In this guide, we delve into the intricacies of engine upkeep, focusing on effective strategies for maintaining robust functionality and addressing common issues that arise with high-performing power systems. This resource is crafted for those looking to enhance the lifespan and efficiency of their engines through methodical care and informed maintenance practices.

Understanding the foundational aspects of these power units is crucial for any owner or mechanic. In this document, we explore essential maintenance techniques, part replacement schedules, and troubleshooting methods that will help prevent breakdowns and extend usability. Whether you’re dealing with cooling systems, fuel lines, or exhaust management, each area is covered in detail, empowering you to make informed adjustments and repairs.

By following the structured steps provided here, even those with limited experience can gain confidence in addressing engine concerns. This guide not only offers procedural insights but also provides safety tips and

Ford 6.9 Diesel Repair Manual

This section provides an overview of essential guidance for maintaining and restoring this specific power system. Covering key topics, the guide emphasizes best practices for system care and performance enhancements.

- Routine Maintenance: Regular checkups are critical to ensure each component functions efficiently. Addressing minor adjustments and fluid replacements can prevent larger issues.

- Engine Health: Monitoring core parts like injectors and the cooling system supports optimal function. Simple inspections can reveal areas needing immediate attention.

- Fuel System Inspection: Periodic fuel filter changes, line checks, and overall system cleaning keep it running smoothly, reducing the chance of clogs or interruptions.

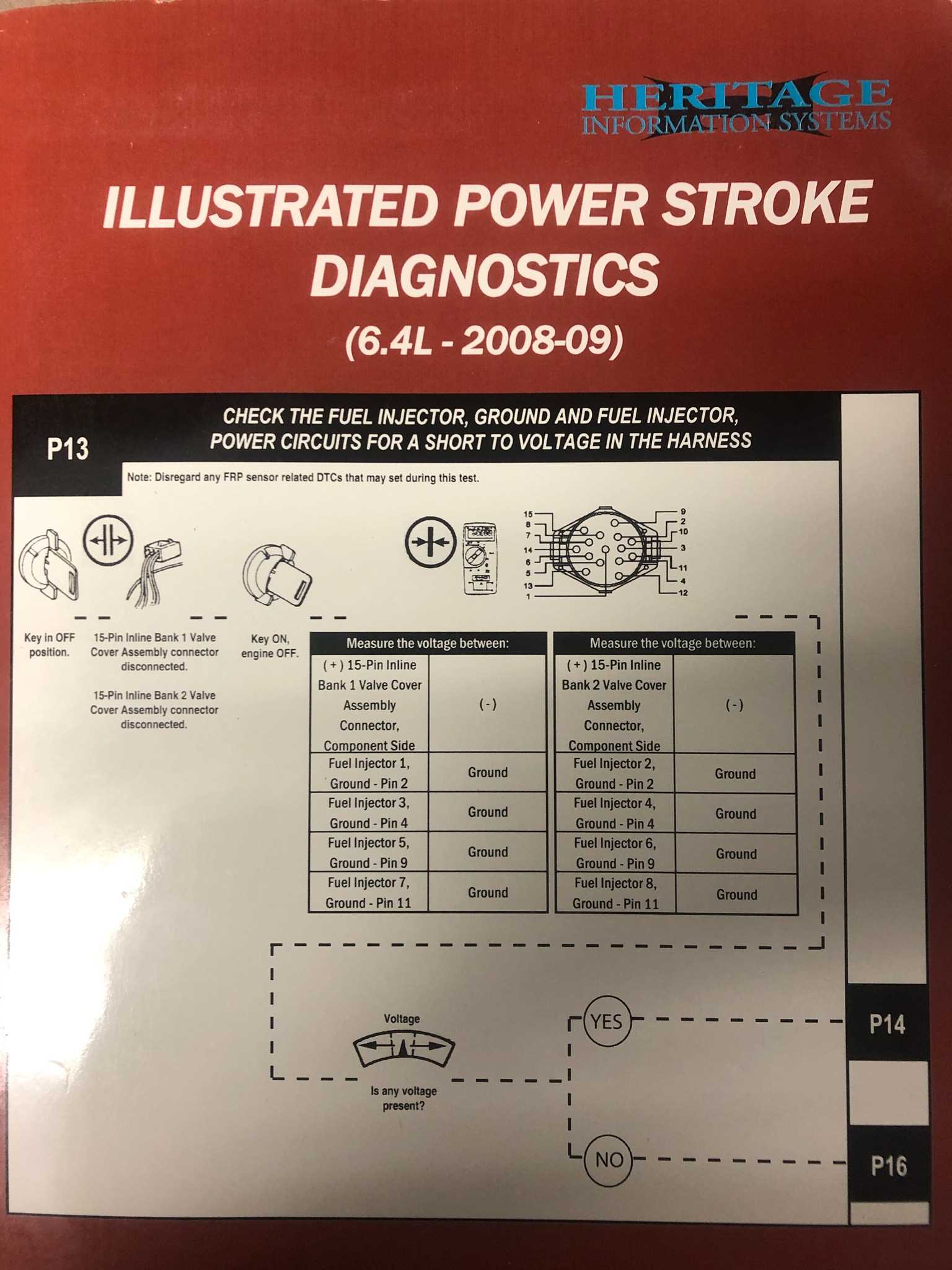

- Electrical Connections: Ensuring that all wiring, connectors, and switches are secure is vital for consistent performance. Frequent tests can prevent power issues.

Overview of the Ford 6.9 Diesel Engine

This engine model represents a significant achievement in powertrain engineering, specifically crafted for heavy-duty applications and known for its reliability and long-term performance. Designed for drivers needing a sturdy power source, it serves as a cornerstone in vehicle history, widely praised for its enduring structure and capability in handling demanding tasks.

Core Characteristics and Specifications

Characterized by a robust build and considerable torque output, this engine’s design supports ample power delivery for substantial load-carrying requirements. Its construction combines a well-thought-out fuel system and a highly efficient cooling mechanism, both of which are critical in optimizing performance and ensuring operation

Common Issues and How to Diagnose

Understanding the typical challenges that may arise and knowing how to identify them effectively can save time and prevent further complications. This section outlines frequently encountered problems and provides diagnostic methods for recognizing symptoms accurately.

Engine Performance Problems

One of the most frequent concerns is related to inconsistent engine performance. Symptoms may include rough idling, difficulty starting, or unexpected stalling. These issues often point to fuel delivery or ignition inconsistencies. To diagnose, check fuel lines and filter for blockages and ensure all connections are secure.

Electrical System Troubles

Electrical issues can lead to erratic operation or total malfunction of various systems. Causes may range from wiring faults to battery degradation. Look for visible signs of wear on cables, inspect grounding points, and test battery voltage to confirm if replacement or repair is necessary.

Maintenance Tips for Longevity

Keeping your vehicle in peak condition requires a focus on consistent upkeep and attention to critical components. Regular maintenance not only enhances performance but also extends the life of the engine, minimizing long-term repair costs and improving overall efficiency. This section covers essential practices that can help you achieve lasting durability and reliability.

Regular Fluid Checks and Replacement

- Inspect all fluid levels frequently, including coolant, oil, and transmission fluids.

- Replace engine oil at recommended intervals to maintain lubrication and preven

Essential Tools for Diesel Repairs

When it comes to maintaining powerful engines, the right set of tools can make all the difference in achieving effective results. Selecting a high-quality toolkit not only ensures safety but also boosts the accuracy of each procedure. This section outlines indispensable equipment tailored for engine servicing and fine-tuning, offering insights into how each tool contributes to smoother, more efficient maintenance.

Wrenches and Socket Sets are fundamental for handling a wide range of fasteners across the engine compartment. These tools, available in both metric and imperial sizes, enable secure tightening and loosening of bolts without causing damage to sensitive components.

Torque Wrench is crucial for achieving precise torque levels, which ensures that

Troubleshooting Fuel System Problems

Ensuring optimal performance of the fuel delivery mechanism is crucial for maintaining the overall efficiency of any engine. This section focuses on identifying and resolving common issues that may arise within the fuel system. By understanding potential malfunctions and their symptoms, you can take informed steps to restore functionality and enhance performance.

Common Symptoms of Fuel System Issues

Recognizing the signs of fuel system problems is the first step toward effective troubleshooting. Some typical indicators include:

Symptom Possible Cause Engine won’t start Clogged fuel filter or empty tank Poor acceleration Faulty fuel pump or dirty injectors Engine stalling Air in the fuel lines or low fuel pressure Unusual engine noise Inadequate fuel supply or faulty injectors Troubleshooting Steps

To effectively address fuel system malfunctions, follow these systematic steps:

- Check the fuel level in the tank to ensure there is sufficient fuel.

- Inspect the fuel filter for blockages and replace it if necessary.

- Test the fuel pump operation by listening for sounds during ignition or using a pressure gauge.

- Examine the fuel lines for any leaks or cracks that could allow air to enter.

- Clean or replace the fuel injectors if they are suspected of being clogged.

Electrical Components and Their Functions

This section delves into the various electrical elements present in the engine system and their critical roles in ensuring optimal performance. Understanding these components is essential for diagnosing issues and maintaining efficient operation. Each part contributes uniquely to the overall functionality, affecting both performance and reliability.

Key Electrical Components

Among the essential elements are the starter motor, which initiates the engine’s operation, and the alternator, responsible for charging the battery and powering electrical systems while the engine runs. Additionally, the ignition coil plays a crucial role in converting battery voltage into the high voltage needed for ignition.

Understanding Their Roles

Components such as the battery store electrical energy, while the fuses protect circuits from overloads. The wiring harness connects these parts, ensuring efficient electrical flow. Proper functioning of these elements is vital for seamless engine operation and overall vehicle reliability.

Cooling System Care and Repairs

Proper maintenance and attention to the cooling system are essential for optimal engine performance and longevity. This system plays a crucial role in regulating temperatures, preventing overheating, and ensuring efficient operation. Neglecting this component can lead to significant issues, including engine damage and reduced efficiency. Therefore, understanding how to care for and address potential problems is vital for any vehicle owner.

Regular Inspection and Maintenance

Routine checks of the cooling system should include examining the coolant level, inspecting hoses for wear, and ensuring that the radiator is free from debris. Regularly replacing the coolant is necessary to prevent corrosion and maintain the system’s efficiency. Using the correct type of coolant is equally important, as it can significantly impact the performance and lifespan of the entire cooling system.

Troubleshooting Common Issues

Common problems that may arise in the cooling system include leaks, overheating, and malfunctioning thermostats. Identifying the source of a leak promptly can prevent further damage. Overheating issues may stem from a faulty radiator or a malfunctioning water pump, requiring immediate attention. By addressing these concerns early, you can save on costly repairs and ensure that the engine remains in peak condition.

Understanding the Exhaust and Emissions System

The exhaust and emissions system plays a crucial role in managing the output of harmful gases from the engine. This system is designed to minimize environmental impact while ensuring the engine operates efficiently. By effectively channeling exhaust gases and utilizing various components, it contributes to better performance and compliance with regulatory standards.

Key Components of the System

At the heart of the exhaust and emissions setup are several vital elements, including the exhaust manifold, catalytic converter, and muffler. The exhaust manifold collects gases from the engine cylinders and directs them toward the rest of the system. The catalytic converter is essential for reducing toxic emissions, transforming harmful substances into less harmful ones before they are expelled. Finally, the muffler ensures that noise produced by the engine is minimized, allowing for a quieter operation.

Maintenance and Troubleshooting

Regular maintenance of the exhaust and emissions system is essential for optimal performance. Checking for leaks, blockages, or corrosion can prevent more significant issues down the line. If the system is not functioning correctly, it may lead to increased emissions and reduced efficiency. Addressing these problems promptly can improve the vehicle’s overall performance and prolong its lifespan.

Rebuilding the 6.9 Diesel Engine

Revitalizing an engine is a meticulous process that can enhance performance and extend the lifespan of a vehicle. This endeavor involves a series of steps that require careful attention to detail and a comprehensive understanding of engine components. By following systematic procedures, enthusiasts can effectively restore functionality and reliability, ensuring the powertrain operates at its peak.

The initial phase entails disassembly, where all components are methodically removed and inspected. This critical step allows for the identification of wear, damage, or areas that require replacement. Careful documentation of each part’s condition and the order of disassembly is essential for a successful reassembly.

Next, the components undergo cleaning and refurbishment. This may include machining parts to restore tolerances, replacing seals and gaskets, and ensuring that all surfaces are free from debris. Quality control during this stage is crucial, as it sets the foundation for the engine’s efficiency and effectiveness.

After thorough inspection and cleaning, it is time to reassemble the engine. This process involves meticulously putting together each part in the correct sequence while adhering to specified torque settings. Attention to detail during this stage is vital to prevent future issues.

Once the reassembly is complete, the engine must undergo a series of tests to ensure it operates smoothly. Initial startup should be approached with caution, monitoring for any unusual noises or leaks. Following successful testing, the vehicle can return to service, benefitting from the improved performance and reliability that come from a comprehensive overhaul.

Transmission Compatibility and Upgrades

This section explores the various options available for enhancing the transmission system of heavy-duty vehicles. Understanding the compatibility of different transmission types is crucial for optimizing performance and ensuring smooth operation. By examining available upgrades, vehicle owners can make informed decisions to improve durability and efficiency.

Identifying Compatible Transmissions

When considering modifications, it is essential to identify which transmission units are compatible with your vehicle’s existing setup. Factors such as bolt patterns, input shaft lengths, and electrical connections play a vital role in ensuring proper fitment. Consulting compatibility charts or expert sources can provide valuable insights into suitable transmission options.

Potential Upgrades for Enhanced Performance

Upgrading the transmission can significantly impact vehicle performance. Options such as high-performance torque converters, heavy-duty clutches, and advanced electronic controls can enhance power delivery and improve shift quality. Investing in these upgrades not only boosts acceleration but also contributes to overall vehicle reliability.

Recommended Fluids and Lubricants

Proper maintenance of your vehicle greatly depends on the quality and type of fluids and lubricants used. Selecting the right products ensures optimal performance, longevity, and efficiency of various systems within the engine. Here, we discuss essential fluids and lubricants that are crucial for maintaining your vehicle’s health.

Engine Oil: It is vital to choose a high-quality engine oil that meets the specifications required for your vehicle’s engine. Look for oils that offer excellent viscosity at various temperatures and provide adequate protection against wear and deposits.

Transmission Fluid: Using the correct transmission fluid is crucial for smooth shifting and overall performance. Always refer to the manufacturer’s recommendations to ensure compatibility with your transmission system.

Coolant: Maintaining an optimal operating temperature is essential for engine health. A suitable coolant will not only help regulate temperatures but also prevent corrosion and scale buildup in the cooling system.

Brake Fluid: Ensure that you utilize the appropriate brake fluid for your braking system. The right fluid will maintain brake performance and prevent moisture buildup, which can lead to brake failure.

Grease and Lubricants: Regular lubrication of moving parts is critical to prevent friction and wear. Select high-quality greases designed for automotive applications, ensuring they meet specific performance criteria.

In conclusion, using recommended fluids and lubricants is essential for enhancing the performance and durability of your vehicle. Always consult your owner’s guidelines for specific product recommendations and service intervals.