Understanding the intricacies of mechanical systems is essential for anyone involved in heavy machinery or automotive applications. This guide serves as a vital resource for those seeking to enhance their knowledge and skills in the upkeep and troubleshooting of complex machinery. Through careful examination of various components and systems, readers will gain insights that are crucial for ensuring optimal performance and longevity.

The document encompasses detailed instructions and practical tips designed to address common challenges faced during maintenance tasks. By following structured processes, users can effectively diagnose issues and implement solutions, thereby minimizing downtime and enhancing efficiency. The focus is on empowering individuals with the knowledge to navigate the intricacies of machinery care confidently.

Whether you are a seasoned technician or a novice looking to expand your understanding, this compilation offers valuable information that can significantly impact your ability to maintain and optimize performance. With a blend of technical expertise and accessible language, this resource aims to bridge the gap between theory and practical application.

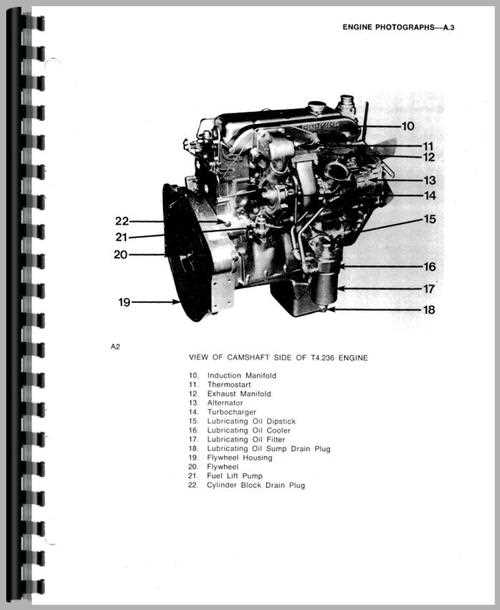

Understanding Perkins Engines

This section provides insights into a renowned brand known for its robust power solutions. The focus here is on the design philosophy, operational efficiency, and maintenance practices that characterize these powerful machines. Understanding these components is essential for maximizing performance and longevity in various applications.

Key Features

Notable attributes include durability, fuel efficiency, and versatility. These systems are engineered to meet the demands of multiple sectors, offering reliability in challenging environments. Their modular construction allows for easy access and serviceability, making them a popular choice among operators.

Maintenance Considerations

Regular upkeep is crucial to ensure optimal functionality. Key practices involve checking fluid levels, inspecting components for wear, and adhering to scheduled service intervals. These measures can significantly extend operational life and enhance performance.

| Feature | Benefit |

|---|---|

| Durability | Resistant to wear and tear, ensuring long-term use |

| Fuel Efficiency | Lower operational costs through reduced fuel consumption |

| Versatility | Suitable for various applications across industries |

| Modular Design | Facilitates easy maintenance and part replacement |

Common Issues with Perkins Engines

When it comes to high-performance machinery, certain complications can frequently arise, impacting both functionality and efficiency. Understanding these common challenges is essential for operators and technicians alike to ensure optimal performance and longevity.

Fuel System Problems

One of the most prevalent difficulties encountered involves the fuel delivery mechanism. Blockages in filters or injectors can lead to inadequate fuel flow, resulting in poor combustion and reduced power output. Regular maintenance and timely replacement of filters can mitigate these issues.

Cooling System Failures

Another critical area of concern is the cooling system. Overheating can occur due to various factors, such as coolant leaks, radiator obstructions, or a malfunctioning thermostat. It’s vital to monitor coolant levels and check for any signs of wear or damage to avoid severe repercussions on the machinery’s overall performance.

Being proactive in identifying and addressing these challenges not only enhances operational efficiency but also extends the lifespan of the equipment.

Essential Tools for Engine Repair

When undertaking maintenance or troubleshooting tasks on any mechanical unit, having the right instruments is crucial for success. A well-equipped workspace not only enhances efficiency but also ensures safety and accuracy during the process. This section outlines key tools that every technician should have on hand to facilitate effective work.

Basic Hand Tools

Fundamental hand tools form the backbone of any workshop. Wrenches, screwdrivers, and pliers are indispensable for loosening and tightening various components. Socket sets are particularly valuable, as they provide versatility for different sizes and types of fasteners. Additionally, torque wrenches are essential for applying the correct force to avoid damage to parts.

Diagnostic Equipment

Beyond basic tools, diagnostic devices play a vital role in identifying issues. Multimeters allow for electrical testing, while compression gauges help assess the condition of internal systems. Having access to such equipment enables a more thorough analysis, leading to informed decisions about necessary actions.

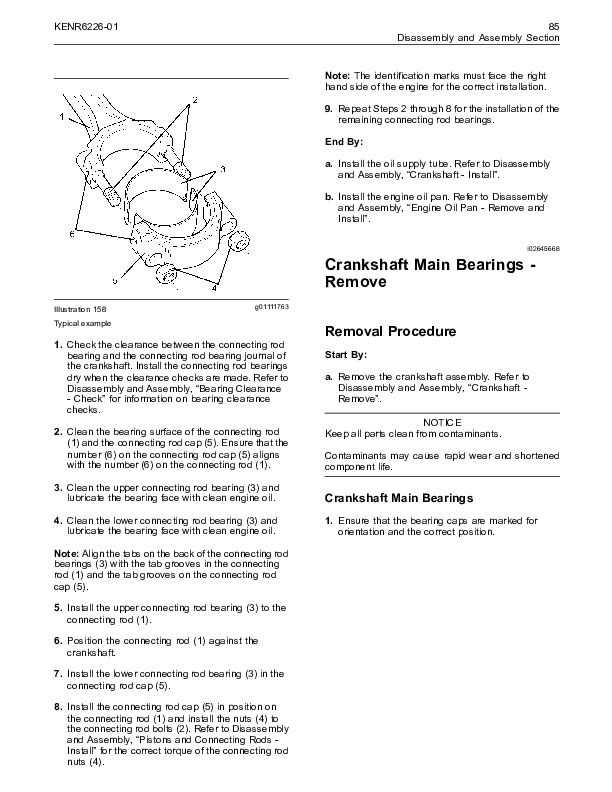

Step-by-Step Repair Procedures

This section outlines a systematic approach to troubleshooting and fixing issues related to heavy machinery power units. Following a structured process ensures that each aspect is thoroughly examined and addressed, leading to efficient resolution of problems.

Preparation Steps

- Gather necessary tools and equipment.

- Ensure a clean workspace to avoid contamination.

- Review safety protocols to mitigate risks.

Diagnostic Process

- Identify symptoms and gather performance data.

- Conduct visual inspections for obvious damage.

- Utilize diagnostic tools for detailed analysis.

- Document findings and prioritize issues.

By meticulously following these steps, users can effectively address malfunctions and maintain optimal performance.

Maintenance Tips for Longevity

Ensuring the long-term performance of machinery requires diligent attention and care. Regular upkeep not only enhances functionality but also prevents potential issues that may arise from neglect. Following a structured maintenance routine can significantly extend the lifespan of your equipment.

Regular Inspections

Frequent evaluations of components play a crucial role in identifying wear and tear before they escalate into serious problems. Check for signs of corrosion, leaks, or unusual noises during operation. Keeping a detailed log of these inspections can help track performance trends over time.

Proper Lubrication

Applying the right lubricants at appropriate intervals is essential for reducing friction and heat buildup. Ensure that you use products that meet the specifications of your machinery. Over-lubricating can be as detrimental as under-lubricating, so adhering to recommended guidelines is vital.

Diagnostic Techniques for Perkins Engines

Effective troubleshooting is crucial for maintaining optimal performance in machinery. Identifying issues quickly not only minimizes downtime but also enhances the longevity of the equipment. This section will explore various strategies and methods to assess functionality and pinpoint malfunctions.

One of the primary approaches involves systematic observation and data collection. By monitoring key parameters, operators can detect irregularities early on. Additionally, utilizing advanced diagnostic tools can provide valuable insights into the condition of the components. Here are some essential techniques:

| Technique | Description | Benefits |

|---|---|---|

| Visual Inspection | Conducting a thorough visual examination of parts for signs of wear or damage. | Quick identification of obvious issues, no specialized tools required. |

| Performance Testing | Running the unit under controlled conditions to assess power output and efficiency. | Establishes baseline performance metrics for comparison. |

| Fluid Analysis | Testing lubricants and coolants for contaminants and degradation. | Can reveal internal wear patterns and potential failures. |

| Diagnostic Software | Using specialized programs to analyze electronic control systems and parameters. | Provides detailed insights and can facilitate troubleshooting. |

| Vibration Analysis | Monitoring vibrations to detect imbalances or misalignments. | Early detection of mechanical issues that may lead to significant damage. |

Implementing these techniques systematically will enhance the ability to diagnose and address issues effectively. Regular maintenance and thorough assessments contribute to the overall reliability and performance of the machinery.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks. By adhering to proper protocols, one can significantly reduce the risk of accidents and injuries. This section outlines essential guidelines to follow while performing work on machinery.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Disconnect power sources before starting any work to prevent accidental activation.

- Keep a first aid kit nearby and know how to use its contents in case of an emergency.

- Organize tools and parts to prevent tripping hazards and maintain a clutter-free environment.

In addition to personal safety, it is crucial to maintain a safe working environment. This involves being aware of surroundings and potential hazards.

- Inspect tools regularly for any signs of wear or damage.

- Follow manufacturer guidelines for specific tasks and procedures.

- Use proper lifting techniques to avoid injury when handling heavy components.

- Be mindful of flammable materials and store them safely away from heat sources.

- Work with a partner when dealing with large or complex tasks to ensure assistance is available if needed.

By following these safety precautions, individuals can create a secure environment that promotes efficiency and minimizes risks during maintenance activities.

Finding Quality Replacement Parts

When it comes to maintaining machinery, sourcing top-notch components is crucial for ensuring optimal performance and longevity. Quality parts not only enhance functionality but also minimize the risk of future malfunctions. Therefore, it’s essential to understand how to identify and acquire the best alternatives available in the market.

Assessing Compatibility and Standards

Before purchasing any component, it’s important to verify its compatibility with your specific model. Researching specifications and industry standards can guide you in selecting parts that are designed to work seamlessly with your machinery. Always check for certifications that indicate adherence to quality benchmarks.

Reliable Sources for Parts

To ensure you receive authentic components, consider sourcing from reputable suppliers. Authorized dealers and well-known distributors typically offer reliable products along with warranties. Additionally, online marketplaces can provide a wide range of options, but it is advisable to read reviews and ratings to gauge the credibility of the seller.

Understanding Engine Specifications

Grasping the details of mechanical specifications is crucial for anyone involved in the maintenance and enhancement of power units. These characteristics serve as guidelines, ensuring optimal performance and longevity of the machinery. A thorough comprehension allows operators to make informed decisions regarding service and modifications.

Key Parameters to Consider

Several fundamental aspects must be examined, including displacement, power output, and torque ratings. Displacement refers to the total volume of the cylinders, affecting efficiency and performance. Meanwhile, power output indicates the maximum energy produced, while torque measures the rotational force available at different speeds. Understanding these parameters helps in assessing capabilities and limitations.

Impact of Specifications on Performance

The relationship between these parameters significantly influences overall functionality. For example, a unit with higher torque is typically better suited for heavy-duty tasks, whereas a focus on power output may enhance speed and agility. Additionally, fuel efficiency is often impacted by how these specifications align with operational needs. Properly matching requirements with characteristics can lead to improved productivity and reduced operational costs.

Performance Upgrades for Perkins Engines

Enhancing the efficiency and power output of machinery can significantly improve overall productivity. There are various approaches to boost performance, ensuring that your equipment operates at its best while maintaining reliability.

Below are some effective strategies to consider for achieving optimal results:

- Air Intake Improvements:

- Upgrade to high-flow air filters to increase airflow.

- Consider installing a performance intake manifold for better air distribution.

- Fuel System Enhancements:

- Install larger fuel injectors for increased fuel delivery.

- Utilize high-performance fuel pumps to maintain pressure during operation.

- Exhaust Modifications:

- Replace the exhaust system with a free-flow design to reduce back pressure.

- Add a performance muffler to enhance sound and efficiency.

- Tuning and Calibration:

- Reprogram the control unit to optimize fuel mapping and ignition timing.

- Conduct regular diagnostics to adjust settings based on performance metrics.

- Weight Reduction:

- Identify and eliminate unnecessary components to improve power-to-weight ratio.

- Consider using lighter materials in modifications and replacements.

Implementing these enhancements can lead to notable improvements in power, efficiency, and responsiveness. Careful planning and execution will ensure that your machinery continues to perform reliably while achieving the desired upgrades.

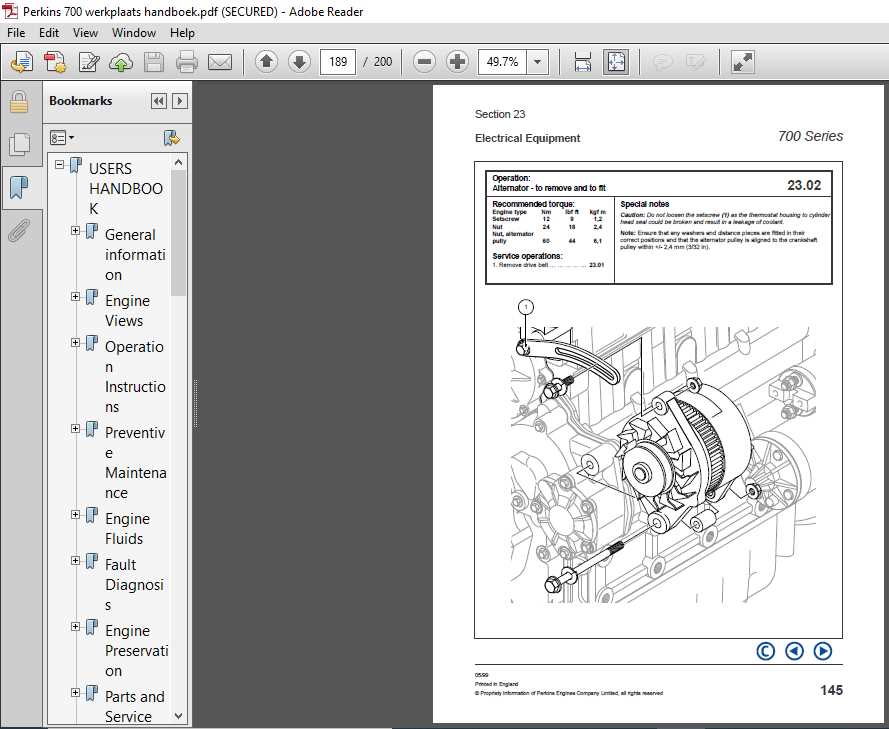

Troubleshooting Electrical Systems

Diagnosing issues within power systems is crucial for maintaining optimal performance and reliability. This process involves a systematic approach to identify faults and rectify them efficiently. Understanding the basic components and their functions is essential to pinpoint the source of problems effectively.

Common Symptoms and Initial Checks

When electrical systems exhibit irregularities, certain signs often manifest. Flickering lights, unusual sounds, or failure to start are common indicators of underlying issues. Begin troubleshooting by checking connections for corrosion or looseness. Verify the integrity of fuses and circuit breakers to ensure they are functioning correctly. These preliminary steps can often reveal straightforward problems that can be resolved easily.

Advanced Diagnostics

If initial checks do not yield results, more advanced diagnostic techniques may be necessary. Utilizing a multimeter can help assess voltage levels and continuity throughout the system. Inspecting wiring for damage or shorts is also critical. Additionally, consulting schematics can provide insights into the system’s layout, helping to isolate complex issues that may not be apparent through surface-level inspections.

Oil Change and Filter Replacement

Regular maintenance of your machinery’s lubrication system is essential for optimal performance and longevity. Ensuring clean oil circulation and filtering contaminants plays a crucial role in preventing wear and tear. This section outlines the steps involved in replacing the lubricant and its filtration system to maintain peak efficiency.

Steps for Oil Change

Start by warming up the system slightly to thin the lubricant, allowing it to drain more easily. Once warmed, turn off the machine and secure it on a level surface. Remove the drain plug and allow the old oil to fully exit into a suitable container. Afterward, replace the drain plug and prepare to add fresh lubricant.

Filter Replacement Process

Locate the filtration component and remove it carefully. Before installing a new filter, apply a thin layer of new lubricant to the rubber gasket on the new filter. This ensures a proper seal. Install the new filter and tighten it according to the manufacturer’s specifications. Finally, fill the system with the appropriate amount of fresh lubricant, checking levels to ensure accuracy.

Frequently Asked Questions About Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting of machinery. Understanding typical issues and their solutions can help users optimize performance and longevity. Here, we present some of the most frequently encountered questions to assist you in navigating the intricacies of upkeep.

Common Issues and Solutions

| Question | Answer |

|---|---|

| What are the signs of a malfunction? | Unusual noises, vibrations, and performance drops often indicate underlying problems. |

| How often should I perform maintenance? | Regular checks every 100 hours of operation are recommended, along with seasonal inspections. |

| Can I perform servicing myself? | Yes, basic tasks can be done by the owner, but complex issues should be handled by professionals. |

| What tools do I need for basic tasks? | A set of hand tools, diagnostic equipment, and safety gear are essential for routine work. |

Safety Considerations

Always prioritize safety during maintenance activities. Use protective equipment and follow guidelines to prevent accidents. If you are unsure about any procedure, consult a specialist for guidance.