Ensuring the longevity and smooth operation of an automobile involves more than just routine checkups. It demands a thorough understanding of the key procedures and maintenance tasks necessary to keep a car in optimal condition. The following sections provide an extensive overview of techniques and insights, designed to help vehicle owners navigate common mechanical issues, routine upkeep, and various other essential practices for keeping an older model running like new.

With detailed explanations of different components and systems, this guide will assist in identifying problems early, allowing for timely intervention before minor issues escalate. From the engine to the electrical setup, each aspect is covered to offer a holistic approach to automotive care, empowering individuals to manage tasks confidently and efficiently. Regular attention to detail can significantly extend a vehicle’s life and enhance driving performance.

Whether dealing with general wear and tear, troubleshooting unexpected symptoms, or understanding the intricacies of various parts, this guide aims to be an indispensable resource. By delving into the mechanics, it equips owners with the necessary knowledge to address potential challenges, ensuring a well-maintained and reliable driving experience.

Essential Tools for DIY Repair

When working on automotive maintenance, having the right equipment is crucial for success. The right set of tools not only makes tasks easier but also ensures that the work is done safely and efficiently. With the proper gear, even complex tasks can be approached with confidence, turning challenging jobs into manageable projects.

A comprehensive toolkit should include a variety of hand tools, such as wrenches, screwdrivers, and pliers. These are fundamental for disassembling and reassembling various components. Additionally, socket sets in different sizes are indispensable for tasks involving bolts and nuts of different diameters, providing the necessary leverage and fit.

Power tools like impact wrenches and electric drills can speed up the process and reduce manual effort, especially when dealing with stubborn bolts. For more precision tasks, torque wrenches are essential to ensure that fasteners are tightened to the specified levels, preventing damage or mechanical failure.

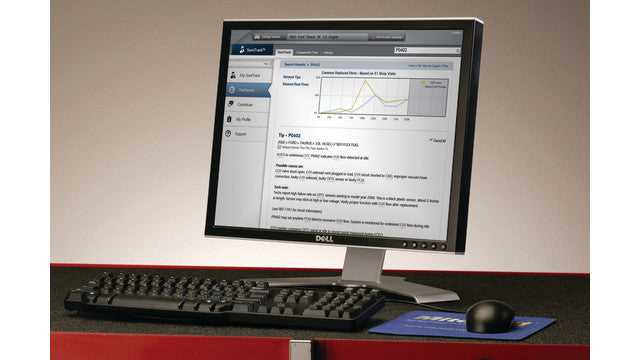

Other important items include diagnostic tools like code readers, which help identify issues by scanning the vehicle’s system for error codes. Jack stands and a hydraulic floor jack are also necessary for safely lifting the car when accessing components underneath. These tools form the foundation for effectively tackling a wide range of automotive tasks.

Choosing the Right Equipment for Your 1994 Cutlass Ciera

When selecting components and tools for your classic vehicle, it’s essential to consider compatibility and quality to ensure reliable performance. Properly chosen equipment can make maintenance smoother and enhance the car’s longevity, helping to avoid issues related to mismatched or substandard parts. Below is a guide on key items to prioritize and their role in maintaining optimal functionality.

| Equipment Category | Description | Key Considerations |

|---|---|---|

| Engine Parts | Essential for the vehicle’s overall performance, including components like spark plugs, belts, and filters. | Ensure items match the engine specifications for proper fit and efficiency. |

| Suspension and Brakes | Critical for ride comfort and safety, covering shocks, struts, brake pads, and rotors. | Choose parts designed for durability and responsiveness under varying road conditions. |

| Electrical Components | Includes batteries, wiring, and lighting systems, which affect the vehicle’s starting ability and overall electrical health. | Opt for components that meet or exceed original equipment standards for reliability. |

| Fluids and Lubricants | Vital for reducing friction and preventing wear, such as engine oil, transmission fluid, and brake fluid. | Use high-quality fluids compatible with the vehicle’s requirements to maintain optimal performance. |

By choosing the right equipment, you not only maintain the vehicle’s value but also enhance driving pleasure and safety. Regular assessments of each component’s condition can help identify when replacements or upgrades are necessary, ensuring the vehicle remains dependable over the years.

Common Mechanical Issues and Solutions

Many vehicles, especially those with considerable mileage, can encounter typical mechanical problems. These issues can range from minor inconveniences to significant failures that affect overall performance and safety. Understanding common symptoms and practical solutions can help in diagnosing and addressing problems effectively, ensuring a more reliable driving experience.

Engine Stalling or Rough Idling

One frequently reported problem is the engine stalling or running unevenly when idle. This can be caused by various factors such as clogged fuel injectors, a dirty throttle body, or faulty ignition components. Regular cleaning of the throttle body and fuel system additives can help alleviate these symptoms, while replacing spark plugs or ignition wires might be necessary for persistent cases.

Transmission Shifting Problems

Another common issue is difficulty with gear changes. This may manifest as delayed shifting, slipping, or harsh engagement of gears. Potential causes include low fluid levels, worn transmission components, or a failing torque converter. Regular fluid checks, timely servicing, and, if needed, component replacement can significantly improve shifting performance.

Overheating

Overheating is a concern that often arises due to a malfunctioning cooling system. Possible reasons include a faulty thermostat, a leaking radiator, or a failing water pump.

Troubleshooting Typical Problems in the 1994 Oldsmobile

Addressing common issues in vehicles of this era involves understanding the key areas where they may develop problems over time. This section outlines some frequent challenges faced by owners and provides insights into resolving them efficiently. The aim is to enhance the vehicle’s reliability by tackling these issues early, ensuring smooth performance and reducing the need for extensive repairs.

Engine Performance Issues

One prevalent issue observed in older cars involves inconsistencies in engine behavior, such as rough idling, stalling, or lack of power. These symptoms can often be traced back to components like spark plugs, the ignition system, or even a clogged fuel filter. Regular inspection and timely replacement of these elements can help maintain engine efficiency and prevent more serious mechanical problems from developing.

Electrical System Failures

With age, vehicles may experience electrical problems, which manifest as non-functioning lights, unresponsive dashboard indicators, or starter difficulties. Such issues could be linked to a weakened battery, corroded wiring, or a faulty alternator. To ensure dependable operation, periodic testing of the electrical system and prompt addressing of any irregularities is crucial.

Engine Maintenance Tips and Tricks

Proper care of the power unit ensures that the vehicle runs smoothly and efficiently for years to come. Regular maintenance not only enhances performance but also prevents costly repairs. Following some key practices can help keep the engine in optimal condition and extend its longevity.

Regular Oil Changes

Consistently changing the oil is essential for maintaining engine health. Fresh oil lubricates moving parts, reduces friction, and helps to prevent wear and tear. Check the oil level frequently, and top it up if necessary, to ensure that it stays within the recommended range. Using the correct oil type for your engine is also crucial for optimal performance.

Inspecting Belts and Hoses

Regularly inspecting belts and hoses for signs of wear, such as cracks, fraying, or leaks, can help prevent breakdowns. Replacing damaged components promptly will maintain the proper functioning of various systems connected to the engine. Make sure to also check the tension of belts to avoid slippage or excessive wear.

| Maintenance Task | Recommended Frequency |

|---|---|

| Oil and Filter Change | Every 3,000 to 5,000 miles |

| Inspect Belts and Hoses | Every 6

Optimizing Engine Performance in Your Cutlass CieraEnhancing the efficiency and responsiveness of your vehicle’s engine is crucial for a smooth driving experience. By focusing on several key areas, you can significantly improve the power output and fuel economy, ensuring that your ride remains both enjoyable and reliable. This guide will provide insights into various methods to boost your engine’s performance. Regular Maintenance ChecksKeeping up with regular maintenance is essential for maintaining optimal engine function. This includes changing the oil and filters at recommended intervals, as clean oil lubricates components effectively and reduces friction. Additionally, inspect and replace worn spark plugs to ensure proper ignition and improve combustion efficiency. Regular tune-ups can also help identify potential issues before they escalate into major problems. Upgrading Key ComponentsConsider enhancing your vehicle with upgraded parts designed to improve performance. A high-flow air intake system can increase airflow to the engine, leading to better combustion and increased power. Similarly, installing a performance exhaust system can reduce back pressure, allowing exhaust gases to exit more freely. Investing in quality components tailored for your model can result in a noticeable improvement in power delivery and throttle response. Electrical System Inspection and RepairThe functionality of an automotive electrical system is crucial for overall vehicle performance. Regular assessment and maintenance of this system can prevent potential issues and enhance reliability. This section provides guidance on evaluating and addressing common electrical components to ensure optimal operation. Visual Inspection: Begin with a thorough visual examination of all accessible wiring and connectors. Look for signs of wear, corrosion, or damage that could lead to malfunctions. Ensure that all connections are secure and free of any debris that might interfere with electrical flow. Battery Check: The battery is a vital component in any electrical system. Test the battery’s voltage using a multimeter. A fully charged battery should measure around 12.6 volts or higher. Additionally, inspect the terminals for corrosion and clean them if necessary to ensure a solid connection. Fuse Evaluation: Fuses protect various circuits from overloads. If electrical components are not functioning, check the relevant fuses. Replace any that are blown with fuses of the same rating to prevent further issues. Wiring Integrity: Assess the condition of the wiring harnesses. Pay particular attention to areas where wires may rub against metal surfaces, as this can lead to short circuits. Use electrical tape or protective sleeves to secure and insulate any vulnerable sections. Component Testing: Utilize a multimeter to check the functionality of critical electrical components such as switches, relays, and sensors. Refer to specifications for resistance and voltage readings to ensure components operate within their intended parameters. Professional Assistance: If issues persist after conducting inspections and basic repairs, seek the expertise of a qualified technician. Advanced diagnostics may be necessary to identify and resolve underlying problems within the electrical system. How to Handle Wiring and Fuse IssuesTackling electrical problems in a vehicle can be daunting, yet it is essential for ensuring optimal performance and safety. Common symptoms of wiring and fuse troubles include malfunctioning lights, non-operational accessories, or unexpected electrical failures. By understanding the basic principles of electrical systems, vehicle owners can effectively identify and resolve these challenges. Identifying Wiring ProblemsBegin by examining the wiring harnesses for signs of wear, fraying, or corrosion. Check connections to ensure they are secure and free from dirt or moisture. Use a multimeter to test for continuity in the circuits, which will help pinpoint areas of concern. If you notice any damaged wires, it is crucial to repair or replace them promptly to prevent further issues. Addressing Fuse ConcernsFuses serve as vital protectors of electrical circuits. If you encounter an electrical failure, the first step is to locate the fuse box and inspect the fuses for any that may be blown. A visual inspection may suffice, but using a multimeter can provide a more accurate assessment. If you need to replace a fuse, ensure you select one with the correct amperage to avoid future electrical problems. Proactive maintenance is key to avoiding wiring and fuse complications. Regularly check electrical components and connections, and address any signs of damage immediately to maintain a reliable vehicle. Brake System Care and UpkeepMaintaining the braking mechanism is essential for ensuring vehicle safety and performance. Regular attention to this critical system can prevent costly repairs and enhance driving experience. Proper upkeep involves routine inspections, timely replacements, and understanding the components that make up the braking system. Routine Inspections: Regularly checking brake pads, rotors, and fluid levels is vital. Look for signs of wear, such as squeaking noises or a soft brake pedal, which may indicate that servicing is needed. Observing any changes in braking response can provide early warnings of potential issues. Fluid Management: Brake fluid is a crucial component that requires periodic replacement. Contaminated or low fluid levels can lead to decreased braking efficiency. Ensure to check the fluid reservoir and top it off as necessary, and follow manufacturer recommendations for complete fluid changes. Component Replacement: Over time, brake pads and rotors will wear down and need replacing. It is advisable to replace pads before they become too thin to avoid damaging the rotors. Always use quality parts that meet or exceed original specifications to maintain optimal performance. Professional Servicing: While some maintenance tasks can be performed at home, seeking professional assistance for complex issues is wise. Technicians have the expertise and tools to diagnose and repair any underlying problems effectively, ensuring the braking system remains reliable and safe. Ensuring Safe Stopping Power for Your VehicleMaintaining effective braking systems is crucial for safe driving. A well-functioning stopping mechanism not only enhances safety but also boosts the overall performance of your automobile. Regular assessments and timely interventions can prevent potential accidents and ensure a smooth ride. To keep your vehicle’s stopping power in top condition, consider the following key aspects:

Implementing a consistent maintenance schedule is recommended to address any issues promptly. Here are some practices to follow:

By prioritizing the upkeep of the stopping system, you can significantly enhance both safety and driving experience. Remember, a reliable braking system is not just a necessity; it is a fundamental aspect of responsible vehicle ownership. Transmission Troubleshooting and FixesAddressing issues with the transmission system is crucial for maintaining optimal vehicle performance. Recognizing early signs of malfunction can prevent extensive damage and costly repairs. This section outlines common problems, diagnostic steps, and potential solutions to ensure your vehicle remains in peak condition. Common Symptoms of Transmission ProblemsDrivers may encounter various symptoms indicating transmission issues. These include unusual noises, such as grinding or whining sounds, slipping gears, or delayed engagement when shifting. Additionally, warning lights may illuminate on the dashboard, signaling the need for immediate attention. Monitoring these indicators can help identify potential problems early. Troubleshooting StepsBegin troubleshooting by checking the fluid level and condition. Low or dirty fluid can lead to inadequate lubrication and overheating. If the fluid appears burnt or contains debris, a complete flush and replacement may be necessary. Next, inspect the transmission filter for clogs that could restrict fluid flow. Regular maintenance is vital in preventing many transmission-related issues. If symptoms persist after these checks, consider using a diagnostic scanner to retrieve error codes from the vehicle’s computer. These codes provide insight into specific faults within the transmission system, allowing for targeted repairs. Consulting with a qualified technician can also provide valuable expertise in addressing complex issues. Addressing Gearbox Problems in the Oldsmobile

Issues with the transmission system can significantly impact vehicle performance, leading to a range of driving difficulties. Recognizing symptoms early on is crucial for effective troubleshooting and resolution. Common signs of transmission trouble include unusual noises, slipping gears, and fluid leaks. Timely intervention can prevent further damage and costly repairs. Begin by diagnosing the problem through a visual inspection of the transmission fluid. Low or dirty fluid may indicate a leak or require replacement. If the fluid level is adequate, check for any unusual sounds while the engine is running, which may suggest internal component wear or failure. Pay attention to any warning lights on the dashboard, as these can provide valuable insights into system malfunctions. For minor issues, performing a fluid change or filter replacement can restore functionality. However, more complex problems may require a thorough examination by a qualified technician. Utilizing diagnostic tools can help identify underlying faults, ensuring accurate repairs and a return to optimal performance. Regular maintenance is key to extending the life of the transmission system. Following manufacturer recommendations for service intervals can help prevent issues before they arise. Keeping an eye on fluid quality and listening for abnormal sounds can lead to early detection and timely resolution of potential gearbox concerns. Cooling System Check and RepairsThe cooling system is crucial for maintaining optimal engine temperature, preventing overheating, and ensuring smooth performance. Regular inspection and maintenance of this system can help identify potential issues before they escalate, leading to costly damages. Understanding the components and functions of the cooling system will enable you to perform effective checks and necessary adjustments. Key Components to Inspect

Steps for System Maintenance

By following these guidelines, you can ensure the longevity and efficiency of the cooling system, ultimately enhancing the overall performance of your vehicle. |