Understanding the intricacies of machinery upkeep is essential for ensuring longevity and optimal performance. Regular attention to details can prevent minor issues from evolving into significant challenges. This segment delves into essential practices and insights that aid in maintaining your outdoor power equipment.

Effective troubleshooting can enhance your ability to address common problems encountered during operation. Familiarizing oneself with various components and their functionalities is crucial for diagnosing issues accurately. This knowledge empowers users to perform necessary adjustments and replacements when required.

By following structured procedures and employing the right techniques, individuals can confidently navigate the complexities of equipment care. Whether you’re a seasoned professional or a novice, these guidelines will serve as a valuable resource for enhancing your mechanical expertise.

Understanding Bolens BL160 Features

Exploring the essential attributes of this outdoor power equipment reveals its versatility and performance capabilities. Each feature is designed to enhance functionality, making it suitable for various landscaping tasks.

Key Attributes

- Engine Power: The robust engine provides ample strength for tackling tough jobs.

- Cutting Width: A wide cutting deck ensures efficient mowing and reduces time spent on large areas.

- Adjustable Height: The ability to modify cutting height allows for customized grass management.

- Durable Construction: Built with high-quality materials to withstand wear and tear, ensuring longevity.

User-Friendly Features

- Easy Start System: Simplifies the ignition process for a hassle-free experience.

- Comfort Grip Handles: Designed for ease of use, reducing strain during operation.

- Efficient Fuel Consumption: Engineered for optimal fuel use, enhancing productivity and reducing costs.

Common Issues with Bolens BL160

Understanding the typical problems that arise with outdoor equipment can help users maintain optimal performance. Many owners encounter similar challenges, which can often be resolved with some basic troubleshooting knowledge.

Here are some frequent concerns that may arise:

- Starting Difficulties: Engines may struggle to start due to fuel issues, battery problems, or ignition system failures.

- Overheating: This can occur from low oil levels, a clogged air filter, or cooling system malfunctions.

- Uneven Cutting: Dull blades or improper deck height can lead to inconsistent results while mowing.

- Loss of Power: This issue may be linked to fuel flow restrictions, air filter blockages, or worn spark plugs.

- Transmission Problems: Users might experience slipping gears or difficulty in shifting, often due to low fluid levels or worn components.

Addressing these issues promptly can enhance the longevity and efficiency of your equipment. Regular maintenance checks and timely repairs can prevent more significant problems down the line.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment to optimal condition. Follow these instructions closely to ensure each component functions effectively and efficiently.

-

Assess the Issue: Begin by identifying the specific problem. Look for signs of wear or damage, such as:

- Unusual noises during operation

- Difficulty starting the engine

- Inconsistent power output

-

Gather Necessary Tools: Collect all required tools and materials before starting the process. Common items include:

- Screwdrivers

- Wrenches

- Replacement parts

-

Disassemble the Unit: Carefully take apart the machinery to access internal components. Make sure to:

- Keep track of screws and small parts

- Document the order of disassembly for reassembly

-

Inspect Components: Examine each part for signs of damage or wear. Focus on:

- Filters

- Belts

- Wiring connections

-

Replace or Repair: Depending on your findings, either replace faulty parts or perform necessary repairs. Ensure:

- New components meet the manufacturer’s specifications

- All repairs are secure and functional

-

Reassemble the Equipment: Carefully put the unit back together, following your documentation. Confirm:

- All parts are reinstalled correctly

- No tools or materials are left inside

-

Test Functionality: Start the equipment to check if the issue has been resolved. Observe:

- Performance under normal operating conditions

- Any lingering issues or new symptoms

By following these systematic steps, you can effectively restore functionality and enhance the lifespan of your machinery.

Tools Required for Maintenance

Ensuring optimal performance and longevity of your equipment necessitates the right set of instruments. Familiarizing yourself with essential tools not only simplifies the upkeep process but also enhances efficiency, allowing for effective troubleshooting and timely interventions.

Essential Hand Tools

A basic toolkit should include a variety of hand tools such as wrenches, screwdrivers, and pliers. These instruments are crucial for loosening or tightening components, as well as for making adjustments as needed. Having a complete set will facilitate smoother maintenance sessions and enable quick resolutions to common issues.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be necessary for more complex tasks. Items like multimeters, torque wrenches, and diagnostic gauges can provide deeper insights into performance metrics and help identify underlying problems. Investing in these tools can significantly streamline the maintenance process and enhance your overall experience.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is essential for preventing accidents and injuries. Adopting a proactive approach to safety not only protects the individual but also enhances the efficiency of the work being undertaken.

Wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and sturdy footwear. This gear acts as a barrier against potential hazards that may arise during the process.

It is crucial to disconnect power sources before beginning any work. This simple step minimizes the risk of electrical shock and ensures that the equipment remains inactive while you address issues.

Maintain a clean and organized workspace to prevent tripping hazards and facilitate easy access to tools and components. A tidy area allows for better focus and reduces the likelihood of accidents.

Additionally, be aware of surrounding environmental conditions. Working in well-lit areas and ensuring proper ventilation can greatly enhance safety and comfort. Always have a first aid kit readily available in case of emergencies.

Lastly, consult any available guidelines and recommendations to ensure compliance with safety standards. Understanding the specific requirements of the task at hand will help mitigate risks and ensure a successful outcome.

Engine Troubleshooting Tips

Addressing issues with small engines can often seem daunting, but a systematic approach can help pinpoint the source of the problem. By following a series of logical steps, you can effectively diagnose and resolve many common engine-related issues.

Here are some essential tips to assist in troubleshooting:

- Check Fuel Supply:

- Ensure the tank has enough fuel.

- Inspect the fuel lines for cracks or blockages.

- Verify the fuel is fresh and free from contaminants.

- Inspect the Ignition System:

- Examine the spark plug for wear or fouling.

- Check the ignition coil for proper operation.

- Make sure all connections are secure and free from corrosion.

- Evaluate Air Intake:

- Inspect the air filter for dirt or damage.

- Ensure there are no obstructions in the intake pathway.

- Confirm the carburetor is clean and functioning correctly.

- Examine Engine Oil:

- Check the oil level and condition.

- Change the oil if it appears dirty or has not been changed recently.

- Look for leaks around the seals and gaskets.

By systematically checking these components, you can often identify and resolve issues before they escalate. Regular maintenance is key to ensuring long-term performance and reliability.

Fuel System Inspection Techniques

Ensuring optimal performance of a machine’s fuel system is crucial for its reliability and efficiency. A thorough examination of this system can prevent potential issues and enhance overall functionality. This section outlines essential methods for assessing various components related to fuel delivery and storage.

Start by visually inspecting the fuel tank for signs of corrosion or leaks. Any deterioration in the tank can lead to fuel contamination and performance problems. Check the fuel lines for cracks, wear, or obstructions, as these can impede fuel flow and affect engine performance.

Next, examine the fuel filter, ensuring it is clean and free of debris. A clogged filter can restrict fuel supply, causing the engine to underperform. If the filter appears dirty, it may need replacement to maintain efficient operation.

Additionally, assess the fuel pump’s functionality by listening for unusual noises during operation. A well-functioning pump should operate quietly and consistently. If you detect irregular sounds, it may indicate a malfunction that requires further investigation.

Lastly, verify the fuel quality. Contaminated or old fuel can lead to engine issues. Consider sampling the fuel and checking for water or particulate matter, which can compromise performance. Regular inspections and prompt maintenance of the fuel system will help ensure the longevity and efficiency of the machine.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of outdoor equipment is essential for maintaining optimal performance. Understanding how to identify faults and malfunctions can save time and prevent further damage. This section outlines the key steps and techniques used to assess the electrical components effectively.

Start with a Visual Inspection: The first step in troubleshooting involves examining the wiring, connectors, and components for any visible signs of wear, corrosion, or damage. Look for loose connections or frayed wires that could lead to interruptions in the electrical flow.

Utilize Diagnostic Tools: Employing tools such as multimeters can provide valuable insights into the condition of the electrical system. Measuring voltage, resistance, and continuity helps pinpoint problematic areas. Ensure that all readings fall within the manufacturer’s specified ranges.

Check the Battery: A faulty battery is often the root of electrical issues. Verify that the battery is fully charged and capable of holding a charge. Examine the terminals for corrosion and clean them if necessary to ensure a good connection.

Inspect Fuses and Relays: Fuses and relays act as protectors for the electrical system. A blown fuse or a malfunctioning relay can disrupt functionality. Replace any damaged fuses and test relays to ensure they operate correctly.

Test Individual Components: If specific parts are suspected of malfunctioning, isolate and test them individually. This approach helps to confirm whether the issue lies within that component or elsewhere in the system.

By following these diagnostic steps, users can effectively troubleshoot electrical problems and maintain the reliability of their equipment.

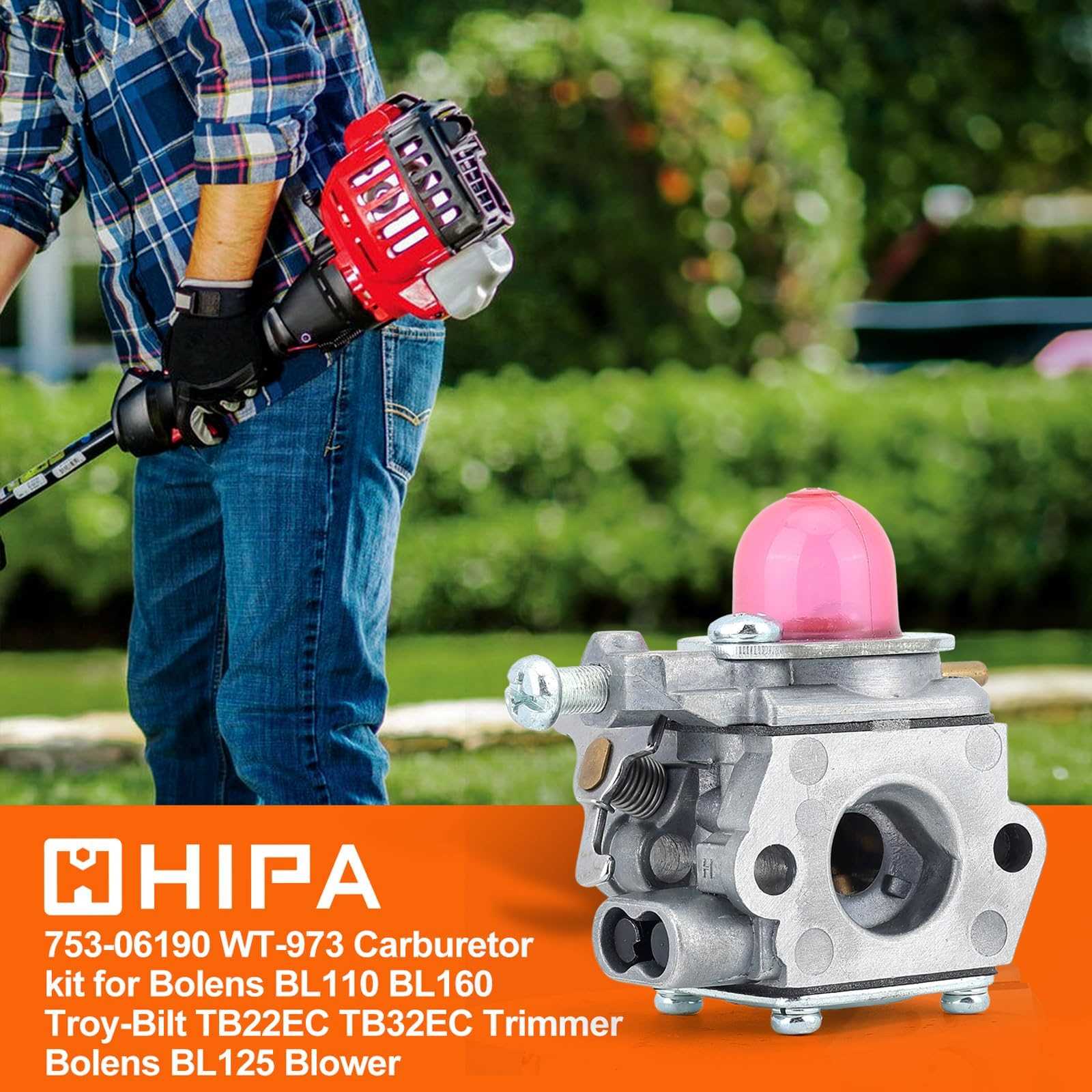

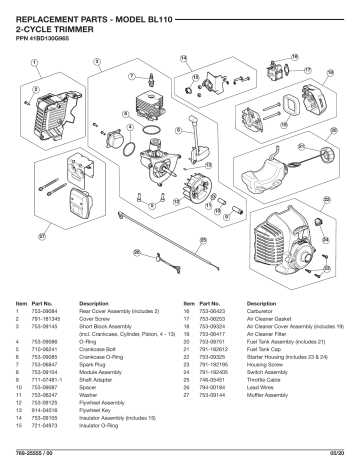

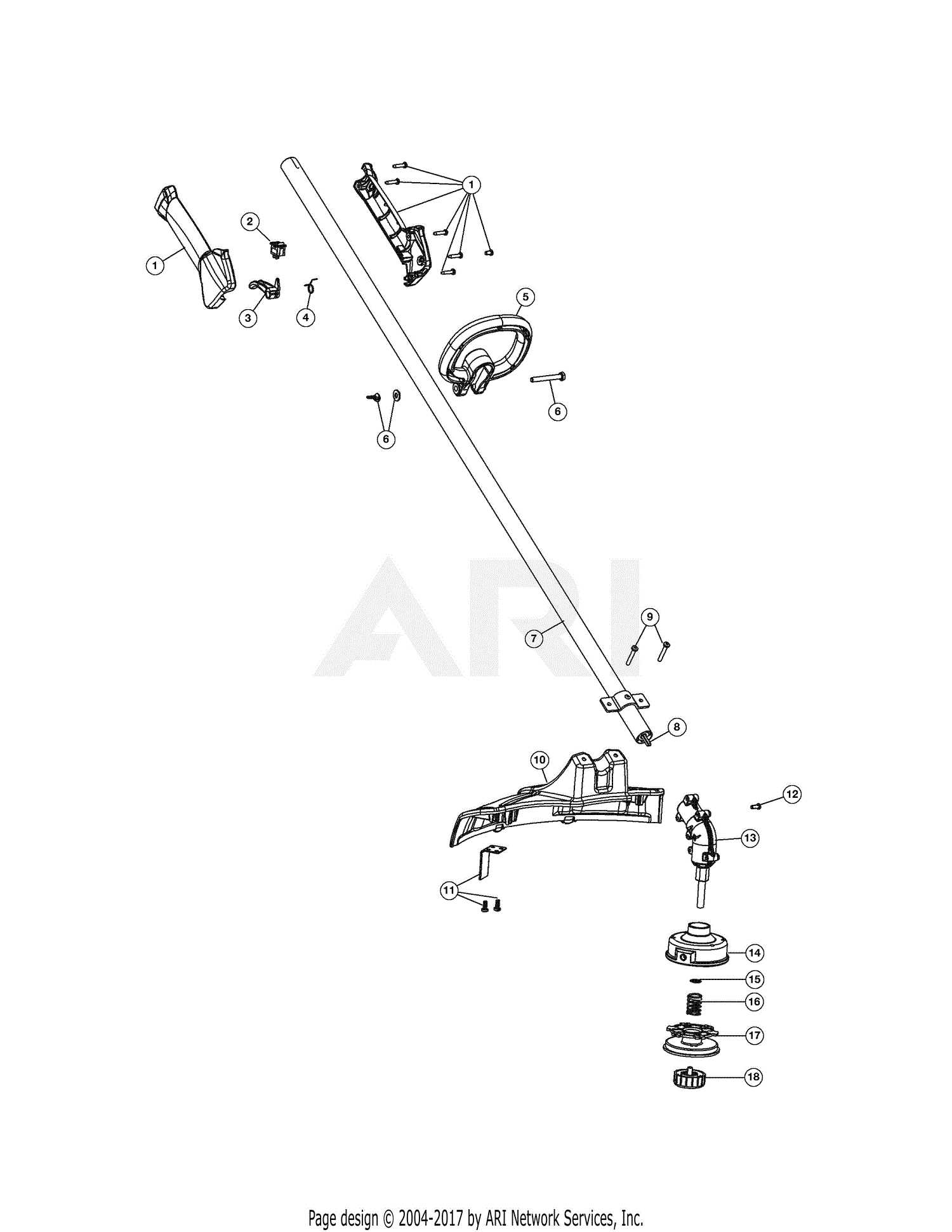

Replacing Worn-Out Parts

Maintaining optimal performance in machinery often involves the timely substitution of components that show signs of wear. Identifying these parts early can prevent further damage and ensure that your equipment runs smoothly and efficiently. This section outlines the essential steps and considerations for replacing components that have deteriorated over time.

Identifying Worn Parts

The first step in the replacement process is recognizing which components are no longer functioning effectively. Look for signs such as unusual noises, decreased efficiency, or visible damage. Regular inspections can help pinpoint areas that require attention, allowing for proactive measures before issues escalate.

Replacement Process

Once the worn components have been identified, it is crucial to gather the appropriate tools and replacement parts. Follow manufacturer guidelines for installation to ensure compatibility and proper functioning. After installation, conduct a thorough test to verify that the equipment is operating as intended, making adjustments if necessary. Keeping a record of replacements can also aid in future maintenance planning.

Regular Maintenance Best Practices

Consistent upkeep of your equipment is essential for ensuring optimal performance and longevity. By following a structured approach to maintenance, you can prevent potential issues and enhance the overall efficiency of your machine.

1. Routine Inspections: Conduct regular checks to identify any wear and tear. Look for loose components, leaks, or unusual noises that may indicate a problem.

2. Cleaning: Keep your equipment clean by removing dirt and debris. Regular cleaning not only improves appearance but also helps in spotting issues early.

3. Lubrication: Ensure moving parts are properly lubricated to reduce friction and wear. Follow the manufacturer’s recommendations for suitable lubricants and intervals.

4. Filter Replacement: Change air and fuel filters as needed. Clogged filters can hinder performance and efficiency, so check them regularly.

5. Battery Maintenance: Inspect battery terminals for corrosion and ensure connections are secure. A well-maintained battery can prevent unexpected failures.

6. Seasonal Checkups: Before each season, perform a thorough examination of your equipment to prepare it for the demands of the upcoming workload.

7. Documentation: Keep a maintenance log detailing services performed and any issues encountered. This record can be invaluable for tracking performance and planning future upkeep.

By adhering to these best practices, you can significantly extend the lifespan of your equipment while ensuring it operates at peak performance.

Accessing the User Manual Online

Finding the appropriate documentation for your equipment can significantly enhance your experience and ensure optimal performance. Online resources provide a convenient way to access essential guides and support materials, allowing users to troubleshoot issues and maintain their devices effectively.

Steps to Find the Documentation

- Start by visiting the official website of the manufacturer.

- Navigate to the support or resources section.

- Use the search feature to enter your model number or name.

- Look for downloadable PDFs or online versions of the documentation.

- Check for any supplementary resources such as FAQs or community forums.

Benefits of Online Access

- Instant availability: Access documents anytime without waiting for physical copies.

- Search functionality: Quickly find specific information within the document.

- Updates: Stay informed about the latest revisions and tips directly from the source.

- Cost-effective: Free access to crucial materials saves money on printouts or purchases.

Finding Replacement Parts Easily

Locating suitable components for maintenance and upgrades can be a straightforward process with the right approach. Understanding where to search and what resources are available makes all the difference in ensuring your equipment runs smoothly.

| Source | Description |

|---|---|

| Online Retailers | Many websites specialize in a wide range of parts, often with user-friendly search features. |

| Local Dealerships | Authorized dealers can provide genuine parts and expert advice. |

| Forums and Communities | Engaging with online groups can yield recommendations and tips for finding hard-to-get items. |

| Second-Hand Markets | Used parts can be found at lower prices, though quality should be verified. |

Utilizing these resources effectively will ultimately enhance your ability to maintain and optimize your equipment. Knowledge of part compatibility and availability is key to successful upkeep.