Maintaining outdoor machinery is essential for optimal performance and longevity. This section provides insights into common issues that may arise with your equipment, along with effective solutions. Understanding the intricacies of your machine can significantly enhance its functionality and prevent unnecessary breakdowns.

From basic upkeep to complex troubleshooting, having a thorough understanding of the necessary procedures is crucial. This guide is designed to empower users by offering detailed information that covers various aspects of machinery care. Whether you are a seasoned operator or a novice, the tips and techniques outlined here will help you tackle any challenges you may encounter.

Investing time in proper maintenance not only extends the life of your equipment but also ensures safety and efficiency during operation. By familiarizing yourself with the key components and their functions, you can make informed decisions and perform essential tasks with confidence. Dive into the specifics to enhance your knowledge and skills in maintaining your machinery effectively.

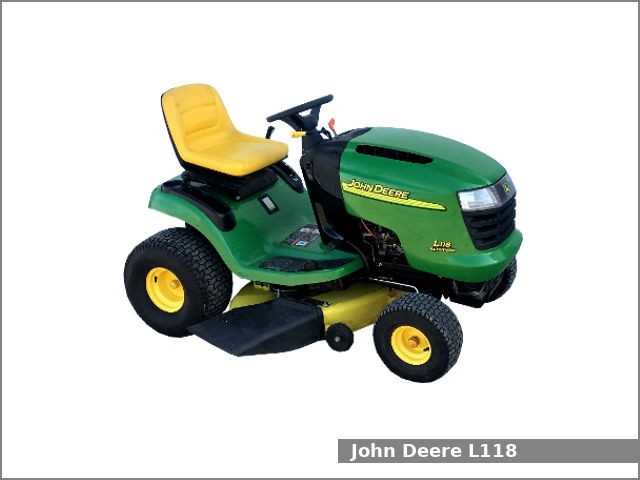

Understanding the John Deere L118

This section delves into the intricate workings and features of a popular lawn care machine. By exploring its design and functionality, users can better appreciate how it operates and the advantages it offers for maintaining outdoor spaces. Recognizing the key components and their roles is essential for effective usage and maintenance.

Key Features and Specifications

The machine boasts a robust engine and a user-friendly design, making it suitable for various landscaping tasks. Equipped with a reliable transmission system, it ensures smooth operation across different terrains. Additionally, the cutting deck is engineered for optimal grass handling, providing a clean and precise cut.

Maintenance and Care Tips

Regular upkeep is crucial for longevity. Routine checks on the engine, belts, and blades help prevent potential issues. Users should also pay attention to the oil levels and air filters, as these play a significant role in performance. By adhering to recommended practices, one can ensure that the equipment remains efficient and reliable over time.

Common Issues with the L118 Model

Every mechanical device can experience challenges over time, and this particular model is no exception. Users often encounter a range of typical problems that can affect performance and efficiency. Understanding these issues can help in troubleshooting and maintaining optimal functionality.

Engine Performance Problems

One of the most frequent concerns involves engine performance. Users may notice difficulties with starting, reduced power, or unusual noises during operation. These symptoms can stem from various factors, including fuel delivery issues, air filter blockages, or spark plug wear. Regular maintenance and inspections are essential to ensure that the engine runs smoothly.

Cutting Deck Malfunctions

Another common issue pertains to the cutting deck. Users might face uneven cutting, grass clumping, or the blades failing to engage properly. Such problems can arise from dull blades, improper deck height adjustments, or even debris buildup. Keeping the cutting deck clean and sharp is crucial for achieving a clean cut and maintaining the overall efficiency of the machine.

Essential Tools for Repair

Having the right equipment is crucial for maintaining and restoring machinery efficiently. This section outlines the fundamental instruments that can significantly ease the process, ensuring that tasks are completed effectively and safely.

First and foremost, a comprehensive set of wrenches is essential. Both metric and imperial sizes should be included to accommodate various fasteners. Additionally, socket sets provide the versatility needed for different applications, allowing for quick adjustments and tight fittings.

Moreover, screwdrivers of various types and sizes are necessary to tackle different screws, from flathead to Phillips. A reliable set of pliers is also invaluable, as they can grip, twist, and cut with precision, making them a versatile tool for numerous tasks.

For electrical components, having a multimeter is crucial for diagnosing issues and ensuring connections are functioning properly. A sturdy workbench with a vise can facilitate repairs by providing stability and support during intricate tasks.

Lastly, safety gear, including gloves and goggles, should never be overlooked. Protecting oneself while working on machinery is paramount to prevent injuries and ensure a smooth workflow.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your equipment in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of your machinery. Following a structured routine can prevent minor issues from escalating into significant problems.

1. Check the Oil Level: Begin by ensuring that the engine oil is at the appropriate level. Low oil can lead to severe engine damage. Use the dipstick to assess the level and top off if necessary.

2. Inspect the Air Filter: A clean air filter is vital for efficient operation. Remove the filter and check for dirt and debris. Clean or replace it as needed to maintain proper airflow.

3. Sharpen the Blades: Dull blades can result in uneven cutting and additional strain on the engine. Regularly inspect and sharpen the blades to achieve a clean cut.

4. Check the Tires: Proper tire pressure is essential for stability and performance. Inspect the tires for wear and maintain the recommended pressure levels.

5. Clean the Undercarriage: Remove grass clippings and debris from the undercarriage to prevent rust and ensure smooth operation. A clean surface also helps with efficient grass discharge.

6. Battery Maintenance: Check the battery terminals for corrosion and ensure a secure connection. Clean as necessary and test the battery’s charge level regularly.

7. Inspect Belts and Cables: Examine all belts and cables for wear or damage. Replace any that show signs of fraying to avoid unexpected failures during operation.

By following these straightforward steps, you can ensure that your machinery runs smoothly and efficiently for years to come. Regular attention to these areas minimizes the risk of breakdowns and enhances overall performance.

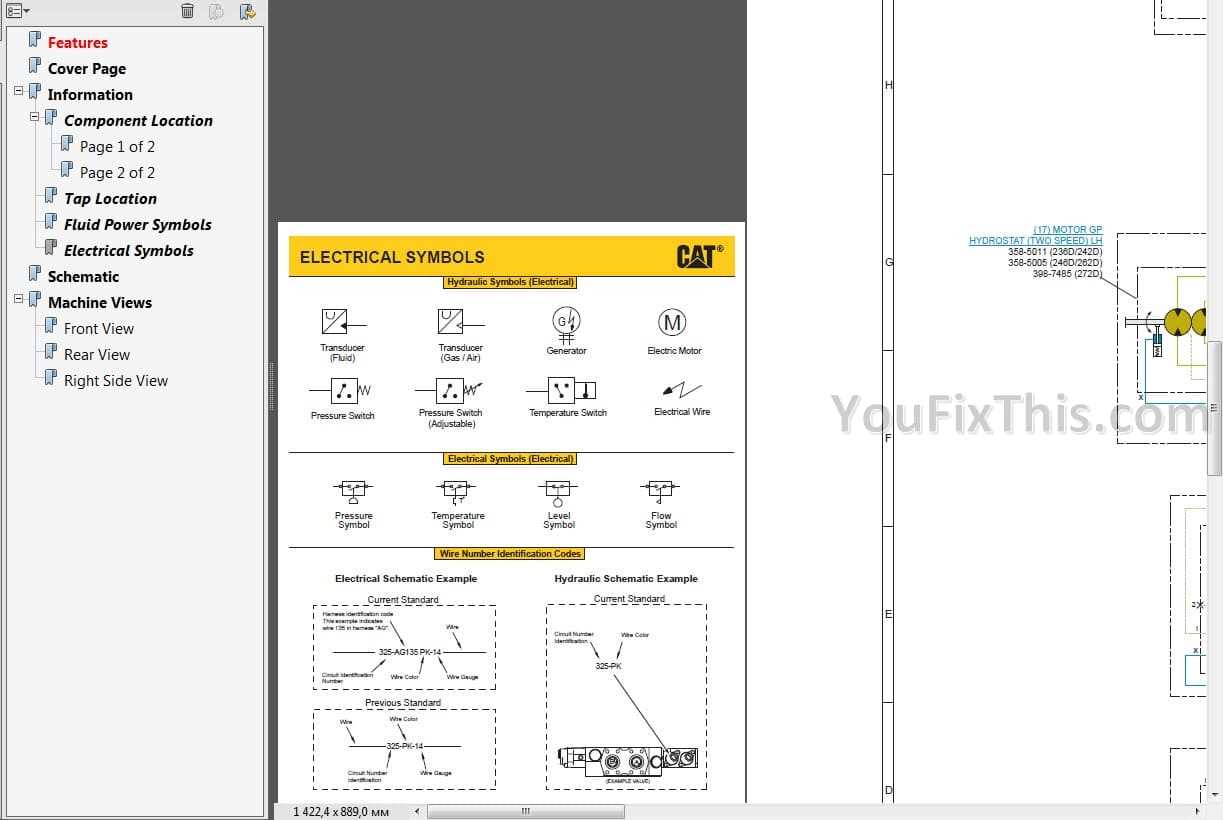

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of your machine is essential for optimal performance. By systematically evaluating the various components, you can identify and rectify problems that may hinder functionality. Understanding the common symptoms and their underlying causes will enable efficient resolution.

Begin your troubleshooting process by checking the power source and connections. Loose or corroded terminals can lead to poor conductivity, causing intermittent power failures. Use a multimeter to assess voltage levels and continuity.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No power | Dead battery | Charge or replace the battery |

| Lights dim | Poor connection | Inspect and clean connections |

| Intermittent starting | Faulty ignition switch | Test and replace switch if necessary |

| Blown fuse | Overload or short circuit | Check for shorts and replace fuse |

By following these steps and addressing the highlighted issues, you can ensure that the electrical system operates smoothly, thereby enhancing the overall performance of your equipment.

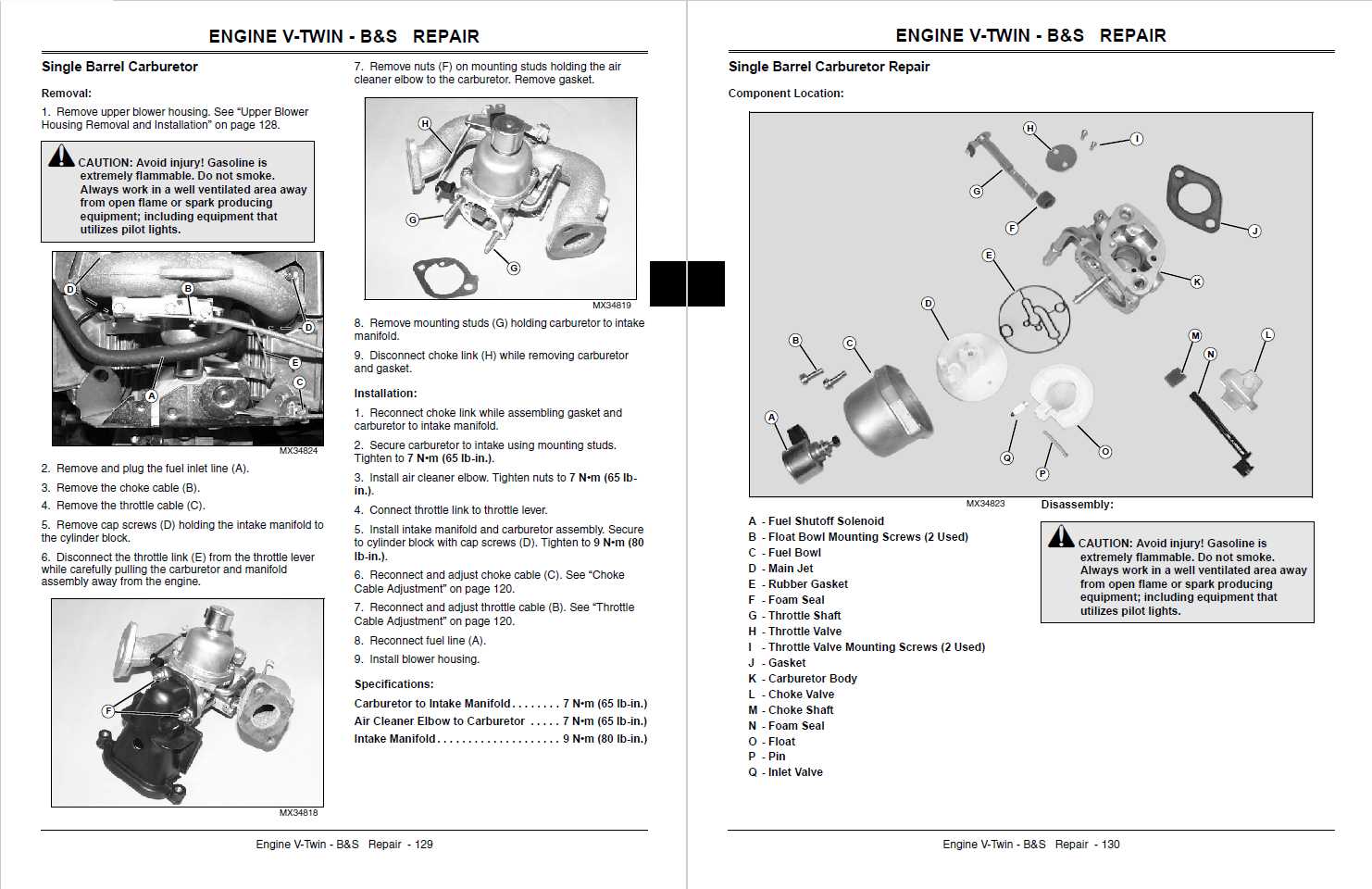

Engine Problems and Solutions

Engines are complex machines that can encounter various issues over time, affecting performance and reliability. Identifying these problems promptly can help prevent further damage and ensure smooth operation. This section outlines common engine troubles and provides practical solutions to address them effectively.

One frequent issue is overheating, which can be caused by low coolant levels or a malfunctioning thermostat. To resolve this, check the coolant reservoir and refill as necessary. If the thermostat is faulty, replacing it will often restore normal operating temperatures.

Another common concern is difficulty starting the engine. This may stem from a weak battery or fuel delivery problems. Inspect the battery for charge and connections; if necessary, jump-start or replace it. Additionally, ensure that fuel lines are clear and the fuel filter is not clogged.

Unusual noises, such as knocking or grinding, can indicate internal wear or damage. Listening carefully can help pinpoint the source. If the noise persists, it’s advisable to consult a professional for an in-depth inspection to avoid serious complications.

Lastly, poor fuel efficiency can signal a range of issues, from dirty air filters to improper tire pressure. Regularly replacing air filters and checking tire inflation can significantly improve overall efficiency. For persistent problems, a thorough diagnostic may be necessary to identify underlying causes.

Deck and Blade Maintenance Tips

Maintaining the cutting deck and blades of your lawn equipment is essential for ensuring optimal performance and achieving a well-manicured lawn. Regular care not only extends the lifespan of these components but also enhances cutting efficiency, resulting in a healthier and more vibrant landscape.

Cleaning and Inspection

Regular cleaning of the deck and blades is crucial to prevent grass buildup and rust. After each use, remove any clippings and debris using a brush or a hose. Inspect the blades for wear or damage; sharp blades make clean cuts, while dull ones can tear grass, leading to a stressed lawn. For best results, sharpen blades at least once per season or as needed.

Proper Adjustment and Storage

Ensure that the cutting height is correctly adjusted to suit your lawn type and conditions. This not only promotes healthy growth but also prevents scalping. Additionally, store your equipment in a dry place to avoid moisture-related issues. Before the off-season, consider performing a thorough inspection and making necessary adjustments to prepare for the next mowing cycle.

Fuel System Care Instructions

Proper maintenance of the fuel system is essential for optimal performance and longevity of the machinery. Regular attention to this area can prevent costly issues and ensure smooth operation. Following these guidelines will help you keep the fuel system in top condition.

Routine Checks

- Inspect fuel lines for cracks or leaks.

- Check fuel filters regularly and replace as needed.

- Ensure that the fuel tank is clean and free of debris.

Fuel Quality

- Use high-quality fuel to prevent engine problems.

- Avoid storing fuel for extended periods to reduce contamination.

- Consider adding fuel stabilizers if storage is necessary.

By adhering to these practices, you can effectively enhance the functionality and reliability of the equipment’s fuel system.

Seasonal Checklists for Longevity

Maintaining equipment throughout the year is essential for optimal performance and durability. By following specific seasonal guidelines, owners can ensure that their machinery remains in peak condition, ready for use whenever needed. These checklists not only help in identifying potential issues early but also enhance the overall lifespan of the tools.

Spring: Begin with a thorough inspection. Clean filters and replace oils to prepare for heavy use. Check belts and hoses for wear, ensuring everything is functioning smoothly.

Summer: Monitor cooling systems closely during hot months. Ensure that batteries are charged and connections are secure. Regularly clean the exterior to prevent overheating and buildup of debris.

Fall: As the season changes, prepare for storage. Drain fluids as necessary, and check for rust or damage. Cover the machinery to protect it from the elements and ensure proper ventilation.

Winter: Conduct a full inspection before hibernation. Maintain battery charge levels and keep equipment clean. Consider using fuel stabilizers to prevent degradation during storage.

By adhering to these seasonal practices, owners can significantly prolong the life and efficiency of their equipment, ensuring it remains reliable for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can greatly enhance its performance and longevity. Whether you are in need of specific items due to wear and tear or upgrades, understanding the best sources can save time and ensure quality.

Authorized Dealers

One of the most reliable sources for components is through authorized dealers. These establishments typically offer genuine products that are guaranteed to fit your machinery. Additionally, staff members are often knowledgeable about compatibility and can assist in identifying the right parts for your needs.

Online Marketplaces

The internet is a treasure trove for sourcing replacement components. Websites dedicated to machinery parts frequently feature a wide array of options, including new, refurbished, and aftermarket items. When shopping online, ensure to verify the seller’s reputation and check customer reviews to avoid any pitfalls.

Remember: Always cross-reference part numbers and specifications to confirm compatibility before making a purchase. This will help ensure you get the correct items for effective repairs and maintenance.

Safety Precautions During Repairs

Ensuring a safe working environment is essential when conducting maintenance tasks on equipment. Taking the necessary precautions can prevent accidents and promote efficiency. Being mindful of potential hazards and implementing protective measures will help create a secure atmosphere for both the technician and the machinery involved.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes items such as gloves, goggles, and sturdy footwear to safeguard against injuries. Proper attire minimizes the risk of cuts, bruises, or exposure to harmful substances. Additionally, ensuring that hair is secured and loose clothing is avoided can further enhance safety during maintenance activities.

Work Area Organization

Maintaining a tidy and organized work area significantly reduces the likelihood of accidents. Tools should be stored in designated locations, and any spills should be cleaned immediately to prevent slips. Clear pathways and adequate lighting are also vital in promoting a safe working environment, allowing for easy movement and visibility throughout the task.