Understanding the intricacies of automotive systems is essential for enthusiasts and professionals alike. This section offers a comprehensive overview of how to maintain and enhance the performance of luxury automobiles, ensuring longevity and efficiency. Each vehicle is a marvel of engineering, requiring specialized knowledge to navigate its complexities.

Through detailed explanations and step-by-step instructions, users will gain insights into troubleshooting common issues, performing routine checks, and implementing upgrades. This guide is designed to empower owners with the skills necessary to care for their vehicles effectively.

Whether you are looking to improve functionality or address specific challenges, this resource serves as a valuable companion. With a focus on practical solutions, it caters to both novices and seasoned mechanics, promoting a deeper appreciation for the art of automotive care.

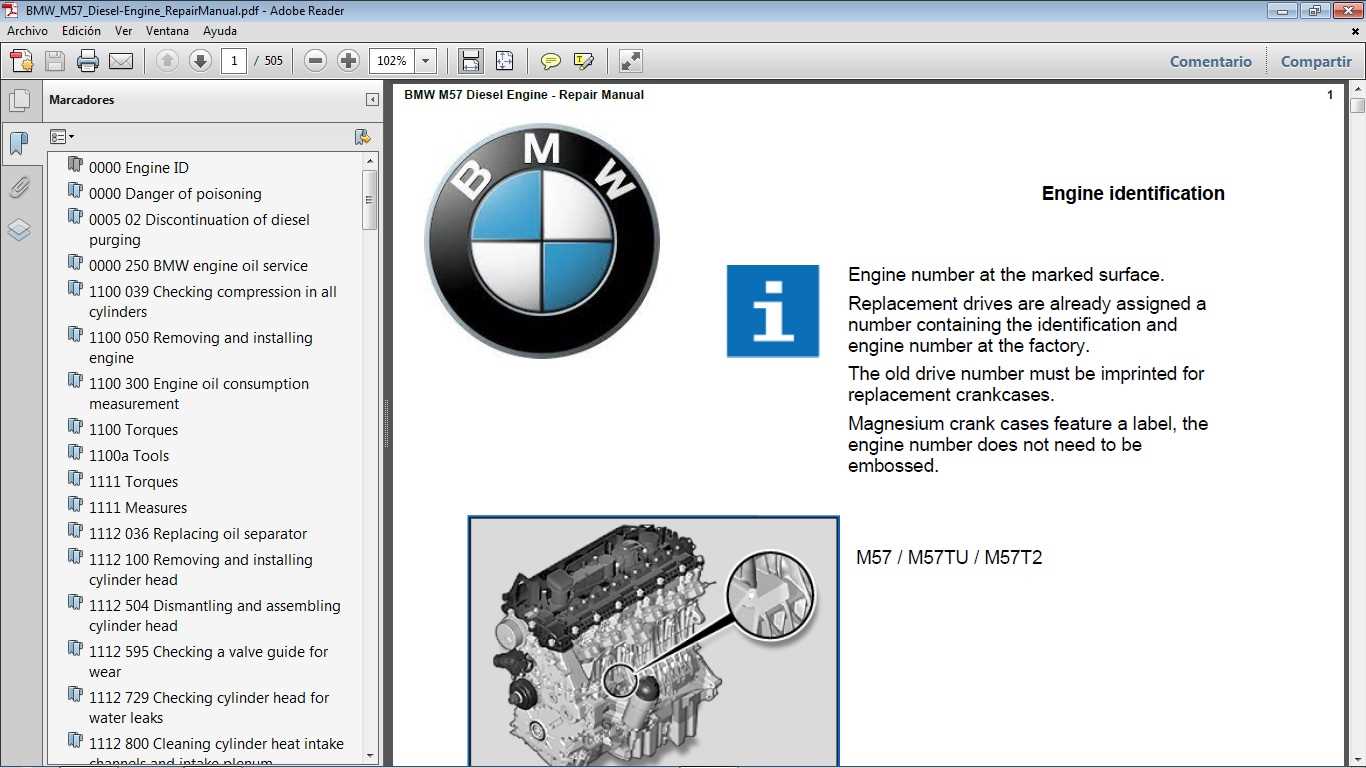

This section aims to provide a comprehensive overview of the essential elements that contribute to the performance and functionality of automotive power units. Understanding these components is crucial for effective maintenance and troubleshooting.

- Overview of Power Unit Structure

- Key Parts and Their Functions

- Fuel Delivery Systems Explained

- Ignition Mechanisms: An In-Depth Look

- Cooling Systems: Importance and Maintenance

- Lubrication and Its Role in Performance

- Exhaust Systems: Components and Their Functions

- Understanding Electrical Systems

- Sensor Technology and Its Impact

- Common Issues and Their Solutions

- Upgrades and Modifications

- Best Practices for Long-Term Care

Common Engine Issues in BMWs

Many automobile enthusiasts encounter various mechanical challenges that can affect performance and reliability. Understanding these prevalent concerns is essential for any vehicle owner aiming to maintain their automobile in optimal condition.

Frequent Mechanical Failures

One of the primary issues reported is related to components that wear out over time. This can manifest as decreased power output or unusual noises during operation. Regular inspections can help identify these signs early, potentially saving owners from more significant expenses in the future.

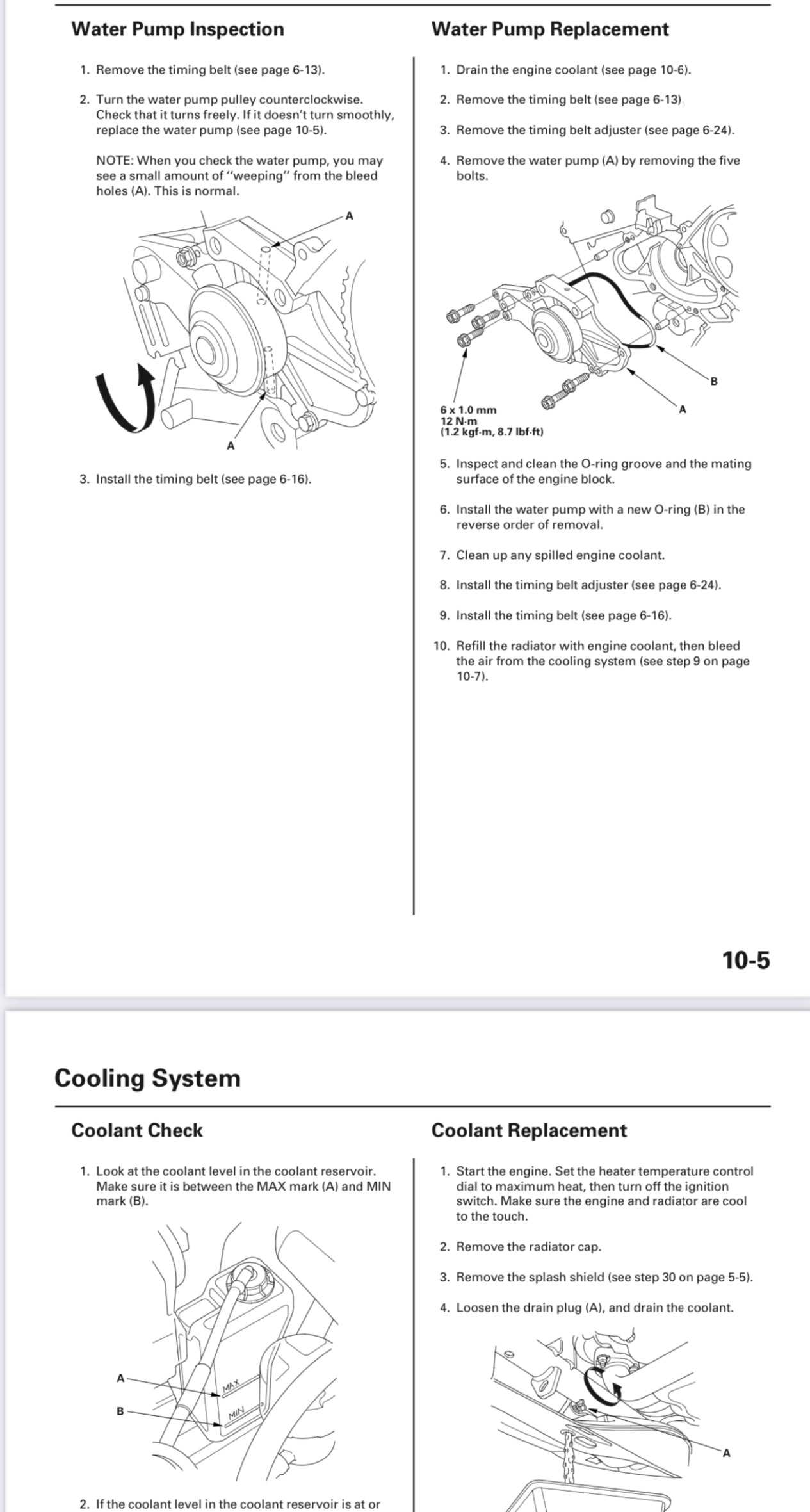

Cooling System Problems

The cooling system is crucial for maintaining appropriate operating temperatures. Issues such as coolant leaks or thermostat failures can lead to overheating, which may cause further complications. It is advisable to monitor coolant levels and check for any visible leaks periodically.

Essential Tools for Engine Repair

When tackling complex mechanical tasks, having the right instruments is crucial for achieving success. Quality tools not only facilitate the work but also ensure safety and precision during the process. Understanding the essentials can streamline efforts and enhance the overall experience.

Basic Hand Tools

Every enthusiast should possess a set of fundamental hand instruments. Items such as wrenches, sockets, and screwdrivers are indispensable for various tasks. These tools allow for easy manipulation of components and contribute to effective disassembly and assembly of parts.

Diagnostic Equipment

In addition to hand tools, diagnostic gear plays a vital role in identifying issues. Devices such as multimeters and scan tools provide valuable insights into system performance. Utilizing these instruments can help pinpoint malfunctions, ensuring a more targeted approach to troubleshooting.

Step-by-Step Engine Disassembly Process

This section provides a comprehensive guide on the systematic approach to taking apart a power unit. Understanding the correct sequence of actions is crucial for ensuring that each component is handled properly and can be reassembled without issues.

Preparation and Tools

Before beginning the disassembly, gather all necessary tools and ensure a clean workspace. Proper preparation minimizes the risk of damage and facilitates a smooth workflow.

- Wrenches and sockets

- Screwdrivers (flathead and Phillips)

- Pliers and cutters

- Magnetic trays for small parts

- Work gloves and safety glasses

Disassembly Steps

- Disconnect the battery to ensure safety.

- Remove external accessories such as the alternator and starter motor.

- Take off the intake and exhaust manifolds.

- Detach the valve covers and remove the timing components.

- Carefully lift out the cylinder head and place it on a clean surface.

- Remove the crankcase, taking care to note the placement of all bolts.

- Inspect each component for wear or damage as they are disassembled.

Following these steps methodically will help maintain organization and ensure that the disassembly process is efficient.

Diagnosing Engine Problems Effectively

Identifying issues within a vehicle’s power unit requires a systematic approach that combines observation and analytical skills. By focusing on symptoms and applying logical reasoning, one can pinpoint underlying complications and determine the most appropriate solutions.

Common Symptoms to Observe

Pay close attention to unusual noises, vibrations, or changes in performance. These indicators often provide vital clues regarding potential faults. For example, a knocking sound may suggest internal wear, while a drop in power could indicate a fuel delivery issue.

Utilizing Diagnostic Tools

Implementing specialized diagnostic equipment can greatly enhance the accuracy of assessments. Tools such as code readers and pressure gauges allow for precise measurements, facilitating a more thorough investigation. Regularly updating these tools ensures compatibility with the latest vehicle technologies.

Rebuilding Techniques for BMW Engines

This section focuses on various methods employed to restore performance and longevity in high-performance automotive power units. Effective strategies are crucial for ensuring optimal functionality and efficiency during the reconstruction process.

When considering the overhaul of such complex systems, it is essential to follow systematic procedures that enhance both reliability and performance. Below are some key techniques utilized in the restoration process:

| Technique | Description |

|---|---|

| Disassembly | Carefully taking apart components to assess wear and damage. |

| Inspection | Thorough examination of parts for signs of fatigue and failure. |

| Cleaning | Removing deposits and contaminants to ensure optimal performance. |

| Reconditioning | Restoring critical components to factory specifications. |

| Reassembly | Carefully putting components back together while following torque specifications. |

| Tuning | Adjusting settings for improved performance and efficiency. |

Implementing these techniques will lead to a successful restoration project, ultimately enhancing the overall performance of the vehicle.

Maintenance Tips for Engine Longevity

Ensuring the prolonged functionality of your vehicle’s power unit involves several essential practices. Regular upkeep not only enhances performance but also significantly extends the lifespan of critical components. Implementing these strategies can help maintain optimal conditions and prevent premature wear.

First and foremost, routine fluid changes are crucial. Keeping lubricants and coolants at appropriate levels ensures smooth operation and reduces friction between moving parts. It’s advisable to follow manufacturer recommendations regarding intervals for these changes.

Additionally, monitoring air filters plays a vital role in performance. Clean filters allow for better airflow, contributing to efficient combustion. Regularly inspecting and replacing filters as needed can lead to improved fuel efficiency and overall functionality.

Furthermore, periodic inspections of belts and hoses can prevent unexpected breakdowns. These components are integral to the overall system, and replacing them before signs of wear appear can save time and money in the long run.

Lastly, maintaining a consistent driving style can contribute to the longevity of the entire system. Avoiding aggressive acceleration and sudden stops reduces stress on various parts, promoting a more durable operation.

Replacing Engine Parts Safely

Ensuring the safe replacement of mechanical components is crucial for maintaining vehicle performance and longevity. Proper procedures not only protect the vehicle but also safeguard the individual performing the task. Adhering to guidelines and using appropriate tools can significantly reduce the risk of accidents and errors during the replacement process.

Essential Tools and Equipment

Before starting the replacement process, it’s important to gather the necessary tools. Here are some essential items:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts |

| Screwdriver Set | For removing and securing screws |

| Jack Stands | To securely lift the vehicle |

| Torque Wrench | To apply the correct force to fasteners |

Safety Precautions

Implementing safety measures is vital throughout the process. Always ensure that the vehicle is on a stable surface and utilize jack stands for support. Wearing protective gear such as gloves and goggles can help prevent injuries. Furthermore, it’s essential to disconnect the power source to avoid electrical hazards while working on components.

Electrical Systems in BMW Engines

The electrical systems within modern vehicles play a crucial role in ensuring optimal performance and functionality. These systems encompass a range of components that work together to provide power, control, and communication among various parts of the vehicle.

Key Components

- Batteries: Serve as the primary power source, storing energy for electrical operations.

- Alternators: Convert mechanical energy into electrical energy, replenishing the battery during operation.

- Wiring Harnesses: Facilitate the connection between various electrical components, ensuring proper communication and functionality.

- Sensors: Monitor various parameters, providing critical data for system adjustments.

- Control Units: Manage the operation of electrical components, interpreting data from sensors to optimize performance.

Maintenance Tips

- Regularly inspect battery terminals for corrosion and ensure tight connections.

- Check wiring for signs of wear or damage, and replace as necessary.

- Keep connectors clean to prevent poor electrical contact.

- Monitor the health of the alternator and replace it if performance declines.

- Stay informed about software updates for control units to ensure optimal functionality.

Fuel System Troubleshooting Guidelines

This section aims to provide practical approaches for diagnosing issues within the fuel delivery system of a vehicle. Understanding the common problems and their symptoms can significantly aid in effective maintenance and restoration of optimal performance.

Check for Fuel Leaks: Inspect all fuel lines, connections, and the tank for any signs of leakage. Even minor leaks can affect performance and pose safety hazards. If any leaks are detected, they should be addressed immediately.

Inspect the Fuel Filter: A clogged fuel filter can restrict flow and lead to poor engine performance. Regular replacement of the filter is essential for ensuring a consistent supply of fuel to the system.

Examine the Fuel Pump: Listen for unusual sounds from the fuel pump when the ignition is turned on. A failing pump may not create the necessary pressure, leading to inadequate fuel delivery. Testing the pump’s pressure with a gauge can provide definitive insights.

Evaluate Fuel Quality: Contaminated fuel can cause various issues. Ensure that the fuel used is clean and meets the required standards. If necessary, drain the tank and replace the fuel to eliminate any contaminants.

Analyze Fuel Injectors: Clogged or malfunctioning injectors can disrupt fuel spray patterns, resulting in poor combustion. Cleaning or replacing faulty injectors is crucial for maintaining efficiency and performance.

Cooling System Repairs and Upgrades

The efficiency of a vehicle’s cooling apparatus is crucial for maintaining optimal performance and longevity. This section focuses on essential enhancements and troubleshooting techniques that can significantly improve the functionality of the cooling mechanism.

Common Issues and Solutions

Identifying frequent problems within the cooling system is the first step toward effective resolution. Here are some prevalent concerns:

- Overheating: Often caused by coolant leaks, blocked hoses, or a malfunctioning thermostat.

- Insufficient coolant flow: This can be due to a failing water pump or air pockets within the system.

- Corrosion and buildup: Regular maintenance is essential to prevent deposits that hinder performance.

Upgrades for Enhanced Performance

Implementing upgrades can lead to improved efficiency and reliability. Consider the following modifications:

- Upgrading to a high-performance radiator: This can enhance heat dissipation and overall cooling efficiency.

- Installing an aftermarket thermostat: A lower temperature rating can help maintain optimal engine temperatures under demanding conditions.

- Utilizing high-quality coolant: Advanced formulations can provide better protection against corrosion and thermal breakdown.

Engine Performance Optimization Strategies

Enhancing the capabilities of your vehicle’s power unit can significantly improve overall efficiency and responsiveness. By implementing various techniques, enthusiasts can maximize performance while ensuring longevity and reliability.

Tuning and Calibration

Adjusting settings and calibrating systems are essential for achieving optimal functionality. Consider the following methods:

- Custom tuning to match specific driving conditions.

- Updating software for advanced control modules.

- Utilizing performance chips to enhance power delivery.

Maintenance Practices

Regular upkeep is crucial for maintaining peak performance. Key practices include:

- Routine inspections of vital components.

- Changing fluids and filters at recommended intervals.

- Using high-quality parts for replacements to prevent failures.

Resources for Further Learning

Enhancing your knowledge and skills in automotive maintenance can be greatly supported by a variety of educational materials and platforms. These resources can provide in-depth insights, practical guidance, and the latest developments in the field.

Consider exploring online courses, webinars, and video tutorials offered by automotive experts. These platforms often cover a wide range of topics, from fundamental concepts to advanced techniques, allowing you to learn at your own pace. Additionally, joining forums and online communities can facilitate knowledge sharing and provide valuable advice from experienced enthusiasts.

Books and publications dedicated to automotive technology also serve as excellent references. They often include comprehensive explanations, troubleshooting tips, and diagrams that can enhance your understanding of various systems and components. Libraries and bookstores frequently carry a selection of titles that cater to different skill levels.

Lastly, attending workshops or local classes can provide hands-on experience, allowing you to apply what you’ve learned in a practical setting. Engaging with professionals and peers in these environments can enrich your learning experience and build your confidence in tackling automotive tasks.