Every vehicle enthusiast understands the importance of proper upkeep for their automobile. A thorough understanding of maintenance procedures is essential for ensuring longevity and optimal performance. This guide serves as a valuable resource for individuals looking to delve into the specifics of their rugged utility vehicle.

From basic troubleshooting techniques to in-depth mechanical insights, this document covers a wide array of topics relevant to the maintenance and care of your trusted companion. Whether you are a novice seeking foundational knowledge or an experienced hand looking to refine your skills, the information provided will empower you to tackle various challenges with confidence.

Equipped with detailed illustrations and step-by-step instructions, this guide offers clarity and accessibility. By following these recommendations, you will not only enhance the functionality of your vehicle but also cultivate a deeper appreciation for its intricate design and engineering.

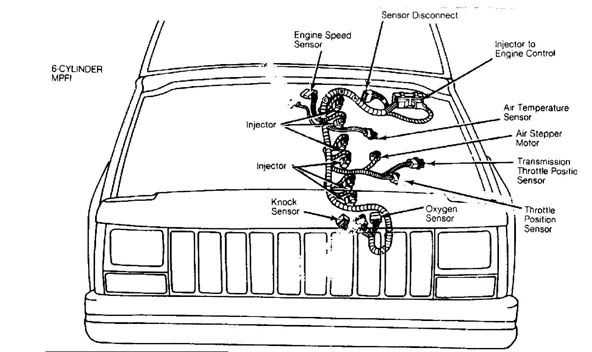

Overview of the 1992 Jeep Cherokee

This section provides a comprehensive look at a well-known SUV model that gained popularity for its robust design and versatility. Engineered to handle various terrains, it is often favored for both urban commuting and off-road adventures. The vehicle combines practicality with a rugged aesthetic, appealing to a wide range of drivers.

Design and Features

The exterior boasts a distinctive silhouette, characterized by angular lines and a commanding presence. Inside, the cabin is designed for comfort and utility, featuring ample storage space and a user-friendly layout. Technology options from its era provide essential functionality, enhancing the overall driving experience.

Performance and Capabilities

Equipped with a range of powerful engines, this model delivers impressive performance both on and off the beaten path. The advanced four-wheel drive system allows for enhanced traction and stability, making it a reliable choice for adventurous outings. Durability is a key attribute, ensuring longevity and dependability in various driving conditions.

Common Issues Faced by Owners

Vehicles of a certain age often present a variety of challenges that owners must navigate. Understanding these prevalent problems can help in maintaining the longevity and performance of the vehicle, ensuring a smoother driving experience. Here, we outline some of the most frequent complications reported by users.

Electrical System Failures

Many owners encounter issues related to the electrical systems. Problems can range from malfunctioning lights to difficulties with starting the engine. These electrical anomalies can stem from worn-out wiring or faulty connections.

Transmission Problems

Another common concern involves the transmission, which may exhibit signs of slipping or rough shifting. Such issues can lead to significant performance drops and, if not addressed promptly, can escalate into more serious complications.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Electrical Failures | Dim lights, starting issues | Inspect wiring, replace fuses |

| Transmission Problems | Slipping, rough shifts | Check fluid levels, consult a specialist |

| Suspension Wear | Unstable ride, noise | Replace worn components |

Essential Tools for Repair

Having the right equipment is crucial for any maintenance task. Whether you’re performing routine checks or addressing specific issues, certain instruments will enhance efficiency and effectiveness. This section outlines the fundamental tools necessary for successful vehicle upkeep.

Basic Hand Tools

- Wrenches: A variety of sizes will help in loosening or tightening nuts and bolts.

- Sockets: Ratchet sets are invaluable for reaching fasteners in tight spaces.

- Drivers: Flathead and Phillips screwdrivers are essential for handling various screws.

- Pliers: Needle-nose and adjustable pliers can manage small parts and offer grip in confined areas.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Oil Filter Wrench: Simplifies the removal of stubborn oil filters.

- Multimeter: Essential for diagnosing electrical issues.

- Jack and Stands: Provide safe elevation for undercarriage work.

Equipping yourself with these tools will facilitate a smoother and more productive experience when tackling various tasks. Proper preparation can lead to successful outcomes and a longer lifespan for your vehicle.

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure the longevity and reliability of your vehicle. Following a systematic approach to maintenance not only enhances performance but also helps identify potential issues before they escalate. This section outlines key procedures that every owner should be familiar with to maintain their automobile in optimal condition.

Routine Checks

Performing routine inspections is crucial. These checks should be carried out at specified intervals or after certain mileage milestones.

- Check oil levels and condition.

- Inspect coolant levels and inspect for leaks.

- Examine brake fluid and replace as needed.

- Assess tire pressure and tread depth.

- Test battery condition and connections.

Scheduled Maintenance Tasks

In addition to routine checks, specific tasks should be performed at regular intervals to keep your vehicle running smoothly.

- Change the engine oil and filter every 3,000 to 5,000 miles.

- Replace air filters every 15,000 to 30,000 miles.

- Inspect and replace spark plugs every 30,000 miles.

- Flush and replace coolant every two years.

- Check and service the transmission fluid according to manufacturer recommendations.

Adhering to these procedures will contribute significantly to your vehicle’s performance and reliability, ensuring a safer driving experience.

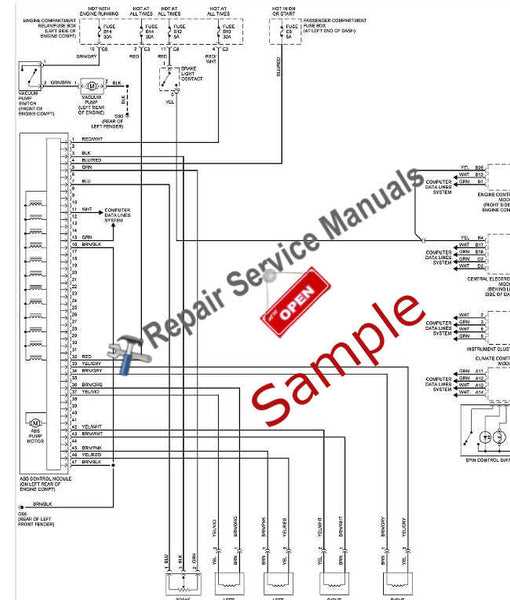

Electrical System Troubleshooting Guide

Understanding the intricacies of an automobile’s electrical framework is crucial for efficient maintenance and performance. This guide serves to assist in identifying common issues related to the electrical components, offering practical solutions and steps to rectify malfunctions. A systematic approach will facilitate troubleshooting and enhance the longevity of the vehicle’s electrical systems.

Common Symptoms of Electrical Issues

Identifying signs of electrical failure is the first step in effective diagnosis. Below are some prevalent symptoms that may indicate problems within the electrical system:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Dim or Flickering Lights | Weak battery or faulty alternator | Test battery voltage; inspect alternator operation |

| Non-Functional Accessories | Blown fuse or wiring issue | Check and replace fuses; examine wiring for damage |

| Engine Won’t Start | Dead battery or starter failure | Jump-start the vehicle; test starter functionality |

| Unusual Electrical Smells | Short circuit or overheating components | Inspect for burnt wires; check electrical connections |

Step-by-Step Diagnostic Process

To effectively diagnose electrical concerns, follow these structured steps:

- Conduct a visual inspection of the battery and connections for corrosion or damage.

- Utilize a multimeter to check voltage levels across critical components.

- Examine fuses and relays, replacing any that are damaged.

- Trace wiring for continuity and check for any signs of wear or shorts.

- Test each electrical component individually to isolate faulty parts.

Engine Performance Enhancements

Improving the efficiency and power of your vehicle’s engine can lead to a more exhilarating driving experience. By focusing on specific modifications and upgrades, enthusiasts can achieve significant gains in performance, responsiveness, and overall satisfaction. The following strategies provide a comprehensive overview of how to enhance engine capabilities effectively.

| Enhancement Type | Description | Benefits |

|---|---|---|

| Cold Air Intake | Replaces the factory air intake system with one that allows for cooler, denser air. | Increased horsepower and torque, improved throttle response. |

| Performance Exhaust System | Upgrades the exhaust components to reduce back pressure and improve exhaust flow. | Enhanced engine sound, increased power output. |

| ECU Tuning | Reprograms the engine control unit for optimized fuel maps and ignition timing. | Improved fuel efficiency, higher horsepower and torque. |

| Upgraded Fuel Injectors | Replaces standard injectors with high-performance alternatives to increase fuel delivery. | Better acceleration and overall engine performance. |

| High-Performance Spark Plugs | Installs plugs designed for improved ignition and combustion efficiency. | Smoother operation, increased fuel efficiency. |

Each of these modifications can contribute to a more powerful and efficient engine, allowing for a thrilling driving experience while maintaining reliability. Always consider compatibility and manufacturer guidelines before proceeding with any upgrades to ensure optimal results.

Transmission Repair Techniques

Maintaining the functionality of a vehicle’s transmission system is essential for optimal performance. Understanding various methods for addressing common issues can significantly enhance longevity and efficiency. This section outlines key techniques that can be employed to resolve typical transmission challenges.

Common Issues and Their Solutions

- Fluid Leaks: Regularly check for fluid levels and inspect for leaks. If a leak is detected, identify the source and replace damaged seals or gaskets.

- Slipping Gears: This can often be remedied by adjusting the linkage or replacing the transmission fluid. Ensure the fluid is at the correct level and is not contaminated.

- Unresponsive Shifting: Inspect the transmission control module and wiring. In some cases, recalibrating the module may resolve the issue.

Preventive Maintenance Tips

- Regularly change the transmission fluid according to the manufacturer’s guidelines.

- Inspect the transmission filter and replace it when necessary to prevent debris accumulation.

- Monitor performance regularly to detect any early signs of malfunction.

- Ensure that all connections and mounts are secure to avoid vibrations that may cause damage.

By employing these techniques and being proactive in maintenance, vehicle owners can effectively manage their transmission systems and prolong the life of their automotive investments.

Suspension System Maintenance Tips

The suspension system plays a crucial role in vehicle stability, comfort, and overall performance. Regular upkeep is essential to ensure its longevity and functionality. Proper maintenance not only enhances ride quality but also contributes to the safety of the vehicle.

1. Regular Inspections: Periodically check for any signs of wear or damage. Look for leaks in shock absorbers, cracks in bushings, and other visible issues. Early detection can prevent more significant problems down the line.

2. Check Tire Condition: Tires are closely linked to the suspension system. Ensure they are properly inflated and have adequate tread depth. Uneven tire wear can indicate alignment or suspension issues that need addressing.

3. Alignment Adjustments: Proper wheel alignment is vital for even tire wear and vehicle handling. If you notice the vehicle pulling to one side or the steering wheel is off-center, it may be time for an alignment check.

4. Lubrication: Many suspension components have joints that require lubrication. Regularly grease these parts to minimize friction and wear, which can extend the life of the suspension system.

5. Monitor Ride Height: Changes in ride height can signal underlying issues. If the vehicle appears lower or higher than normal, it may indicate a problem with the springs or struts that requires attention.

6. Replacement of Worn Parts: As components age, they may need replacement. Pay attention to any unusual noises or changes in handling, and replace worn-out parts promptly to maintain optimal performance.

By following these maintenance tips, you can ensure that your vehicle’s suspension system remains in top condition, providing a safe and comfortable driving experience.

Braking System Inspection Checklist

The braking system is a crucial component of vehicle safety, requiring regular examination to ensure optimal performance. This checklist serves as a guide for evaluating the key elements of the braking system, helping to identify potential issues before they escalate.

1. Brake Pads: Inspect for wear and tear. Look for any signs of thinning or uneven surface, which may indicate the need for replacement.

2. Brake Rotors: Check for warping, scoring, or excessive rust. Ensure that the rotors are smooth and have an even surface to provide effective stopping power.

3. Brake Fluid: Verify the fluid level and quality. Ensure that the fluid is free from contaminants and check for any leaks in the system.

4. Brake Lines: Examine all brake lines for signs of wear, cracks, or leaks. Ensure connections are secure and free of corrosion.

5. Calipers: Inspect calipers for proper function. Check for any signs of sticking or uneven movement, which could affect braking efficiency.

6. Master Cylinder: Evaluate the master cylinder for leaks and ensure it is functioning correctly. A faulty master cylinder can lead to reduced braking performance.

7. Brake Pedal: Test the brake pedal feel. It should not feel spongy or sink to the floor when pressed. Any abnormalities may indicate underlying issues.

8. Anti-lock Braking System (ABS): If equipped, check the ABS for proper operation. Listen for unusual sounds during activation and ensure the warning light functions correctly.

Following this checklist will help maintain the effectiveness of the braking system, promoting both safety and performance on the road.

Cooling System Maintenance Practices

Effective management of the cooling system is essential for the longevity and optimal performance of any vehicle. Regular attention to this system can prevent overheating, reduce wear, and improve overall efficiency. A well-maintained cooling system not only protects the engine but also contributes to the vehicle’s reliability on the road.

Routine Checks and Inspections

Performing routine inspections is crucial for identifying potential issues before they escalate. Key areas to focus on include hoses, clamps, and the radiator. Look for signs of leaks, cracks, or wear that could compromise the system’s integrity. Additionally, checking the coolant levels and ensuring the appropriate mixture of antifreeze and water can significantly impact performance.

Coolant Replacement Schedule

Adhering to a specific coolant replacement schedule helps maintain the system’s effectiveness. Over time, coolant can become contaminated or lose its protective properties. Following the manufacturer’s recommendations regarding the frequency of coolant changes ensures that the system remains clean and free from harmful deposits.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and clamps | Every 6 months | Replace any damaged parts |

| Check coolant levels | Monthly | Top off as necessary |

| Flush and replace coolant | Every 2 years | Use recommended coolant type |

| Inspect the radiator | Every 6 months | Clean any debris |

Exhaust System Repairs Explained

The exhaust system plays a crucial role in a vehicle’s performance and emissions control. Understanding the intricacies of this system is essential for maintaining optimal function and compliance with environmental standards. Regular maintenance and timely interventions can prevent costly issues and enhance the driving experience.

Common Issues and Symptoms

Drivers may encounter various signs indicating that the exhaust system requires attention. Unusual noises, such as hissing or rattling, can signal leaks or loose components. Decreased fuel efficiency and a noticeable decrease in engine power often suggest a blockage or malfunction within the system. Additionally, the presence of a strong odor or the illumination of warning lights on the dashboard can indicate underlying problems that necessitate further investigation.

Repair Techniques and Solutions

Addressing exhaust system issues typically involves inspecting and identifying damaged parts, such as the muffler, catalytic converter, or pipes. Repairs may range from sealing minor leaks to replacing entire sections of the system. Utilizing high-quality materials and following precise techniques ensures durability and effectiveness in restoring functionality. For complex problems, seeking professional assistance is advisable to guarantee proper diagnosis and repair execution.

Interior Repair and Maintenance Guide

This section focuses on the upkeep and restoration of the vehicle’s interior, emphasizing the importance of a clean and well-maintained environment for both aesthetics and functionality. Regular attention to the interior components can enhance comfort and prolong the lifespan of materials, ensuring a pleasant driving experience.

Essential Maintenance Tips

- Cleaning Upholstery: Regular vacuuming and spot cleaning can prevent dirt buildup. Use appropriate cleaners for different materials.

- Dashboard Care: Dust and wipe down the dashboard with a soft cloth. Avoid harsh chemicals that may damage surfaces.

- Trim and Moldings: Inspect for scratches and wear. Use trim protectants to restore and protect these areas.

Common Issues and Solutions

- Faded Fabrics: Consider using fabric dye or professional cleaning services to refresh colors.

- Cracked Dash: Repair kits are available to fill and cover cracks effectively.

- Loose Panels: Tighten screws and use adhesive where necessary to secure loose parts.

By regularly addressing these areas, you can maintain an inviting and functional interior space that enhances overall driving satisfaction.

Finding Reliable Replacement Parts

When it comes to maintaining your vehicle, sourcing dependable components is crucial for optimal performance and longevity. Whether you’re looking for new, used, or aftermarket options, ensuring quality and compatibility can significantly impact your repair experience. In this section, we’ll explore strategies for identifying trustworthy sources for parts that meet your needs.

Researching Suppliers

Start by researching suppliers in your area or online. Look for vendors with a solid reputation and positive reviews from previous customers. Websites dedicated to automotive parts often feature customer ratings and feedback, which can guide you in selecting reliable sources. Additionally, consider reaching out to local auto shops for recommendations on where to find quality components.

Understanding Compatibility

Before making a purchase, it’s essential to verify that the parts you intend to buy are compatible with your vehicle model. Use the original specifications or consult online databases to cross-reference parts. High-quality components may come with warranties, further assuring their reliability. Taking these steps will help you avoid issues down the line and ensure your vehicle runs smoothly.