This section provides essential information for those seeking to understand the intricacies of maintaining heavy-duty vehicles. It encompasses various aspects that ensure optimal performance and longevity, offering guidance tailored to the specific needs of robust machinery.

With a focus on practical knowledge, this guide aids owners in navigating the complexities of their vehicles. Whether it’s routine checks or addressing more significant concerns, having a thorough understanding of operational requirements is crucial. By following the outlined procedures, users can effectively manage their equipment and minimize downtime.

In addition, the content emphasizes the importance of using appropriate tools and techniques, ensuring that each task is performed with precision. A well-maintained vehicle not only enhances reliability but also contributes to safety on the road. Adhering to these guidelines will empower users to take charge of their maintenance routine.

Overview of Heavy-Duty Truck Models

This section provides a comprehensive look at various heavy-duty truck models, focusing on their specifications, capabilities, and applications. Understanding these vehicles’ features can greatly aid in maintaining and optimizing their performance.

Heavy-duty trucks are designed for demanding tasks, making them essential in various industries. Here are some key aspects to consider:

- Engine Options: Different models offer a range of powerful engine configurations, catering to various towing and hauling needs.

- Payload Capacity: These vehicles are built to carry substantial loads, with specific models designed for particular weight limits.

- Performance Features: Many heavy-duty trucks come equipped with advanced technology to enhance handling, stability, and fuel efficiency.

- Interior Comfort: Modern designs focus on providing a comfortable driving experience, with ergonomic seating and advanced infotainment systems.

Each model serves unique purposes across industries such as construction, transportation, and agriculture. This diversity allows owners to choose vehicles that best meet their operational requirements.

Common Repair Issues in Super Duty

This section addresses frequent challenges encountered by owners of heavy-duty vehicles. Understanding these common concerns can help in timely maintenance and ensure optimal performance. Awareness of potential problems allows for better preparation and informed decisions regarding service needs.

Several issues may arise during the lifespan of these robust machines, often relating to specific components that are heavily utilized. Below is a table summarizing typical problems and their symptoms.

| Issue | Symptoms | Suggested Solutions |

|---|---|---|

| Transmission Slippage | Unresponsive acceleration, high RPMs without speed increase | Fluid check and replacement, possible transmission overhaul |

| Brake Wear | Squeaking noise, reduced stopping power | Inspection and replacement of brake pads and rotors |

| Electrical Problems | Dashboard warning lights, malfunctioning accessories | Battery testing, wiring inspection, or component replacement |

| Suspension Issues | Unusual noises, poor ride quality | Check and replace shocks or struts, alignment adjustment |

Being aware of these typical issues can assist owners in maintaining their vehicles effectively and extending their longevity. Regular inspections and timely interventions are key to ensuring smooth operation.

Tools Needed for Maintenance

Proper upkeep of heavy-duty vehicles requires a variety of specialized equipment to ensure functionality and longevity. Utilizing the right instruments can simplify tasks and enhance efficiency during routine service checks.

Wrenches and Sockets: A comprehensive set of wrenches, including both standard and metric sizes, is essential for loosening and tightening fasteners. Socket sets, particularly those with various drive sizes, provide versatility for different bolt types.

Torque Wrench: This tool is crucial for applying the correct amount of force to nuts and bolts, preventing damage caused by over-tightening.

Diagnostic Scanner: An advanced diagnostic tool is necessary for identifying issues within the vehicle’s electronic systems, allowing for timely troubleshooting and repairs.

Fluid Containers: Having designated containers for various fluids, such as oil, coolant, and transmission fluid, is important for efficient maintenance and reducing mess.

Safety Gear: Personal protective equipment, including gloves, goggles, and masks, is vital to ensure safety while performing maintenance tasks.

Step-by-Step Repair Procedures

This section outlines a systematic approach to performing maintenance and troubleshooting on heavy-duty vehicles. By following these detailed instructions, users can effectively diagnose issues and implement necessary fixes to ensure optimal performance.

Start by gathering all required tools and materials before beginning any procedure. Carefully assess the area that requires attention, and consult any relevant specifications to ensure compliance with safety standards.

Next, proceed with the disassembly of components as needed, keeping track of all parts and fasteners for reassembly. Take special care to document any observations during this phase, as they may assist in future diagnostics or repairs.

Once disassembly is complete, inspect each component for wear or damage. Replace any defective parts with high-quality alternatives to maintain the integrity of the system. Follow the reverse order of disassembly for reassembly, ensuring all connections are secure and correctly positioned.

Finally, conduct a thorough test of the vehicle’s systems to confirm that all repairs have been successfully completed and that functionality has been restored. Regularly revisiting these procedures can help maintain the vehicle’s reliability and extend its lifespan.

Understanding Engine Specifications

Grasping the intricacies of engine specifications is essential for optimizing vehicle performance and maintenance. This knowledge encompasses various parameters that dictate how an engine operates, including power output, torque, displacement, and fuel efficiency. By understanding these elements, one can make informed decisions regarding modifications, repairs, and overall vehicle care.

Key aspects to consider include the engine’s horsepower and torque ratings, which influence acceleration and towing capabilities. Displacement, measured in liters or cubic inches, refers to the total volume of all the cylinders combined and plays a crucial role in determining engine power. Fuel efficiency ratings provide insights into the vehicle’s economy, allowing for better budgeting and planning for fuel expenses.

Moreover, specifications related to engine type, such as V6 or V8 configurations, impact overall design and functionality. Understanding the interplay between these specifications enables vehicle owners to enhance performance and longevity, ensuring a smoother and more reliable driving experience.

Transmission Troubleshooting Techniques

This section provides essential methods for diagnosing issues related to the gearbox system. Proper identification of problems can significantly enhance the efficiency and longevity of the vehicle’s performance. Understanding common symptoms and applying systematic approaches are key to effective troubleshooting.

Common Symptoms of Transmission Issues

- Slipping gears

- Delayed or rough shifting

- Fluid leaks under the vehicle

- Unusual noises during operation

- Warning lights on the dashboard

Troubleshooting Steps

- Check fluid levels and quality; replace if contaminated.

- Inspect for leaks around seals and gaskets.

- Examine the transmission filter for blockages.

- Test the electrical connections and sensors for proper function.

- Utilize diagnostic tools to read error codes for additional insight.

Implementing these strategies will aid in accurately identifying and resolving transmission-related concerns, leading to a smoother driving experience.

Suspension and Steering Maintenance

Proper care of the suspension and steering systems is essential for ensuring vehicle stability and driver comfort. Regular inspections and maintenance help identify wear and tear, ultimately prolonging the lifespan of these critical components.

Routine checks should include examining shock absorbers, struts, and linkages for any signs of leakage or damage. It’s also important to ensure that all fasteners are secure and that rubber bushings are in good condition to prevent unnecessary noise and handling issues.

Furthermore, aligning the wheels periodically is vital to maintain optimal handling and tire longevity. This procedure not only enhances performance but also minimizes uneven tire wear, contributing to safer driving conditions.

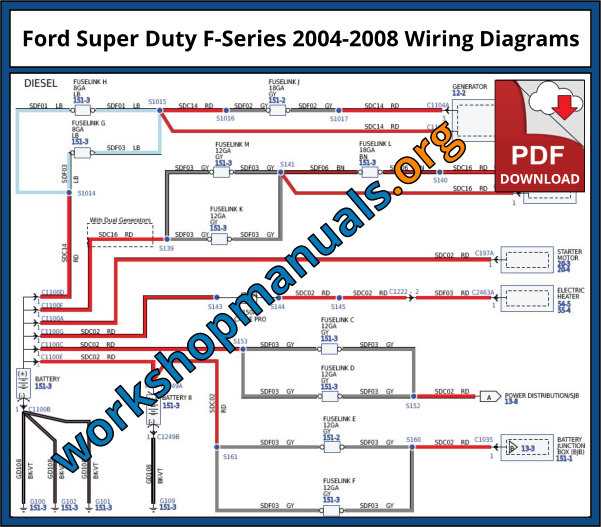

Electrical System Diagnostics Guide

This section aims to provide a comprehensive approach to diagnosing issues within the electrical framework of heavy vehicles. Understanding the fundamental components and their interactions is essential for efficient troubleshooting and maintenance.

The following steps outline a systematic method for identifying and resolving electrical malfunctions:

- Initial Assessment:

- Check for visible damage to wiring and connectors.

- Ensure that all fuses are intact and functioning.

- Power Supply Verification:

- Use a multimeter to check voltage levels at various points.

- Confirm the ground connections are secure and free from corrosion.

- Component Testing:

- Isolate and test individual components like switches, sensors, and relays.

- Refer to specifications for expected performance criteria.

- Systematic Troubleshooting:

- Utilize wiring diagrams to trace circuits and identify potential faults.

- Employ diagnostic tools to read error codes, if applicable.

- Final Verification:

- After repairs, recheck all connections and components.

- Conduct a test run to ensure the system operates as intended.

By following these guidelines, technicians can effectively diagnose and resolve electrical issues, ensuring reliable performance of heavy-duty vehicles.

Safety Considerations During Repairs

Ensuring safety during maintenance tasks is paramount for both the technician and the equipment. Proper precautions must be taken to mitigate risks associated with working on heavy machinery. A thorough understanding of safety protocols can prevent accidents and injuries.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes items such as gloves, goggles, and protective footwear. Wearing these items not only safeguards against physical injuries but also minimizes exposure to harmful substances.

Work Environment Safety

Maintaining a clean and organized workspace is crucial. Ensure that tools are easily accessible and that the area is free from clutter. Proper lighting and ventilation also contribute to a safer environment, reducing the risk of accidents while facilitating a more efficient workflow.

Resources for Parts and Accessories

When maintaining and upgrading your vehicle, having access to quality components and enhancements is essential. Various sources offer a wide range of products that cater to different needs, ensuring that you can find exactly what you’re looking for to keep your vehicle in top condition.

Online Retailers

Numerous online platforms provide a vast selection of parts and accessories. These retailers often feature user reviews, detailed product descriptions, and competitive pricing, making it easier for you to compare options. Utilizing filters to narrow down your search can help you quickly locate the necessary items for your specific requirements.

Local Auto Parts Stores

Visiting local automotive stores can be advantageous for immediate needs. These shops usually have knowledgeable staff who can offer advice on suitable components and accessories. Additionally, buying locally allows you to inspect items before purchase, ensuring compatibility with your vehicle.

Online forums and communities can also serve as valuable resources. Engaging with fellow enthusiasts can lead to recommendations for trustworthy suppliers and insights into product performance.