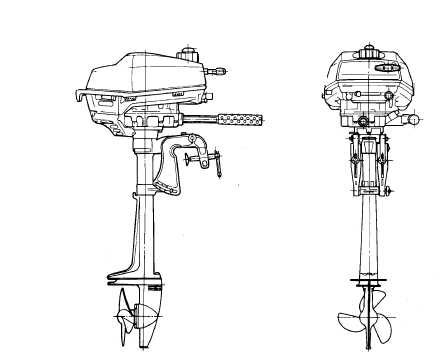

When it comes to small watercraft, ensuring the longevity and efficiency of an outboard engine is crucial. This guide explores essential aspects of maintaining and troubleshooting a compact yet powerful 15 horsepower model, ideal for various types of vessels. Proper care, timely assessments, and familiarization with key procedures can make a significant difference in performance, fuel efficiency, and the overall lifespan of the engine.

In the following sections, we’ll delve into each component and system, examining typical issues and practical solutions that will empower users to keep their equipment in prime condition. From initial diagnostics to detailed solutions for common concerns, this resource is crafted to make complex procedures understandable and approachable for all experience levels.

Whether it’s enhancing fuel efficiency, addressing occasional mechanical setbacks, or ensuring smooth operation on every journey, each segment provides valuable insight. This resource aims to equip every boat owner with the necessary know-how to confidently handle a variety of maintenance tasks, ensuring consistent performance and reliability on the water.

Understanding Honda BF15A Engine Maintenance

Proper engine care is crucial to ensuring a long and efficient life for your outboard motor. Regular attention to key components and adherence to a consistent upkeep schedule can prevent unexpected malfunctions and optimize performance, especially in demanding marine environments.

Key Areas for Routine Inspection

Several core components should be routinely checked and serviced. Regular inspections help identify wear and tear before they evolve into larger issues. Prioritizing the upkeep of these parts supports reliable engine function and minimizes costly repairs over time.

| Component | Recommended Service Frequency | |

|---|---|---|

| Fuel System | Every 50 hours | |

| Cooling System | Every 100 hours | |

| Spark Plugs | Every 100 hours | |

| Propeller | Each use | |

| Oil & Filters | Every 50 hours or annually |

| Step | Description |

|---|---|

| 1 | Inspect the existing attachment for any signs of damage or wear. Look for cracks, dents, or missing parts. |

| 2 | Use the appropriate tool to remove the existing device. Be cautious not to damage the shaft during removal. |

| 3 | Clean the shaft thoroughly to remove any debris or corrosion that may interfere with the new attachment. |

| 4 | Position the new device onto the shaft, ensuring it aligns properly with the locking mechanism. |

| 5 | Secure the attachment by tightening the locking mechanism to the manufacturer’s specifications. |

| 6 | Conduct a final inspection to ensure everything is in place and securely fastened before testing. |

Regular maintenance and timely replacement of the propulsion device contribute to the longevity and efficiency of the entire system. Follow these steps diligently to ensure your equipment operates at its best.

Cooling System Checks and Repairs

Maintaining optimal temperature regulation in an outboard engine is crucial for its performance and longevity. This section outlines essential procedures for inspecting and servicing the cooling apparatus to prevent overheating and ensure efficient operation. Regular assessments and prompt interventions can significantly enhance reliability during use.

Inspection Procedures

Begin by examining the coolant level and quality. Ensure that the coolant is free from contaminants and that the levels are within the recommended range. Check hoses and connections for signs of wear or leaks, as these can lead to inadequate cooling. Additionally, verify that the water intake screen is clear of debris to facilitate proper water flow.

Common Issues and Solutions

If overheating is detected during operation, the following issues may be responsible:

| Issue | Potential Causes | Suggested Actions |

|---|---|---|

| Insufficient Coolant | Leak, evaporation | Top up coolant and check for leaks |

| Clogged Cooling System | Debris accumulation | Flush the system with fresh water |

| Faulty Water Pump | Wear and tear | Inspect and replace the water pump if necessary |

Addressing these concerns promptly can prevent severe damage and extend the service life of the engine. Regular maintenance checks will ensure that the cooling system operates efficiently and effectively.

Routine Oil and Filter Replacement

Regular maintenance of your marine engine is essential for optimal performance and longevity. One of the key aspects of this upkeep involves the timely replacement of lubricating fluid and the filtration system. This procedure not only ensures smooth operation but also protects vital components from wear and tear caused by contaminants.

Steps for Oil Replacement

Begin by ensuring that the engine is warm, as this helps the fluid to drain more easily. Using the appropriate tools, remove the drain plug and allow the old lubricant to flow into a suitable container. Once the fluid has completely drained, replace the drain plug securely to prevent leaks.

Changing the Filter

Next, locate the filtration unit. Use a filter wrench to unscrew the old filter carefully, ensuring any residual fluid is captured. Before installing the new filter, apply a small amount of fresh oil to the gasket to create a better seal. Screw on the new filter hand-tight, and then proceed to fill the engine with fresh lubricant, following the manufacturer’s specifications.

Finally, start the engine and let it run for a few minutes, checking for leaks and ensuring that the oil pressure is within normal limits. Regularly monitoring and maintaining these elements will greatly enhance the engine’s performance and lifespan.

Testing and Tuning the Ignition System

The ignition system is a crucial component in ensuring optimal performance and reliability of your engine. Proper testing and adjustment of this system can enhance fuel efficiency, improve starting reliability, and reduce emissions. In this section, we will explore the necessary steps for assessing and fine-tuning the ignition system, ensuring it operates at peak efficiency.

To effectively evaluate the ignition system, you will need a few essential tools such as a multimeter, spark tester, and timing light. Below is a table outlining the basic steps for testing and tuning:

| Step | Description |

|---|---|

| 1 | Check the battery voltage to ensure adequate power supply to the ignition system. |

| 2 | Inspect the ignition coils for any signs of wear or damage. Replace if necessary. |

| 3 | Use a spark tester to confirm that the spark plugs are firing correctly. Replace faulty plugs. |

| 4 | Adjust the ignition timing using a timing light, following the manufacturer’s specifications. |

| 5 | Test the entire system under load to ensure optimal performance during operation. |

By following these steps, you can ensure that the ignition system operates efficiently, leading to improved engine performance and longevity.

Winterizing Tips for Honda BF15A Engine

Preparing your outboard motor for the colder months is crucial to ensure its longevity and optimal performance when spring arrives. Proper winterization helps prevent damage from freezing temperatures, corrosion, and other environmental factors. This section provides essential guidelines for safeguarding your marine engine during the off-season.

Essential Steps for Engine Winterization

Follow these important steps to effectively winterize your marine power unit:

| Step | Description |

|---|---|

| 1. Drain the Cooling System | Remove all water from the cooling system to prevent freezing and subsequent damage. Run the engine for a few minutes while disconnected from the water source to expel residual water. |

| 2. Change the Oil | Replace the engine oil and oil filter to prevent contaminants from causing corrosion during the winter months. Fresh oil protects engine components. |

| 3. Stabilize the Fuel | Add fuel stabilizer to the fuel tank and run the engine briefly to circulate it throughout the fuel system. This prevents fuel degradation and potential clogs. |

| 4. Inspect the Battery | Check the battery condition and charge it fully. Store it in a cool, dry place and ensure connections are clean and corrosion-free. |

| 5. Cover the Engine | Use a protective cover to shield the motor from dust and moisture during storage. This helps prevent rust and other environmental damage. |

Final Considerations

Taking the time to properly prepare your outboard engine for winter can significantly extend its lifespan and maintain its reliability. Adhering to these guidelines will ensure that your motor is ready for a smooth start when the boating season resumes.