When it comes to maintaining classic vehicles, keeping essential components in optimal condition is vital. This guide serves as a comprehensive resource for enthusiasts aiming to extend the lifespan and performance of their automobiles. Each section covers various areas of maintenance, helping you to identify and resolve potential issues, ensuring a smoother and safer drive.

In this resource, you’ll find detailed advice on inspecting and servicing both the exterior and interior systems, along with tips for troubleshooting common concerns. From checking the engine’s performance to adjusting interior mechanisms, each topic is explained with practical insights. Whether you are new to this model or a seasoned owner, these guidelines will enhance your understanding of key vehicle systems.

Explore this guide for step-by-step instructions, expert recommendations, and essential techniques to keep your vehicle in peak condition. With this comprehensive approach, routine maintenance becomes straightforward, empowering you to handle tasks effectively and preserve your vehicle’s value for years to come.

1990 Jeep Wrangler Repair Manual

The guide provides a comprehensive overview for those looking to maintain and enhance the durability of this classic off-road vehicle. Designed with the enthusiast in mind, the instructions cover essential aspects of upkeep, ensuring continued performance and reliability.

Maintenance Tips for Longevity

Regular care and attention can significantly extend the life of your vehicle. The document covers all the necessary checks, including engine upkeep, fluid replacements, and the inspection of wear-prone components. Adhering to these steps helps prevent unexpected issues and promotes smoother operation.

Problem-Solving Common Issues

Encountering common challenges can be part of the ownership

Essential Tools for Jeep Wrangler Repair

When working on any off-road vehicle, having the right set of tools makes all the difference. Proper equipment ensures that tasks are completed efficiently, safely, and with a level of precision that promotes long-term reliability. Whether tackling small adjustments or major fixes, quality tools are a foundational part of every project.

Basic Hand Tools

Standard hand tools are the cornerstone of any toolkit. A well-rounded set of wrenches, screwdrivers, and pliers is crucial for handling the wide variety of bolts, screws, and fasteners found on rugged vehicles. Investing in adjustable and ratcheting versions can enhance flexibility and save time when reaching hard-to-access areas. Additionally, a sturdy torque wrench allows for precise tightening, preventing over-tightening or loosening during intense off-road conditions.

Specialized Equipment

Alongside hand tools, certain specialized items can be invaluable. A hydraulic jack and jack stands provide essential support during repairs beneath the vehicle, ensuring safety and stability. For electrical work, a reliable multimeter is indispensable for diagnosing and troubleshooting wiring issues. Having a high-quality socket set with both standard and deep sockets will also prove beneficial, as they accommodate various bolt sizes and configurations across different vehicle components.

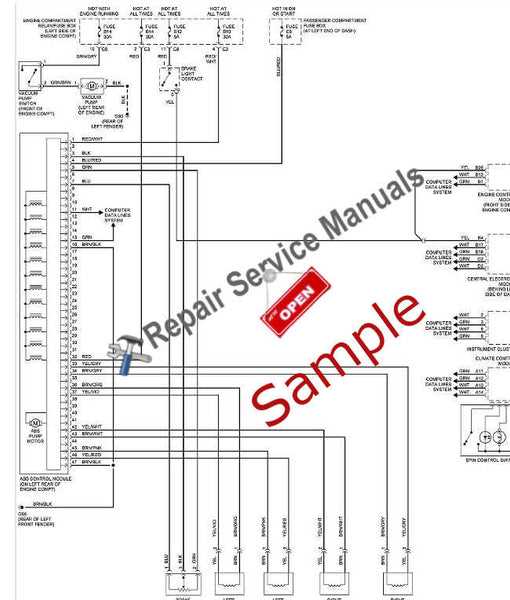

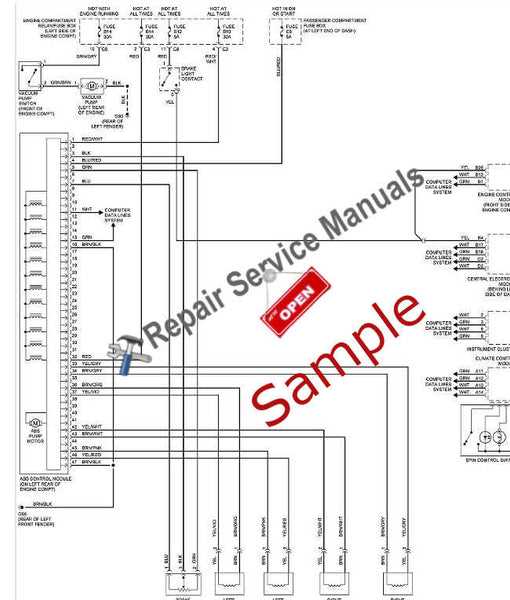

Understanding Vehicle Electrical Systems

The electrical systems in vehicles are complex networks designed to support essential functions and enhance driver experience. By understanding the basics of these systems, you gain insight into how various components interact, ensuring that all electrical parts operate smoothly. Grasping these fundamentals can be highly beneficial for diagnosing issues and performing general maintenance.

Main Components of the Electrical System

Most vehicle electrical setups consist of a few primary components. These include the battery, which stores power; the alternator, which recharges the battery while the engine is running; and fuses, which protect circuits from overloading. Together, these parts provide power to the lights, dashboard, ignition, and various auxiliary systems.

Troubleshooting Common Electrical Issues

Identifying electrical problems often starts with recognizing common symptoms, such as dim lights or slow engine turnover. Issues can stem from a variety of sources, including a weak battery, loose connections, or a malfunctioning alternator. By learning to pinpoint these symptoms, you can address minor concerns before they evolve into more significant repairs.

| Component |

Function |

| Battery |

Stores electrical power for starting the engine and powering accessories. |

| Alternator |

Generates electrical power to recharge the battery and run electrical components while driving. |

| Fuses |

Protect circuits by breaking connections during power

Basic Engine Troubleshooting Techniques

Engine troubleshooting often requires a methodical approach to identify issues effectively. A variety of symptoms can indicate underlying problems, and recognizing these signs early can prevent further complications. By addressing small issues as they arise, one can maintain optimal performance and avoid more extensive repairs.

Initial Visual Inspection: Begin with a thorough visual check to spot any visible signs of wear or damage, such as loose or frayed belts, corroded battery terminals, or fluid leaks. This step can reveal simple issues before diving into more complex diagnostics.

Checking Fluid Levels: Consistently low or dirty oil, coolant, or other fluids may signal leaks or internal wear. Ensuring all levels are correct helps the engine run smoothly and efficiently.

Listen for Unusual Sounds: Odd noises, like knocking or hissing, can suggest various issues, from ignition problems to exhaust leaks. Paying attention to these sounds helps in narrowing down the possible sources of engine trouble.

Test En

Repairing the Transmission System

The transmission system is a complex network that ensures power from the engine is efficiently transferred to the wheels. Proper maintenance and adjustments can greatly improve the vehicle’s performance and longevity, reducing wear on essential components.

Signs of Transmission Issues

Before starting any work, it’s important to identify symptoms indicating transmission challenges. Common signs include unusual noises, difficulty shifting gears, or inconsistent power transfer. Recognizing these early can prevent further complications.

- Grinding or Clunking Sounds: These noises often indicate worn parts or the need for lubrication adjustments.

- Delayed Gear Shifts: Hesitation when shifting might suggest fluid level issues or possible component misalignment.

- Fluid Leaks: Transmission fluid leakage is a clear indicator that seals or gaskets need attention.

Basic Steps for Transmission Service

Routine inspection and service can be carried out with basic tools and moderate mechanical knowledge. Follow these steps to maintain a reliable transmission system:

- Inspect Transmission Fluid: Regularly check fluid levels and

Brake System Maintenance and Repairs

Ensuring the optimal performance of a vehicle’s stopping mechanism is crucial for safety and functionality. Regular upkeep and timely fixes can significantly enhance the lifespan of the components involved. This section provides essential guidelines for maintaining and addressing issues related to braking systems, focusing on practical steps that can be undertaken.

Routine Inspection Procedures

Conducting periodic assessments is vital for identifying potential problems before they escalate. Check for any signs of wear on brake pads and rotors, as well as inspect the fluid levels in the braking reservoir. Pay attention to unusual noises or vibrations while applying the brakes, as these may indicate underlying issues. Regularly replacing worn components can prevent costly repairs in the long run.

Common Issues and Solutions

Some frequent complications that arise include squeaking noises, reduced braking efficiency, or a spongy pedal feel. These symptoms may point to various concerns, such as air in the brake lines, contaminated brake fluid, or worn-out pads. Bleeding the brake lines can help remove trapped air, while flushing and replacing the fluid can ensure optimal performance. Addressing these problems promptly will enhance safety and driving comfort.

How to Replace Suspension Parts

Replacing suspension components is essential for maintaining a vehicle’s stability and handling. This process typically involves inspecting the various parts of the suspension system, identifying any worn or damaged elements, and carefully replacing them with new parts to restore optimal performance.

Step-by-Step Guide

Begin by lifting the vehicle securely using a jack and placing jack stands under the frame to ensure safety. Remove the wheel to gain access to the suspension components. Next, inspect the control arms, bushings, shocks, and struts for any signs of wear or damage. Mark the locations of any bolts and nuts for reference during reassembly.

Installing New Components

Once the worn parts are identified, remove them by loosening the fasteners with the appropriate tools. Carefully detach the damaged components and replace them with new ones, ensuring all connections are tight. Finally, reattach the wheel, lower the vehicle, and perform a test drive to confirm that the suspension is functioning correctly. Regular maintenance of these parts will enhance your vehicle’s performance and safety on the road.

Fixing Common Fuel System Issues

Addressing frequent challenges within the fuel delivery framework is essential for maintaining optimal vehicle performance. Understanding the signs of malfunctioning components can lead to timely interventions, ensuring a smoother operation and preventing more severe complications down the line.

Identifying Symptoms of Fuel System Malfunctions

Common indicators of fuel system problems include engine stalling, difficulty starting, and poor acceleration. If the engine hesitates or lacks power during acceleration, it may signify issues such as clogged filters or failing fuel pumps. Paying attention to these symptoms allows for early diagnosis and resolution.

Troubleshooting and Solutions

To troubleshoot, begin by checking the fuel filter for blockages. Replacing a dirty filter can restore fuel flow. Next, inspect the fuel pump for proper operation; if it’s not delivering adequate pressure, replacement may be necessary. Regular maintenance and inspection of these components can significantly enhance vehicle reliability.

Body and Frame Restoration Tips

Restoring the structure and exterior of a vehicle requires careful planning and attention to detail. This process involves not only aesthetic enhancements but also ensuring the integrity and durability of the body and frame. Proper techniques and materials are essential for achieving long-lasting results.

Materials and Tools Required

Before beginning any restoration work, gather the necessary materials and tools. Below is a list of common items needed for body and frame restoration:

| Materials |

Purpose |

| Rust treatment solutions |

To remove and prevent rust formation |

| Body filler |

To repair dents and imperfections |

| Primer and paint |

For a protective and aesthetic finish |

| Welding supplies |

To fix frame components securely |

| Sandpaper and grinding tools |

For smoothing surfaces before painting |

Step-by-Step Restoration Process

Follow these steps for effective restoration of the body and frame:

- Begin by thoroughly inspecting the vehicle’s structure for any signs of damage or rust.

- Remove any rust using appropriate treatments and tools, ensuring a clean surface.

- Apply body filler to any dents or scratches, then sand it smooth once dry.

- Weld any necessary repairs to the frame, ensuring all joints are secure.

- Finish with primer and paint for protection and a polished look.

Jeep Wrangler Cooling System Repairs

The cooling system is essential for maintaining optimal engine temperature and preventing overheating issues. Regular maintenance and timely interventions are crucial to ensure efficient functioning and longevity of this vital component.

Common Issues: Various problems can arise within the cooling system, including leaks, blockages, and faulty components. Identifying these issues early can prevent more severe damage to the engine.

Inspection and Diagnosis: Start by checking coolant levels and inspecting hoses for any signs of wear or leaks. A pressure test can help detect hidden leaks. Additionally, examining the radiator and thermostat ensures they operate effectively.

Repair Solutions: Depending on the issue, repairs may include replacing damaged hoses, flushing the radiator to remove debris, or installing a new thermostat. Regularly checking the coolant quality and changing it as needed is vital for system health.

Preventive Measures: To minimize future issues, it is advisable to maintain proper coolant levels, regularly inspect components, and follow a routine maintenance schedule. This proactive approach can enhance performance and reduce the likelihood of costly repairs.

Upgrading the Exhaust System

Enhancing the exhaust system is a popular modification among automotive enthusiasts seeking improved performance and a more aggressive sound. By upgrading key components, you can optimize airflow, which may lead to increased horsepower and torque. This section explores various options and considerations for enhancing your vehicle’s exhaust system.

Benefits of an Enhanced Exhaust System

Upgrading the exhaust can yield numerous advantages, including better engine efficiency, reduced back pressure, and improved fuel economy. Furthermore, a performance exhaust often provides a deeper, more satisfying sound that can significantly enhance the driving experience.

Components to Consider for Upgrade

| Component |

Description |

| Headers |

Replaces factory exhaust manifolds to improve exhaust flow and reduce restrictions. |

| Cat-Back System |

A complete system from the catalytic converter to the exhaust tip, designed for enhanced performance. |

| Mufflers |

Upgrading to performance mufflers can change exhaust sound and reduce back pressure. |

| Exhaust Pipes |

Larger diameter pipes can facilitate better exhaust flow, improving overall performance. |

|