Understanding the intricacies of vehicle cooling and heating systems is crucial for any car owner or enthusiast. These systems play a vital role in ensuring comfort during journeys, regardless of weather conditions. When issues arise, having access to comprehensive resources can make the difference between a minor inconvenience and a costly repair.

In this section, we delve into a wealth of informative documents designed to empower individuals to diagnose and address problems related to air conditioning and heating units in their vehicles. By following structured guidance, users can gain insights into troubleshooting techniques, component functions, and maintenance practices.

Moreover, these invaluable resources not only assist in fixing current issues but also promote a proactive approach to vehicle upkeep. With the right information at hand, anyone can enhance their understanding of these essential systems, ensuring a comfortable and enjoyable driving experience year-round.

Understanding Automotive AC Systems

Climate control systems are essential components in vehicles, designed to maintain comfort by regulating temperature and humidity levels within the cabin. These systems operate using a combination of mechanical and thermodynamic principles, ensuring a pleasant environment regardless of external weather conditions. Understanding their fundamental workings can help diagnose issues and enhance maintenance practices.

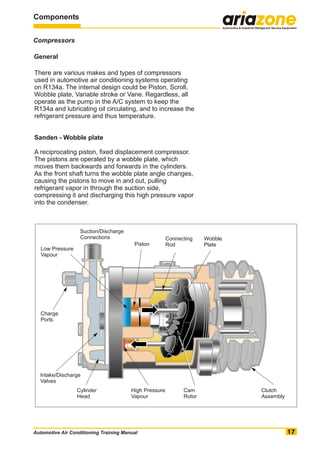

At the heart of these systems lies a closed loop that circulates refrigerant, a substance that easily transitions between liquid and gas states. This cycle allows for heat absorption and dissipation, creating a cool atmosphere inside the vehicle. Key components include the compressor, condenser, expansion valve, and evaporator, each playing a crucial role in the overall function.

| Component | Function |

|---|---|

| Compressor | Pressurizes the refrigerant and moves it through the system. |

| Condenser | Cool the high-pressure refrigerant, allowing it to transition into a liquid state. |

| Expansion Valve | Regulates the flow of refrigerant into the evaporator, dropping its pressure. |

| Evaporator | Absorbs heat from the cabin air, cooling the air as refrigerant evaporates. |

By comprehending these elements and their interactions, one can gain valuable insights into how to maintain optimal performance and address potential malfunctions effectively.

Common AC Issues in Vehicles

Air conditioning systems in vehicles are essential for maintaining comfort during travel, especially in hot weather. However, they can experience various problems that affect their efficiency and performance. Understanding these common issues can help owners identify symptoms early and seek appropriate solutions.

Insufficient Cooling

One of the most frequent complaints is insufficient cooling. This can stem from several factors, including low refrigerant levels or a malfunctioning compressor. When the system struggles to produce cold air, it often leads to discomfort for passengers and can indicate a need for service.

Unpleasant Odors

Another issue drivers may encounter is unpleasant odors emanating from the vents. This can be a result of mold or mildew growth within the system, particularly in humid environments. Regular maintenance and cleaning of the components can help mitigate this problem and ensure a fresher atmosphere inside the vehicle.

Addressing these issues promptly not only enhances comfort but also prolongs the lifespan of the cooling system. Regular checks and preventive measures are key to ensuring optimal performance.

Tools Needed for AC Repair

Maintaining and fixing an air conditioning system requires a specific set of instruments to ensure efficiency and effectiveness. Understanding which tools are essential can make the process smoother and more successful. Below is a comprehensive list of necessary equipment for anyone looking to troubleshoot and enhance their cooling system.

Essential Instruments

- Refrigerant Gauges

- Vacuum Pump

- Wrenches and Socket Set

- Multimeter

- Screwdrivers (Flat and Phillips)

Additional Equipment

- Leak Detection Tools

- Hoses and Fittings

- Thermometer

- AC Manifold Gauge Set

- Safety Gear (Gloves and Goggles)

Having these tools on hand not only facilitates the troubleshooting process but also ensures that any adjustments or replacements can be done effectively. Proper equipment contributes significantly to the overall performance and longevity of the cooling system.

Step-by-Step Repair Guide

This section aims to provide a comprehensive walkthrough for addressing common issues in vehicle climate control systems. By following a systematic approach, you can enhance your understanding and skill set, leading to effective troubleshooting and resolution of problems.

Step 1: Diagnosis – Begin by identifying the symptoms of the issue. Listen for unusual noises, check for inconsistent cooling or heating, and observe any warning lights on the dashboard. Document these observations for reference.

Step 2: Gather Tools – Ensure you have all necessary tools at hand. Commonly required items include wrenches, screwdrivers, and diagnostic equipment. Having everything prepared will streamline the process.

Step 3: Access the System – Locate and open the relevant panels to gain access to the components of the climate control system. Ensure the vehicle is turned off and the keys are removed for safety.

Step 4: Inspect Components – Examine individual parts such as the compressor, condenser, and hoses for signs of wear, damage, or leaks. Take notes on any findings that may require attention.

Step 5: Perform Tests – Use diagnostic tools to test the functionality of each component. Check for electrical connections, fluid levels, and other operational parameters to pinpoint the root cause of the issue.

Step 6: Execute Repairs – Based on your diagnosis, carry out the necessary actions, whether it involves replacing parts, sealing leaks, or recharging the system. Follow the recommended guidelines for each task.

Step 7: Reassemble – Once repairs are completed, carefully reassemble any panels or covers that were removed. Ensure all screws and fasteners are securely tightened to prevent future issues.

Step 8: Test the System – Start the vehicle and test the climate control system to verify that the issue has been resolved. Monitor its performance and listen for any abnormal sounds.

Step 9: Document Your Work – Keep a record of the repairs performed and any parts replaced. This documentation can be valuable for future maintenance and troubleshooting.

By following these steps, you can effectively address issues in your vehicle’s climate control, ensuring optimal performance and comfort.

Diagnosing Refrigerant Leaks

Identifying the presence of refrigerant leaks is a crucial step in maintaining optimal performance in cooling systems. A drop in efficiency often signals underlying issues, and pinpointing these leaks can prevent further complications. This section outlines various methods to detect refrigerant loss effectively.

| Method | Description | Advantages |

|---|---|---|

| Visual Inspection | Examine components for signs of oil or refrigerant residue. | Quick and non-invasive. |

| Ultrasonic Leak Detectors | Use sound waves to locate escaping refrigerant. | Highly accurate and effective in noisy environments. |

| Electronic Leak Detectors | Utilize sensors to identify the presence of refrigerant in the air. | Reliable and easy to use. |

| Bubble Test | Apply a soapy solution to suspect areas and look for bubbles. | Simple and cost-effective. |

| Fluorescent Dye | Add dye to the system and use a UV light to find leaks. | Visual confirmation of leak locations. |

By employing these techniques, technicians can accurately diagnose refrigerant leaks, ensuring the system operates efficiently and effectively.

Replacing AC Compressors Effectively

Ensuring optimal performance of a vehicle’s cooling system often hinges on the effective replacement of key components. When it comes to the compressor, understanding the intricacies of the process can significantly impact the overall functionality and longevity of the system. This section delves into essential steps and considerations to achieve a successful installation.

Preparation and Tools

Before embarking on the replacement journey, gathering the necessary tools is crucial. Commonly required instruments include wrenches, a socket set, and refrigerant recovery equipment. Additionally, ensuring a clean workspace helps prevent contamination and damage to the new compressor. Proper preparation not only streamlines the process but also enhances safety and efficiency.

Installation Steps

Begin by safely disconnecting the battery and releasing any remaining refrigerant in the system. Remove the old compressor carefully, taking note of all connections and mounting points. When installing the new unit, follow the manufacturer’s guidelines regarding torque specifications and alignment. After securing the compressor, recharge the system with the appropriate refrigerant and check for leaks to confirm a successful replacement.

Electrical Components in AC Systems

The functionality of air conditioning systems relies heavily on various electrical components that work in unison to ensure optimal performance. Understanding these elements is essential for diagnosing issues and maintaining system efficiency. Each component plays a crucial role, contributing to the overall operation of the cooling mechanism.

Compressors serve as the heart of the cooling system, responsible for circulating refrigerant through the entire setup. They rely on electrical energy to function, converting it into mechanical power that compresses the refrigerant. When this component malfunctions, it can lead to significant drops in cooling efficiency.

Fans are another vital element, moving air across the evaporator and condenser coils. Electric motors power these fans, which help facilitate heat exchange. A failure in the fan motor can cause the system to overheat or fail to cool effectively.

Sensors monitor various parameters within the system, such as temperature and pressure. These electrical devices provide feedback to the control unit, ensuring that the system operates within specified limits. If a sensor fails, it may result in erratic system behavior or complete shutdown.

Lastly, relays and fuses play a protective role in the electrical circuit. Relays control the flow of electricity to different components, while fuses prevent overloads that could damage the system. Understanding the function of these protective elements is crucial for troubleshooting electrical issues within the air conditioning framework.

Maintaining Your AC System

Keeping your air conditioning system in optimal condition is essential for ensuring a comfortable driving experience. Regular upkeep not only enhances efficiency but also extends the lifespan of the unit. By following a few simple practices, you can prevent common issues and enjoy consistent performance throughout the year.

Regular Inspections

Filter Replacement

Replacing the air filter is another vital aspect of maintenance. A clean filter promotes better airflow and helps your system operate more efficiently. Check the manufacturer’s recommendations for replacement intervals, and consider replacing it more frequently if you drive in dusty conditions.

Upgrading to Modern AC Technologies

In the quest for enhanced comfort and efficiency, many vehicle owners are considering the transition to contemporary climate control systems. These advancements not only improve the overall driving experience but also contribute to energy savings and environmental sustainability. Embracing the latest technologies can significantly elevate performance while reducing maintenance challenges.

Benefits of Modern Systems

Contemporary climate control solutions offer numerous advantages. Improved efficiency is one of the primary benefits, as modern units are designed to consume less energy while delivering superior cooling performance. Additionally, they often feature smart technology that allows for precise temperature management and better integration with other vehicle systems, enhancing overall functionality.

Considerations for Upgrade

When contemplating an upgrade, it’s essential to evaluate compatibility with existing components. Researching potential systems is crucial to ensure they meet specific needs without compromising other functionalities. Furthermore, understanding the necessary adjustments and installation requirements will help facilitate a smooth transition to these advanced technologies.

Cost Factors in AC Repairs

Understanding the financial aspects of air conditioning system issues is essential for vehicle owners. Various elements contribute to the overall expenses, influencing both the time required for diagnostics and the price of necessary components. By recognizing these factors, individuals can make informed decisions regarding their cooling system troubles.

One significant aspect is the complexity of the problem. Simple issues, such as a refrigerant recharge, typically incur lower costs compared to more complicated challenges like compressor failure or leaks in the system. The severity of the malfunction directly correlates with the labor and parts required to restore functionality.

Another critical factor is the type of vehicle. Different makes and models often require specific tools and expertise, which can lead to varying labor rates. Additionally, the availability of parts can affect pricing, with rare components often being more expensive and harder to source.

Geographic location also plays a role in the cost structure. Labor rates can differ significantly between urban and rural areas, as well as from one region to another. Furthermore, local competition among service providers can influence pricing strategies, offering potential savings for consumers.

Lastly, the overall condition of the air conditioning system should not be overlooked. A well-maintained system may incur lower costs in the long run, while a neglected unit could lead to more frequent issues and higher expenses. Investing in regular maintenance can ultimately save vehicle owners from significant financial burdens associated with major failures.

Safety Precautions During Repairs

Ensuring a safe environment while performing maintenance tasks is crucial for both the technician and the vehicle. Various hazards may arise, making it essential to adhere to specific guidelines that minimize risks and promote a secure workspace.

Personal Protective Equipment

Using appropriate personal protective gear is vital. This includes items such as gloves, safety goggles, and steel-toed boots. These components protect against potential injuries from sharp tools, hazardous substances, and heavy components. Always assess the task at hand to determine the necessary protective items.

Work Environment Organization

Maintaining an organized workspace enhances safety significantly. Ensure that tools are neatly arranged and that the area is free from clutter. Additionally, proper ventilation is necessary when handling chemicals or working in confined spaces. Regularly check for spills or obstacles that could lead to accidents, and address them promptly.