Owning a reliable grass-cutting machine can greatly enhance the beauty of your outdoor space. Proper care and upkeep are essential to ensure longevity and optimal performance. This section provides valuable insights and practical advice on how to address common issues that may arise, ensuring your device continues to function efficiently.

Understanding the inner workings of your lawn care equipment is crucial. From routine checks to troubleshooting, every aspect plays a significant role in maintaining peak functionality. This guide will assist you in navigating the various components and provide step-by-step instructions to handle repairs and adjustments effectively.

Equipped with the right knowledge, you can confidently tackle any challenge that arises during your ownership experience. This resource aims to empower you with the skills needed to perform maintenance tasks and extend the lifespan of your valuable tool.

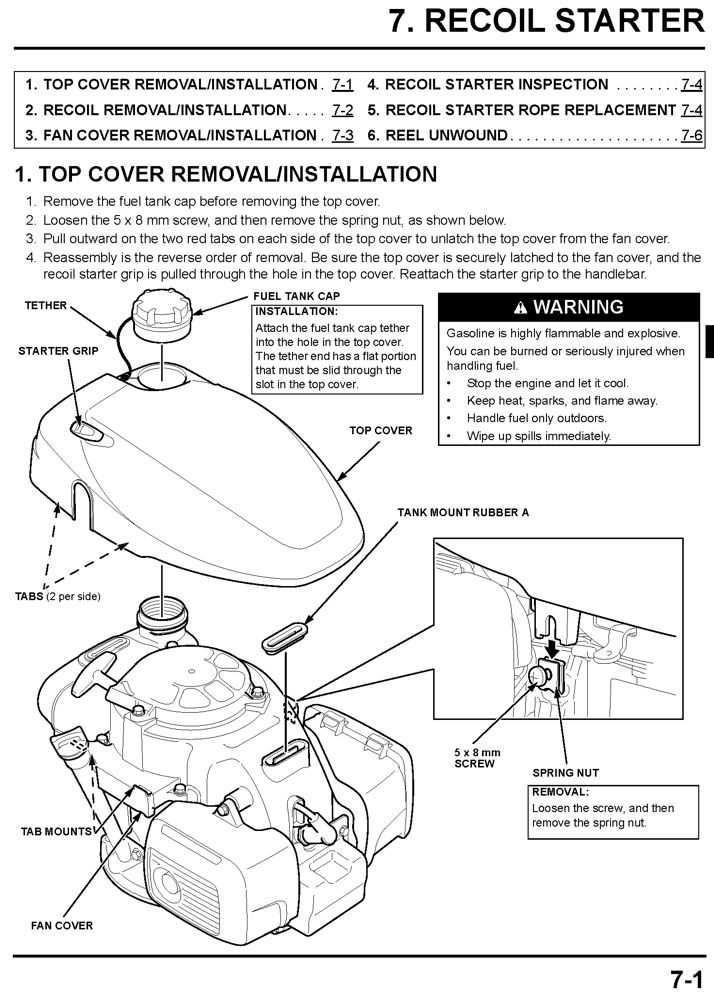

Understanding Your Honda HRX217

When it comes to maintaining your lawn care equipment, grasping the essential components and their functions is crucial. This knowledge ensures efficient operation and longevity of your machine. A deeper understanding allows users to diagnose issues, perform routine tasks, and enhance overall performance.

The featured model is equipped with a powerful engine that delivers impressive cutting performance. Engine type influences not only the effectiveness of cutting grass but also the ease of starting and fuel efficiency. Familiarity with its specifications will guide you in achieving optimal results.

Additionally, the design incorporates advanced features such as adjustable cutting heights and self-propelling mechanisms. These functionalities enhance user experience by providing customizable options to tackle various terrains and grass conditions. Mastering these elements can significantly improve the efficiency and enjoyment of your lawn maintenance activities.

Lastly, understanding the basic maintenance tasks, such as oil changes and blade sharpening, is vital for preserving the machine’s performance. Regular upkeep not only extends the lifespan but also contributes to a better lawn care experience.

Essential Tools for Maintenance

Proper upkeep of outdoor equipment is crucial for ensuring longevity and optimal performance. Having the right instruments at hand can make maintenance tasks not only easier but also more efficient. This section outlines the fundamental tools needed to keep your machinery running smoothly.

Basic Hand Tools

Every maintenance kit should include a variety of hand tools. These typically consist of wrenches, screwdrivers, and pliers. Wrenches are essential for loosening and tightening bolts, while screwdrivers help in adjusting various components. Pliers are versatile tools useful for gripping and bending materials.

Specialized Equipment

In addition to basic hand tools, consider investing in specialized equipment. Oil changers and spark plug wrenches can simplify routine maintenance tasks. An oil changer allows for quick and clean fluid replacement, while a spark plug wrench is specifically designed to remove and install spark plugs with ease. These tools can significantly enhance the efficiency of maintenance procedures.

Common Issues and Solutions

In any mechanical device, certain challenges may arise that can hinder performance and efficiency. Understanding these common problems and their corresponding solutions is essential for maintaining optimal functionality.

-

Engine Won’t Start:

If the power unit fails to ignite, check the fuel level and ensure that the spark plug is functioning properly. A clogged fuel line could also be the culprit.

-

Inefficient Cutting Performance:

Dull blades can significantly impact cutting efficiency. Regularly inspect and sharpen the blades to maintain a clean cut.

-

Excessive Vibration:

Vibration may be caused by an unbalanced blade or loose components. Tighten all fasteners and ensure that the blade is correctly aligned.

-

Stalling During Operation:

If the equipment stalls frequently, it may be due to improper throttle settings or obstructions in the cutting path. Adjust the throttle and clear any debris.

-

Fuel Leaks:

Leaks can occur due to worn seals or damaged fuel lines. Inspect the fuel system for any cracks or wear, and replace damaged components as necessary.

By addressing these prevalent issues promptly, users can enhance the longevity and performance of their equipment.

Step-by-Step Engine Troubleshooting

Troubleshooting engine issues requires a systematic approach to identify and resolve common problems. This guide provides a detailed method to help you assess performance concerns, ensuring efficient operation.

1. Verify Fuel Supply: Begin by checking the fuel tank for adequate fuel levels. Ensure the fuel is fresh and free from contaminants, as stale fuel can lead to starting difficulties.

2. Examine the Spark Plug: Remove the spark plug and inspect it for wear or damage. A worn or fouled plug may hinder ignition. Clean or replace the spark plug if necessary.

3. Assess Air Filter Condition: Check the air filter for dirt and blockages. A clogged filter restricts airflow, impacting engine performance. Clean or replace it as needed.

4. Inspect the Carburetor: If the engine fails to start or runs poorly, inspect the carburetor for clogs. Clean the carburetor to ensure proper fuel delivery and air mixture.

5. Review Electrical Connections: Examine all electrical connections, including wiring and terminals, for corrosion or loose connections. Ensure the ignition system is functioning correctly.

6. Test Compression: Use a compression tester to check the engine’s compression levels. Low compression may indicate internal wear or damage that needs attention.

7. Evaluate Exhaust System: Inspect the exhaust system for blockages or leaks. A restricted exhaust can cause performance issues and reduce efficiency.

By following these steps, you can effectively troubleshoot and address engine issues, leading to improved performance and reliability.

Maintaining the Cutting Blades

Proper upkeep of the cutting edges is essential for achieving optimal performance and longevity of your equipment. Regular attention ensures that these components remain sharp and effective, resulting in a cleaner cut and enhanced efficiency during operation.

Sharpening: It is crucial to routinely sharpen the blades to maintain their cutting ability. Dull blades can lead to uneven cuts and increased strain on the motor. Utilize a file or sharpening tool specifically designed for this purpose. Aim for a consistent angle to ensure an even edge.

Inspection: Regularly examine the blades for any signs of wear or damage. Look for nicks, dents, or rust, which can compromise performance. If you notice significant damage, consider replacing the blades to ensure the best results.

Cleaning: After each use, remove grass clippings and debris from the blades. A clean cutting surface prevents buildup that can lead to rust and deterioration. Use a brush or cloth to wipe down the edges, ensuring they remain in good condition.

Lubrication: Apply a light coat of oil to the pivot points of the blades to reduce friction and prevent rust. This simple step can prolong the life of the components and improve overall functionality.

By following these guidelines, you can ensure that the cutting edges operate effectively, delivering excellent performance and extending the lifespan of your equipment.

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring the longevity and performance of your lawn care equipment. By adhering to a seasonal maintenance checklist, you can prevent potential issues and enhance the efficiency of your machine. This proactive approach helps in identifying wear and tear early, ensuring a smooth operation throughout the year.

Spring Maintenance:

- Inspect and replace the air filter to ensure optimal airflow.

- Sharpen or replace the cutting blade for a clean cut.

- Check and change the oil to keep the engine running smoothly.

- Clean the exterior and undercarriage to prevent rust and debris buildup.

Summer Care:

- Monitor fuel levels and use fresh fuel to prevent engine issues.

- Inspect spark plugs for wear and replace if necessary.

- Ensure that the cooling system is clean to avoid overheating.

Autumn Preparation:

- Perform a thorough cleaning before winter storage.

- Drain fuel or add a stabilizer to prevent deterioration.

- Check belts and cables for any signs of wear.

Winter Storage:

- Store in a dry, sheltered location to protect from moisture.

- Cover to prevent dust accumulation and potential damage.

- Perform a full inspection before the next season begins.

By following this comprehensive checklist, you ensure that your equipment remains in peak condition, ready for every task that comes its way.

Cleaning the Air Filter

Maintaining optimal performance of your equipment requires regular attention to essential components, including the air filter. A clean filter ensures that the engine receives adequate airflow, which is crucial for efficient operation and longevity.

To effectively clean the air filter, follow these steps:

- Turn off the engine and ensure the unit is cool to prevent any accidents.

- Locate the air filter housing, typically situated on the side or top of the engine.

- Remove the cover of the housing by unscrewing or unclipping it.

- Carefully take out the air filter from the housing.

Once the filter is removed, proceed with the cleaning process:

- Use a soft brush or compressed air to gently remove dust and debris from the filter surface.

- If the filter is excessively dirty, consider washing it with soap and water. Allow it to dry completely before reinserting.

- Check for any signs of damage or wear. Replace the filter if it is torn or overly degraded.

After cleaning, reassemble the components by reversing the earlier steps. Ensure that the air filter is securely placed and the housing cover is properly fastened. Regular maintenance of this part will enhance the overall efficiency of your equipment.

Changing the Oil Correctly

Regularly replacing the lubricant is essential for maintaining optimal performance and extending the lifespan of your outdoor power equipment. Proper oil changes help ensure smooth operation and prevent potential damage to internal components.

Follow these steps to execute an oil change effectively:

- Gather Necessary Tools and Materials:

- Fresh lubricant

- Oil catch pan

- Wrench or socket set

- Funnel

- Rags or paper towels

- Prepare the Equipment:

- Ensure the engine is off and cool to prevent burns.

- Place the unit on a flat surface for stability.

- Drain the Old Lubricant:

- Locate the drain plug and remove it using the appropriate tool.

- Position the catch pan beneath the plug to collect the old oil.

- Allow sufficient time for complete drainage.

- Replace the Oil Filter (if applicable):

- Remove the old filter carefully.

- Install the new filter, ensuring a secure fit.

- Add New Lubricant:

- Using a funnel, pour the fresh oil into the designated fill opening.

- Refer to the manufacturer’s specifications for the correct type and amount.

- Check Oil Level:

- Use the dipstick to ensure the lubricant is at the appropriate level.

- Add more oil if necessary, repeating the check until correct.

- Dispose of Old Oil Properly:

- Transfer the used lubricant to a sealed container.

- Take it to a local recycling center or disposal facility.

By following these guidelines, you can ensure the longevity and efficiency of your equipment while maintaining a clean and responsible approach to oil disposal.

Replacing the Spark Plug

Regular maintenance of outdoor power equipment includes the replacement of ignition components to ensure optimal performance. A worn or damaged spark element can lead to starting difficulties and reduced efficiency, making timely replacement essential.

To initiate the process, first, gather the necessary tools: a spark plug socket, a ratchet wrench, and a torque wrench. Before proceeding, ensure the unit is powered off and completely cool to avoid injury. Disconnect the ignition wire to prevent accidental starts.

Next, locate the ignition component, which is typically situated on the engine. Use the spark plug socket to carefully unscrew it from its housing. Inspect the removed part for signs of wear such as carbon buildup or damage; these indications will help determine the need for replacement.

Install the new ignition component by threading it into place by hand to avoid cross-threading. Once seated, use the torque wrench to tighten it to the manufacturer’s specifications, ensuring a secure fit without over-tightening.

Finally, reconnect the ignition wire and test the equipment to confirm proper operation. Regular checks and replacements will enhance the longevity and reliability of your machine.

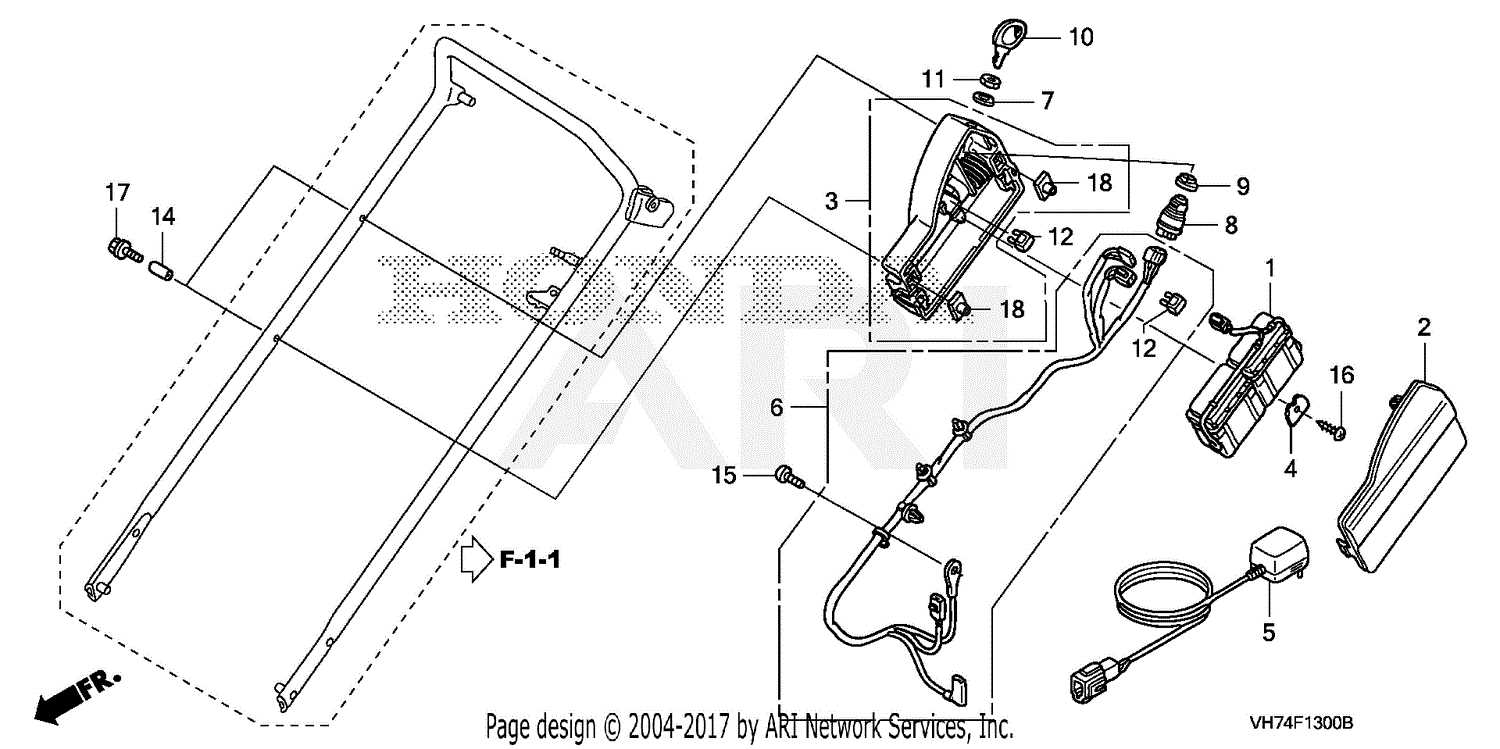

Adjusting the Handle Height

Properly setting the height of the handle is essential for comfortable operation and effective maneuverability. Adjusting this component can significantly enhance user experience, allowing for a more efficient and ergonomic grip during use.

Tools Required

To begin the adjustment process, ensure you have a suitable wrench or screwdriver on hand. These tools will allow you to loosen or tighten the necessary bolts for the height modification.

Adjustment Procedure

Start by identifying the adjustment points on the handle assembly. Loosen the bolts slightly to allow for movement. Next, raise or lower the handle to your preferred height. Once positioned, securely tighten the bolts to ensure stability during operation. It’s advisable to test the new height by gripping the handle and ensuring it feels comfortable before resuming use.

Storing Your Mower Safely

Properly storing your lawn care equipment is essential for ensuring its longevity and optimal performance. Whether it’s during the off-season or after a maintenance session, taking the right precautions can prevent damage and ensure that your device is ready for use when needed.

1. Choose a Suitable Location: Select a dry, well-ventilated area for storage. Avoid damp spaces, as moisture can lead to rust and corrosion. A shed or garage is often ideal, but ensure it is clean and free of debris.

2. Clean the Equipment: Before storing, remove any grass clippings, dirt, or debris. This not only helps prevent rust but also keeps pests away. Use a brush and a cloth to clean the surfaces thoroughly.

3. Drain Fuel: If your device is not going to be used for an extended period, consider draining the fuel tank to prevent gumming and clogging. Alternatively, add a fuel stabilizer to keep the fuel fresh.

4. Check for Damage: Inspect the machinery for any wear or damage. Address any issues before storing it to avoid further complications in the future.

5. Use Covers: Invest in a good-quality cover to protect the machine from dust, moisture, and other environmental factors. Ensure that the cover is breathable to prevent moisture buildup.

By following these guidelines, you can ensure that your lawn maintenance tool remains in excellent condition, ready for action when the time comes.