The realm of heavy-duty vehicle maintenance encompasses a wide range of intricacies and technical details. Proper understanding of the inner workings and components is crucial for ensuring optimal performance and longevity. This section delves into the essential knowledge required for effective upkeep of robust machinery, providing insights into common issues and solutions.

Equipping oneself with comprehensive guidelines can greatly enhance the efficiency of troubleshooting and servicing. From identifying mechanical failures to implementing systematic approaches for restoration, having access to detailed information allows for informed decision-making. Here, we aim to offer valuable resources and advice tailored to the specific needs of those engaged in the upkeep of formidable transportation units.

Moreover, familiarity with operational techniques not only streamlines maintenance processes but also contributes to safety on the road. This guide serves as a foundational tool for both novices and experienced professionals, ensuring a thorough grasp of necessary practices and innovations in the field. With the right knowledge, the challenges associated with maintaining large vehicles can be effectively managed, leading to a more reliable and efficient fleet.

Mack Truck Engine Overview

This section provides a comprehensive insight into the power sources used in heavy-duty vehicles, emphasizing their significance in performance and reliability. Understanding the fundamental components and systems is essential for optimal functioning and longevity.

| Component | Description |

|---|---|

| Cylinder Block | The core structure housing the cylinders, where combustion occurs, contributing to the overall strength and durability. |

| Fuel System | A critical assembly responsible for delivering fuel to the combustion chambers, ensuring efficient energy production. |

| Cooling System | This system prevents overheating by circulating coolant, maintaining optimal operating temperatures for performance. |

| Lubrication System | Essential for reducing friction between moving parts, this system extends the lifespan of components and enhances efficiency. |

| Exhaust System | Responsible for directing harmful gases away from the power source, this system also helps in minimizing noise and improving efficiency. |

A thorough understanding of these elements contributes to better maintenance practices and overall vehicle performance. Knowledge of how each component interacts ensures effective troubleshooting and enhances operational efficiency.

Common Engine Issues in Mack Trucks

When it comes to heavy-duty vehicles, understanding typical problems can significantly enhance longevity and performance. Various factors can contribute to mechanical failures, affecting overall operation and efficiency.

- Overheating: A prevalent issue often caused by coolant leaks or a malfunctioning thermostat.

- Oil Leaks: Commonly arise from worn seals or gaskets, leading to potential damage if not addressed promptly.

- Fuel System Problems: Issues such as clogged filters or failing injectors can hinder performance and fuel efficiency.

- Electrical Failures: Battery issues or faulty wiring can result in starting difficulties or erratic operation.

- Exhaust Emissions: Elevated emissions levels may indicate underlying problems in the combustion process.

Regular monitoring and maintenance can help prevent these challenges, ensuring the vehicle operates smoothly and reliably over time.

Tools Needed for Engine Repairs

Successful maintenance and refurbishment of heavy machinery require a well-equipped workspace and a selection of essential implements. Having the right tools not only streamlines the process but also enhances safety and efficiency. Below is a list of critical instruments to consider when undertaking such tasks.

- Wrenches: A variety of sizes, including socket and open-end, to handle different fasteners.

- Screwdrivers: Both flathead and Phillips types in various sizes for a range of applications.

- Pliers: Needle-nose and locking pliers for gripping and twisting tasks.

- Torque Wrench: To ensure proper tightening of bolts and nuts to manufacturer specifications.

- Oil Filter Wrench: A specialized tool for removing and installing oil filters easily.

In addition to the basic tools, consider the following:

- Jack and Jack Stands: For safely lifting and supporting the machinery.

- Compression Tester: To evaluate the integrity of the combustion chambers.

- Multimeter: For checking electrical systems and components.

- Diagnostic Scanner: To retrieve error codes and perform system checks.

- Cleaning Supplies: Including brushes and solvents for maintaining cleanliness during the job.

Having these tools readily available will significantly improve the effectiveness of your maintenance efforts and help ensure a smooth operation throughout the process.

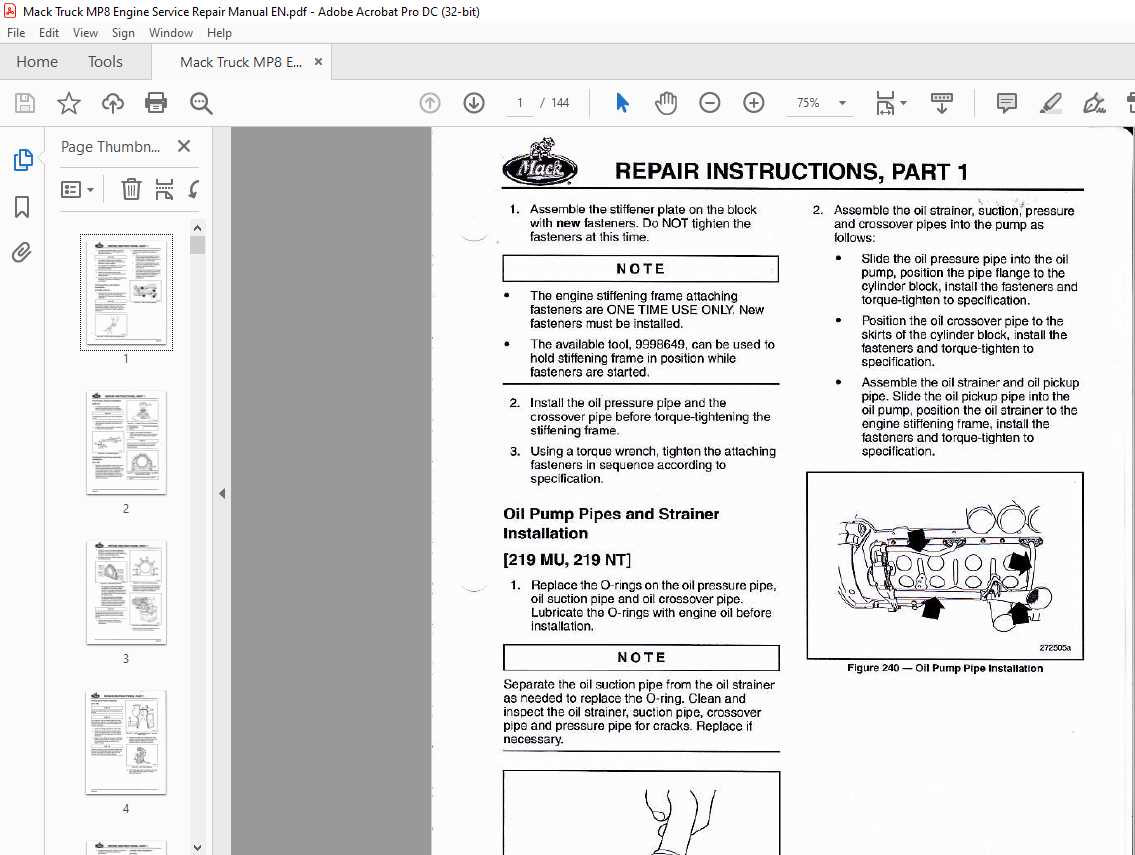

Step-by-Step Engine Maintenance Guide

This guide provides essential procedures to ensure optimal performance and longevity of your vehicle’s power unit. By following a systematic approach, you can prevent potential issues and enhance efficiency over time.

1. Regular Fluid Checks

Start by inspecting all vital fluids, including oil, coolant, and transmission fluid. Ensuring that these liquids are at the correct levels and free from contaminants is crucial for smooth operation.

2. Air Filter Replacement

The air intake component should be checked and replaced as necessary. A clean filter allows for proper airflow, which is essential for maintaining performance and fuel efficiency.

3. Spark Plug Inspection

Examine the ignition components for wear and deposits. Replacing spark plugs at recommended intervals will help maintain optimal combustion and reduce emissions.

4. Battery Care

Check the battery terminals for corrosion and ensure a secure connection. A well-maintained battery can prevent starting issues and prolong its lifespan.

5. Belts and Hoses Examination

Inspect all belts and hoses for signs of wear, cracks, or leaks. Timely replacement can prevent more significant failures and costly repairs down the line.

6. Cleanliness Maintenance

Keep the exterior of the machinery clean to prevent debris accumulation. Regular cleaning can enhance visibility for inspections and improve overall functionality.

7. Professional Inspections

Schedule periodic professional evaluations. Technicians can identify potential issues that may not be apparent during routine checks, ensuring comprehensive care.

By adhering to this maintenance guide, you can ensure your vehicle operates at its best, minimizing unexpected disruptions and maximizing reliability.

Replacing Mack Truck Engine Parts

Replacing components within heavy-duty vehicles is a crucial task that ensures optimal performance and longevity. This process requires careful consideration and understanding of the specific parts involved, as well as adherence to best practices for a successful outcome.

Identifying Necessary Components

Before proceeding with any replacement, it’s essential to identify the parts that require attention. Common components to inspect include:

- Filters

- Belts

- Pulleys

- Fuel injectors

- Seals and gaskets

Assessing these items will help in determining the overall condition and performance of the machinery.

Steps for Replacement

- Preparation: Gather all necessary tools and new components.

- Disassembly: Carefully remove the faulty parts, taking care not to damage surrounding areas.

- Installation: Position the new parts and secure them as per the manufacturer’s specifications.

- Testing: After installation, conduct a thorough test to ensure functionality.

Following these steps diligently will contribute to the reliability and efficiency of the vehicle in operation.

Understanding Engine Specifications and Features

This section explores the critical aspects that define the performance and efficiency of a power unit. By examining various characteristics, operators can make informed decisions and optimize functionality for diverse applications.

Key Specifications

- Displacement: Refers to the total volume of all cylinders, impacting power output.

- Compression Ratio: Influences fuel efficiency and overall power.

- Horsepower: Measures the unit’s power capacity, crucial for performance.

Essential Features

- Turbocharging: Enhances air intake, boosting performance.

- Fuel System: The type and efficiency of the system affect operational costs.

- Cooling Mechanisms: Vital for maintaining optimal temperatures during operation.

Troubleshooting Engine Performance Problems

Addressing performance issues in heavy machinery requires a systematic approach to identify underlying causes. Whether it’s a lack of power, irregular idling, or excessive noise, recognizing the symptoms and understanding their potential origins can significantly enhance operational efficiency.

Common Symptoms and Their Causes

Observing distinct signs can help pinpoint the source of the problem. For instance, a noticeable drop in power may indicate fuel delivery issues or air intake blockages. Irregular idling could stem from faulty sensors or electrical malfunctions. It’s crucial to analyze each symptom thoroughly to establish a reliable diagnosis.

Diagnostic Techniques

Utilizing diagnostic tools can streamline the troubleshooting process. Visual inspections should always precede more complex evaluations. Checking for leaks, worn components, or loose connections is vital. Additionally, employing electronic diagnostic equipment can provide valuable insights into performance metrics, helping to confirm suspicions about specific issues.

Preventive Measures for Engine Longevity

Ensuring the durability and efficiency of your machinery requires a proactive approach. By implementing specific practices, you can significantly extend the lifespan of your mechanical components, minimizing unexpected breakdowns and costly interventions.

- Regular Maintenance Checks: Schedule consistent evaluations to identify potential issues early.

- Quality Lubricants: Use high-grade oils and fluids to reduce friction and wear.

- Cooling System Care: Maintain optimal temperatures by regularly checking coolant levels and hoses.

- Fuel Quality Monitoring: Utilize clean and appropriate fuel types to prevent residue buildup.

In addition to these essential practices, monitoring operating conditions plays a crucial role in sustaining performance.

- Temperature Regulation: Keep an eye on temperature gauges to prevent overheating.

- Load Management: Avoid overloading to reduce strain on components.

- Vibration Assessment: Regularly inspect for unusual vibrations, which can indicate underlying problems.

By adhering to these guidelines, you create a robust framework for preserving the efficiency and reliability of your machinery over time.

Resources for Mack Truck Owners

For enthusiasts and operators of heavy-duty vehicles, having access to reliable information and support is crucial. This section provides a comprehensive overview of valuable resources that can enhance the ownership experience and ensure optimal performance.

- Online Forums: Engaging with fellow vehicle owners can be invaluable. Online communities offer a platform to share experiences, ask questions, and find solutions.

- Manufacturer Websites: Official websites often provide detailed specifications, parts catalogs, and contact information for customer support.

- Service Centers: Authorized service facilities offer expertise and specialized tools necessary for maintenance and troubleshooting.

In addition to these resources, many owners benefit from educational materials such as:

- Workshops and Training Sessions: Participating in hands-on learning experiences can deepen understanding of vehicle systems.

- Instructional Videos: Online platforms like YouTube host numerous tutorials that cover a range of topics from basic maintenance to advanced diagnostics.

- Publications and Journals: Subscribing to industry-specific magazines can keep owners informed about the latest trends and technologies.

Leveraging these resources can empower owners to maintain their vehicles effectively and enhance their longevity.

Seeking Professional Help: When to Call

In the world of heavy machinery, there are moments when personal expertise may not suffice. Understanding when to seek assistance from trained professionals is crucial for maintaining optimal performance and safety. Here are some scenarios that indicate it may be time to reach out for expert help.

Signs That Professional Assistance Is Needed

- Persistent Issues: If problems recur despite your attempts to resolve them, it’s a sign that deeper expertise is required.

- Complex Diagnostics: When faced with intricate mechanical failures, a professional’s diagnostic tools and experience can provide accurate assessments.

- Safety Concerns: Any situation that compromises safety should prompt an immediate call for professional intervention.

- Time Constraints: If repairs are urgent and your skills or time are limited, professionals can expedite the process.

Choosing the Right Professional

- Research credentials and experience in handling similar machinery.

- Seek recommendations from trusted sources to ensure quality service.

- Verify availability and response time to meet your urgent needs.

By recognizing these signs and knowing when to enlist professional help, you can ensure that your machinery operates safely and efficiently, ultimately extending its lifespan.