Ensuring the optimal performance of your lawn care equipment is essential for achieving a well-manicured outdoor space. Understanding the intricacies of these machines can help users troubleshoot issues, perform routine upkeep, and enhance their longevity. This guide serves as a comprehensive resource for enthusiasts seeking to maintain their machines effectively.

In this section, readers will discover a wealth of knowledge on common challenges faced by users, along with step-by-step instructions to tackle them. Whether it’s adjusting blades, addressing engine troubles, or understanding electrical systems, the insights provided will empower users to take control of their equipment’s health.

With an emphasis on practical solutions and easy-to-follow guidance, this resource will simplify the maintenance process. By familiarizing oneself with the operational principles and common faults, users can ensure their machines remain in top-notch condition, ready to tackle any lawn care task.

Murray Riding Mower Repair Manual

This section aims to provide a comprehensive guide for maintaining and troubleshooting garden vehicles. Understanding the intricacies of these machines ensures longevity and optimal performance, allowing users to efficiently manage their outdoor tasks.

Regular maintenance is crucial to prevent common issues that can arise during operation. Key aspects include checking fluid levels, inspecting belts and blades, and ensuring electrical components are functioning correctly. By adhering to a systematic approach, operators can identify potential problems before they escalate.

In case of mechanical failures, it’s essential to have a methodical process for diagnostics. This involves recognizing symptoms, consulting relevant resources, and applying appropriate solutions. Detailed descriptions of components and their functions facilitate a better understanding of the vehicle’s system, making repairs more manageable.

Utilizing available resources, including online forums and technical documentation, can greatly enhance the knowledge base for handling various challenges. Engaging with a community of enthusiasts provides additional insights and support, fostering a deeper appreciation for the machinery.

Ultimately, having a structured approach to upkeep and troubleshooting enables users to maintain their equipment in peak condition, ensuring reliable performance for years to come.

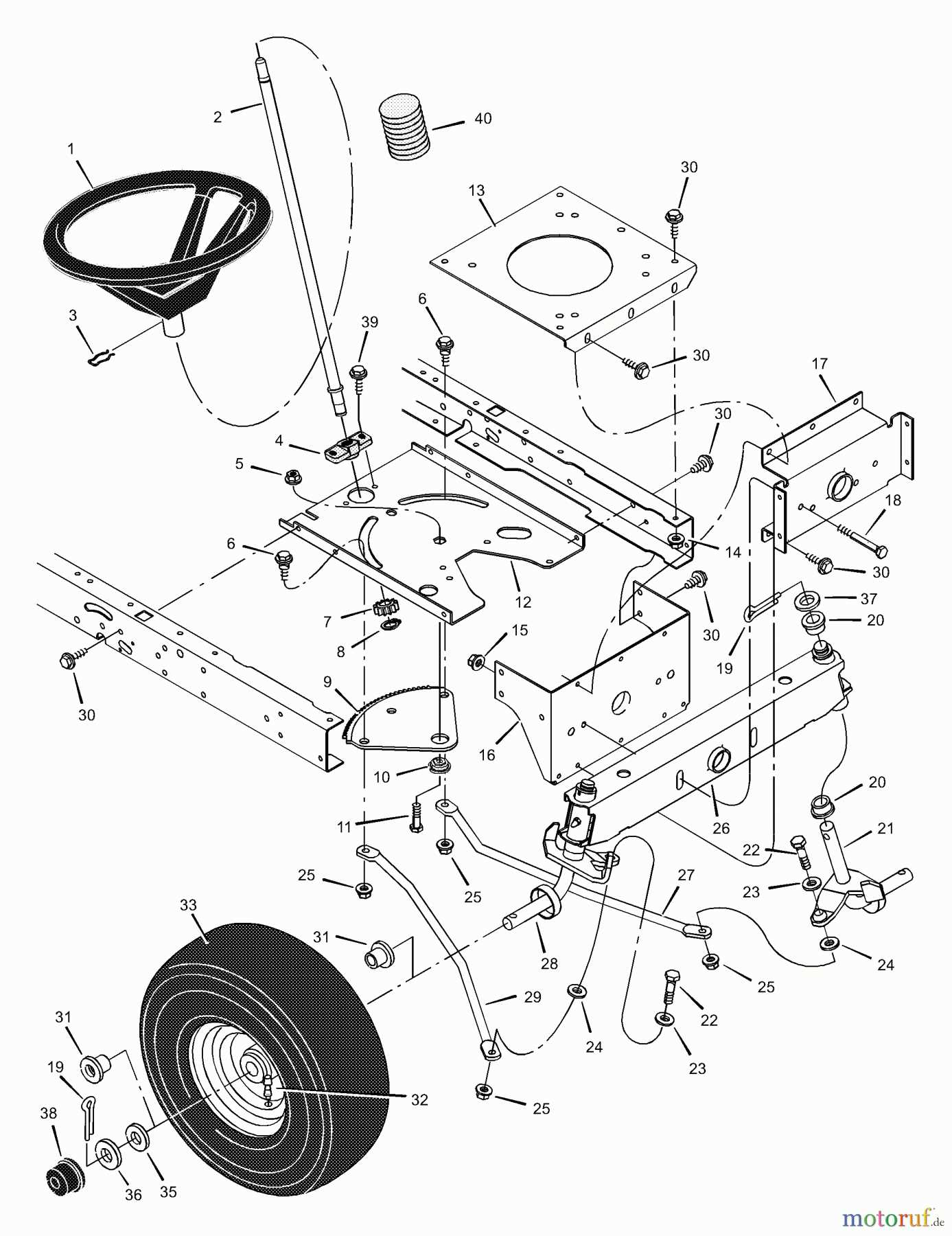

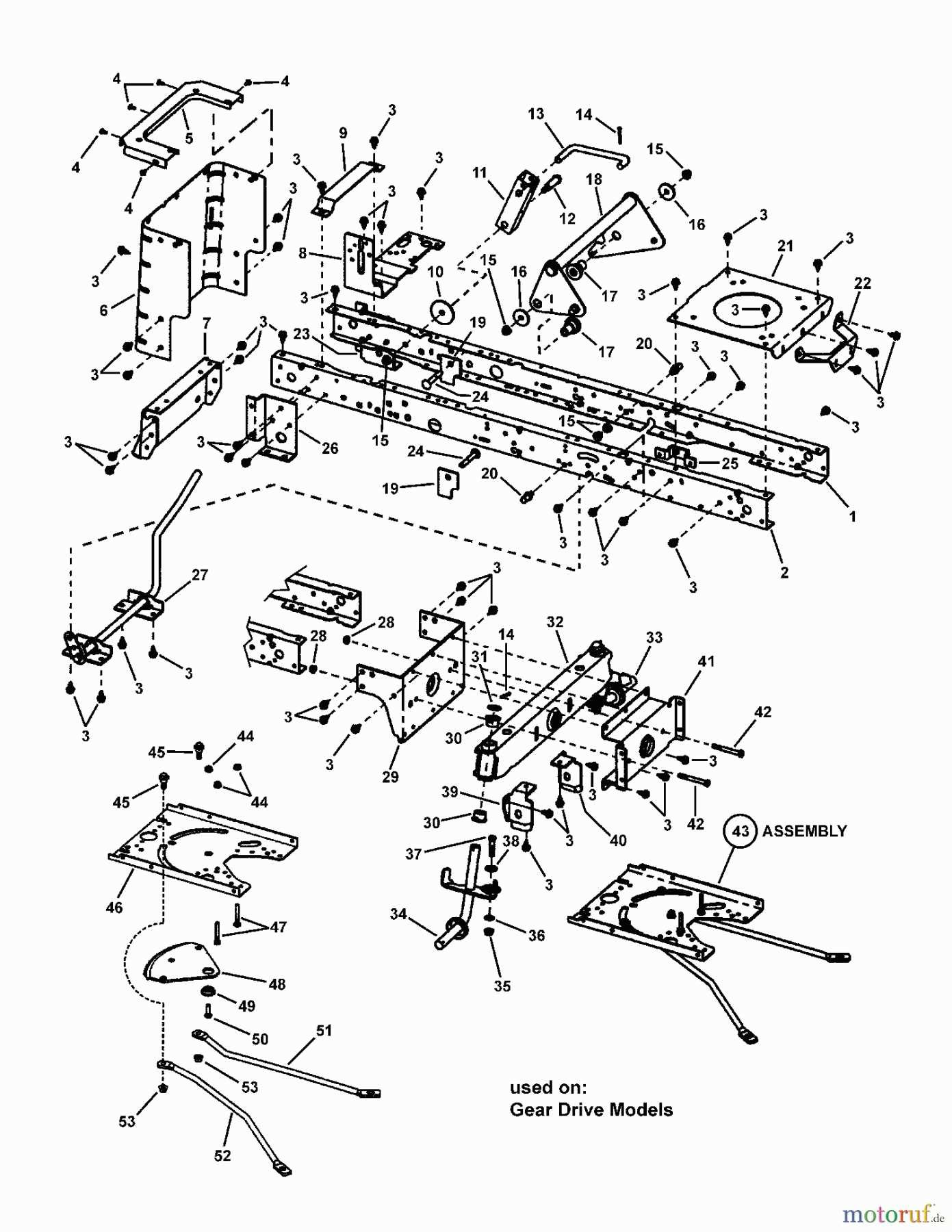

Understanding Your Mower’s Components

Gaining insight into the various elements of your lawn care machine is essential for effective maintenance and optimal performance. Each component plays a significant role in the overall functionality, ensuring that tasks are completed efficiently and effectively.

Engine: The heart of the equipment, responsible for powering all operations. Understanding its features and specifications can help you troubleshoot issues and enhance performance.

Transmission: This part transmits power from the engine to the wheels, allowing for smooth movement. Familiarity with its mechanics can aid in resolving mobility concerns.

Deck: The cutting mechanism that dictates the quality of the trim. Knowledge about its adjustment and maintenance can significantly impact the aesthetic of your lawn.

Controls: These allow you to operate the machine effectively. Knowing how each lever and switch functions ensures you can navigate and utilize the equipment to its full potential.

Wheels: Essential for mobility, understanding their maintenance can prevent wear and ensure a smooth ride across various terrains.

By familiarizing yourself with these essential parts, you can better care for your equipment, leading to prolonged lifespan and improved functionality.

Common Issues with Riding Mowers

Operating a lawn care vehicle can present various challenges that users often encounter. Understanding these common problems can lead to quicker resolutions and more efficient usage. Here, we will explore typical complications and their potential causes.

Frequent Complications

- Engine Troubles

- Electrical Failures

- Blade Malfunctions

- Fuel Issues

Engine Troubles

One of the most prevalent difficulties involves the engine not starting or stalling during operation. Possible causes include:

- Insufficient fuel

- Clogged air filter

- Battery issues

Electrical Failures

Another common concern relates to the electrical system. Users may experience problems such as:

- Dead battery

- Faulty ignition switch

- Worn-out wiring connections

Step-by-Step Troubleshooting Guide

This guide provides a structured approach to identifying and resolving issues with outdoor equipment. By following these steps, you can systematically diagnose common problems and implement effective solutions, ensuring optimal performance and longevity.

Begin by assessing the symptoms observed. This initial evaluation will guide you in pinpointing potential areas of concern. Next, gather necessary tools and materials for the troubleshooting process. Below is a table outlining common issues, potential causes, and recommended actions.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Empty fuel tank | Refill with fresh fuel |

| Uneven cutting | Dull blades | Sharpen or replace blades |

| Excessive vibration | Loose components | Tighten all fasteners |

| Smoke from engine | Overfilled oil | Drain excess oil |

After following the recommendations, conduct a final inspection to ensure all adjustments were effective. This systematic approach not only resolves immediate issues but also helps in maintaining overall functionality.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for effective maintenance tasks. These tools not only enhance efficiency but also ensure that each job is executed with precision and care. Understanding which items are fundamental can significantly simplify your work process.

Basic Hand Tools

A set of reliable hand tools forms the backbone of any maintenance toolkit. Items such as wrenches, screwdrivers, and pliers are indispensable for loosening and tightening components. It is advisable to invest in a sturdy toolbox to keep these essentials organized and easily accessible.

Diagnostic Instruments

In addition to hand tools, diagnostic instruments play a vital role in troubleshooting issues. A multimeter can be essential for checking electrical systems, while a compression tester aids in evaluating engine performance. Using these devices helps identify problems swiftly, leading to more effective solutions.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and care. Implementing simple yet effective practices can significantly enhance performance and durability. By focusing on routine checks and timely interventions, you can prevent common issues and prolong the useful lifespan of your machinery.

First, regularly inspect and clean all accessible components to remove debris and dirt buildup. This not only improves efficiency but also helps in identifying potential problems early on. Pay close attention to filters, as clogged ones can hinder performance. Replacing them as per the manufacturer’s recommendations is crucial.

Next, lubricate moving parts according to the prescribed schedule. Proper lubrication minimizes wear and tear, allowing for smooth operation. Additionally, ensure that fluid levels are monitored and maintained, as insufficient levels can lead to overheating and damage.

Lastly, store your equipment in a dry and sheltered area to protect it from harsh weather conditions. Covering it when not in use adds an extra layer of protection, helping to maintain its condition over time. By following these maintenance tips, you can enjoy reliable performance and extend the life of your machinery.

How to Replace the Blade

Changing the cutting tool is an essential maintenance task that ensures efficient operation and optimal performance. Properly replacing this component can lead to a cleaner cut and improved functionality. Follow these steps to effectively perform this task.

Step 1: Gather Necessary Tools

Before beginning, ensure you have the right equipment. You will need a socket wrench, safety gloves, and a replacement cutting tool suitable for your machine.

Step 2: Prepare the Equipment

Always turn off the engine and disconnect the spark plug wire to prevent accidental starts. This safety measure is crucial during maintenance.

Step 3: Access the Cutting Tool

Lift the chassis or access the underside where the cutting tool is located. This may involve removing protective covers or guards, depending on your specific model.

Step 4: Remove the Old Cutting Tool

Using the socket wrench, loosen the bolt that secures the current tool in place. Carefully detach it and set it aside, taking note of any washers or spacers that may be present.

Step 5: Install the New Cutting Tool

Position the new tool where the old one was located. Ensure it aligns correctly and use the bolt to secure it tightly. Do not overtighten, as this could damage the equipment.

Step 6: Reassemble and Test

Replace any covers or guards that were removed earlier. Reconnect the spark plug wire and start the engine to ensure everything operates smoothly. Check for any unusual noises or vibrations.

Following these steps will help maintain your equipment’s efficiency and longevity, contributing to a well-kept landscape.

Engine Care and Maintenance

Proper upkeep of the engine is essential for ensuring optimal performance and longevity. Regular attention to maintenance tasks can prevent issues that might lead to costly repairs. This section provides guidance on best practices for maintaining engine health, focusing on routine inspections and necessary procedures.

Routine Inspections

Conducting regular checks is crucial for identifying potential problems before they escalate. Inspect the air filter for dirt and debris, as a clean filter enhances airflow and efficiency. Additionally, examine the spark plug for wear and deposits; replacing it as needed can improve ignition and performance. Regularly monitoring oil levels and condition is also vital, as clean oil ensures smooth operation and reduces friction.

Scheduled Maintenance Tasks

Adhering to a maintenance schedule helps maintain engine efficiency. Change the oil at recommended intervals to ensure proper lubrication. Replace the fuel filter regularly to prevent clogs that can hinder performance. Keeping the cooling system clean and free from debris is also essential, as overheating can cause severe damage. Following these tasks will significantly contribute to the engine’s reliability and functionality.

Electrical System Diagnostics

Effective evaluation of the electrical framework is essential for ensuring optimal performance and reliability. Identifying issues within the circuitry can prevent unnecessary disruptions and prolong the lifespan of the equipment. This section provides a comprehensive overview of the diagnostic approaches that can be utilized to troubleshoot electrical malfunctions.

Understanding Common Symptoms

Familiarizing oneself with typical indicators of electrical problems is crucial. Common signs may include failure to start, flickering lights, or erratic behavior of components. Recognizing these symptoms early can assist in pinpointing the underlying issues, enabling a more efficient resolution process.

Diagnostic Techniques

Utilizing appropriate tools and methods is vital for accurate assessment. Multimeters, for instance, can measure voltage, current, and resistance, helping to identify faulty connections or components. Additionally, visual inspections of wiring and connectors can reveal wear or damage that may lead to operational failures.

Hydraulic System Overview

The hydraulic system is a crucial component in various machinery, providing efficient power transfer through fluid movement. This system utilizes pressurized liquid to perform tasks such as lifting, steering, and other functions that require significant force. Understanding its operation is essential for effective maintenance and troubleshooting.

At its core, the system consists of several key elements, including a pump, valves, and cylinders. The pump generates the necessary pressure, pushing fluid through the system. Valves control the flow of this fluid, directing it to specific components as needed. Finally, cylinders convert hydraulic energy into mechanical force, enabling various operations.

Maintaining the integrity of the hydraulic system is vital for optimal performance. Regular checks for leaks, fluid levels, and component wear can prevent potential failures. Properly understanding this system enhances both operational efficiency and longevity of the machinery.

Seasonal Preparation Checklist

As the seasons change, it is essential to ensure that your outdoor equipment is ready for optimal performance. This checklist will guide you through important maintenance tasks to enhance longevity and efficiency. By following these steps, you can ensure that your machinery remains in peak condition, ready to tackle various tasks throughout the year.

Maintenance Tasks

| Task | Description | Frequency |

|---|---|---|

| Inspect Blades | Check for damage or dullness and sharpen or replace as needed. | Before each season |

| Change Oil | Replace old oil with fresh lubricant to maintain engine health. | Every season |

| Clean Air Filter | Remove debris and dirt to ensure proper airflow to the engine. | Monthly |

| Check Tires | Inspect for wear and ensure proper inflation for optimal traction. | Monthly |

| Inspect Battery | Check for corrosion and ensure proper connections to prevent starting issues. | Every season |

Additional Considerations

In addition to the tasks listed, it’s important to store your equipment properly during the off-season. This includes cleaning thoroughly, covering with a protective tarp, and storing in a dry location. Taking these steps can help prevent rust and damage from environmental factors.

Where to Find Replacement Parts

Locating suitable components for your outdoor equipment can be a straightforward process if you know where to look. Numerous resources are available, ranging from local retailers to online platforms, making it easier to obtain the necessary items to keep your machine in optimal condition.

Here are some effective avenues to explore:

| Source | Description |

|---|---|

| Local Hardware Stores | Many community hardware stores stock essential parts for various models, offering convenience and immediate access. |

| Specialty Shops | Dedicated stores for outdoor machinery often have a wide selection of components and knowledgeable staff to assist you. |

| Online Retailers | Websites like Amazon or eBay provide a vast inventory of parts, often with user reviews to guide your choice. |

| Manufacturer’s Website | The official site may offer a catalog of parts specific to your equipment, ensuring compatibility and quality. |

| Local Classifieds | Check community bulletin boards or online classifieds for second-hand parts, which can be cost-effective. |