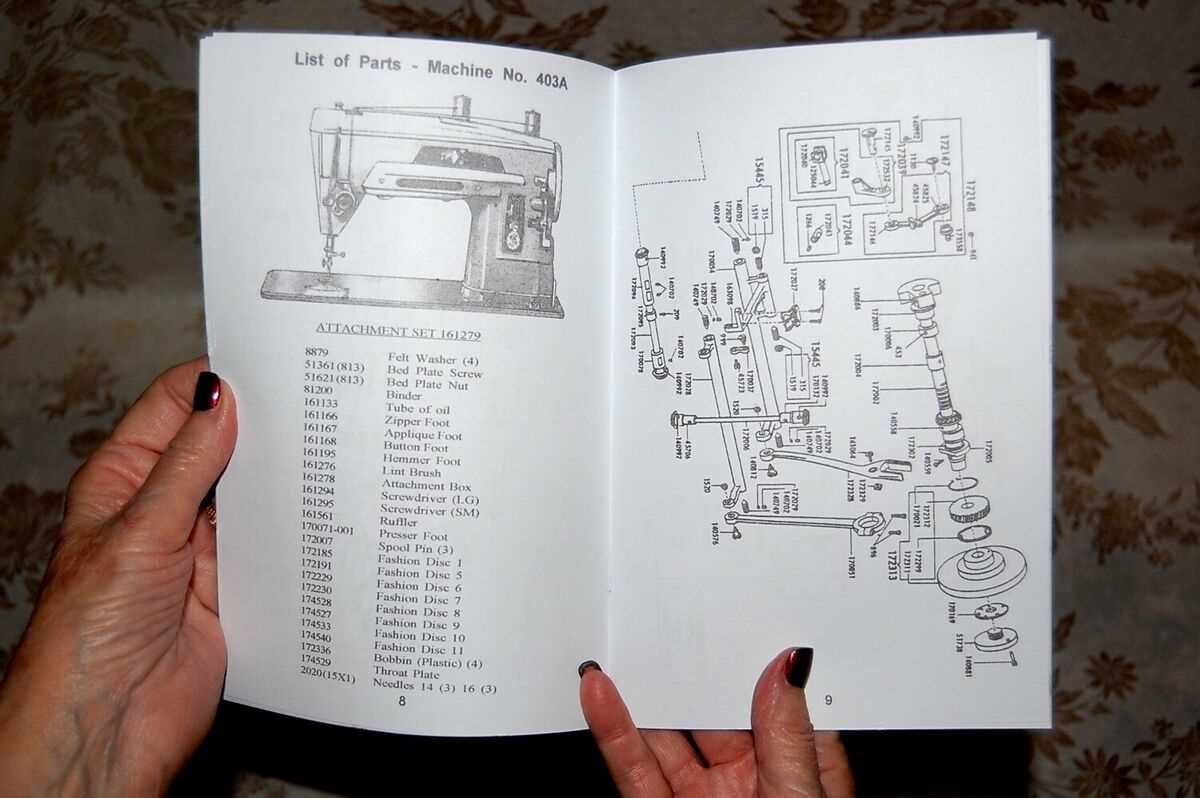

Resources for Replacement Parts

Finding the right components for your sewing machine can be essential for maintaining its performance and longevity. Whether you are looking for specific gears, belts, or other essential elements, a variety of resources are available to assist you in sourcing high-quality replacement items.

Online Marketplaces

- eBay: A great platform for both new and used parts, often at competitive prices.

- Amazon: Offers a wide range of components with customer reviews to guide your choices.

- Etsy: Ideal for unique or vintage pieces, often handmade or refurbished.

Specialty Retailers

- Sewing Supply Stores: Local shops often carry a variety of parts or can order them for you.

- Dedicated Parts Suppliers: Websites focusing specifically on sewing machine components provide extensive catalogs.

- Craft Fairs: A good place to find unique or hard-to-find items, as well as expert advice.

Utilizing these resources can help ensure your machine operates smoothly and continues to meet your sewing needs.