In the realm of compact energy solutions, the importance of understanding the intricacies of your device cannot be overstated. Whether for camping, outdoor events, or emergency situations, knowing how to maintain and troubleshoot these vital tools is essential for their longevity and performance. This section delves into the key aspects of ensuring that your portable power unit operates smoothly and efficiently.

Effective upkeep involves recognizing potential issues before they escalate into significant problems. Familiarizing yourself with the components and functionality of your equipment will empower you to address minor concerns swiftly. This knowledge not only enhances your confidence but also maximizes the utility of your investment.

Additionally, understanding the maintenance procedures can significantly improve the reliability of your portable power solution. From routine checks to more involved service tasks, being equipped with the right information is crucial. In the following sections, we will explore practical tips and step-by-step guidance that will aid you in maintaining optimal performance and extending the lifespan of your device.

Overview of Honda EU2000i Generator

This section provides a comprehensive understanding of a compact power solution designed for various outdoor activities and home use. Renowned for its reliability and efficiency, this portable device is suitable for camping, tailgating, and emergency backup situations.

Key Features

One of the standout characteristics is its lightweight design, making it easy to transport. Additionally, it boasts a quiet operation, allowing users to enjoy nature without disruptive noise. With an impressive fuel efficiency, it can run for extended periods on minimal fuel, which is ideal for prolonged outdoor trips.

Applications and Benefits

This power source serves multiple purposes, from providing energy for small appliances to supporting recreational activities. Its versatility and ease of use make it a favorite among outdoor enthusiasts and homeowners alike. Furthermore, the durability of the unit ensures it can withstand varying weather conditions, promising dependable performance over time.

Common Issues with EU2000i Generators

Portable power units are essential for various applications, but they can encounter several challenges over time. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their equipment.

Here are some frequent issues experienced with these portable devices:

- Starting Difficulties: Users may find it hard to start the unit, which can be caused by a drained battery, stale fuel, or issues with the ignition system.

- Overheating: Continuous operation under heavy loads or blocked vents can lead to overheating, which may trigger automatic shutdowns.

- Noisy Operation: Excessive noise can indicate loose components or problems with the muffler, affecting both performance and user comfort.

- Voltage Fluctuations: Inconsistent output can result from faulty wiring, worn-out parts, or issues with the voltage regulator.

- Fuel System Blockages: Clogs in the fuel line or a dirty carburetor can hinder fuel flow, leading to reduced efficiency or stalling.

Identifying these issues early on can prevent further complications and ensure reliable operation during critical times.

Essential Tools for Repairing EU2000i

When it comes to maintaining and fixing portable power equipment, having the right set of instruments is crucial for effective and safe service. A well-equipped toolkit not only simplifies the process but also enhances the overall efficiency of your work. Understanding the essential instruments required can make all the difference when tackling various issues.

Socket Wrenches: These are indispensable for loosening and tightening bolts. A set that includes both standard and metric sizes will cover most needs.

Phillips and Flathead Screwdrivers: A range of both types will ensure you can address screws of various shapes and sizes, allowing for easier access to internal components.

Multimeter: This tool is vital for diagnosing electrical issues. It can help measure voltage, current, and resistance, giving insights into potential faults.

Torque Wrench: For ensuring that bolts are tightened to the manufacturer’s specifications, a torque wrench is essential, especially when dealing with critical engine components.

Air Compressor: Keeping the interior free of dust and debris is important. An air compressor can help blow out accumulated particles that might interfere with performance.

Cleaning Supplies: Brushes, cloths, and appropriate solvents are necessary for maintaining cleanliness and ensuring that parts function smoothly without obstructions.

By gathering these tools, you will be well-prepared to handle any maintenance tasks effectively, ensuring longevity and optimal performance of your portable power device.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of portable power units. Following a systematic approach to maintenance can prevent common issues and enhance reliability. This section outlines key procedures that should be performed periodically to keep your equipment running smoothly.

Scheduled Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace the oil to ensure proper lubrication and performance. |

| Air Filter Cleaning | Every 50 hours | Remove and clean the air filter to maintain airflow and efficiency. |

| Spark Plug Inspection | Every 100 hours | Check and replace the spark plug as needed for optimal ignition. |

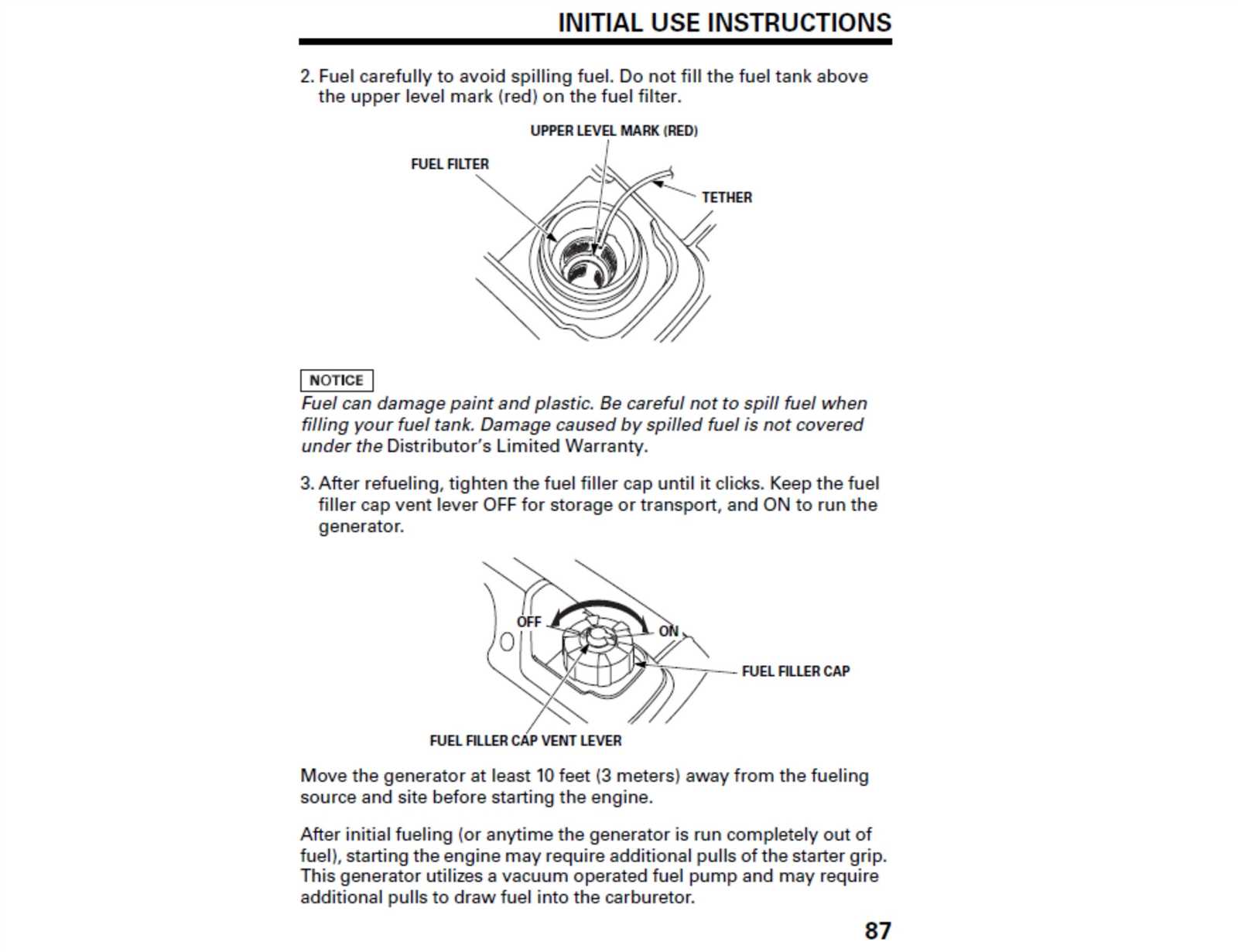

| Fuel System Check | Before each use | Inspect the fuel lines and filter for any signs of wear or blockage. |

Additional Tips for Maintenance

Ensure that the unit is always clean and free from debris. Regularly check the battery connections and terminals for corrosion. It is also advisable to store the unit in a dry environment to prevent moisture-related issues. Following these guidelines will help maximize the lifespan and functionality of your portable energy solution.

Electrical System Troubleshooting Guide

This section provides essential insights for diagnosing and resolving issues related to the electrical components of your device. Understanding the common symptoms and potential causes can significantly enhance your troubleshooting process, leading to efficient repairs and optimal performance.

Initial Assessment: Begin by checking the power supply. Ensure that all connections are secure and that the outlet is functioning properly. A multimeter can be a valuable tool for measuring voltage and continuity in the system.

Common Issues: If the unit fails to start or runs inconsistently, the problem may lie within the ignition system or the battery. Look for loose wires, corroded terminals, or damaged components. Visual inspections can often reveal underlying issues that may not be immediately apparent.

Testing Components: When troubleshooting, it’s crucial to isolate each component. Test the ignition coil, spark plug, and battery individually to determine if they are functioning correctly. Replacing faulty parts can restore proper operation.

Consulting Documentation: Refer to technical documents or user manuals that accompany your device for specific troubleshooting steps. These resources often include diagrams and detailed instructions that can facilitate a more thorough examination of the electrical system.

Safety Precautions: Always prioritize safety when working with electrical systems. Disconnect the power source before conducting any repairs, and use insulated tools to avoid electrical shock.

Fuel System Diagnostics and Solutions

The efficiency of any portable power source heavily relies on its fuel system. Proper functioning ensures optimal performance and reliability, while issues can lead to unexpected failures. This section delves into common problems within the fuel system and offers effective solutions to restore functionality.

| Issue | Symptoms | Solution |

|---|---|---|

| Clogged Fuel Filter | Poor performance, difficulty starting | Replace the fuel filter regularly; clean if reusable. |

| Dirty Fuel Lines | Inconsistent power output, stalling | Inspect and clean fuel lines; replace if damaged. |

| Fuel Contamination | Engine misfiring, reduced efficiency | Drain the fuel tank; refill with fresh, clean fuel. |

| Faulty Fuel Pump | Engine won’t start, sputtering | Test the pump’s functionality; replace if necessary. |

| Incorrect Fuel Mixture | Excessive smoke, overheating | Ensure the correct fuel-oil ratio; adjust as needed. |

Regular maintenance and timely diagnostics of the fuel system can significantly enhance performance and prolong the lifespan of the equipment. By understanding potential issues and their solutions, users can minimize downtime and ensure efficient operation.

Replacing the Oil and Filter

Regular maintenance of your portable power source is essential for optimal performance and longevity. One of the key aspects of this upkeep involves changing the lubricant and filtration system, ensuring that the internal components function smoothly and efficiently.

Before starting the replacement process, gather the necessary tools and materials:

- New oil

- Oil filter

- Wrench or socket set

- Oil catch pan

- Funnel

- Clean rags

Follow these steps to effectively replace the oil and filter:

- Preparation: Ensure the equipment is turned off and has cooled down completely. This prevents burns and makes the task safer.

- Drain the old oil: Position the oil catch pan beneath the drain plug. Remove the plug carefully and allow the used lubricant to completely drain out.

- Replace the filter: Locate the oil filter and use the wrench to loosen it. Remove the old filter and replace it with a new one, making sure to apply a small amount of fresh oil to the gasket for a better seal.

- Refill with new oil: Replace the drain plug securely. Using a funnel, pour the new lubricant into the designated fill area, ensuring you do not overfill.

- Check levels: After adding oil, allow a moment for it to settle, then use the dipstick to verify that the oil level is within the recommended range.

- Dispose of waste properly: Collect the used oil and filter for disposal in accordance with local regulations.

By following these steps, you help maintain the efficiency and reliability of your equipment, ensuring it runs smoothly for many years to come.

Starting Problems and Their Fixes

Encountering difficulties when attempting to start a portable power source can be frustrating. Various factors may contribute to this issue, and understanding them can lead to effective solutions. Here, we outline common causes of starting troubles and their corresponding remedies.

Common Causes

- Fuel Issues: Old or contaminated fuel can hinder ignition.

- Battery Problems: A weak or dead battery may prevent starting.

- Air Blockages: Clogged air filters can restrict airflow, impacting performance.

- Electrical Connections: Loose or corroded connections can disrupt the starting process.

Suggested Solutions

- Inspect and Replace Fuel: Use fresh fuel and ensure it is clean and appropriate for the unit.

- Check the Battery: Test the battery voltage and replace it if necessary.

- Clean Air Filters: Regularly check and clean or replace air filters to ensure proper airflow.

- Tighten Connections: Examine all electrical connections for corrosion or looseness, and tighten as needed.

By addressing these common issues, you can enhance the reliability and performance of your portable power equipment.

Parts Replacement for EU2000i

Maintaining optimal performance of your portable power unit often requires timely substitutions of worn or damaged components. Understanding the key elements that may need replacing is essential for ensuring longevity and efficiency. This section delves into the most common parts that may require attention over time.

Fuel System Components: The fuel filter and carburetor are critical for smooth operation. A clogged filter can restrict fuel flow, while a malfunctioning carburetor can lead to poor performance. Regular checks and replacements can prevent these issues.

Air Intake Parts: The air filter plays a vital role in maintaining proper airflow. A dirty or damaged filter can significantly hinder efficiency and increase fuel consumption. Replacing the air filter periodically is advisable to ensure optimal operation.

Electrical System Elements: Spark plugs are crucial for ignition. Worn or fouled plugs can result in hard starting or misfires. Inspecting and replacing them as needed will help maintain reliable performance.

Exhaust System Parts: Mufflers and exhaust pipes can wear out or become obstructed over time. Ensuring these components are in good condition is important for reducing noise and improving overall efficiency.

By keeping an eye on these critical components and replacing them as necessary, users can ensure their unit remains in peak condition, enhancing both performance and reliability.

When to Seek Professional Help

Understanding when to consult an expert can significantly impact the longevity and performance of your equipment. While many issues can be resolved with basic knowledge and tools, there are circumstances where professional assistance is necessary to avoid further complications or damage.

It is crucial to recognize specific signs that indicate the need for expert intervention. Below are some key indicators:

| Indicator | Description |

|---|---|

| Persistent Issues | If a problem recurs despite attempts to fix it, professional help may be required. |

| Strange Noises | Unusual sounds during operation can signal underlying mechanical issues that need specialized attention. |

| Smoke or Odors | Any visible smoke or burning smell indicates a serious fault and should prompt immediate professional evaluation. |

| Electrical Failures | Issues with power output or functionality can pose safety risks and require a qualified technician. |

| Lack of Experience | If you’re unfamiliar with troubleshooting methods, seeking an expert can prevent costly mistakes. |

Recognizing these indicators early can save time and resources, ensuring that your equipment remains in optimal condition.