Maintaining a high-performance motorcycle is essential for ensuring its longevity and optimal functioning. Proper care and attention to detail can significantly enhance the riding experience and prevent unexpected issues. This section aims to provide comprehensive insights into effective maintenance practices that every motorcycle enthusiast should consider.

Understanding the intricacies of motorcycle components is crucial for both novice and experienced riders. From routine checks to advanced troubleshooting, knowledge of various aspects can empower owners to tackle challenges confidently. This guide emphasizes the importance of systematic approaches, enabling riders to navigate repairs and upkeep with ease.

Moreover, having access to relevant information and resources can simplify the maintenance process. Familiarity with the essential tools and techniques will help ensure that each task is performed efficiently. This resource serves as a valuable reference for enhancing skills and promoting a deeper appreciation for the mechanics of two-wheeled vehicles.

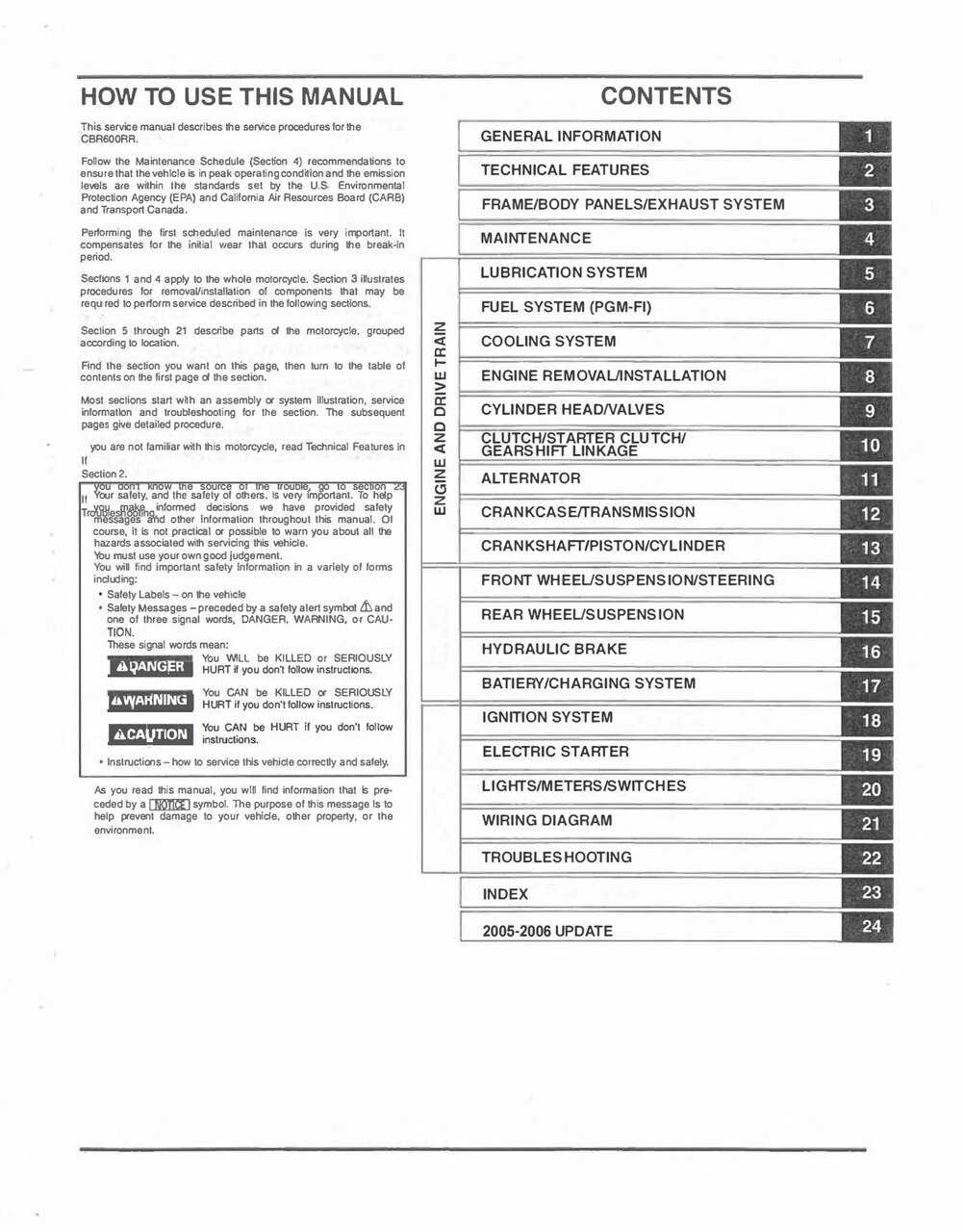

2004 CBR600RR Overview

This section provides an insight into a popular sportbike known for its impressive performance and agility. Designed for riders who seek a balance of speed and handling, this model has gained a reputation for its engineering excellence and user-friendly features.

Equipped with a powerful engine and advanced technology, this motorcycle delivers an exhilarating riding experience on both the road and the track. Its aerodynamic design contributes to improved stability and reduced drag, making it a favored choice among enthusiasts.

| Feature | Description |

|---|---|

| Engine Type | Liquid-cooled, four-stroke inline-four |

| Displacement | 599 cc |

| Power Output | Maximum power of approximately 120 hp |

| Weight | About 410 lbs (wet) |

| Brakes | Dual disc front brakes, single disc rear brake |

Essential Tools for Repairs

To maintain a smooth, efficient workflow during any bike maintenance, having the right set of tools at hand is essential. These tools streamline the process and help ensure that tasks are completed accurately and with minimal hassle. Here’s an overview of fundamental equipment every enthusiast should consider for effective upkeep and adjustments.

Basic Hand Tools

- Socket Set: A complete set of sockets in various sizes is indispensable for reaching and loosening bolts across different parts of the bike.

- Torque Wrench: To secure bolts with precise pressure, a torque wrench is key to avoiding overtightening.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for numerous small tasks, from removing covers to accessing internal parts.

- Allen Wrenches: Most modern bikes require these hex keys, especially for tasks involving smaller components.

Specialized Equipment

- Chain Breaker and Rivet To

Maintenance Schedule for CBR Sport Bike

Regular upkeep is essential to ensure your sport bike performs optimally and maintains reliability over time. Following a structured schedule can prevent wear-related issues and extend the machine’s lifespan, making each ride safer and more enjoyable.

Daily Checks

- Inspect fluid levels, including oil and coolant, ensuring they are within the recommended range.

- Examine tire pressure and tread condition for safe handling and grip.

- Check lights, including headlights and indicators, to ensure visibility and signaling.

Periodic Maintenance

Beyond daily checks, certain parts and systems need attention at regular intervals. Follow these guidelines to keep components in top shape:

- Every 1,000 miles: Change the engine oil and inspect the oil filter for wear.

- Every 3,000 miles: Inspect the chain tension, lubricate as necessary, and check brake pads for optimal stopping power.

- Every 6,000 miles: Replace the air filter, inspect the spark plugs, and examine all electrical connections.

- Common Issues and Fixes

Motorcycles, especially those built for performance, can encounter various challenges over time. Routine use, environmental factors, and component wear may lead to common mechanical and electrical issues. Identifying these typical concerns early and applying straightforward solutions can help keep the machine running smoothly and prevent further complications.

Engine Overheating: One frequent problem with high-performance engines is overheating. This can result from insufficient coolant levels, a malfunctioning radiator fan, or clogged coolant lines. To resolve this, ensure the cooling system is clean, the coolant is at optimal levels, and the fan is operational.

Electrical Malfunctions: Electrical issues can often arise due to wiring wear or battery faults. Symptoms may include difficulties starting, flickering lights, or unresponsive indicators. Regularly inspect wiring for frays, secure connections, and confirm the battery’s health to avoid these interruptions.

Chain and Sprocket Wear: Over time, chains and sprockets may stretch or wear down, affecting performance and safety. Regularly check for tension and alignment, and apply appropriate

Electrical System Troubleshooting

Diagnosing the electrical components of a motorcycle is essential for maintaining reliable performance and ensuring all systems function as intended. Electrical challenges can arise from various sources, and understanding the nature of these issues helps in identifying solutions effectively.

Common Electrical Issues

- Battery-related concerns, such as insufficient charge or degraded performance

- Loose or corroded connections affecting power flow

- Worn-out fuses causing interruptions in system functionality

- Damaged or faulty wiring impacting circuit continuity

Steps for Effective Diagnosis

- Battery Inspection: Check for signs of corrosion around terminals and ensure the battery holds a full charge.

- Fuse Examination: Inspect fuses for any visible damage, replacing any that appear blown to restore connections.

- Wire Connections: Verify that all co

Engine Oil and Filter Change

Maintaining the engine’s lubrication system is essential for optimal performance and longevity. Regularly changing the oil and filter ensures that the engine operates smoothly, minimizing wear and tear. This section outlines the necessary steps to effectively perform this crucial maintenance task.

Before beginning the process, gather the required tools and materials to facilitate a smooth operation. This preparation will help ensure that everything is in place for an efficient oil change.

Required Tools and Materials Wrench set Oil filter wrench Oil catch pan Fresh engine lubricant New oil filter Funnel Start by warming up the engine briefly to ensure the oil flows easily during drainage. Turn off the engine and place the vehicle securely on a level surface. Locate the drain plug beneath the engine and position the oil catch pan underneath it to collect the used lubricant.

Next, remove the drain plug with the appropriate wrench, allowing the old oil to flow completely into the catch pan. After draining, reinstall the drain plug securely. Proceed to remove the old oil filter using the oil filter wrench, taking care to catch any remaining oil that may spill out.

Apply a small amount of fresh oil to the rubber seal of the new oil filter, then install it, ensuring it is snug but not overly tight. Finally, fill the engine with the new oil using the funnel, checking the manufacturer’s recommendations for the correct quantity and viscosity.

After filling, start the engine and let it run for a few minutes. This will circulate the new oil and allow you to check for leaks around the filter and drain plug. Turn off the engine and check the oil level with the dipstick, adding more if necessary.

Brake System Inspection and Service

The braking system is crucial for ensuring safety and control while riding. Regular assessment and maintenance of this system are essential to avoid malfunctions and enhance performance. This section provides guidance on how to effectively evaluate and service the braking components.

Inspection Procedures

Conducting thorough inspections of the braking system involves several key steps:

- Check brake fluid levels and inspect for any leaks.

- Examine brake pads for wear and replace if necessary.

- Inspect brake discs for any signs of damage or warping.

- Assess brake lines for any signs of wear or corrosion.

- Test the brake lever and pedal for proper function and response.

Maintenance Recommendations

To ensure optimal performance of the braking system, consider the following maintenance tips:

- Replace brake fluid every 1-2 years to maintain hydraulic efficiency.

- Clean brake components regularly to prevent buildup of dirt and debris.

- Lubricate moving parts to ensure smooth operation.

- Regularly inspect and tighten all mounting bolts and components.

By adhering to these inspection and service practices, riders can maintain their braking system in optimal condition, ensuring a safer and more enjoyable riding experience.

Replacing Tires on CBR600RR

Changing the rubber components on a sportbike is a crucial maintenance task that ensures safety and enhances performance. This section will guide you through the essential steps involved in removing old tires and fitting new ones. Proper techniques and tools will help ensure a smooth transition, providing optimal handling and grip on the road.

Preparation Steps

- Gather necessary tools: tire levers, wrenches, and a torque wrench.

- Ensure you have a suitable replacement tire that meets the manufacturer’s specifications.

- Make sure the bike is on a stable stand to prevent any accidents during the process.

Installation Process

- Loosen the wheel nuts using a wrench.

- Carefully lift the motorcycle and remove the wheel from the fork or swingarm.

- Deflate the old tire completely before attempting to remove it from the rim.

- Use tire levers to pry the tire off the rim, working gradually around the wheel.

- Place the new tire onto the rim, ensuring proper alignment with the directional markings.

- Inflate the tire to the recommended pressure and check for any leaks.

- Reattach the wheel to the bike and secure it with the wheel nuts, using the torque wrench to tighten them to the specified settings.

Suspension Adjustments and Upgrades

Proper tuning and enhancements of the suspension system play a vital role in optimizing the performance and handling characteristics of a motorcycle. By fine-tuning various aspects, riders can achieve a more personalized experience tailored to their riding style and conditions. Understanding the different elements that contribute to the suspension setup can greatly enhance comfort and control on the road or track.

Importance of Suspension Tuning

Adjusting the suspension settings can significantly impact the bike’s stability, grip, and overall response. Factors such as preload, compression, and rebound damping can be altered to suit individual preferences. Riders should regularly evaluate these settings to ensure they align with the intended usage, whether for casual riding or competitive events.

Upgrading Suspension Components

In addition to adjustments, upgrading suspension components can lead to substantial improvements in performance. High-quality forks and shocks provide better feedback and handling, allowing for increased confidence while navigating turns and obstacles. Investing in aftermarket options can transform the riding experience, providing a noticeable enhancement in both comfort and capability.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for ensuring optimal performance and longevity of your motorcycle. Regular attention to this system can prevent overheating and potential engine damage. Below are some valuable suggestions to help you maintain an effective cooling system.

Regular Inspection

Routine checks of the cooling components are crucial. Look for signs of wear, leaks, or damage in hoses and radiators. Early detection can save you from costly repairs later on.

Fluid Levels and Quality

Maintaining the correct fluid levels is vital for efficient cooling. Ensure the coolant is at the recommended level and check its condition. If the fluid appears dirty or has debris, consider replacing it with fresh coolant to enhance performance.

Maintenance Task Frequency Notes Inspect hoses Every ride Look for cracks or leaks Check coolant level Weekly Top up if necessary Flush cooling system Annually Replace old coolant Inspect radiator Monthly Clean debris for proper airflow Bodywork Repairs and Painting

This section focuses on the essential aspects of restoring and refinishing the external components of a motorcycle. It covers various techniques for addressing cosmetic damage and enhancing the overall appearance of the vehicle.

Common types of bodywork damage include:

- Scratches and scuffs on panels

- Dents caused by impacts

- Cracks in fairings

To achieve a professional finish, follow these steps:

- Assess the extent of the damage and gather necessary tools and materials.

- Clean the affected areas thoroughly to remove dirt and grease.

- Sand down rough edges around the damage to create a smooth surface for repair.

- Apply appropriate fillers for dents and cracks, allowing them to cure as instructed.

- Once cured, sand the filled areas to blend with the surrounding surface.

- Prime the prepared sections to ensure proper paint adhesion.

- Choose a suitable paint and apply it evenly, allowing adequate drying time between coats.

- Finish with a clear coat to protect the paint and enhance shine.

Regular maintenance of the bodywork not only improves aesthetics but also prolongs the lifespan of the motorcycle components.

Wiring Diagrams and Schematics

This section focuses on the importance of electrical diagrams and schematics in understanding the wiring layout of a motorcycle. These visual representations serve as essential tools for troubleshooting and maintaining electrical systems, providing a clear overview of connections and components.

Electrical diagrams illustrate the relationships between various elements, while schematics depict the actual circuitry and signal flow. By studying these illustrations, enthusiasts and technicians can gain insights into the functioning of lighting, ignition, and other critical systems. Accurate diagrams facilitate efficient repairs and modifications, ensuring the reliability and performance of the motorcycle.

Familiarity with these diagrams enhances one’s ability to diagnose issues effectively and implement solutions. Whether dealing with wiring faults or upgrading components, a thorough understanding of the electrical layout is invaluable for any motorcycle owner or technician.

Performance Enhancements for CBR600RR

Improving the capabilities of a high-performance motorcycle can significantly elevate the riding experience. Various modifications and upgrades can enhance speed, handling, and overall power. By focusing on specific areas such as the engine, suspension, and exhaust system, riders can achieve better performance and responsiveness.

Engine Modifications

Enhancing the engine’s performance is crucial for maximizing speed and acceleration. Consider the following upgrades:

- High-Performance Air Filter: Installing a premium air filter can improve airflow, resulting in increased horsepower.

- Fuel Management System: Upgrading to an advanced fuel management system allows for precise tuning, optimizing fuel delivery.

- Performance Exhaust System: A lightweight exhaust system not only reduces weight but also improves exhaust flow, enhancing engine output.

Suspension and Handling Enhancements

Improving the suspension and handling characteristics can lead to a more stable and agile ride. Here are some recommendations:

- Adjustable Forks: Upgrading to adjustable front forks enables riders to customize their suspension settings based on personal preferences.

- Aftermarket Shock: Installing a high-quality shock absorber can significantly enhance rear-end stability and comfort.

- Performance Tires: Choosing tires with better grip and durability can improve cornering performance and overall control.