Effective upkeep of agricultural machinery is essential for optimal performance and longevity. This resource aims to provide essential insights into the intricacies of maintaining a specific model of equipment, ensuring that users can efficiently address common issues and perform routine checks. By following systematic guidelines, operators can enhance the lifespan and reliability of their machines.

Understanding the mechanics and functionalities of your machinery is crucial for preventing malfunctions and ensuring smooth operations. This guide delves into the various components that require regular attention, offering practical advice and step-by-step procedures. Equipped with this knowledge, users can confidently navigate the challenges of maintenance.

In addition to routine checks, recognizing the signs of wear and tear is vital. This document will highlight key indicators that suggest when intervention is necessary, allowing for timely repairs and minimizing downtime. Emphasizing a proactive approach can save both time and resources in the long run.

Ultimately, mastering the art of equipment care empowers operators, providing them with the skills to tackle issues head-on. Whether you’re a seasoned professional or a novice, this guide serves as a valuable tool in ensuring that your machinery continues to perform at its best.

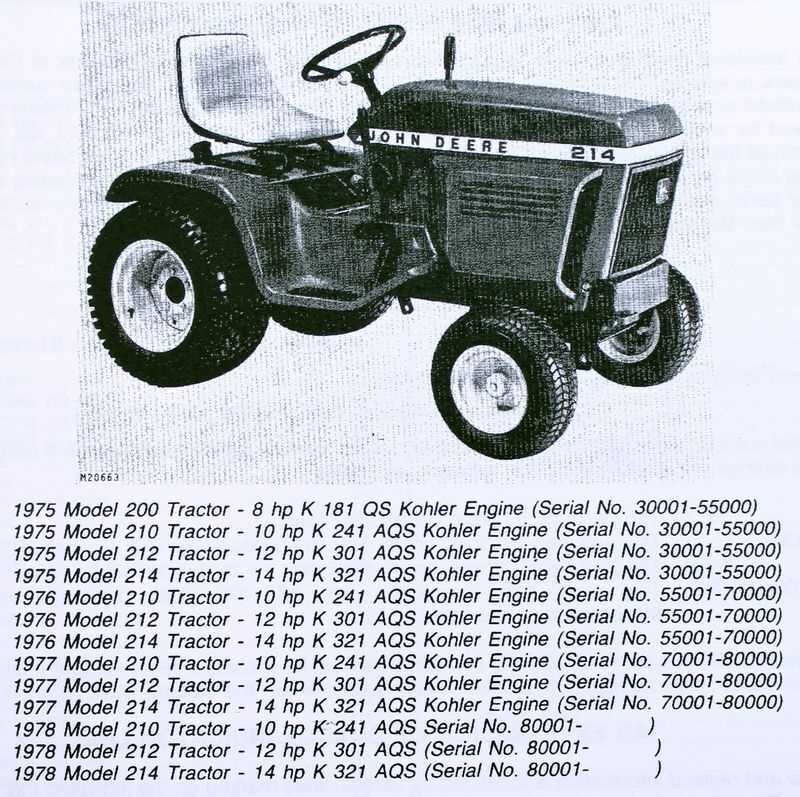

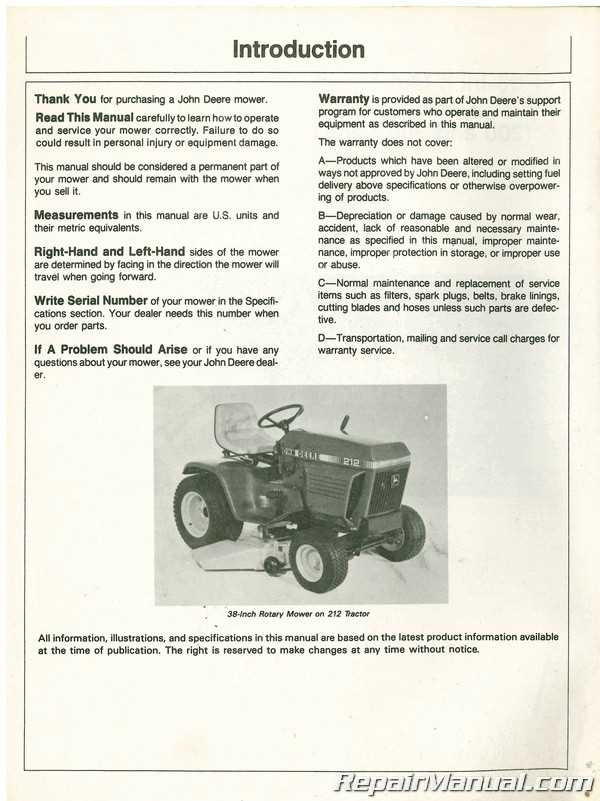

Overview of John Deere 212

This section aims to provide a comprehensive look at a well-known lawn and garden equipment model, highlighting its features, specifications, and overall significance in the realm of outdoor machinery. With a focus on its design and performance, we will explore what sets this model apart from its peers.

Features and Specifications

The model boasts a robust engine and user-friendly controls, making it suitable for various landscaping tasks. It is equipped with a durable cutting deck that enhances efficiency and ensures a clean cut. Additionally, its compact design allows for easy maneuverability in tight spaces.

Significance in the Market

This model has earned a reputation for reliability and performance, appealing to both homeowners and professionals. Its combination of power and versatility has made it a popular choice among enthusiasts, solidifying its place in the competitive outdoor equipment landscape.

Common Issues with John Deere 212

When it comes to lawn maintenance machinery, certain challenges frequently arise, impacting performance and efficiency. Understanding these common problems can help users identify and address them promptly, ensuring smooth operation and longevity of the equipment.

Engine Troubles

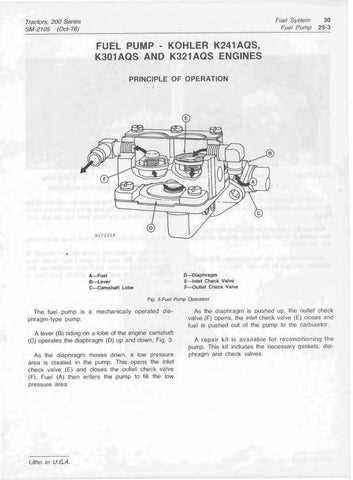

One prevalent issue involves the engine, which may exhibit difficulties starting or running smoothly. These symptoms could stem from various causes, such as fuel line blockages, faulty spark plugs, or air filter restrictions. Regular inspection and maintenance can mitigate these concerns and enhance reliability.

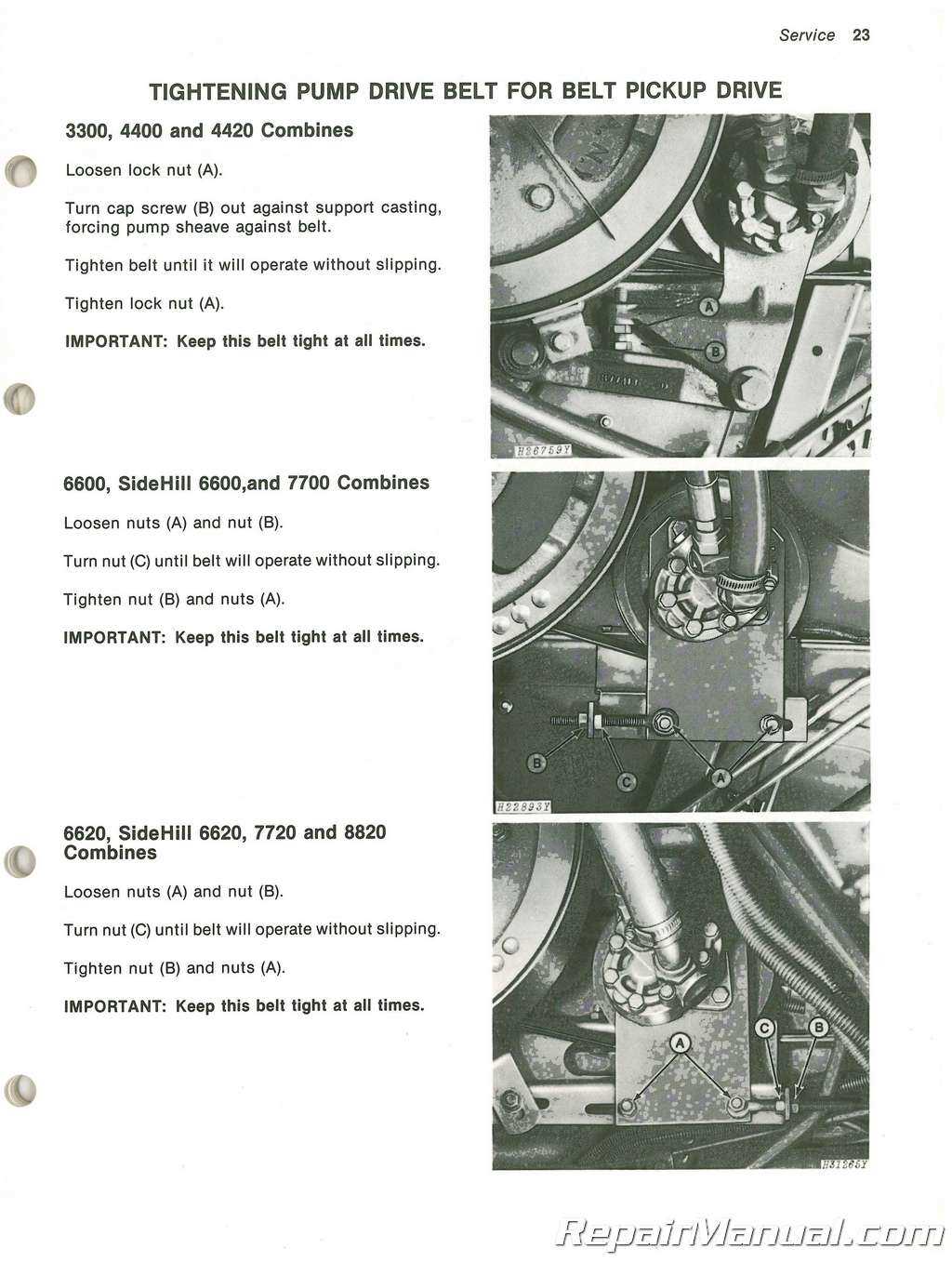

Transmission and Drive Problems

Another area of concern often pertains to the transmission system. Users may encounter issues with shifting gears or unexpected slips while driving. This can result from low fluid levels, worn-out belts, or misaligned components. Ensuring proper lubrication and timely replacements can help maintain optimal functionality.

Essential Tools for Repair

Having the right instruments on hand is crucial for effective maintenance and troubleshooting. A well-equipped workspace not only enhances efficiency but also ensures safety during the process. Below are some indispensable items that every technician should consider when undertaking mechanical tasks.

Basic Hand Tools

- Wrenches: A variety of sizes is essential for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips types should be included for different applications.

- Pliers: Useful for gripping, twisting, and cutting wire or small components.

- Socket Sets: These allow for quick changes between different sizes, ideal for various nuts and bolts.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Multimeter: A vital tool for diagnosing electrical issues and measuring voltage, current, and resistance.

- Oil Filter Wrench: Simplifies the removal of oil filters, particularly in tight spaces.

- Grease Gun: Essential for lubricating moving parts to prolong their lifespan.

Equipping yourself with these tools will facilitate a smoother workflow and enhance the likelihood of successful outcomes in any mechanical endeavor.

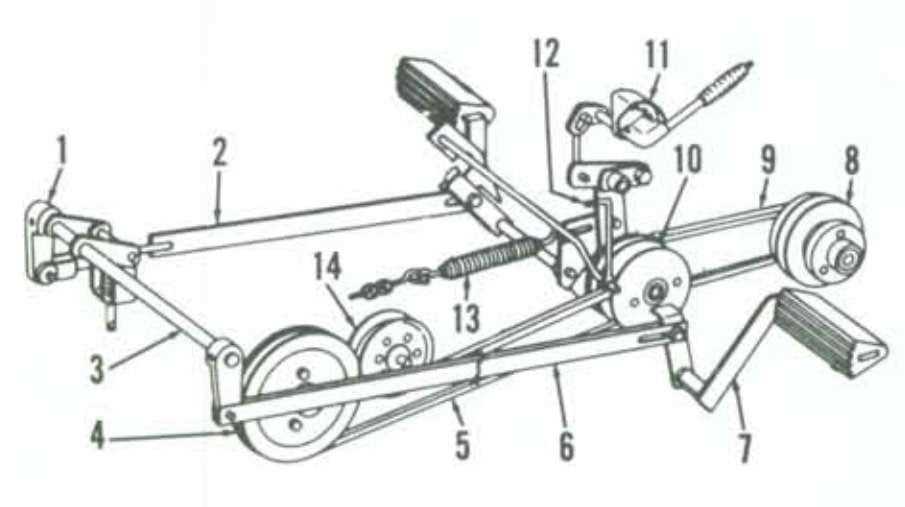

Step-by-Step Repair Procedures

This section provides a comprehensive approach to addressing common issues with your equipment. Following a structured process can significantly enhance your efficiency and ensure a successful resolution to any malfunctions. Each step is designed to guide you through troubleshooting, disassembly, and reassembly, emphasizing clarity and safety throughout the operation.

Initial Diagnosis

Begin by identifying the symptoms your machinery is exhibiting. Observation is crucial; take note of any unusual sounds, vibrations, or performance issues. Consult the specifications to compare expected vs. actual performance. Document your findings, as this information will be valuable in guiding your subsequent steps.

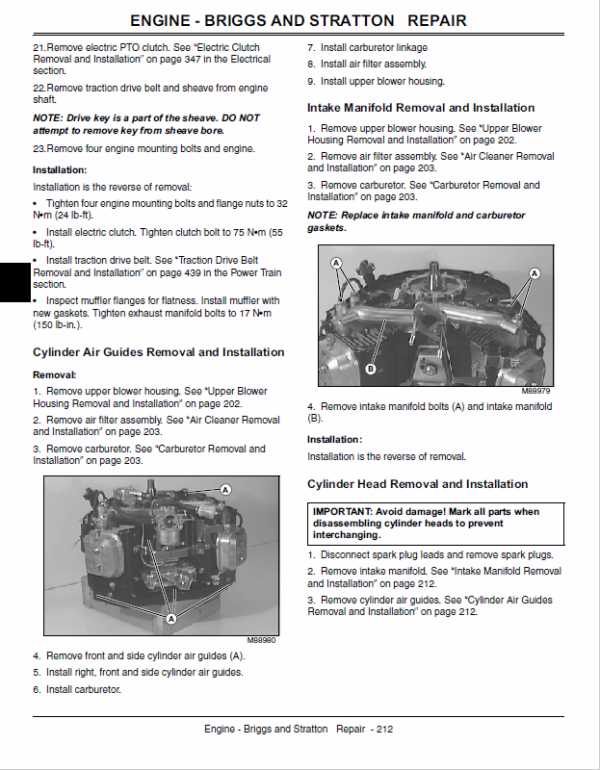

Disassembly and Inspection

Once you have pinpointed the area of concern, carefully disassemble the relevant components. Utilize appropriate tools to avoid damage. Safety should always be your priority; ensure that the machine is powered off and disconnected from any energy sources. As you disassemble, inspect each part for wear and tear, taking note of any components that require replacement. A meticulous inspection will help in avoiding future issues.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires regular attention and care. By following some essential maintenance practices, you can prevent wear and tear, enhance performance, and minimize costly repairs. Consistent upkeep not only optimizes efficiency but also guarantees reliable operation when you need it most.

Routine Inspections

Conducting regular inspections is critical for identifying potential issues before they escalate. Look for signs of wear, unusual noises, or fluid leaks. Keeping a maintenance log can help track any changes over time.

Proper Lubrication

Maintaining adequate lubrication is vital for reducing friction and preventing component damage. Use the recommended lubricants and apply them at specified intervals to ensure all moving parts operate smoothly.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Checks | Weekly | Check oil and coolant levels regularly. |

| Filter Replacement | Every 50 hours | Replace air and fuel filters to maintain efficiency. |

| Tire Inspection | Monthly | Check tire pressure and tread for safety. |

Parts Replacement Guidelines

When dealing with machinery maintenance, proper guidelines for component replacement are essential to ensure optimal performance and longevity. Understanding when and how to substitute parts can significantly affect the overall functionality and reliability of the equipment.

Before proceeding with any substitutions, it is crucial to identify the specific part that needs replacement. Conduct a thorough inspection to diagnose the issue accurately. Refer to the specifications and recommendations provided by the manufacturer to select appropriate replacement components that match the original equipment in terms of size, shape, and functionality.

Once the correct part is identified, follow systematic procedures for removal and installation. Ensure that all necessary tools are on hand to avoid interruptions during the process. Pay attention to safety precautions to prevent injuries or damage to other parts of the machinery.

After installation, test the equipment under normal operating conditions to confirm that the replacement has been successful. Monitor the performance closely for a period following the replacement to detect any anomalies early on.

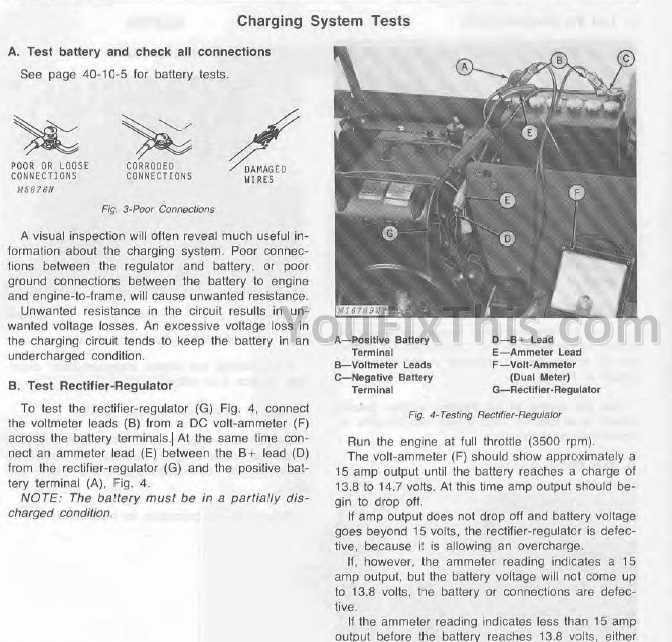

Electrical System Troubleshooting

The electrical system of machinery is vital for optimal performance, and identifying issues can be crucial for effective operation. This section focuses on common problems that may arise within the electrical components and provides guidance on how to diagnose and resolve them efficiently.

1. Power Issues: If the equipment fails to start, it may be due to battery problems, poor connections, or blown fuses. Begin by checking the battery charge and terminals for corrosion. Ensure that all wiring is intact and that the fuse is functioning properly.

2. Faulty Components: Components such as the ignition switch, relays, and sensors can malfunction, leading to erratic behavior. Test each part individually to confirm their operational status. Replacing defective components can restore proper functionality.

3. Grounding Problems: Inadequate grounding can cause electrical shorts and erratic equipment performance. Verify that all ground connections are secure and free from rust or damage.

4. Wiring Inspections: Inspect all wiring for signs of wear, fraying, or exposure. Damaged wires can lead to short circuits and other electrical issues. Replacing damaged wiring is essential for safety and reliability.

5. Diagnostic Tools: Utilize multimeters and test lights to measure voltage and continuity within the system. These tools can help pinpoint issues more accurately and save time during troubleshooting.

By following these guidelines, operators can effectively diagnose and address electrical concerns, ensuring their equipment remains reliable and efficient.

Engine Maintenance Best Practices

Ensuring optimal performance and longevity of an engine requires a commitment to regular upkeep and attention to detail. By following a set of established guidelines, operators can minimize downtime and maximize efficiency. This section outlines essential practices that contribute to the overall health of the engine.

Regular Oil Changes

One of the most critical aspects of engine care is the timely replacement of lubricating oil. Over time, oil can degrade and lose its effectiveness, leading to increased friction and wear. Establishing a routine schedule for oil changes, based on operating hours or manufacturer recommendations, will help maintain smooth functionality and prevent costly repairs.

Air Filter Maintenance

The air filter plays a vital role in protecting the engine from harmful particles. A clean air filter ensures proper airflow, which is essential for efficient combustion. Regular inspection and replacement of the air filter, especially in dusty environments, can significantly enhance performance and fuel efficiency. Keeping this component in good condition is crucial for optimal engine operation.

Hydraulic System Care and Repair

Maintaining the functionality of a hydraulic system is essential for optimal performance in various machinery. This segment focuses on crucial practices and considerations for ensuring the longevity and efficiency of hydraulic components. Proper care can prevent costly breakdowns and enhance overall reliability.

Routine Maintenance

Regular inspection of hydraulic fluid levels and quality is vital. Contaminated fluid can lead to significant wear on components. It is advisable to change the hydraulic fluid according to the manufacturer’s recommendations. Additionally, keeping filters clean and replacing them as necessary helps in maintaining the system’s health.

Troubleshooting Common Issues

Identifying problems early can save time and resources. Common issues include leaks in hoses or fittings, which should be addressed promptly. Inspecting seals and connections can help in detecting potential failures before they escalate. Additionally, monitoring pressure levels can provide insights into system performance, enabling timely interventions.

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. A comprehensive seasonal checklist can help you identify critical tasks that need attention during different times of the year. By following these guidelines, you can maintain efficiency and avoid potential issues.

| Task | Spring | Summer | Fall | Winter |

|---|---|---|---|---|

| Inspect Fluids | Change oil and filter | Check coolant levels | Inspect fuel system | Drain fuel if not in use |

| Check Tires | Inspect for wear | Check pressure | Ensure proper inflation | Inspect for cracks |

| Clean Components | Wash and degrease | Remove debris | Clear air filters | Protect against moisture |

| Examine Belts and Cables | Inspect for fraying | Check tension | Replace if necessary | Lubricate connections |

| Test Safety Features | Check emergency stops | Inspect alarms | Verify lights | Ensure proper function |

Adhering to this seasonal checklist will contribute significantly to the reliable operation of your machinery, enhancing productivity and reducing the likelihood of breakdowns. Regular attention to these tasks fosters a proactive approach to maintenance, ensuring that your equipment is always ready for action.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when performing maintenance tasks on machinery. Proper precautions can prevent accidents, injuries, and equipment damage. Understanding the risks and adhering to safety protocols not only protects the individual but also enhances the efficiency of the maintenance process.

Essential Safety Measures

Before commencing any work, it is vital to assess the workspace and gather the necessary protective gear. Here are some key safety measures to consider:

| Safety Gear | Description |

|---|---|

| Gloves | Wear durable gloves to protect hands from sharp edges and hazardous materials. |

| Safety Glasses | Use safety glasses to shield eyes from debris and chemical splashes. |

| Steel-Toed Boots | Opt for steel-toed footwear to safeguard feet against heavy objects. |

| Ear Protection | Utilize ear protection when operating loud machinery to prevent hearing damage. |

Work Area Organization

Maintaining an organized workspace significantly reduces the likelihood of accidents. Ensure tools and materials are stored properly and that the area is free from clutter. Regularly inspect equipment for any faults before use to minimize risks and enhance safety during maintenance tasks.

Resources for Further Assistance

When facing challenges with your equipment, accessing reliable resources can significantly enhance your troubleshooting experience. This section aims to provide valuable avenues for obtaining additional guidance and information, ensuring you can effectively address any issues that may arise.

Online Forums and Communities

Engaging with fellow enthusiasts and professionals in online platforms can offer a wealth of knowledge. Many users share their experiences, solutions, and tips that can be beneficial for resolving various concerns. Below are some popular forums where you can seek help:

| Forum Name | Website | Focus Area |

|---|---|---|

| Tractor Forum | tractorforum.com | General equipment discussion |

| Garden Tractor Forums | gardentractorforum.com | Specific to garden tractors |

| Reddit: r/Tractors | reddit.com/r/Tractors | Community-driven discussions |

Professional Support Services

If you require more specialized assistance, consider reaching out to certified technicians or support services. These professionals can provide detailed insights and hands-on help tailored to your specific model. Here are a few options to consider:

| Service Provider | Contact Info | Specialization |

|---|---|---|

| Local Dealerships | Visit your local dealership for in-person support | Authorized servicing |

| Mobile Mechanics | Search for mobile mechanics in your area | On-site repairs and maintenance |

| Online Consultation Services | Check websites offering virtual consultations | Remote troubleshooting assistance |