Owning a high-performance outdoor vehicle requires a deep understanding of its components and proper care techniques. This resource serves as a valuable asset for enthusiasts and operators alike, offering essential insights into the upkeep and enhancement of your machine’s functionality.

In the world of garden and lawn equipment, knowledge is power. Familiarizing yourself with the intricacies of your equipment not only extends its lifespan but also enhances its efficiency. This guide will delve into various aspects, ensuring you can tackle any issues that arise with confidence.

Whether you are facing minor adjustments or significant challenges, having access to detailed information will equip you with the necessary tools to address potential problems effectively. Understanding the operational guidelines and maintenance procedures is crucial for optimal performance and longevity.

Understanding the John Deere LX279

This section delves into the features and specifications of a popular lawn maintenance machine, highlighting its capabilities and operational aspects. By examining the design and functionality, users can gain insight into how this equipment enhances yard care and landscaping tasks.

Engine Performance: The machine is equipped with a robust power unit, designed to deliver efficient performance while maintaining fuel economy. Its smooth operation allows for effective handling of various terrains, making it suitable for diverse landscaping needs.

Cutting System: The cutting mechanism is engineered to provide a precise and even finish. With adjustable height settings, it accommodates different grass types and user preferences, ensuring optimal results with every use.

Comfort Features: User comfort is prioritized in this model, featuring an ergonomic seat and intuitive controls. These elements contribute to a more enjoyable mowing experience, reducing fatigue during extended periods of operation.

Maintenance Considerations: Regular upkeep is essential for longevity and performance. Understanding the key components and their functions can help owners effectively maintain their equipment, ensuring it remains in top condition for years to come.

In summary, a comprehensive understanding of this lawn care machine enhances the user’s ability to maximize its potential, leading to improved results in outdoor maintenance tasks.

Common Issues with LX279 Mowers

When it comes to lawn maintenance equipment, certain challenges tend to arise that can hinder performance. Understanding these common problems can help users troubleshoot effectively and ensure their machine operates smoothly.

Typical Problems Encountered

Several issues are frequently reported by owners of these mowers, often stemming from wear and tear or improper maintenance. Addressing these concerns promptly can extend the life of the equipment and enhance its functionality.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty spark plug, fuel issues | Check battery charge, replace spark plug, ensure fuel is fresh |

| Uneven Cutting | Dull blades, uneven tire pressure, deck height | Sharpen or replace blades, check tire pressure, adjust deck height |

| Overheating | Clogged air filter, low oil level, debris buildup | Clean or replace air filter, check oil level, remove debris |

Preventive Measures

Regular maintenance is crucial to avoid these issues. Following a consistent schedule for cleaning, checking fluid levels, and inspecting components can greatly reduce the likelihood of encountering these problems.

Essential Tools for Repairing LX279

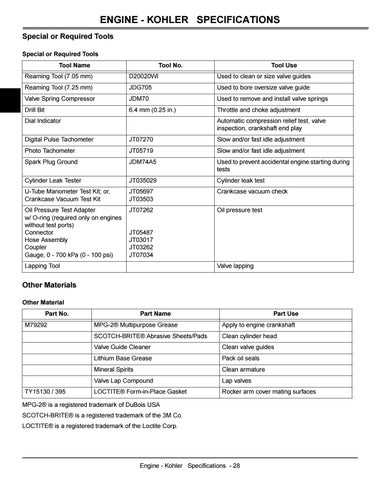

Having the right equipment is crucial when it comes to maintaining and fixing your machine. Whether you’re dealing with routine maintenance or more extensive troubleshooting, the tools you choose can make all the difference. Below is a list of essential instruments that will help ensure a smooth and efficient process.

- Socket Set: A comprehensive socket set is vital for loosening and tightening various fasteners.

- Wrenches: Adjustable and fixed wrenches are necessary for accessing tight spots and working on components.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will be needed for different screws throughout the machine.

- Pliers: Needle-nose and standard pliers can help with gripping, twisting, and cutting tasks.

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications, preventing damage.

Additionally, consider the following:

- Multimeter: Essential for diagnosing electrical issues and testing circuit continuity.

- Oil Filter Wrench: A specialized tool for changing oil filters easily.

- Jack Stands: Crucial for safely lifting the machine when working underneath.

- Work Gloves: Protect your hands from sharp edges and hot components.

Equipping yourself with these essential tools will not only streamline your maintenance tasks but also enhance your overall experience with the equipment.

Step-by-Step Maintenance Guide

This section aims to provide a comprehensive approach to keeping your equipment in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the machinery. Follow these systematic steps to ensure everything runs smoothly.

-

Visual Inspection:

- Check for any signs of wear and tear.

- Look for leaks or unusual noises.

- Ensure that all safety guards are in place.

-

Fluid Levels:

- Inspect engine oil and replace if necessary.

- Check coolant levels and top off as needed.

- Examine hydraulic fluid and ensure it is at the recommended level.

-

Filter Maintenance:

- Replace air filters to maintain proper airflow.

- Change fuel filters to prevent engine clogs.

- Check and clean oil filters regularly.

-

Blade and Tire Checks:

- Sharpen or replace blades as necessary for efficient cutting.

- Inspect tires for proper inflation and tread wear.

- Rotate tires if needed to ensure even wear.

-

Electrical System Review:

- Test battery condition and clean terminals.

- Inspect wiring for frays or damage.

- Check lights and signals for functionality.

By adhering to this guide, you can keep your equipment performing at its best and prevent costly repairs down the line.

How to Troubleshoot Engine Problems

When faced with engine issues, identifying the root cause is essential for effective resolution. Understanding the common symptoms and systematically addressing them can lead to successful repairs. This section provides guidance on diagnosing engine malfunctions and restoring optimal performance.

Begin by observing any unusual sounds, vibrations, or warning lights. These indicators can often point to specific problems. For example, knocking noises may suggest internal wear, while excessive smoke could indicate combustion issues. Pay attention to any changes in performance, such as difficulty starting or reduced power, which can also signal underlying troubles.

Next, check essential components like fuel supply, air intake, and ignition systems. Ensure that the fuel tank is adequately filled and that fuel filters are clean. Inspect air filters for blockages, as restricted airflow can hinder engine efficiency. Additionally, verify that spark plugs are functioning correctly, as they play a critical role in ignition.

If the engine still exhibits problems after these checks, it may be necessary to conduct a compression test. This procedure measures the pressure within the cylinders, helping to identify issues such as worn piston rings or valves that are not sealing properly. Low compression can severely impact performance and requires immediate attention.

In more complex situations, consulting with a professional may be beneficial. Technicians have access to specialized tools and diagnostic equipment that can provide deeper insights into the problem. Regular maintenance and timely inspections can also prevent many common engine issues from developing.

Electrical System Diagnostics for LX279

The electrical system of any equipment is crucial for its optimal performance. Diagnosing issues within this system can prevent minor problems from escalating into major failures. A systematic approach to troubleshooting electrical components ensures that each element functions correctly, contributing to the overall efficiency of the machine.

Start by examining the battery. Ensure it is charged and connections are secure. A weak or faulty battery can lead to various electrical malfunctions. Next, check the fuses; a blown fuse can interrupt power supply to essential components. Replace any damaged fuses and test the system again.

Moving on to the wiring harness, inspect for any visible signs of wear or damage. Corroded or loose connections can create intermittent issues. Utilize a multimeter to measure voltage across critical points, verifying that the system receives appropriate power levels.

Finally, evaluate the switches and relays. Test their functionality to ensure they operate correctly under various conditions. Understanding the role of each component in the electrical system helps pinpoint issues effectively and facilitates a quicker resolution.

Blade Replacement Procedures Explained

Replacing the cutting blades on your machine is essential for maintaining optimal performance and ensuring a clean cut. This process, while straightforward, requires attention to detail and adherence to safety protocols. Properly executing blade replacement not only enhances efficiency but also extends the lifespan of the equipment.

Step 1: Preparation

Before starting, ensure the engine is off and cool. Disconnect the spark plug wire to prevent accidental starts. Gather the necessary tools, including wrenches, gloves, and safety goggles.

Step 2: Lifting the Equipment

Use a suitable lifting device or jack to elevate the unit securely. This allows easy access to the underside where the blades are located. Always ensure stability before proceeding.

Step 3: Removing the Old Blades

Locate the blade fasteners and use the appropriate tool to remove them. Keep track of the hardware for reinstallation. Carefully detach the blades, taking note of their orientation for correct placement of the new ones.

Step 4: Installing New Blades

Position the new blades in the same orientation as the old ones. Secure them with the fasteners, ensuring they are tightened to the manufacturer’s specifications to prevent loosening during operation.

Step 5: Final Checks

After installation, lower the equipment and reconnect the spark plug wire. Perform a visual inspection to ensure everything is in place. It’s recommended to test the machine at low speed to verify that the blades operate smoothly.

Following these steps will facilitate a successful blade replacement, contributing to the efficiency and longevity of your equipment.

Lubrication Points and Recommendations

Proper maintenance of mechanical equipment is crucial for ensuring longevity and optimal performance. Regular lubrication helps reduce friction, prevent wear, and protect vital components from damage. Understanding the key lubrication points and following specific recommendations can significantly enhance the efficiency and lifespan of your machinery.

Key Lubrication Points

- Engine oil reservoir

- Transmission system

- Wheel bearings

- Pivot points of control arms

- Deck lift mechanism

- Steering components

Lubrication Recommendations

- Use high-quality lubricants that meet manufacturer specifications.

- Check oil levels regularly and top off as necessary.

- Clean lubrication points before applying new grease or oil.

- Follow a regular maintenance schedule based on usage.

- Inspect seals and gaskets for leaks to maintain proper lubrication.

Deck Adjustments for Optimal Performance

Ensuring your mower operates at peak efficiency requires careful attention to deck settings. Proper adjustments not only enhance cutting quality but also prolong the life of your equipment. This section provides essential insights into how to achieve the best performance through effective deck modifications.

To maintain an even cut and improve grass health, consider the following key adjustments:

- Height Adjustment: Regularly check and set the cutting height based on grass type and seasonal conditions. Aim for a height that promotes healthy growth while minimizing stress on the blades.

- Leveling: Ensure the deck is level from side to side and front to back. An uneven deck can lead to uneven cuts, scalping, or missed spots.

- Blade Maintenance: Regularly inspect and sharpen blades to ensure a clean cut. Dull blades can tear grass rather than cutting it, which may lead to disease.

- Deck Cleanliness: Keep the underside of the deck free from grass buildup. This improves airflow and cutting efficiency.

By following these guidelines, you can enhance the performance of your mowing equipment, ensuring it runs smoothly and effectively throughout the mowing season.

Seasonal Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment throughout the year. By implementing a seasonal maintenance routine, you can enhance performance and extend the lifespan of your machinery. Here are some valuable tips to consider for each season:

Spring Maintenance

- Inspect and replace any worn belts and blades to ensure optimal cutting performance.

- Change the oil and replace the oil filter to promote engine health.

- Clean air filters and replace them if they show signs of wear or dirt accumulation.

Summer Maintenance

- Check tire pressure and inspect for any signs of damage or wear.

- Regularly clean the deck and remove grass clippings to prevent rust.

- Ensure all moving parts are well-lubricated to avoid overheating.

Autumn Maintenance

- Prepare the engine for winter by adding fuel stabilizer to prevent deterioration.

- Drain the fuel system if the equipment will be stored for an extended period.

- Inspect and clean spark plugs, replacing them if necessary.

Winter Maintenance

- Store machinery in a dry, sheltered location to protect it from the elements.

- Cover equipment with tarps or specialized covers to prevent dust accumulation.

- Perform a thorough inspection and address any repairs needed before the next season.

By following these seasonal guidelines, you can ensure that your equipment remains in peak condition, ready to tackle the tasks ahead with efficiency and reliability.

Parts and Accessories for LX279

Ensuring optimal performance and longevity of your lawn equipment requires the right components and additional tools. A well-curated selection of parts and accessories can enhance functionality and tailor the machine to specific tasks. This section delves into essential items that contribute to both maintenance and operational efficiency.

Replacement Components: Regular wear and tear necessitate the replacement of key parts. Focus on obtaining high-quality blades, belts, and filters. These components play a crucial role in maintaining performance and ensuring a clean cut. Using original equipment ensures compatibility and reliability.

Attachments: Various attachments can expand the versatility of your machine. Options like baggers, mulchers, and snow plows allow for multi-season use, enhancing productivity. When selecting attachments, consider the specific tasks and the compatibility with existing equipment.

Maintenance Supplies: Keeping your equipment in prime condition requires adequate maintenance supplies. Oil, lubricants, and cleaning agents are essential for regular upkeep. Investing in these supplies can prevent costly repairs and prolong the lifespan of your machinery.

Safety Gear: Don’t overlook the importance of safety accessories. Proper footwear, gloves, and eyewear are essential for protecting yourself during operation. Prioritizing safety ensures a secure working environment while using your equipment.

In summary, equipping your machine with the right parts and accessories not only improves functionality but also enhances safety and efficiency. Careful selection and regular maintenance can lead to better performance and extended durability of your lawn equipment.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks. Proper precautions help prevent accidents and injuries, creating a more efficient workspace. By adhering to safety guidelines, individuals can protect themselves and those around them while working with machinery.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace clean and organized to minimize hazards.

- Disconnect the power source before beginning any maintenance tasks.

It is also important to be aware of the specific risks associated with the equipment being serviced. Familiarizing oneself with operational manuals and guidelines can provide valuable insights into safe practices.

- Always use tools and equipment as intended to prevent misuse and potential injuries.

- Maintain a clear communication line with others in the area to avoid distractions.

- Follow all safety protocols specific to the machinery to ensure compliance.

- Have a first-aid kit readily available in case of emergencies.

By following these safety measures, individuals can significantly reduce the risk of accidents and create a more productive maintenance experience.

When to Seek Professional Help

Knowing when to enlist the assistance of an expert can save time, money, and frustration. Some situations are better handled by those with specialized knowledge and experience. This section outlines key indicators that suggest it might be wise to turn to a professional for assistance.

Signs You Need Expert Assistance

- Persistent Issues: If the same problem keeps recurring despite your attempts to resolve it.

- Lack of Expertise: When the tasks required exceed your technical knowledge or skills.

- Time Constraints: If you find that troubleshooting is consuming too much of your time, impacting other important activities.

- Safety Concerns: When a task poses potential hazards, it is prudent to consult a qualified technician.

- Complex Repairs: When the required repairs involve intricate systems or components that require specialized tools or training.

Benefits of Professional Help

- Efficiency: Experts can often diagnose and fix issues more quickly than someone without experience.

- Quality Assurance: Professionals provide warranties and guarantees, ensuring peace of mind.

- Comprehensive Solutions: They offer insights and recommendations that might not be immediately apparent to the untrained eye.

- Cost-Effectiveness: While there is an upfront cost, avoiding further damage can ultimately save money.