Maintaining a versatile all-terrain vehicle requires a thorough understanding of its components and systems. This section provides valuable insights and guidance for enthusiasts looking to enhance their knowledge about upkeep and troubleshooting. Whether you’re a seasoned mechanic or a casual user, having access to reliable information can significantly improve your hands-on experience.

Detailed instructions and practical tips are essential for ensuring your vehicle operates efficiently under various conditions. This guide emphasizes the importance of regular assessments and informed decisions regarding repairs and modifications. With the right approach, you can extend the lifespan of your vehicle while maximizing its performance on challenging terrains.

Moreover, familiarity with the essential tools and techniques can empower you to tackle common issues independently. Embracing a proactive attitude towards maintenance not only enhances your vehicle’s reliability but also elevates your overall driving experience. Explore this section to uncover the best practices for achieving optimal functionality and safety on your adventures.

Understanding Jeep JK Maintenance

Regular upkeep is essential for ensuring the longevity and reliability of your vehicle. This section highlights the importance of systematic care and attention to various components, which can significantly enhance performance and safety. Knowing the fundamentals of vehicle servicing allows owners to prevent issues before they escalate, ensuring a smooth and enjoyable driving experience.

Basic maintenance tasks include checking fluid levels, inspecting brakes, and monitoring tire health. Consistent evaluations can help identify wear and tear, allowing for timely interventions. Following a structured routine not only extends the lifespan of critical parts but also contributes to overall efficiency.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 3,000 to 5,000 miles | Replace old oil to ensure smooth engine operation and prevent damage. |

| Tire Rotation | Every 6,000 to 8,000 miles | Switch tire positions to promote even wear and extend tire life. |

| Brake Inspection | Every 12,000 miles | Check brake pads and discs for wear to maintain stopping power. |

| Fluid Levels Check | Monthly | Inspect and top off fluids such as coolant, brake, and transmission fluid. |

| Battery Check | Every 6 months | Examine battery condition and connections to prevent starting issues. |

Common Issues Faced by Owners

Many enthusiasts encounter various challenges when managing their off-road vehicles. These complications can arise from regular wear and tear, environmental conditions, or manufacturing inconsistencies. Understanding these common problems can help drivers effectively address and mitigate potential risks.

Electrical System Malfunctions

One of the frequent concerns involves the electrical system. Owners often report issues with components such as the battery, alternator, and wiring. Symptoms may include flickering lights, difficulty starting the engine, or unexpected power loss. Regular maintenance and inspections can help identify and resolve these issues before they escalate.

Suspension and Steering Problems

Another area of concern lies in the suspension and steering systems. Many individuals experience issues like uneven tire wear, difficulty steering, or strange noises while driving. Proper alignment and timely replacement of worn-out components are crucial for maintaining optimal handling and safety on rugged terrains.

Essential Tools for Repairs

When embarking on a journey to fix your vehicle, having the right equipment is crucial for success. Proper instruments not only enhance efficiency but also ensure the safety and longevity of your machine. This section highlights the indispensable tools that every enthusiast should have at their disposal to tackle common maintenance and upgrade tasks.

Wrenches are fundamental for loosening and tightening various components. A good set of both open-end and box-end wrenches will cover a wide range of nuts and bolts. Additionally, sockets paired with a ratchet can greatly simplify the process of working in tight spaces.

Screwdrivers are another must-have; a mix of flathead and Phillips types will serve you well for various fasteners. Furthermore, pliers, including needle-nose and adjustable varieties, provide excellent grip and leverage for holding and bending materials.

To keep everything organized, a toolbox or a tool bag is essential. It helps you maintain a clean workspace and ensures that your instruments are easily accessible when needed.

Finally, don’t forget about safety gear, such as gloves and goggles, to protect yourself during any work. Investing in quality equipment not only makes the job easier but also enhances your overall experience as you maintain and upgrade your vehicle.

Step-by-Step Guide to Troubleshooting

Identifying and resolving issues in vehicles requires a systematic approach. This section provides a structured method to effectively diagnose problems, ensuring that each potential cause is examined thoroughly. By following this guide, you can enhance your troubleshooting skills and minimize time spent on repairs.

-

Gather Information:

Start by collecting details about the problem. Ask questions such as:

- What symptoms are observed?

- When did the issue begin?

- Has anything changed recently in vehicle usage?

-

Visual Inspection:

Conduct a thorough inspection of the vehicle’s components. Look for:

- Signs of wear or damage

- Fluid leaks

- Loose or disconnected parts

-

Check the Basics:

Examine fundamental systems first:

- Battery condition and connections

- Fluid levels (oil, coolant, brake fluid)

- Tire pressure and condition

-

Use Diagnostic Tools:

Utilize appropriate tools to assist in identifying faults:

- OBD-II scanner for electronic issues

- Multimeter for electrical tests

- Compression gauge for engine performance

-

Consult Resources:

Refer to manuals or online databases for specific issues related to the make and model. This can provide insights into common problems and their solutions.

-

Test and Evaluate:

After making adjustments or repairs, conduct tests to verify the effectiveness of your solutions. Monitor for any recurring symptoms.

By systematically following these steps, you can diagnose and resolve many issues effectively, leading to better vehicle performance and longevity.

How to Replace Jeep JK Parts

Replacing components in your vehicle can significantly enhance its performance and longevity. Whether you’re dealing with wear and tear or upgrading parts, understanding the process is essential for achieving optimal results. This guide will provide you with essential steps and tips to ensure a successful replacement.

1. Gather the Necessary Tools: Before starting any work, assemble all the tools you will need. Common tools include wrenches, sockets, screwdrivers, and safety gear. Having everything on hand will streamline the process and prevent interruptions.

2. Identify the Parts to Replace: Conduct a thorough inspection of your vehicle to identify which components require replacement. Look for signs of damage, rust, or inefficiency. Keeping a list can help you stay organized during the process.

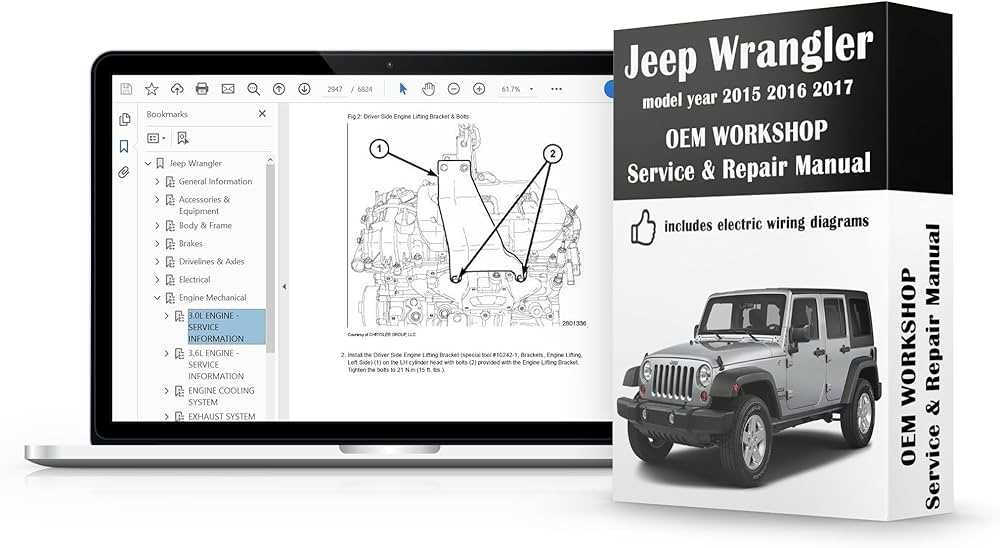

3. Consult Documentation: Refer to detailed guides or online resources to understand the specific steps involved in replacing each part. These documents often include diagrams and instructions that can be invaluable in ensuring accurate reassembly.

4. Safety First: Always prioritize safety when working on your vehicle. Ensure that the vehicle is on a stable surface, use jack stands if needed, and wear protective gear to prevent accidents.

5. Follow the Replacement Steps: For each component, follow the outlined steps meticulously. This often involves removing fasteners, disconnecting connections, and carefully removing the old part. Take note of the order and orientation of parts for reinstallation.

6. Test After Replacement: Once the new part is installed, conduct a thorough test to ensure everything is functioning correctly. Check for any unusual noises or warning lights. Proper testing is crucial to confirm that the replacement has been successful.

7. Maintain Regular Checks: After replacing parts, establish a routine for maintenance checks. Regular inspections can help you catch potential issues early and extend the lifespan of your vehicle.

Upgrading Your Jeep JK Performance

Enhancing the capabilities of your off-road vehicle involves several strategies aimed at improving power, handling, and overall efficiency. These upgrades not only enhance your driving experience but also ensure that your vehicle can tackle various terrains with ease.

One effective way to boost performance is by upgrading the exhaust system. A high-performance exhaust allows for better airflow, resulting in improved engine efficiency and a noticeable increase in horsepower. Additionally, considering a cold air intake can further enhance your engine’s breathing capabilities, providing a significant boost in throttle response.

Suspension modifications are also crucial for optimizing performance, especially when navigating rough trails. Installing high-quality shocks and struts can significantly improve handling and ride quality, providing better stability on uneven surfaces. Moreover, a suspension lift can enhance ground clearance, allowing for larger tires that contribute to improved traction.

Lastly, investing in quality tires designed for off-road conditions will greatly affect your vehicle’s capability. Choose tires that provide excellent grip and durability to tackle challenging environments. With these modifications, you can transform your ride into a powerhouse, ready for any adventure.

Safety Tips for DIY Repairs

Engaging in self-service tasks on your vehicle can be rewarding, but it is essential to prioritize safety throughout the process. Proper precautions can prevent accidents and ensure a smooth experience. Here are key safety considerations to keep in mind.

- Wear Appropriate Gear: Always use safety glasses, gloves, and sturdy footwear to protect yourself from potential hazards.

- Work in a Well-Ventilated Area: Ensure that your workspace is well-ventilated, especially when dealing with chemicals or fumes.

- Use the Right Tools: Employ the correct tools for the job to minimize the risk of injury and damage.

Before starting any task, take a moment to assess your surroundings and ensure that all tools and materials are organized and within reach. This helps to reduce distractions and maintain focus.

- Disconnect the Battery: For electrical work, disconnect the battery to prevent accidental shocks or short circuits.

- Secure the Vehicle: Always use jack stands or ramps to secure the vehicle when working underneath it.

- Keep a Fire Extinguisher Nearby: Have a fire extinguisher accessible in case of emergencies, particularly when working with flammable materials.

By adhering to these guidelines, you can enhance your safety and make the most of your self-service projects. Remember that taking the necessary precautions can lead to a successful and enjoyable experience.

Maintaining Electrical Systems Effectively

Ensuring the reliability of electronic components is crucial for optimal vehicle performance. A well-maintained electrical framework can prevent malfunctions, enhance longevity, and improve overall safety. Regular attention to the various elements of the electrical system will contribute to a smoother driving experience and minimize costly repairs.

To maintain electrical systems efficiently, consider the following key practices:

| Practice | Description |

|---|---|

| Regular Inspections | Conduct periodic checks of wiring, connectors, and components to identify wear or damage. |

| Clean Connections | Ensure all electrical connections are free of corrosion and dirt to maintain conductivity. |

| Check Battery Health | Monitor battery voltage and terminals to prevent starting issues and ensure reliable power supply. |

| Inspect Fuses | Regularly verify the condition of fuses to prevent overloads and electrical failures. |

| Update Software | Keep onboard software up to date to improve performance and fix known issues. |

By adhering to these practices, one can significantly enhance the functionality and dependability of the electrical systems, ultimately leading to a safer and more enjoyable driving experience.

Importance of Regular Fluid Checks

Maintaining optimal performance in any vehicle involves more than just routine maintenance; it also requires frequent monitoring of essential liquids. Regular checks of these fluids ensure that all systems function efficiently, thereby extending the life of the vehicle and enhancing safety. This section highlights the significance of keeping an eye on various fluid levels.

Key Fluids to Monitor

- Engine Oil: Critical for lubrication, it prevents wear and tear on engine components.

- Coolant: Regulates engine temperature and prevents overheating.

- Brake Fluid: Essential for the braking system’s functionality and safety.

- Transmission Fluid: Ensures smooth shifting and prolongs transmission life.

- Power Steering Fluid: Important for ease of steering and handling.

Benefits of Regular Checks

- Preventing Breakdown: Regular fluid assessments can identify potential issues before they escalate into costly repairs.

- Enhanced Performance: Keeping fluids at recommended levels helps maintain optimal vehicle performance.

- Safety Assurance: Proper fluid levels contribute to the overall safety of the vehicle, especially in critical systems like brakes.

- Cost Efficiency: Addressing minor fluid issues promptly can save money by avoiding major repairs in the future.

Handling Off-Road Challenges

Navigating rugged terrains requires more than just a powerful vehicle; it demands skill, preparation, and a keen understanding of the environment. Off-road driving can present various obstacles, from steep inclines to muddy trails, each requiring a unique approach to tackle effectively.

Preparation and Equipment

Before embarking on an adventurous journey, proper preparation is crucial. Here are some essential steps to consider:

- Inspect your vehicle thoroughly to ensure all systems are functioning properly.

- Equip your vehicle with appropriate tires designed for off-road conditions.

- Carry necessary recovery gear, such as tow straps, a shovel, and a spare tire.

- Pack essential supplies, including water, food, and a first aid kit.

Driving Techniques

Mastering the right techniques can significantly enhance your off-road experience. Consider the following tips:

- Maintain a steady speed to avoid getting stuck in soft terrain.

- Use a low gear when climbing steep hills to maintain control.

- Be mindful of tire placement to navigate obstacles without damage.

- When descending, use engine braking to control speed effectively.

By equipping yourself with the right tools and knowledge, you can confidently face any off-road challenge that comes your way.

Resources for Jeep JK Enthusiasts

For those passionate about off-road vehicles and their modifications, a wealth of information and community support is readily available. These resources cater to various aspects of vehicle maintenance, enhancements, and the overall lifestyle associated with these rugged machines.

Online Forums: Engaging with fellow enthusiasts through dedicated online platforms can provide invaluable insights. These forums often feature discussions on troubleshooting, upgrades, and personal experiences that can guide new and seasoned owners alike.

DIY Guides: Many enthusiasts share step-by-step guides that cover everything from basic maintenance to advanced modifications. These comprehensive resources empower individuals to take on projects themselves, fostering a sense of accomplishment and community involvement.

Social Media Groups: Social media platforms host numerous groups focused on vehicle enthusiasts. These communities are perfect for sharing tips, showcasing modifications, and finding camaraderie among like-minded individuals.

Specialty Magazines: Subscribing to magazines dedicated to off-roading can keep enthusiasts updated on the latest trends, products, and events. They often feature expert advice, product reviews, and detailed articles that inspire new projects.

Workshops and Events: Participating in local workshops or attending off-road events provides hands-on experience and the opportunity to learn from professionals. These gatherings not only enhance skills but also allow for networking within the community.

With these resources, enthusiasts can deepen their knowledge and enjoyment of their vehicles, ensuring they are well-equipped for any adventure on or off the road.