Keeping your cutting tool in optimal condition is essential for ensuring efficiency and longevity. This section provides valuable insights into the upkeep and troubleshooting of your machinery, equipping you with the knowledge to address common issues and perform necessary adjustments. Understanding the intricacies of your device can lead to improved performance and satisfaction during use.

In this guide, we will explore various aspects related to the functionality and servicing of your equipment. From basic maintenance routines to more complex troubleshooting techniques, this resource aims to empower you with practical skills. Whether you are a novice or an experienced user, the information presented here will enhance your familiarity with your tool, enabling you to tackle challenges with confidence.

By engaging with the content, you will learn how to identify potential problems before they escalate and discover effective strategies for maintaining peak performance. Adopting a proactive approach to care and management not only prolongs the life of your equipment but also enhances your overall experience as a user. Embrace the opportunity to become more adept at managing your cutting tool with the guidance provided in this comprehensive overview.

When undertaking maintenance tasks, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-equipped workspace can significantly enhance the overall process, allowing for smoother and more precise actions.

Basic Equipment

- Screwdrivers: A variety of sizes and types are necessary to handle different fasteners.

- Wrenches: Both adjustable and fixed wrenches are essential for tightening and loosening bolts.

- Pliers: Useful for gripping, twisting, and cutting wires and components.

- Measuring Tools: Calipers and rulers help in taking accurate measurements.

Specialized Instruments

- Compression Tester: Useful for assessing the condition of combustion chambers.

- Torque Wrench: Ensures that fasteners are tightened to specified levels, preventing damage.

- Fuel System Cleaner: Helps in maintaining optimal performance by cleaning fuel lines and injectors.

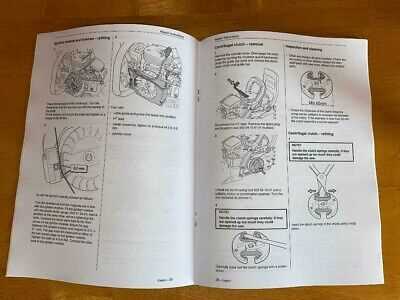

Step-by-Step Engine Disassembly

This section outlines a comprehensive approach to dismantling a power unit effectively. Proper techniques and precautions are essential to ensure that all components are handled with care, minimizing the risk of damage during the process.

Preparation Before Disassembly

- Gather necessary tools: wrenches, screwdrivers, and pliers.

- Ensure a clean, organized workspace to keep track of parts.

- Review any available documentation or guides to understand the assembly layout.

Disassembly Process

- Begin by disconnecting any power sources to prevent accidental operation.

- Remove external coverings or casings to expose the internal parts.

- Carefully take out the fuel system components, noting their positions.

- Proceed to detach the ignition components, ensuring all connections are documented.

- Gradually disassemble the remaining components, placing screws and parts in labeled containers.

Inspecting Engine Components

Regular examination of crucial components is essential for maintaining optimal performance and longevity of any power tool. Understanding how to identify signs of wear and malfunction can significantly enhance the reliability of the equipment.

Key Areas to Examine

- Piston and Cylinder: Look for signs of scoring or damage.

- Fuel System: Ensure there are no leaks or blockages.

- Ignition Components: Check spark plugs for wear and proper gap.

- Exhaust System: Inspect for blockages and corrosion.

Steps for Effective Inspection

- Begin by disconnecting the power source to ensure safety.

- Carefully remove covers to access internal parts.

- Visually inspect each component for any signs of deterioration.

- Use appropriate tools to measure and test critical areas, ensuring everything functions correctly.

Replacing Worn Parts

Over time, components of power tools can experience wear and tear, leading to decreased performance. Addressing these issues promptly is crucial for maintaining optimal functionality. This section outlines the steps to identify and replace worn parts effectively.

Before beginning the replacement process, gather the necessary tools and replacement components. Ensuring you have everything at hand will make the task smoother.

- Tools required:

- Wrenches

- Screwdrivers

- Pliers

- Replacement parts

Next, follow these general steps:

- Identify worn components: Regularly inspect parts for signs of damage or excessive wear.

- Disassemble the unit: Carefully remove screws and bolts to access the internal components.

- Replace damaged parts: Take out the worn elements and install the new ones, ensuring they fit securely.

- Reassemble the tool: Put all components back together, making sure everything is tightened properly.

- Test functionality: After reassembly, perform a test run to ensure that the tool operates smoothly.

Regular maintenance and timely replacement of parts will enhance the longevity of your equipment and ensure efficient operation.

Reassembling the Chainsaw Engine

Reassembling the power unit is a crucial phase in the maintenance process, ensuring all components fit together seamlessly for optimal performance. This section will guide you through the necessary steps to bring your machine back to life effectively.

Essential Tools and Components

- Screwdrivers

- Wrenches

- New gaskets

- Lubricating oil

Step-by-Step Assembly Process

- Start by laying out all parts in an organized manner.

- Begin attaching the crankcase, ensuring proper alignment.

- Install new gaskets to prevent leaks.

- Carefully position the cylinder and secure it tightly.

- Reattach any necessary components such as the fuel system and ignition parts.

- Double-check all connections before final tightening.

Adjusting the Carburetor Settings

Proper adjustment of the fuel mixing mechanism is crucial for optimal performance of the equipment. A well-tuned system ensures efficient fuel combustion, enhancing power output and fuel economy while reducing emissions.

Understanding the Adjustment Process

Before making any changes, familiarize yourself with the key components involved in the adjustment process:

- Mixture Screws: Control the air-fuel mixture ratio.

- Idle Speed Screw: Regulates the idle speed of the unit.

- Throttle: Manages the power output during operation.

Steps for Adjustment

Follow these steps to achieve accurate settings:

- Start the equipment and allow it to reach operating temperature.

- Locate the mixture screws and make initial adjustments to both the low and high settings.

- Adjust the idle speed screw to achieve a steady idle.

- Test the equipment under load to assess performance, making additional tweaks as needed.

- Ensure the unit responds smoothly to throttle changes without hesitation or stalling.

Regular maintenance and careful adjustments will prolong the lifespan of the unit and enhance its operational efficiency.

Testing Engine Performance

This section focuses on evaluating the operational efficiency of the motor, ensuring it meets optimal standards. Proper assessment is crucial for maintaining performance and identifying any underlying issues that may affect functionality.

To effectively gauge the performance, consider the following steps:

- Prepare the necessary tools for measurement, including a tachometer and a compression gauge.

- Ensure the equipment is clean and free from obstructions that could interfere with the readings.

- Conduct a visual inspection to check for any obvious signs of wear or damage.

Once the initial setup is complete, proceed with the following tests:

- RPM Test: Measure the revolutions per minute to determine if the motor is running within specified limits.

- Compression Test: Assess the pressure generated within the combustion chamber to ensure efficient operation.

- Fuel Consumption Evaluation: Monitor how much fuel is utilized during operation to assess efficiency.

After conducting these assessments, compare the results against standard benchmarks to identify any discrepancies. Regular testing can prolong the lifespan and enhance the performance of the unit.

Maintaining Your Chainsaw

Proper upkeep of your cutting tool is essential for ensuring optimal performance and longevity. Regular attention to maintenance not only enhances efficiency but also promotes safety during operation. By following a few fundamental practices, you can keep your device in excellent working condition.

Regular Cleaning

Cleaning the exterior and internal components is crucial. After each use, remove debris and residue that may accumulate. Pay special attention to the guide bar and the chain, as dirt can cause wear and impede function. Using appropriate cleaning agents can help maintain the integrity of the parts.

Inspection of Parts

Routine checks of key components are vital for early detection of potential issues. Examine the cutting tool, lubrication system, and other mechanisms for signs of wear or damage. Identifying problems early can prevent more serious complications and costly repairs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount to prevent accidents and injuries. Adhering to fundamental safety guidelines creates a secure working environment, allowing individuals to focus on their tasks without undue risk.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes sturdy gloves, safety goggles, and hearing protection to shield against potential hazards. Each piece of equipment plays a crucial role in minimizing exposure to harmful elements during the maintenance process.

Work Area Organization

Keeping the workspace organized helps reduce the likelihood of accidents. Ensure that tools are easily accessible and materials are stored safely. A tidy area allows for better visibility and reduces the risk of tripping or mishandling equipment.

Frequently Asked Repair Questions

This section addresses common inquiries related to the maintenance and troubleshooting of motorized cutting tools. Understanding these frequent concerns can help users efficiently resolve issues and enhance the longevity of their equipment.

| Question | Answer |

|---|---|

| What should I do if the tool won’t start? | Check the fuel levels, ensure the spark plug is clean, and verify that the ignition system is functioning properly. |

| How can I improve cutting performance? | Ensure the cutting blade is sharp and correctly tensioned, and inspect the alignment of the components. |

| Why is there excessive vibration during operation? | Excessive vibration can result from an unbalanced blade or loose parts; check and tighten all components as needed. |

| What maintenance should I perform regularly? | Regularly clean the air filter, check the fuel system, and inspect the cutting attachment for wear. |

Resources for Further Assistance

When dealing with mechanical issues, having access to reliable information and support can greatly enhance your understanding and problem-solving capabilities. This section provides various avenues for acquiring additional knowledge and assistance related to maintenance and troubleshooting.

Online Forums and Communities

Participating in online forums and communities dedicated to small engine maintenance can be invaluable. These platforms allow users to share experiences, ask questions, and receive guidance from fellow enthusiasts. Engaging with a community can often lead to discovering solutions that are not found in standard literature.

Professional Services and Workshops

For those who prefer hands-on assistance, seeking out professional services or workshops can provide expert guidance. Many local repair shops offer classes or consultations that can enhance your skills. Additionally, contacting certified technicians can help ensure that you receive quality advice tailored to your specific needs.