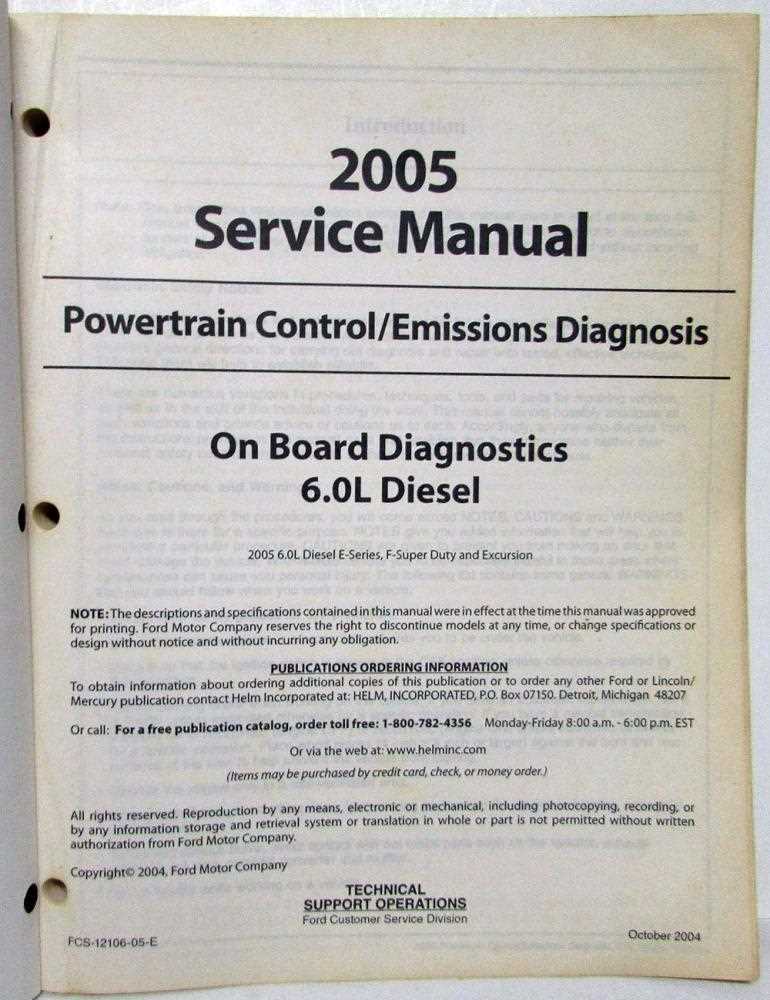

Understanding the intricacies of modern engines is essential for anyone looking to maintain their vehicle’s performance and longevity. This section delves into the critical aspects of engine care, focusing on detailed procedures and insights that ensure optimal functionality.

From troubleshooting common issues to performing essential maintenance tasks, this guide provides valuable knowledge for enthusiasts and professionals alike. With clear explanations and step-by-step instructions, readers will gain the confidence needed to tackle various challenges associated with engine upkeep.

Equipped with this information, users can approach their vehicles with a deeper understanding of the systems at play. Whether it’s enhancing efficiency or addressing specific concerns, the content here serves as a reliable resource for achieving excellence in engine management.

Understanding the 6.0 Powerstroke Engine

This section provides insights into a robust diesel engine renowned for its performance and capabilities. Designed to cater to heavy-duty applications, this power unit combines advanced technology with a reliable structure, making it a popular choice among enthusiasts and professionals alike.

Key Features and Specifications

One of the standout characteristics of this engine is its unique design that enhances fuel efficiency and power output. With a specific displacement and an innovative fuel injection system, it ensures optimal combustion and reduced emissions. Additionally, the cooling system plays a crucial role in maintaining operating temperatures, contributing to the engine’s longevity.

Common Challenges and Maintenance Tips

While this engine is known for its durability, it is not without its challenges. Frequent issues can arise from various components, necessitating regular checks and maintenance. Routine inspections of the fuel system and electrical components can help mitigate potential problems. Moreover, employing quality lubricants and adhering to recommended service intervals will promote optimal performance.

Common Issues with the 6.0 Powerstroke

The engine in question is known for its specific challenges that owners often encounter. Understanding these issues is essential for maintaining optimal performance and ensuring longevity. This section delves into prevalent problems that can arise, helping enthusiasts and mechanics alike recognize and address them effectively.

Frequent Challenges

Several common challenges are associated with this engine type. These include issues related to fuel delivery, overheating, and electrical components, which can lead to diminished performance or even complete failure if not addressed promptly.

Symptoms and Solutions

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Fuel Injector Failure | Rough idling, decreased power | Replace faulty injectors, clean fuel system |

| Overheating | Temperature gauge rising, steam from engine | Check coolant levels, inspect thermostat |

| Electrical Problems | Dashboard warning lights, erratic behavior | Examine wiring, replace faulty sensors |

Awareness of these issues and their symptoms can aid in timely interventions, ultimately prolonging the life of the engine and enhancing overall driving experience.

Tools Needed for Effective Repairs

When undertaking maintenance or fixes on a vehicle, having the right instruments is crucial for achieving optimal results. Proper tools not only enhance efficiency but also ensure that tasks are completed safely and effectively. Below, we outline the essential equipment that every technician should consider having on hand.

Essential Hand Tools

Basic hand tools are the foundation of any maintenance project. A comprehensive toolkit should include wrenches, screwdrivers, and pliers. These instruments allow for easy access to various components and make it simpler to tighten or loosen fasteners. Additionally, having a reliable ratchet set can significantly expedite the process of disassembling and reassembling parts.

Specialized Equipment

For more intricate tasks, specialized tools become necessary. Diagnostic scanners are invaluable for identifying issues and troubleshooting faults within the system. Furthermore, investing in a good quality torque wrench ensures that components are fastened to the correct specifications, preventing damage and ensuring longevity. Other helpful tools may include pneumatic tools for heavy-duty jobs and jacks for safely lifting the vehicle during maintenance.

Step-by-Step Repair Procedures

This section outlines detailed guidelines for performing maintenance and troubleshooting tasks effectively. By following these procedures, users can ensure optimal performance and longevity of their vehicle components.

Preparation and Tools

Before commencing any work, gather the necessary tools and materials. A well-organized workspace will facilitate smoother operations. Commonly required tools include wrenches, screwdrivers, and diagnostic equipment. Always refer to specifications to confirm the required items for each task.

Detailed Procedure

Follow a systematic approach to each procedure. Start by disconnecting the battery to prevent electrical mishaps. Next, remove any obstructive components to access the area needing attention. Carefully inspect parts for wear or damage, and replace as necessary. Upon completion, reassemble all components in reverse order, ensuring tight connections. Finally, reconnect the battery and perform tests to verify successful operation.

Preventive Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle requires a proactive approach to upkeep. Regular attention to various components not only enhances performance but also prevents costly repairs down the line. Implementing a routine maintenance schedule can significantly contribute to the reliability and efficiency of your engine.

Regular Fluid Checks

Monitoring and changing fluids at appropriate intervals is essential. Engine oil should be replaced regularly to maintain optimal lubrication, while coolant levels need to be checked to prevent overheating. Additionally, don’t overlook transmission fluid and brake fluid, as these are crucial for smooth operation and safety.

Inspection of Filters and Belts

Filters play a vital role in maintaining clean airflow and fluid circulation. Regularly replace air and fuel filters to ensure efficiency. Inspecting belts for wear and tear is equally important; replacing them at the first sign of damage can prevent breakdowns and extend the life of the engine.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a vehicle can often be a complex task. Understanding the underlying principles and common indicators can significantly aid in isolating the source of a malfunction. This section will provide a framework for effectively diagnosing these challenges.

Common Symptoms of Electrical Failures

Electrical failures can manifest in various ways. Here are some typical signs that may indicate an issue:

| Symptom | Possible Cause |

|---|---|

| Battery not charging | Faulty alternator or battery connections |

| Lights flickering | Bad ground connection or failing voltage regulator |

| Starter not engaging | Weak battery or defective starter motor |

| Inconsistent power to accessories | Worn wiring or corroded connectors |

Step-by-Step Diagnostic Process

To systematically address electrical issues, follow these steps:

- Begin with a visual inspection of the wiring and connections for signs of wear or damage.

- Test the battery voltage using a multimeter; it should typically read around 12.6 volts when fully charged.

- Check the alternator output while the engine is running; it should provide between 13.5 and 14.5 volts.

- Examine the fuses and relays for continuity; replace any that are blown.

- Utilize diagnostic tools to read any stored trouble codes, guiding further investigation.

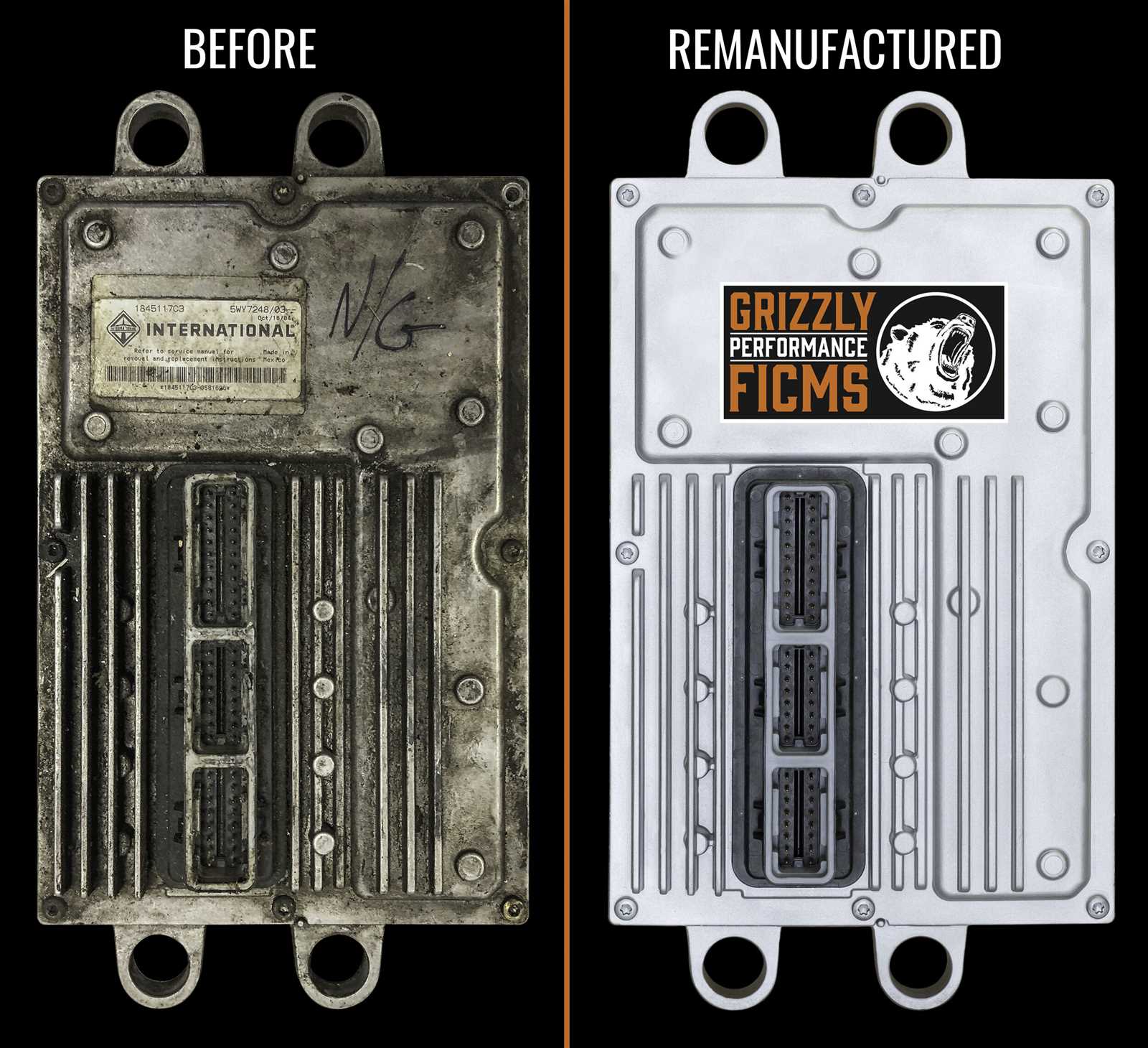

Upgrades and Performance Enhancements

Enhancing the capabilities of your diesel engine can significantly improve its performance and efficiency. A variety of modifications can be made to optimize power output, fuel economy, and overall driving experience. Understanding the most effective upgrades is crucial for achieving the desired results without compromising reliability.

Common Modifications

One popular approach involves upgrading the intake and exhaust systems. By allowing for better airflow, these modifications can enhance engine breathing, leading to increased horsepower and torque. Additionally, implementing a high-performance turbocharger can provide substantial boosts in power, improving acceleration and overall responsiveness.

Electronic Enhancements

Another critical area for improvement is the vehicle’s electronic control unit (ECU). Reprogramming or tuning the ECU can unlock additional performance by optimizing fuel mapping and ignition timing. Coupling this with aftermarket gauges can help monitor vital engine parameters, ensuring that modifications are functioning as intended and maintaining engine health.

Oil and Fluid Specifications Explained

Understanding the appropriate oils and fluids for your vehicle is crucial for optimal performance and longevity. Different systems within the engine require specific substances that meet certain standards to ensure efficient operation and protection against wear. This section will cover the essential specifications and recommendations for various fluids, highlighting their roles and importance in maintaining your vehicle’s health.

Choosing the right engine lubricant is fundamental for reducing friction and wear, while coolant plays a vital role in regulating temperature. Transmission fluid is essential for smooth gear shifts, and brake fluid ensures effective stopping power. Each fluid type has distinct characteristics that must align with the manufacturer’s guidelines.

| Fluid Type | Specification | Recommended Brands |

|---|---|---|

| Engine Oil | 5W-30, API SN/SM | Brand A, Brand B |

| Transmission Fluid | MERCON V | Brand C, Brand D |

| Coolant | HOAT, 50/50 mix | Brand E, Brand F |

| Brake Fluid | DOT 3 or DOT 4 | Brand G, Brand H |

Adhering to these specifications not only promotes efficiency but also prevents potential damage that could arise from using incorrect fluids. Regularly checking and replacing these substances as needed is a key aspect of proactive maintenance.

Cooling System Maintenance and Repair

The efficiency of any engine largely depends on its ability to regulate temperature effectively. Proper upkeep of the cooling apparatus is crucial for preventing overheating and ensuring optimal performance. This section delves into essential practices and procedures for maintaining and addressing issues within this vital system.

Routine Inspection and Servicing

Regular examinations of the cooling components can help identify potential problems before they escalate. Check the coolant level and quality, ensuring it meets the manufacturer’s specifications. Inspect hoses and connections for signs of wear or leaks. Flushing the system periodically is also recommended to remove accumulated debris and contaminants, promoting better heat transfer.

Identifying and Addressing Issues

Should any irregularities arise, such as overheating or unusual noises, it’s important to diagnose the underlying cause promptly. Look for signs of coolant leaks, pressure anomalies, or blockages within the radiator. Replacement of damaged components, such as thermostats or water pumps, may be necessary to restore full functionality and prevent further complications.

Fuel System Troubleshooting Techniques

Diagnosing issues within a fuel system is crucial for maintaining optimal engine performance. Various factors can affect fuel delivery and quality, leading to poor functionality. Implementing systematic approaches can help identify and resolve these complications effectively.

Here are several techniques to assist in troubleshooting:

- Visual Inspection:

- Check for leaks in fuel lines and connections.

- Inspect the fuel filter for dirt or blockages.

- Examine the fuel pump for signs of wear or damage.

- Pressure Testing:

- Utilize a pressure gauge to measure fuel pressure at the injector rail.

- Compare readings against manufacturer specifications.

- Identify any discrepancies that may indicate a failing pump or clogged filter.

- Electrical Diagnostics:

- Inspect electrical connections to the fuel pump and injectors.

- Use a multimeter to check voltage and ground signals.

- Look for faults in wiring that may disrupt functionality.

- Injector Testing:

- Perform a flow test to ensure proper injector operation.

- Use an oscilloscope to analyze injector pulse patterns.

- Identify any irregularities that may indicate malfunctioning injectors.

By following these techniques, you can effectively troubleshoot issues within the fuel system, ensuring reliable operation and enhancing overall performance.

Recognizing Symptoms of Engine Failure

Identifying the early signs of engine malfunction is crucial for maintaining optimal vehicle performance. Understanding these indicators can prevent extensive damage and costly repairs. Drivers should be vigilant about unusual changes in engine behavior, as they often signal underlying issues that need immediate attention.

One of the primary symptoms to watch for is a significant drop in power or acceleration. If the engine struggles to reach speed or feels sluggish, it may indicate mechanical problems. Additionally, an increase in unusual noises, such as knocking or grinding sounds, can be a warning sign that components are failing or misaligned.

Another critical aspect to monitor is the temperature gauge. If the engine overheats or consistently runs at high temperatures, it can lead to severe damage. Unexplained vibrations during operation may also suggest issues with internal parts or imbalances that require inspection.

Furthermore, keep an eye on the exhaust. Excessive smoke, particularly if it appears blue or black, can indicate incomplete combustion or oil leaks. Lastly, check for fluid leaks under the vehicle. Any signs of oil or coolant pooling could suggest a significant issue that needs to be addressed promptly.

Resources for Further Learning

Expanding your knowledge on diesel engine maintenance and troubleshooting can significantly enhance your understanding and skills. Various resources are available to help enthusiasts and professionals alike deepen their expertise in this field.

- Online Forums: Engage with communities that focus on diesel engines. These platforms often feature discussions, troubleshooting tips, and shared experiences from fellow users.

- Video Tutorials: Explore platforms like YouTube for visual guides that demonstrate repair techniques and maintenance procedures. Many experienced mechanics share their insights through step-by-step videos.

- Technical Guides: Seek comprehensive guides and books written by industry experts. These publications often cover various aspects, including diagnostics and performance enhancements.

- Workshops and Classes: Consider enrolling in local workshops or online courses dedicated to diesel engine technology. These educational opportunities provide hands-on experience and professional instruction.

- Manufacturer Websites: Visit official sites for manufacturer resources, including service bulletins and technical specifications. These materials can offer valuable information about specific models and components.

Utilizing these resources can empower you with the knowledge necessary to tackle challenges effectively and improve your overall mechanical proficiency.