In the realm of outdoor machinery, understanding the nuances of maintenance is crucial for ensuring longevity and optimal performance. This section aims to equip users with essential knowledge and insights, focusing on practical techniques and problem-solving strategies. With a thorough grasp of these principles, operators can confidently tackle various challenges that arise during regular use.

Whether dealing with minor adjustments or more complex issues, having access to detailed guidance fosters a proactive approach to care and upkeep. This resource will serve as a valuable companion, providing step-by-step instructions and tips tailored to enhance the functionality of your equipment. Empowering yourself with this information not only saves time and effort but also enhances the overall experience of using your machinery.

Through a clear understanding of common components and their operations, users can identify potential pitfalls and execute effective solutions. Emphasizing the importance of regular checks and timely interventions, this guide underscores the significance of a well-informed operator in the successful management of outdoor equipment.

Overview of John Deere LA130

This section provides a comprehensive look at a specific model designed for residential landscaping tasks. Renowned for its durability and performance, this equipment is an essential tool for maintaining lawns and gardens effectively.

Key Features

Among the notable attributes of this model are its powerful engine and user-friendly controls. The design emphasizes ease of operation, allowing users to navigate various terrains effortlessly. Additionally, the cutting system is engineered for optimal grass handling, ensuring a clean and precise finish.

Maintenance Considerations

To ensure longevity and peak performance, regular upkeep is essential. This involves routine checks of the engine, blades, and overall mechanical components. Staying proactive with maintenance tasks can significantly extend the lifespan of this vital equipment.

Common Issues with the LA130

Many users encounter various challenges with their equipment, affecting performance and usability. Understanding these common problems can assist in troubleshooting and maintaining optimal functionality.

Starting Difficulties: One prevalent issue is the difficulty in starting the machinery. This can be attributed to battery failure, fuel system blockages, or electrical connection problems.

Cutting Performance: Users often report inconsistent cutting results. This may stem from dull blades, incorrect height settings, or buildup of debris beneath the cutting deck.

Transmission Concerns: Another frequent challenge involves the transmission system, which may exhibit slipping or hesitation. This could result from low fluid levels, worn components, or misalignment issues.

Overheating: Overheating is also a common complaint, potentially caused by blocked air vents, low coolant levels, or malfunctioning cooling fans.

Addressing these typical challenges can enhance the longevity and efficiency of the equipment, ensuring a smoother operational experience.

Tools Needed for Repairs

When maintaining machinery, having the right equipment is essential for effective troubleshooting and enhancement. This section outlines the necessary instruments to facilitate various tasks, ensuring efficiency and safety throughout the process.

Basic Hand Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and fixed)

- Pliers (needle-nose and standard)

- Socket set

Specialized Equipment

- Torque wrench

- Multimeter for electrical diagnostics

- Grease gun for lubrication

- Jack and jack stands for lifting

Equipping yourself with these tools not only streamlines the maintenance process but also enhances safety and performance during each task.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of outdoor machinery. This section outlines a systematic approach to maintaining your equipment, focusing on key tasks that should be performed periodically to keep it in top condition.

Routine Inspection

Begin with a thorough examination of the unit. Check for any signs of wear or damage, paying close attention to moving parts and connection points. Inspecting belts, filters, and fluids will help identify potential issues before they escalate. Ensure that all fasteners are secure and that there are no leaks.

Cleaning and Lubrication

After the inspection, proceed to clean various components. Remove dirt, debris, and grass clippings from the exterior and undercarriage. Use appropriate cleaning agents and tools to avoid damage. Lubrication of moving parts is crucial; apply suitable lubricants to bearings, gears, and pivot points to enhance functionality and reduce friction.

How to Replace the Blades

Changing the cutting elements on your lawn care equipment is essential for maintaining an effective and healthy lawn. Sharp and well-aligned blades ensure a clean cut, promoting healthier grass growth and reducing the risk of disease. This process requires attention to detail and a few basic tools.

Gather Necessary Tools

Before starting, make sure you have all the required tools at hand. Common items include a socket wrench, a jack or lift for safety, and protective gloves. Having everything ready will make the process smoother and more efficient.

Remove and Replace the Blades

Begin by lifting the machine securely to access the cutting area. Once exposed, use the socket wrench to remove the bolts holding the blades in place. Carefully detach the old elements and inspect the mounting areas for any debris. Install the new blades, ensuring they are properly aligned and securely fastened before lowering the equipment back to the ground.

Troubleshooting Engine Problems

Addressing issues related to the engine is crucial for maintaining optimal performance. Identifying common symptoms and applying effective solutions can enhance the longevity of your equipment. This section will guide you through various problems and their potential fixes to ensure smooth operation.

Common Symptoms and Causes

Engines may exhibit a variety of signs indicating trouble. Common issues include:

- Difficulty starting: This may stem from a weak battery, fuel delivery problems, or ignition failures.

- Unusual noises: Sounds such as knocking or grinding could signal internal damage or lack of lubrication.

- Overheating: Blocked cooling systems or low coolant levels often lead to excessive temperatures.

Effective Solutions

To resolve engine-related issues, consider the following approaches:

- Battery check: Ensure that the battery is fully charged and connections are secure.

- Fuel inspection: Examine the fuel lines for clogs and verify that the correct fuel type is used.

- Cooling system maintenance: Flush and refill the coolant as needed, and inspect hoses for leaks.

Electrical System Diagnostics

The assessment of the electrical framework is crucial for ensuring optimal performance and longevity of equipment. This process involves identifying and resolving issues related to power distribution, wiring integrity, and component functionality. A systematic approach aids in pinpointing faults and enhancing operational efficiency.

Initially, verifying the power source is essential. Testing the voltage levels can determine if the supply is adequate. Following this, examining wiring connections for any signs of wear or damage is vital. Loose or corroded connections can lead to significant operational issues, so addressing these is necessary for reliable performance.

Furthermore, utilizing diagnostic tools can provide insights into the functionality of electrical components. Multimeters and circuit testers are invaluable in measuring current flow and resistance, helping to identify malfunctioning parts. A thorough examination of switches and relays can also uncover hidden faults that might impede performance.

In conclusion, a comprehensive evaluation of the electrical system not only resolves existing problems but also prevents potential failures. Regular diagnostics and maintenance practices contribute to the reliability and efficiency of the machinery, ensuring smooth operations over time.

Transmission and Drive System Care

Maintaining the transmission and drive mechanism of your equipment is essential for optimal performance and longevity. Regular care ensures smooth operation, enhances efficiency, and minimizes the risk of unexpected breakdowns.

Routine Inspections: Conduct frequent examinations of the drive components to detect wear and tear. Look for signs of leaks, unusual noises, or any irregularities that might indicate potential issues. Early identification can prevent costly repairs.

Fluid Levels: Check and maintain appropriate fluid levels in the transmission system. Adequate lubrication is crucial for reducing friction and heat, which can lead to component failure. Always use the recommended fluids specified by the manufacturer.

Cleaning: Keep the area around the transmission and drive parts clean and free of debris. Accumulated dirt and grime can hinder performance and lead to overheating. Use a soft brush or cloth to remove buildup, ensuring all ventilation areas remain unobstructed.

Adjustments: Periodically check and adjust the drive belt tension as needed. Proper tension ensures efficient power transfer and reduces strain on the system. Consult the guidelines for the correct tension specifications to maintain optimal operation.

Storage Practices: When storing equipment, take care to protect the transmission and drive components. Ensure they are covered and shielded from moisture and extreme temperatures, which can adversely affect their performance.

By following these care practices, you can enhance the reliability and efficiency of your transmission and drive system, ensuring your equipment remains in excellent working condition for years to come.

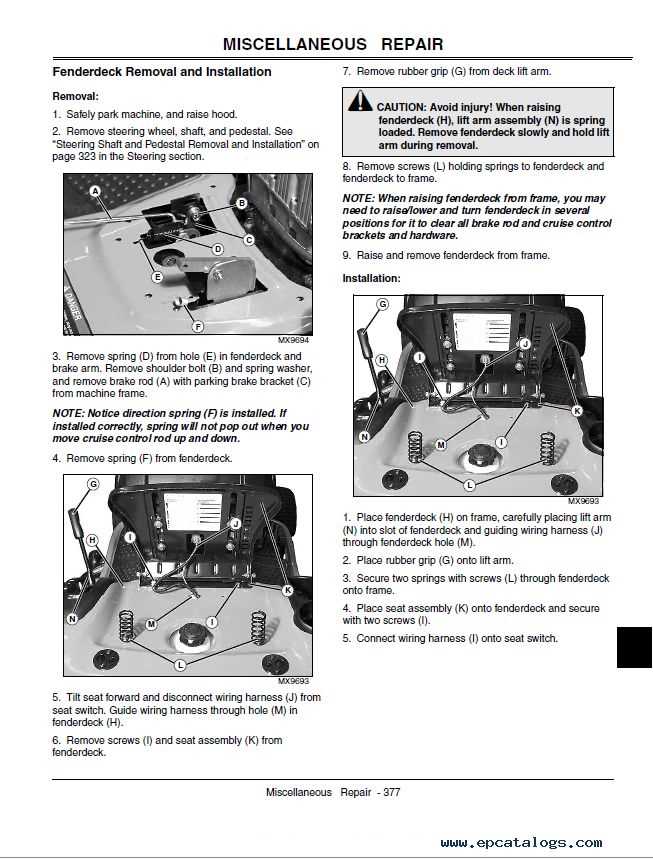

Cleaning and Caring for the Deck

Maintaining the surface of your cutting equipment is essential for optimal performance and longevity. Regular cleaning prevents buildup of grass and debris, ensuring a clean cut and enhancing the lifespan of the machinery.

Essential Cleaning Steps

- Ensure the engine is off and the equipment is cool before starting.

- Lift the deck to access the underside easily.

- Use a brush or scraper to remove any clippings or dirt.

- Rinse with a hose to wash away loosened debris.

- Dry thoroughly to prevent rust formation.

Preventive Care Tips

- Apply a protective coating to the underside to reduce buildup.

- Check for any damage or wear on the blades regularly.

- Lubricate moving parts to maintain smooth operation.

- Store the equipment in a dry place to avoid moisture exposure.

Adjusting the Cutting Height

Properly setting the elevation for the cutting blades is essential for achieving an even and healthy lawn. The ideal height can vary based on grass type and seasonal conditions, making it important to understand the adjustment process to ensure optimal performance of your equipment.

Tools Required

To adjust the cutting height effectively, you will need a few basic tools. These typically include a measuring tape, a wrench or socket set, and possibly a leveling tool to ensure accuracy during the adjustment process. Having these tools on hand will facilitate a smooth adjustment experience.

Adjustment Procedure

Start by positioning the equipment on a flat surface to guarantee accurate readings. Measure the current height of the blades from the ground. Most models have an adjustable mechanism, often found near the wheel assemblies. Turn the adjustment knob or lever to raise or lower the blades to the desired height. After making the adjustments, it’s advisable to recheck the height to confirm it meets your specifications before use.

Winterizing Your Lawn Mower

Preparing your grass cutting machine for the colder months is essential to ensure its longevity and optimal performance. Proper seasonal maintenance helps to protect the engine, prevent damage from frost, and ensures that your equipment is ready for use when spring arrives. This guide outlines key steps to effectively winterize your lawn care device.

Cleaning and Maintenance

Begin by thoroughly cleaning the exterior and underside of the machine to remove any grass clippings, dirt, or debris. Use a brush or a gentle spray of water, taking care not to saturate electrical components. Next, inspect the blades for wear and sharpen or replace them as necessary. Neglecting this step can lead to inefficient cutting and potential engine strain.

Fuel and Lubrication

For optimal preservation, drain the fuel tank to prevent any leftover gasoline from deteriorating and causing engine issues. Alternatively, you can add a fuel stabilizer to the remaining fuel and run the engine for a few minutes to circulate the mixture. Additionally, lubricate all moving parts, including cables and joints, to prevent rust and ensure smooth operation when you resume use in the spring. This simple maintenance can save you from costly repairs down the line.

Finding Replacement Parts

Locating suitable components for maintenance and restoration tasks can be crucial for ensuring optimal performance of your equipment. With a variety of sources available, it’s important to know where to look and how to identify the right pieces for your specific needs.

Online Resources

Many websites specialize in offering components for various machinery, allowing users to search by model and specifications. These platforms often provide detailed descriptions, compatibility information, and customer reviews, helping to make informed choices.

Local Dealers and Distributors

Another reliable option is to consult local dealers or distributors who carry parts for your equipment. Visiting a physical store can also provide the advantage of personalized assistance, enabling you to ask questions and confirm compatibility before making a purchase.