The proper functioning of any machinery heavily relies on the intricacies of its internal components. Understanding these mechanisms is essential for anyone looking to maintain or restore performance in outdoor power equipment. This section aims to provide valuable insights into the intricacies of maintenance and troubleshooting, ensuring that users can keep their machines in optimal condition.

With the right knowledge and resources, even complex issues can be addressed effectively. This guide will navigate through the various elements involved in maintenance, offering practical solutions and detailed instructions. Whether you are a seasoned technician or a novice, having a solid grasp of the core principles will empower you to tackle challenges confidently.

In this exploration, we will delve into common pitfalls, necessary tools, and techniques that can significantly enhance the longevity and efficiency of your machinery. By following the outlined steps and understanding the underlying concepts, you will be well-equipped to manage repairs and perform essential upkeep with ease.

Understanding the MTD Engine Basics

Familiarity with the core components of small machinery is essential for effective maintenance and troubleshooting. This section delves into the fundamental aspects that underpin the functionality of these mechanical units, focusing on their operation and design principles.

Key Components and Their Functions

Each unit comprises several integral parts that work together seamlessly. The primary elements include the combustion chamber, fuel delivery system, and ignition mechanism. Understanding how these components interact helps in diagnosing issues and ensuring optimal performance. For instance, the combustion chamber plays a vital role in energy conversion, while the fuel system ensures that the right mixture reaches it.

Maintenance Essentials

Regular upkeep is crucial for longevity. Simple tasks such as cleaning filters, checking spark plugs, and ensuring proper lubrication can significantly enhance performance. Neglecting these aspects can lead to decreased efficiency and more complex problems over time. A proactive approach is always beneficial, as it not only prolongs the lifespan but also ensures reliable operation during use.

Common MTD Engine Issues

When dealing with outdoor machinery, certain challenges frequently arise that can hinder performance. Understanding these common problems is essential for ensuring optimal operation and longevity of the equipment. This section highlights prevalent concerns users may encounter and provides insights into potential causes and solutions.

Starting Difficulties: One of the most frustrating issues is the inability to initiate the machinery. This can stem from a variety of factors, including a depleted power source, faulty ignition components, or fuel delivery problems. Ensuring all connections are secure and that fuel is fresh can often resolve these issues.

Overheating: Excessive heat can lead to severe damage if not addressed promptly. This condition may arise from inadequate lubrication, a clogged cooling system, or prolonged usage without breaks. Regular maintenance, such as checking oil levels and cleaning cooling fins, is crucial to prevent overheating.

Unusual Noises: Strange sounds during operation can signal underlying issues that require attention. Rattling, knocking, or grinding noises might indicate loose parts or internal damage. It’s important to investigate these sounds quickly to avoid further complications.

Vibrations: Excessive shaking can affect performance and operator comfort. This may result from imbalanced components, worn-out mounts, or debris accumulation. Inspecting and cleaning the unit can often mitigate these vibrations.

Fuel Leaks: Any signs of leakage can pose safety hazards and efficiency problems. Such leaks are often caused by damaged hoses, connections, or seals. Regular inspections can help detect and address these issues before they escalate.

By familiarizing oneself with these typical challenges, users can take proactive steps to maintain their equipment effectively. Early detection and intervention are key to ensuring smooth operation and minimizing downtime.

Essential Tools for Engine Repair

When tackling mechanical challenges, having the right instruments is crucial for achieving success and efficiency. These essential items not only enhance the quality of work but also ensure safety and precision in every task. Understanding what tools are necessary can significantly improve the process and outcomes.

Basic Toolkit Components

- Wrenches: A variety of sizes, including adjustable and socket types, are vital for loosening and tightening components.

- Screwdrivers: Flathead and Phillips screwdrivers come in handy for accessing different types of fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Ratchet and Socket Set: Essential for quick and efficient fastener removal in tight spaces.

Specialized Instruments

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Compression Tester: Measures cylinder pressure to diagnose issues with performance.

- Multimeter: A critical device for checking electrical systems and diagnosing electrical faults.

- Oil Filter Wrench: Facilitates the removal and installation of oil filters, essential for maintenance tasks.

Having a well-equipped workspace with these tools not only streamlines processes but also enhances the overall quality of work, leading to longer-lasting results. Investing in high-quality instruments pays off in both performance and durability.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to troubleshooting and fixing common issues encountered with small machinery. Following a systematic approach ensures that you address problems efficiently while minimizing the risk of further complications.

Begin by gathering all necessary tools and materials, ensuring that you have everything within reach. Safety equipment, such as gloves and goggles, should be worn throughout the process to protect against any hazards.

Next, identify the specific issue at hand. Conduct a visual inspection to detect any obvious signs of wear or damage. Take note of any unusual sounds or performance irregularities, as these can provide clues to the underlying problems.

Once the issue is identified, refer to the appropriate troubleshooting steps. This often involves disassembling certain components to access the areas requiring attention. Use caution when handling delicate parts to prevent additional damage.

After making the necessary adjustments or replacements, reassemble the unit carefully. Ensure that all screws and bolts are tightened to the manufacturer’s specifications to guarantee optimal performance.

Finally, conduct a thorough test of the machinery to confirm that the issue has been resolved. Monitor the operation closely for any signs of recurring problems, and perform regular maintenance to extend the lifespan of the equipment.

Diagnosing Engine Performance Problems

Identifying issues related to the functioning of mechanical systems is essential for maintaining optimal operation. A range of symptoms can signal underlying problems, and understanding these signs allows for timely interventions. This section explores common indicators and systematic approaches to effectively pinpoint performance-related challenges.

Common Symptoms to Observe

Several telltale signs may indicate that something is amiss. Pay attention to unusual noises, fluctuations in speed, or changes in fuel consumption. Unresponsive behavior during operation, such as stalling or hesitation, often warrants further investigation. Additionally, be alert for any warning lights on the dashboard, as they can provide crucial insights into potential malfunctions.

Systematic Troubleshooting Approach

To diagnose issues accurately, employ a structured method. Begin with a visual inspection, checking for loose connections, leaks, or worn components. Next, use diagnostic tools to gather data, allowing for a thorough analysis of performance metrics. Consulting technical specifications can aid in comparing current performance against expected standards, facilitating effective problem resolution.

Replacing Engine Components Effectively

Ensuring the longevity and performance of machinery often requires replacing various parts. This process, while essential, can be daunting without the right approach. Understanding how to efficiently swap out components not only saves time but also enhances the overall functionality of the equipment.

When undertaking this task, it is crucial to follow a systematic approach. Start by gathering the necessary tools and replacement parts. Proper organization and preparation can prevent unnecessary delays and complications during the process.

| Step | Action | Tips |

|---|---|---|

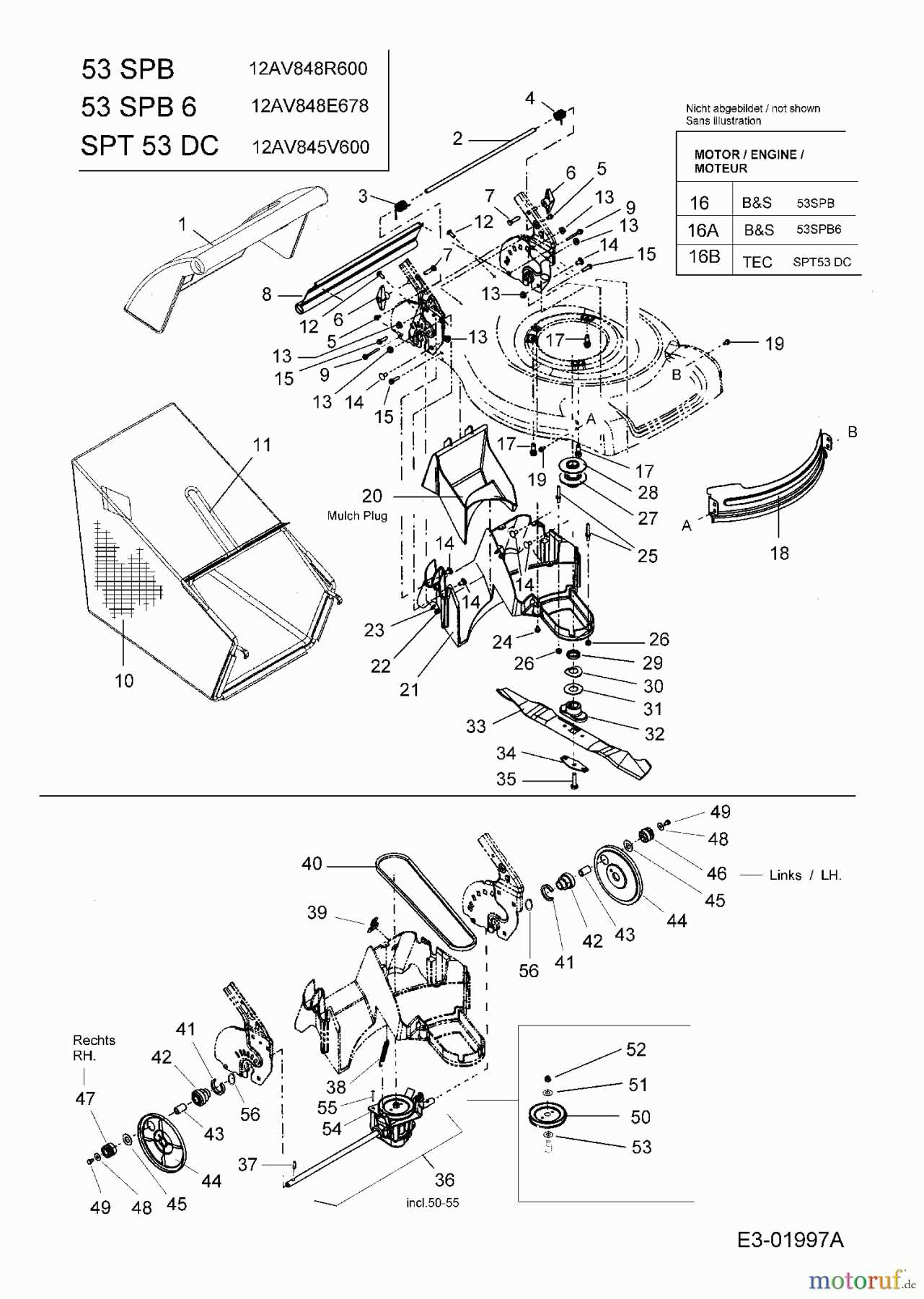

| 1 | Identify the part to be replaced | Refer to diagrams for accuracy |

| 2 | Gather required tools | Keep tools organized for efficiency |

| 3 | Disconnect necessary connections | Label wires and hoses for easier reassembly |

| 4 | Remove the old component | Use appropriate techniques to avoid damage |

| 5 | Install the new part | Follow manufacturer specifications closely |

| 6 | Reconnect all connections | Double-check labels to ensure accuracy |

| 7 | Test functionality | Monitor performance to confirm success |

By following these steps, the process of replacing parts can be streamlined, reducing the risk of errors and enhancing the overall effectiveness of the machinery. Prioritizing attention to detail and methodical execution will lead to better outcomes and increased reliability.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires consistent attention and care. Implementing a routine of simple yet effective practices can greatly enhance performance and reduce the likelihood of issues arising over time.

Regular Cleaning

Cleanliness is vital for optimal functionality. Remove debris and dirt regularly to prevent buildup that can hinder performance. A simple wipe down after each use can make a significant difference.

Check Fluid Levels

Monitoring and maintaining appropriate fluid levels is essential. Regularly inspect and top up lubricants and other fluids to ensure smooth operation and prevent wear and tear.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when undertaking maintenance tasks. Adhering to specific guidelines can help prevent accidents and injuries. It is important to remain vigilant and prioritize safety to protect both yourself and the equipment.

Essential Safety Guidelines

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate footwear to shield against potential hazards. |

| Work in a Well-Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes and reduce the risk of fire. |

| Disconnect Power Sources | Before starting any task, unplug or disconnect batteries to prevent accidental starts. |

| Keep Workspace Organized | A tidy area minimizes the risk of slips, trips, and falls. |

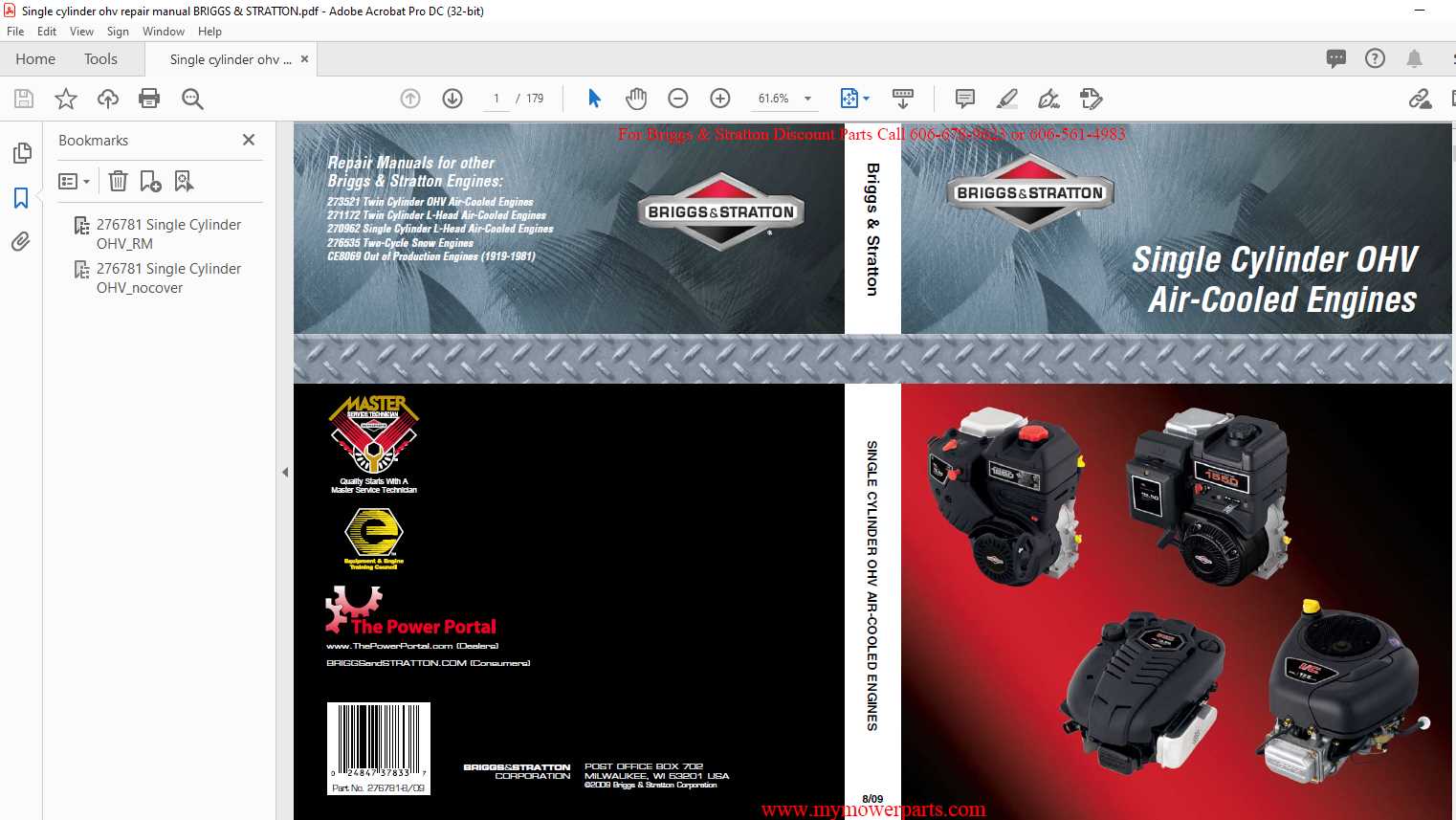

| Follow Manufacturer Instructions | Always refer to official guidance to avoid misuse and ensure proper procedures are followed. |

Emergency Preparedness

Being ready for unexpected situations is vital. Keep a first aid kit accessible, and familiarize yourself with emergency exits and procedures. Regularly review safety protocols to enhance preparedness and response capabilities.

Finding Genuine Replacement Parts

Ensuring optimal performance of your machinery requires the use of authentic components. Genuine parts guarantee compatibility and longevity, which are essential for maintaining functionality. This section will guide you through the process of locating these high-quality substitutes effectively.

Why Choose Authentic Components?

Using original parts offers several advantages, including:

| Benefit | Description |

|---|---|

| Compatibility | Designed specifically for your model, ensuring a perfect fit. |

| Durability | Manufactured to high standards, reducing the risk of premature failure. |

| Warranty | Often accompanied by a manufacturer’s guarantee for peace of mind. |

Where to Find Authentic Parts

Several reliable sources can provide genuine components:

- Official dealerships and authorized retailers

- Manufacturer’s website or customer service

- Reputable online marketplaces that specialize in quality products

By focusing on these avenues, you can ensure that you are acquiring the right parts to keep your equipment running smoothly.

Upgrading Your MTD Engine

Enhancing the performance of your machinery can significantly improve its efficiency and longevity. This section will explore various strategies and modifications that can elevate the capabilities of your equipment, providing you with insights into making thoughtful upgrades that suit your needs.

Performance Enhancements

One effective way to boost performance is by investing in high-quality components. Upgrading elements such as the air intake system can improve airflow, leading to better combustion. Additionally, using a premium fuel can enhance the overall functioning, providing more power and efficiency.

Regular Maintenance and Tuning

Maintaining optimal performance is crucial for longevity. Regularly checking and adjusting the settings can prevent wear and tear, ensuring that all parts operate smoothly. Emphasizing routine tasks, such as changing filters and inspecting spark plugs, can lead to noticeable improvements in functionality. Consider developing a maintenance schedule to keep everything in top shape.