Understanding the intricacies of a specific powertrain can greatly enhance its longevity and performance. This section delves into essential techniques and knowledge needed for effective upkeep, ensuring that enthusiasts and mechanics alike can navigate the complexities of engine care with confidence.

From routine checks to troubleshooting common issues, this resource aims to equip users with the information necessary for achieving optimal functionality. With a focus on practical insights, readers will discover the significance of each component and how to maintain them effectively.

Whether you are a seasoned technician or a novice enthusiast, this guide serves as a valuable tool in fostering a deeper appreciation for automotive systems. By adhering to the outlined practices, individuals can maximize the potential of their engine while minimizing the likelihood of future complications.

Overview of 1UZ-FE Engine

The 1UZ-FE is a remarkable power unit, renowned for its advanced engineering and robust performance characteristics. This V8 engine has gained a reputation for reliability and efficiency, making it a popular choice among automotive enthusiasts and manufacturers alike.

Key Features

- Type: V8 configuration

- Displacement: Approximately 4.0 liters

- Fuel System: Multi-point fuel injection

- Power Output: Varies based on model and tuning

Performance Characteristics

This engine delivers a harmonious blend of power and smooth operation. Its design emphasizes:

- Excellent torque delivery across a broad RPM range

- Minimal vibration and noise for a refined driving experience

- Compatibility with a variety of drivetrain setups

Such attributes contribute to its longevity and appeal in various automotive applications.

Common Issues and Symptoms

When dealing with a complex engine system, various problems may arise that can significantly impact performance and reliability. Identifying these issues early can save time and resources, ensuring that the vehicle operates smoothly.

Engine Overheating: One frequent concern is overheating, which can result from a malfunctioning cooling system or low coolant levels. Symptoms may include temperature gauge readings in the red zone or visible steam from the engine bay.

Oil Leaks: Another common issue is oil leakage, often detectable by dark spots on the ground where the vehicle is parked. This can lead to decreased lubrication and potential engine damage if not addressed promptly.

Starting Difficulties: If the engine struggles to start or makes unusual noises during ignition, it may indicate battery or starter issues. Observing these symptoms can help in diagnosing underlying electrical problems.

Unusual Noises: Strange sounds, such as knocking or grinding, may suggest internal wear or component failure. Paying attention to these noises can provide valuable insights into the engine’s health.

Performance Issues: A noticeable decrease in power or acceleration can indicate fuel delivery problems or air intake issues. Drivers should be vigilant for any changes in responsiveness while driving.

Check Engine Light: Finally, the illumination of the check engine light is a crucial signal that should not be ignored. This warning can point to various faults within the engine system, necessitating further investigation.

Essential Tools for Repairs

Having the right instruments is crucial for effectively addressing mechanical issues. Properly selected equipment can significantly ease the process, ensuring that tasks are completed with precision and efficiency.

Start with a comprehensive toolset that includes basic hand tools such as wrenches, screwdrivers, and pliers. These fundamentals are vital for most disassembly and assembly tasks. Additionally, specialized tools like torque wrenches and diagnostic scanners can enhance the troubleshooting process, allowing for accurate measurements and assessments.

Investing in quality tools is equally important. High-grade materials not only improve durability but also contribute to a more seamless experience when tackling complex procedures. Always keep safety gear on hand, including gloves and goggles, to protect against potential hazards during the process.

Lastly, maintaining an organized workspace aids in efficiency and helps prevent misplacing vital tools. By ensuring that every instrument has its designated spot, you streamline your workflow and reduce frustration, allowing for a more productive environment.

Step-by-Step Maintenance Procedures

This section provides a comprehensive approach to performing essential upkeep tasks. By following these systematic methods, individuals can ensure optimal performance and longevity of the engine. Regular attention to various components is crucial for maintaining efficiency and reliability.

1. Preliminary Inspection: Begin by thoroughly examining the engine for any visible signs of wear or damage. Look for leaks, loose connections, and other potential issues that may require immediate attention.

2. Fluid Checks: Regularly monitor fluid levels, including oil, coolant, and transmission fluid. Ensure that each is at the recommended level and top off as necessary.

3. Filter Replacement: Replace air and oil filters at designated intervals to maintain clean airflow and proper lubrication. This step is vital for enhancing engine performance.

4. Spark Plug Inspection: Remove and inspect spark plugs for wear and carbon buildup. Replace them if necessary to ensure optimal ignition and fuel efficiency.

5. Belt and Hose Evaluation: Check all belts and hoses for signs of cracking, fraying, or leaks. Replace any components that show signs of deterioration to prevent failure during operation.

6. Exhaust System Assessment: Inspect the exhaust system for any rust, leaks, or blockages. Address any issues promptly to maintain proper engine function and emissions control.

7. Battery Maintenance: Clean battery terminals and check for corrosion. Ensure that connections are secure and that the battery is holding a charge.

8. Final Review: After completing all maintenance tasks, conduct a final review to ensure everything is in order. Document any repairs or replacements made for future reference.

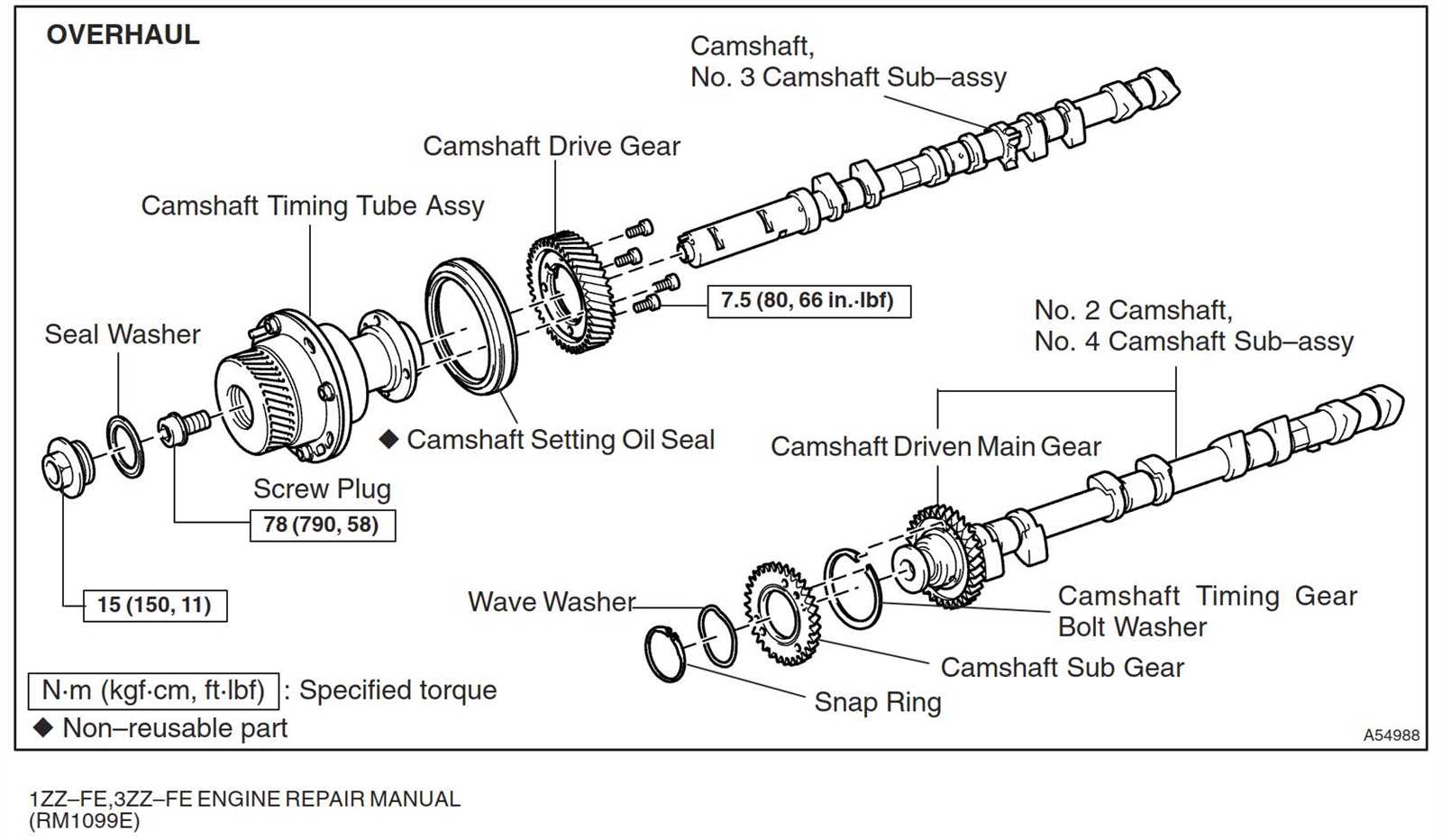

Disassembly and Reassembly Guide

This section provides a comprehensive approach to the careful disassembly and reassembly of complex mechanical systems. Following a systematic method is essential to ensure all components are handled properly and reassembled correctly for optimal performance.

Before starting the process, it is crucial to gather all necessary tools and materials. Having a clean workspace will facilitate better organization and prevent any parts from being lost.

Here are the key steps to follow:

- Preparation:

- Gather tools: wrenches, screwdrivers, pliers, etc.

- Prepare containers for small parts to avoid misplacement.

- Review documentation or guides for specific component layouts.

- Disassembly:

- Start by disconnecting any power sources.

- Carefully remove external covers and panels.

- Label and store fasteners in an organized manner.

- Document the position of components for easier reassembly.

- Inspection:

- Examine each component for wear or damage.

- Clean parts as necessary to remove debris and dirt.

- Replace any worn or damaged parts before reassembly.

- Reassembly:

- Follow the documentation to restore parts in the reverse order of disassembly.

- Ensure all connections are secure and properly aligned.

- Double-check the positioning of components and fasteners.

By adhering to this guide, you can effectively manage the disassembly and reassembly process, leading to successful maintenance and longevity of the system.

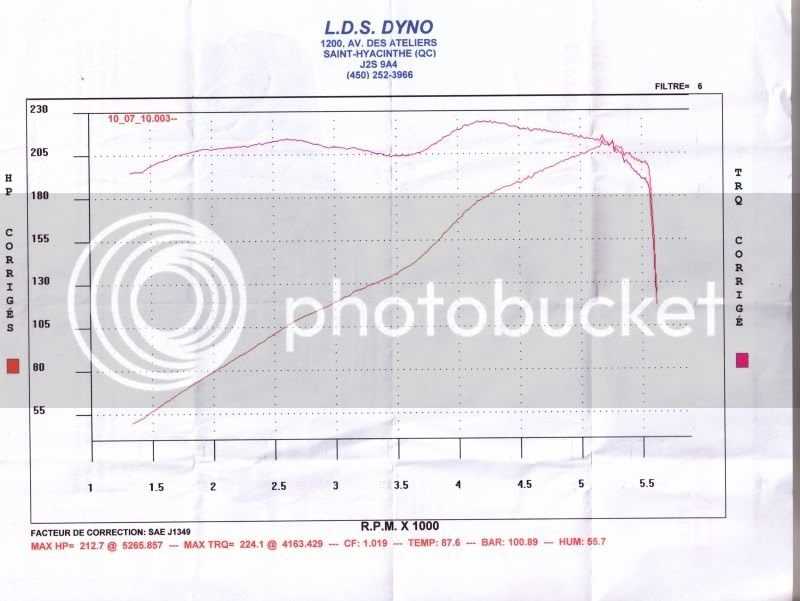

Engine Performance Upgrades

Enhancing the efficiency and power of your vehicle’s powertrain can significantly improve its overall driving experience. Various modifications can be implemented to boost performance, ensuring that the engine operates at its best. This section will explore several effective upgrades that can lead to noticeable improvements.

Common Upgrade Options

There are numerous options available for increasing engine performance. These modifications can range from simple bolt-ons to more complex internal changes, each contributing to better power output and responsiveness.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Cold Air Intake | Replaces the factory air intake system with a high-flow unit to improve airflow. | Increased horsepower and throttle response. |

| Performance Exhaust System | Enhances exhaust flow through larger diameter piping and high-flow mufflers. | Improved sound and power gains. |

| Tuning | Custom software adjustments to the engine’s control unit for optimized performance. | Better fuel efficiency and increased power. |

| Upgraded Fuel Injectors | Higher-flow injectors allow for more fuel delivery to the engine. | Supports increased horsepower from other modifications. |

| Turbocharger/Supercharger | Forced induction systems that compress air entering the engine, increasing power. | Substantial power boosts with proper tuning. |

Considerations for Upgrades

When contemplating enhancements, it is crucial to ensure that modifications are compatible with the existing system. Additionally, consider the balance between performance and reliability, as extreme upgrades may necessitate further changes to maintain engine longevity.

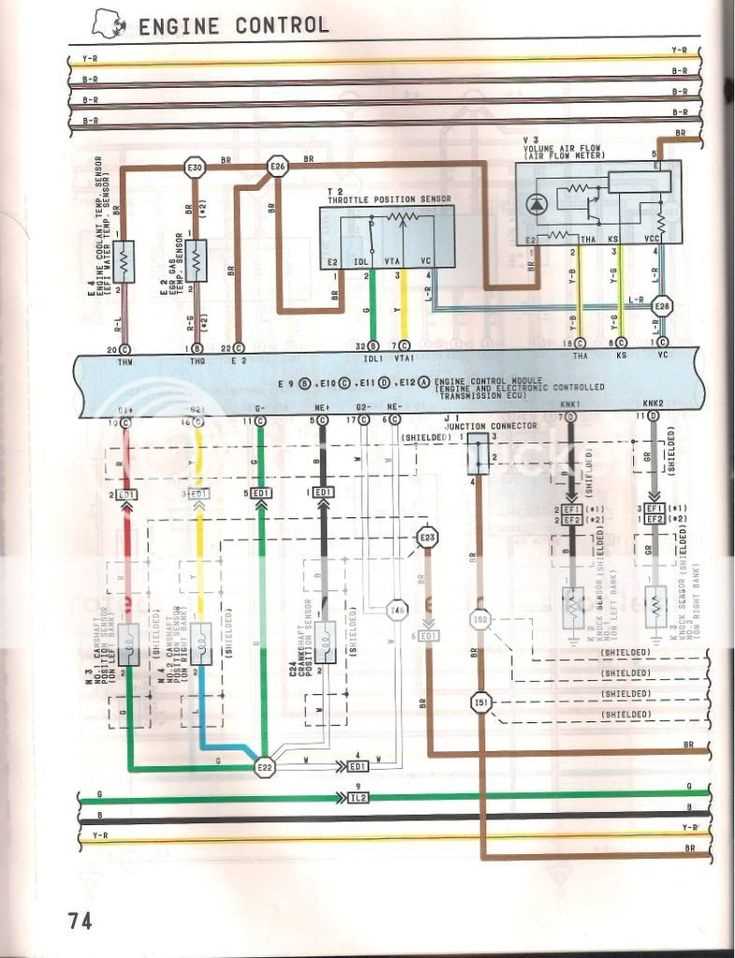

Understanding Electrical Systems

Electrical systems play a crucial role in the functionality and performance of modern vehicles. A comprehensive understanding of these systems is essential for diagnosing issues, conducting maintenance, and ensuring optimal operation.

At the core of electrical systems are various components that interact to power essential functions. Here are the key elements:

- Battery: Stores electrical energy for starting the engine and powering electrical components when the engine is off.

- Alternator: Generates electricity while the engine runs, recharging the battery and powering electrical systems.

- Starter Motor: Initiates engine operation by turning the crankshaft.

- Fuses: Protect circuits from overload by breaking the connection in case of excessive current.

- Wiring Harness: A network of wires that connects various electrical components, facilitating the flow of electricity.

Proper knowledge of these components helps in troubleshooting and enhancing the reliability of electrical systems. Regular checks and maintenance can prevent common issues, ensuring the vehicle operates smoothly and efficiently.

Cooling System Troubleshooting

The efficiency of an engine’s cooling mechanism is vital for maintaining optimal operating temperatures. When issues arise within this system, it can lead to significant engine performance problems. Identifying and resolving these concerns requires a systematic approach to diagnose potential failures effectively.

Common Symptoms of Cooling System Issues

- Overheating of the engine

- Inconsistent temperature readings on the gauge

- Coolant leaks under the vehicle

- Unusual noises from the engine area

Troubleshooting Steps

- Check coolant levels regularly to ensure sufficient fluid is present.

- Inspect for visible leaks around hoses, radiator, and water pump.

- Examine the thermostat for proper operation, replacing it if faulty.

- Flush the cooling system to remove debris and contaminants.

- Test the radiator and hoses for blockages or wear.

Fuel System Inspection Techniques

Assessing the fuel system is crucial for maintaining optimal engine performance. This process involves a series of systematic evaluations to identify any potential issues that could hinder fuel delivery and efficiency. Understanding how to conduct these inspections effectively ensures longevity and reliability in vehicle operation.

Begin by visually examining the fuel lines for any signs of wear, leaks, or corrosion. Pay close attention to connections and fittings, as these are common failure points. Additionally, inspect the fuel filter to determine if it requires replacement based on the manufacturer’s recommendations or observed contamination.

Next, utilize diagnostic tools to check fuel pressure. This measurement will reveal whether the fuel pump is operating within specified parameters. In cases where pressure falls below the acceptable range, further investigation into the pump and associated components is necessary.

Moreover, evaluating the fuel injectors is essential. Listen for unusual sounds that might indicate clogging or malfunction. Testing the injectors for proper spray patterns and flow rates will provide insights into their operational status.

Finally, consider conducting a fuel quality assessment. Contaminated or degraded fuel can significantly affect engine performance. Testing for water, sediments, and other impurities will help ensure that only clean fuel enters the system.

Oil Change and Filter Replacement

Regular maintenance of your vehicle’s lubrication system is essential for optimal performance and longevity. This section covers the essential steps for replacing the oil and filter, ensuring that your engine operates smoothly and efficiently.

Tools and Materials Required

- New oil filter

- Engine oil (check specifications for correct type and capacity)

- Oil drain pan

- Wrench set

- Oil filter wrench

- Funnel

- Rags or shop towels

Procedure

- Start the engine and let it run for a few minutes to warm up the oil, which helps it drain more easily.

- Turn off the engine and ensure the vehicle is on a level surface. Engage the parking brake.

- Position the oil drain pan under the oil pan’s drain plug.

- Using the appropriate wrench, carefully remove the drain plug and allow the old oil to completely drain into the pan.

- Once drained, replace the drain plug and tighten it securely.

- Remove the old oil filter using the oil filter wrench. Before installing the new filter, apply a small amount of new oil to the gasket of the new filter.

- Install the new oil filter, ensuring it is tight but not overly so.

- Using a funnel, pour the new engine oil into the oil filler cap. Refer to the specifications for the correct amount and type.

- Start the engine and let it run for a few minutes, checking for leaks around the oil filter and drain plug.

- After a few minutes, turn off the engine and check the oil level using the dipstick. Add more oil if necessary.

Regularly changing the oil and filter helps to maintain engine efficiency and extend the lifespan of your vehicle. Follow these steps diligently for best results.

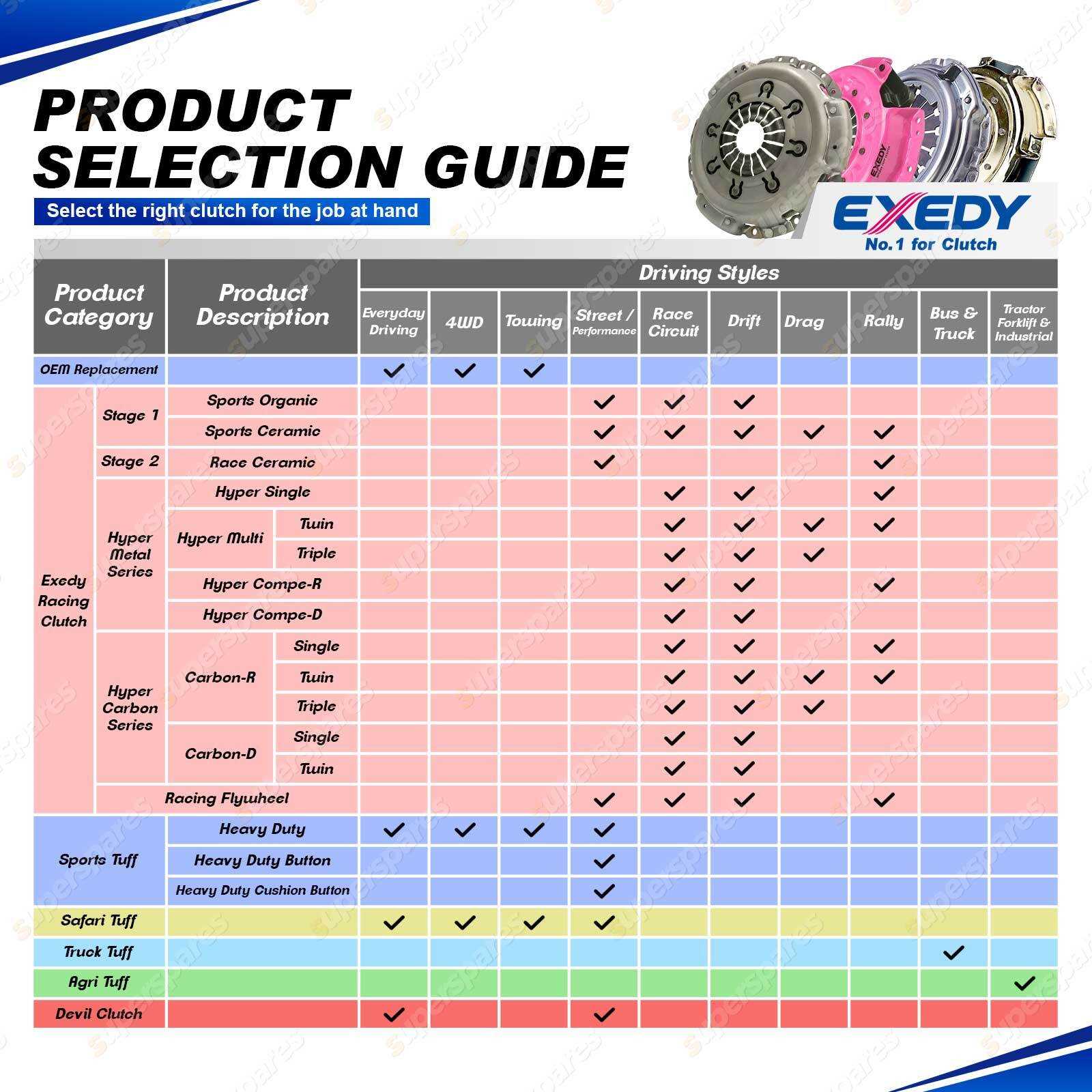

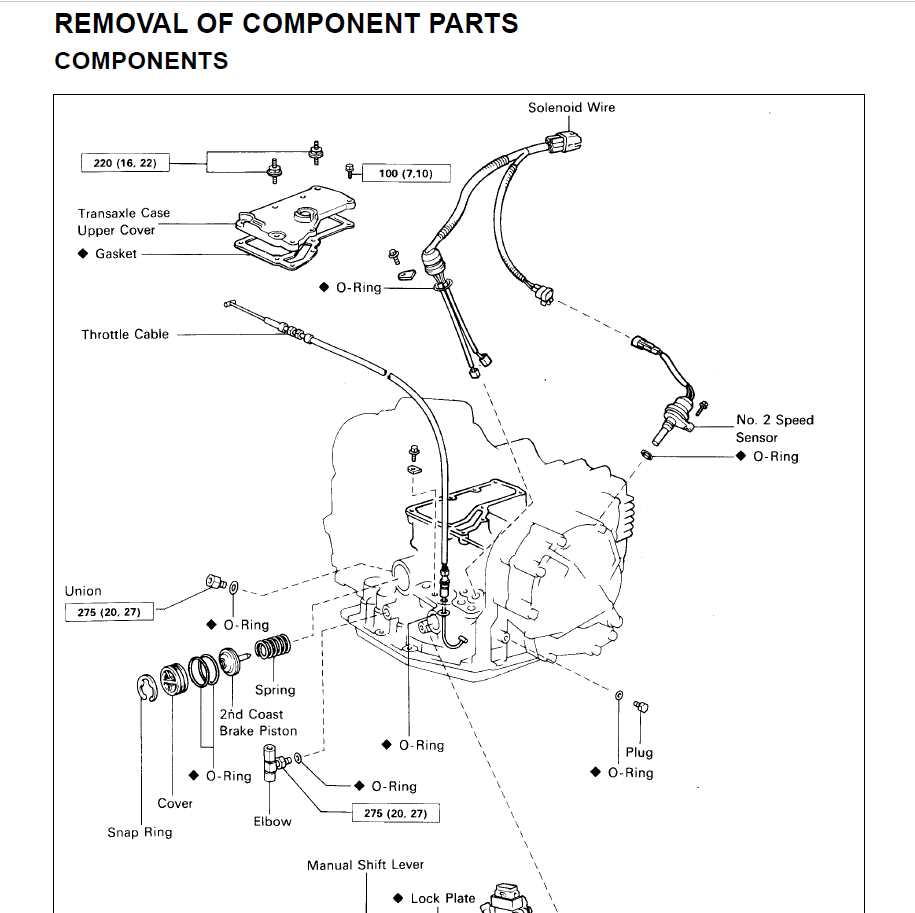

Transmission and Drivetrain Insights

The efficiency and performance of a vehicle heavily depend on its transmission and drivetrain systems. These components work in harmony to ensure smooth power delivery from the engine to the wheels, impacting acceleration, handling, and overall driving experience.

Understanding the key elements of these systems can help enthusiasts and technicians alike appreciate their complexity and the importance of proper maintenance. Below are some critical aspects to consider:

- Transmission Types: Different vehicles utilize various transmission types, including automatic, manual, and continuously variable transmissions (CVT). Each has its advantages and specific applications.

- Drivetrain Configuration: The layout of the drivetrain–front-wheel drive, rear-wheel drive, or all-wheel drive–affects handling characteristics and performance dynamics.

- Gear Ratios: Understanding gear ratios is essential for optimizing engine performance, as they determine how engine power is transmitted to the wheels.

- Fluid Maintenance: Regular inspection and replacement of transmission fluids are crucial to prolonging the lifespan of these systems and ensuring optimal functionality.

By paying attention to these factors, vehicle owners can enhance their understanding and maintenance of the transmission and drivetrain, leading to improved reliability and performance on the road.

Safety Precautions During Repairs

When undertaking maintenance tasks on complex machinery, it is crucial to prioritize safety to prevent accidents and injuries. Ensuring a secure environment and following specific guidelines can significantly reduce risks associated with handling mechanical components.

Personal Protective Equipment

Wearing appropriate protective gear is essential when working with tools and machinery. This includes items such as gloves, goggles, and steel-toed boots, which help shield against potential hazards. Always ensure that your equipment is in good condition and fits properly to provide optimal protection.

Workspace Organization

A well-organized workspace is key to maintaining safety during maintenance tasks. Keep tools and materials neatly arranged to minimize the chance of accidents. Ensure that the work area is free from clutter and that hazardous materials are stored securely. Proper lighting is also important to enhance visibility and reduce the likelihood of mishaps.