Maintaining marine engines is crucial for ensuring optimal performance and longevity. This section provides comprehensive insights into the various aspects of engine upkeep, focusing on troubleshooting common issues and implementing effective solutions. Understanding the mechanics involved can significantly enhance the efficiency of your vessel.

Whether you’re dealing with minor adjustments or more intricate repairs, having a solid foundation in engine maintenance practices is invaluable. Familiarity with the components and their functions will empower you to address potential problems before they escalate. This guide emphasizes practical steps and essential tips to keep your engine running smoothly.

By following the advice outlined here, you’ll be better equipped to handle maintenance tasks with confidence. With the right knowledge and resources, you can ensure your engine operates reliably, providing you with many enjoyable experiences on the water.

This section provides an insight into a specific model of marine propulsion equipment known for its reliability and efficiency. Understanding the fundamental aspects of this engine type is essential for effective maintenance and operation.

Key Features

- Powerful performance suitable for various watercraft.

- Compact design allowing for easy installation and removal.

- Fuel efficiency that contributes to reduced operational costs.

Common Applications

- Ideal for small fishing boats.

- Frequently used in recreational crafts.

- Popular choice for tenders and auxiliary boats.

Common Issues with Outboard Motors

Marine engines are vital for ensuring smooth operation during aquatic activities. However, these engines can encounter several challenges that may hinder performance and reliability. Understanding the typical problems can help users identify and address issues promptly, ensuring optimal functioning.

One frequent concern is fuel-related complications. Contaminated or stale fuel can lead to poor ignition and engine stalling. Additionally, issues with the fuel lines, such as leaks or clogs, can prevent the engine from receiving adequate fuel, causing performance degradation.

Another common issue involves electrical system failures. Corroded connections, worn-out components, or faulty batteries can result in starting difficulties or intermittent power loss. Regular inspection and maintenance of the electrical system are essential to prevent these disruptions.

Cooling system problems are also prevalent. Blocked cooling passages or malfunctioning water pumps can lead to overheating, which may cause severe damage to the engine. Keeping the cooling system clean and ensuring proper water intake are critical steps to maintain engine health.

Lastly, mechanical wear and tear can impact overall performance. Regular checks on the propeller, bearings, and seals are necessary to identify signs of wear. Addressing these issues early can help prolong the lifespan of the engine and improve operational efficiency.

Essential Tools for Repair

When it comes to maintaining marine engines, having the right instruments is crucial for effective service. The appropriate tools not only streamline the process but also enhance the quality of work. Here is a list of indispensable items that every technician should consider for optimal performance.

- Wrenches: Various sizes are essential for loosening and tightening bolts.

- Screwdrivers: A set with different types and sizes to handle screws efficiently.

- Pliers: Useful for gripping and manipulating components during maintenance.

- Socket Set: Ideal for reaching fasteners in tight spaces, providing versatility.

- Multimeter: Critical for checking electrical systems and diagnosing issues.

- Fuel Line Clamp: Prevents spills while working on fuel systems.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

Investing in high-quality tools can significantly improve the efficiency and effectiveness of service tasks. Ensuring you have a comprehensive toolkit will facilitate smoother operations and contribute to the longevity of the engine.

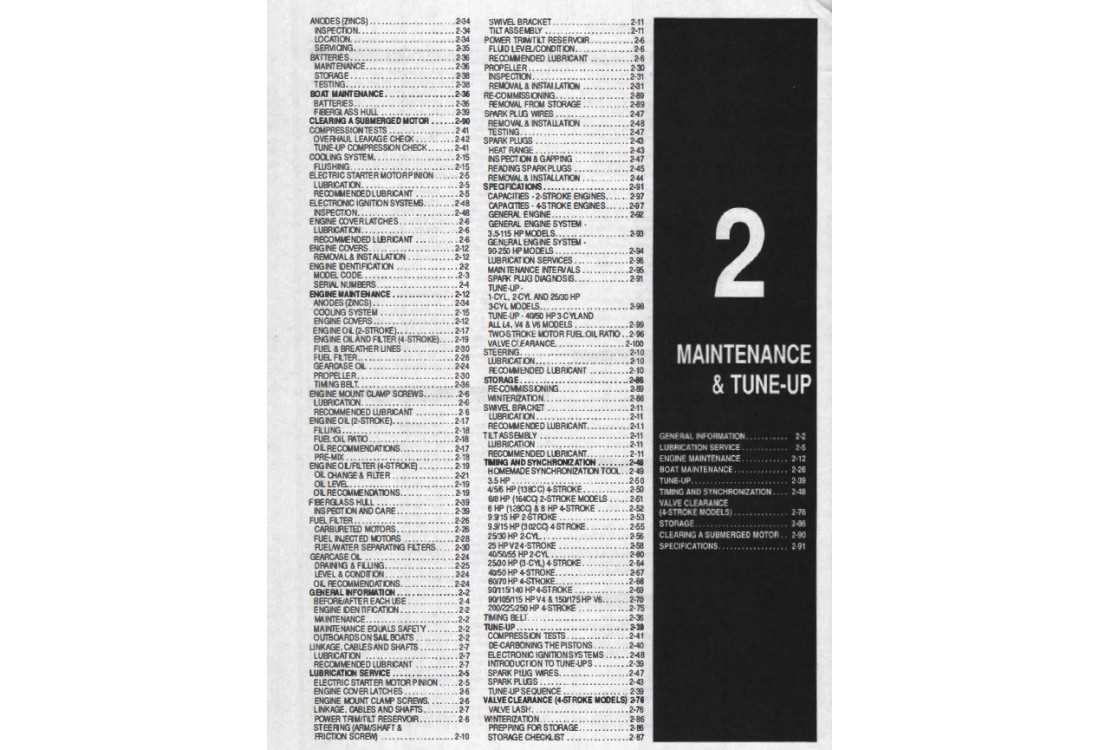

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your marine engine operates smoothly and efficiently. Regular upkeep is essential for longevity and optimal performance. Follow these steps to maintain your equipment effectively.

Essential Tools and Supplies

- Wrench set

- Screwdrivers

- Cleaning supplies

- Lubricants

- Replacement parts

Maintenance Steps

- Start by inspecting the exterior for any visible damage or wear.

- Check fluid levels, including fuel and oil, and top them up as necessary.

- Clean the air filter to ensure optimal airflow.

- Inspect and replace spark plugs if needed.

- Examine the propeller for any signs of damage and clean it thoroughly.

- Run the engine for a short period to check for any unusual sounds.

Engine Troubleshooting Techniques

Troubleshooting an engine can be a complex process that requires careful analysis and methodical approaches. By systematically identifying symptoms and applying logical reasoning, users can diagnose issues effectively and implement appropriate solutions. Understanding common problems and their potential causes is essential for maintaining optimal performance.

Common Symptoms and Their Causes

When faced with engine difficulties, recognizing the signs can significantly aid in pinpointing the underlying issues. Below is a table outlining frequent symptoms along with possible explanations:

| Symptom | Possible Causes |

|---|---|

| Difficulty Starting | Dead battery, faulty starter, or fuel supply issues |

| Overheating | Insufficient coolant, blocked cooling passages, or failing thermostat |

| Loss of Power | Clogged fuel filter, damaged spark plugs, or exhaust restrictions |

Step-by-Step Diagnostic Approach

To effectively diagnose engine issues, follow a structured method. Start by gathering information about the symptoms, then inspect components systematically. Always refer to manufacturer specifications and guidelines to ensure accurate assessments. This approach not only saves time but also enhances the reliability of the findings.

Fuel System Inspection Procedures

Ensuring optimal performance of the fuel delivery components is essential for the effective operation of any marine engine. Regular examination of these elements can help identify potential issues before they escalate into significant problems, thereby prolonging the lifespan of the machinery.

Visual Inspection

Begin by conducting a thorough visual assessment of the entire fuel system. Look for signs of wear, leaks, or corrosion that may affect performance. Pay close attention to the fuel lines, connections, and filter, as these are critical areas prone to damage.

Functional Testing

After the visual check, perform functional tests to ensure all components operate correctly. This includes verifying fuel flow, pressure, and the efficiency of the pump. Use the following table as a guide for troubleshooting any irregularities:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| No fuel flow | Blocked filter or line | Clean or replace the filter and check for obstructions |

| Inconsistent pressure | Faulty pump | Inspect the pump for damage and replace if necessary |

| Fuel leaks | Worn connections | Replace gaskets or tighten connections |

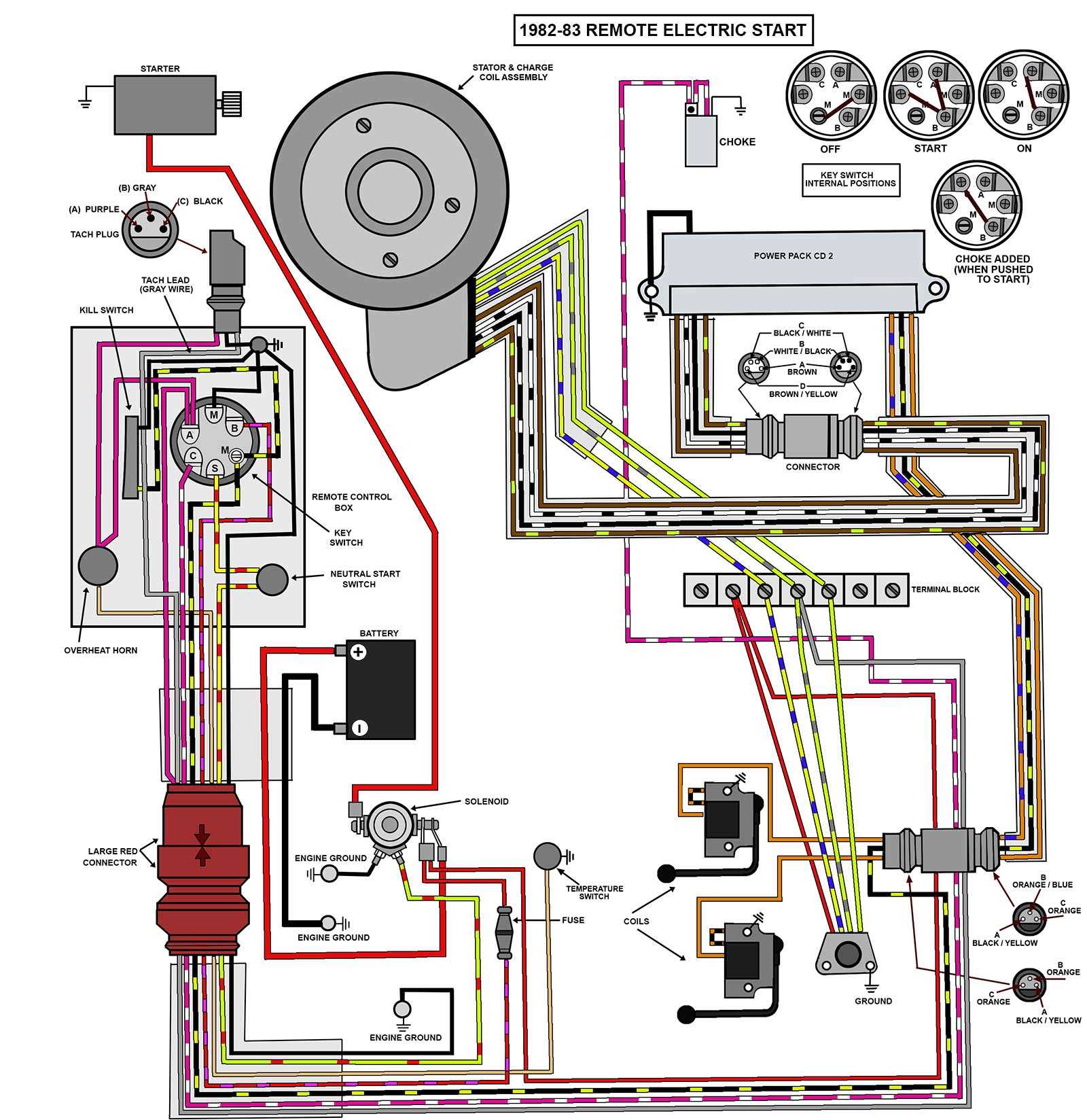

Electrical System Diagnostics

Effective troubleshooting of the electrical system is essential for ensuring optimal performance and reliability. A comprehensive understanding of the components involved and the common issues they face allows for timely identification and resolution of problems.

Power Supply Inspection: Begin by examining the power source, ensuring that connections are secure and corrosion-free. A multimeter can be used to check voltage levels, confirming that the system receives adequate power.

Circuit Continuity Testing: Utilize a continuity tester to verify that electrical circuits are intact. This step is crucial for identifying any breaks or faults in wiring that may hinder functionality.

Component Functionality Assessment: Evaluate individual components such as switches, relays, and fuses. Each part should be tested to ensure it operates correctly, as failures in any single component can affect the entire system.

Grounding Checks: Proper grounding is vital for electrical safety and performance. Ensure that all ground connections are secure and free from oxidation, as poor grounding can lead to erratic behavior and component failures.

By following these diagnostic steps, you can systematically address electrical issues, leading to improved performance and longevity of the unit.

Replacing Spark Plugs Effectively

Ensuring optimal performance of your engine involves regular maintenance, and one of the key aspects is the replacement of ignition components. This process not only enhances efficiency but also prolongs the lifespan of the machine.

Preparation for Replacement

Before starting, gather all necessary tools such as a socket wrench, gap gauge, and the appropriate replacement parts. Make sure to consult specifications for the correct type of plugs, as compatibility is crucial for performance. Disconnect the power source to avoid any accidental starts while working.

Step-by-Step Process

Begin by removing the old plugs carefully to prevent damage to the threads. Inspect the condition of the old components to identify any underlying issues that may need attention. Once removed, check the gap on the new plugs using the gap gauge and adjust as needed. Install the new plugs by hand first to ensure they are threaded correctly, then tighten them gently with the socket wrench. Over-tightening can lead to damage, so a snug fit is ideal.

Finally, reconnect the power source and start the engine to ensure everything is functioning properly. Regularly checking and replacing ignition components will lead to smoother operation and better fuel efficiency.

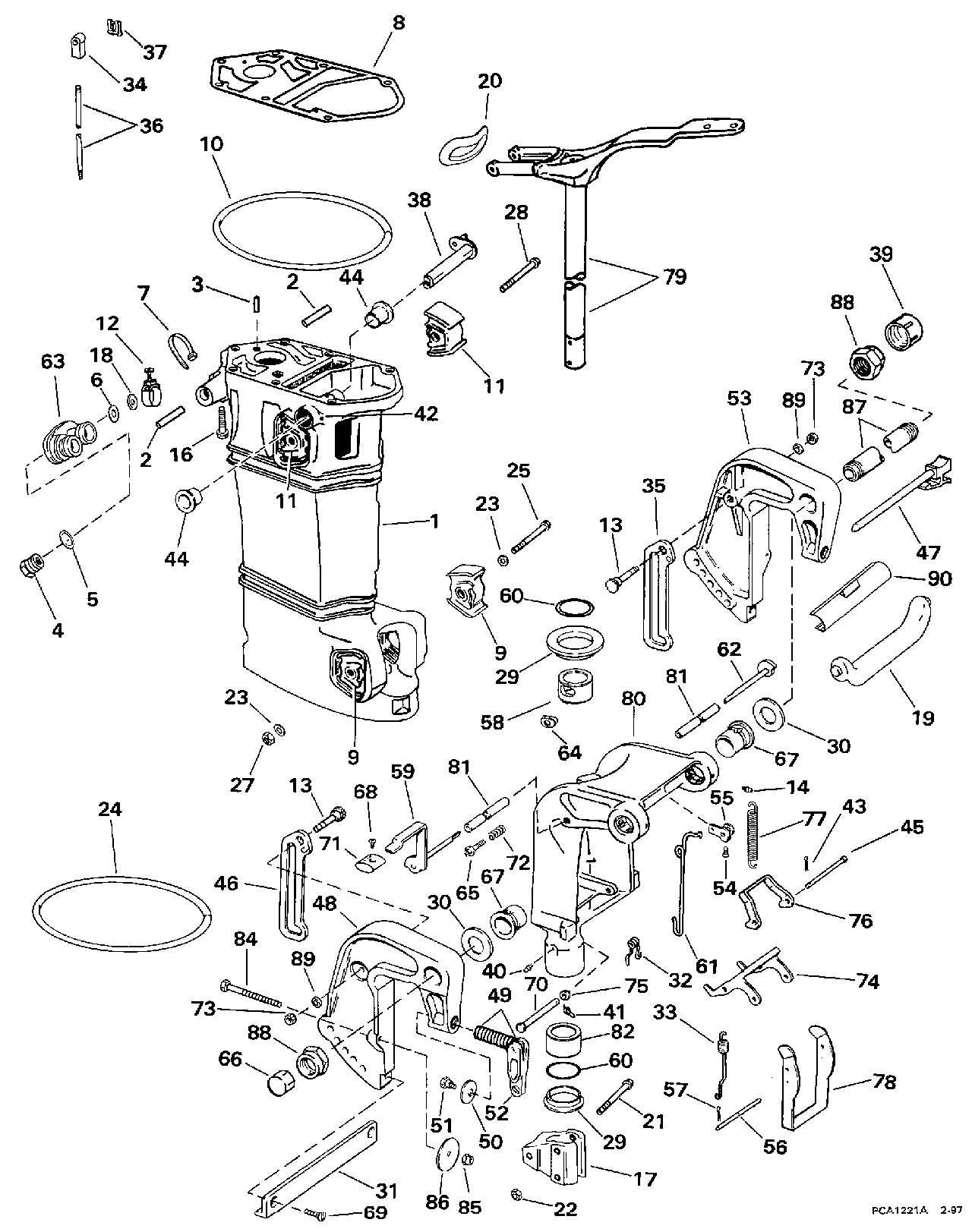

Lower Unit Maintenance Tips

Proper upkeep of the lower unit is essential for ensuring optimal performance and longevity of your watercraft. Regular maintenance helps prevent potential issues and enhances the efficiency of the propulsion system.

Regular Inspections: Conduct routine examinations of the lower unit for signs of wear, corrosion, or damage. Look for any leaks or unusual noises that may indicate underlying problems.

Fluid Changes: Replace the lubricant periodically to keep the gears and components well-lubricated. Ensure to use the recommended type of fluid, as it plays a crucial role in preventing wear and overheating.

Seals and Gaskets: Check seals and gaskets for signs of degradation. Replacing worn seals promptly can help avoid leaks and maintain pressure within the unit.

Cleaning: Keep the lower unit clean by removing debris and marine growth. A clean surface can help in identifying any potential issues more easily.

Professional Servicing: If you encounter significant problems or if you are unsure about any aspect of maintenance, consult a qualified technician for assistance. Professional care can ensure that any repairs or adjustments are done correctly.

Cooling System Checks and Repairs

Ensuring the efficiency of the cooling mechanism is crucial for the longevity and performance of your engine. Regular assessments can help identify potential issues before they escalate, ultimately safeguarding the power unit from overheating and damage.

Start by examining the cooling passages for any blockages or debris that could hinder proper flow. Cleaning these pathways can significantly enhance cooling performance. Additionally, check the water pump for signs of wear or malfunction, as this component plays a vital role in circulating coolant throughout the system.

Inspect the hoses for cracks or leaks, which can lead to coolant loss and overheating. Replacing any damaged hoses promptly will ensure optimal function. Furthermore, consider testing the thermostat to confirm it opens and closes correctly, as a malfunctioning thermostat can disrupt the cooling process.

Lastly, always keep an eye on coolant levels. Regularly topping up and using the appropriate type of coolant will help maintain an efficient cooling system, promoting the overall health of your engine.

Propeller Maintenance and Adjustment

Ensuring the optimal performance of your vessel requires attention to the propeller, a crucial component for efficient navigation. Regular upkeep and precise adjustments can significantly enhance fuel efficiency and overall handling.

Routine Inspection

Begin by examining the propeller for any signs of damage, such as dents, cracks, or corrosion. Regular checks help identify issues early, preventing more extensive repairs down the line. Pay attention to the condition of the blades and the hub, as any irregularities can affect performance.

Adjustment Techniques

When necessary, adjustments should be made to align the propeller with the engine’s output. This can involve trimming the blades or altering the pitch to optimize thrust. Consulting with a professional can provide insights into the ideal settings for your specific vessel type.

Seasonal Storage Recommendations

Proper storage during off-seasons is essential for maintaining the longevity and performance of your aquatic engine. Ensuring that your equipment is prepared for storage helps prevent potential issues when it’s time to resume use. This section outlines key practices for effective seasonal storage, allowing for a smooth transition between active periods.

Preparation Steps

Before placing your engine in storage, it’s crucial to perform thorough maintenance. Start by cleaning the exterior and removing any debris. Check and change the fluids as necessary, including fuel and oil, to avoid contamination. Utilizing a fuel stabilizer can help keep your fuel fresh over time. Additionally, inspect all components for wear and address any minor repairs to prevent further complications later on.

Ideal Storage Conditions

Choose a dry and well-ventilated space for storage, ideally at a consistent temperature. Avoid areas prone to humidity, as moisture can lead to rust and corrosion. If possible, cover your engine with a breathable tarp to protect it from dust and dirt while allowing for ventilation. Regularly checking on the equipment during the storage period can help catch any potential issues before they escalate.

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance on any watercraft engine. Adhering to specific guidelines not only protects the individual performing the task but also enhances the longevity of the equipment. By following appropriate measures, one can prevent accidents and ensure a smooth process.

Essential Safety Guidelines

- Always wear protective gear, including gloves, goggles, and closed-toe shoes.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the power source before starting any work to prevent accidental activation.

- Keep a fire extinguisher nearby in case of emergencies.

Work Environment Considerations

- Maintain a clean and organized workspace to reduce the risk of accidents.

- Avoid working in wet or slippery conditions to prevent falls.

- Be aware of sharp tools and parts; handle them with care.

- Follow all manufacturer recommendations for tools and equipment usage.