Maintaining your lawn tractor is crucial for ensuring its longevity and optimal performance. With proper guidance, you can tackle common issues and enhance the efficiency of your machine. This section delves into the essential aspects of upkeep, offering insights and techniques that empower users to take charge of their equipment.

Understanding the Basics is the foundation of effective maintenance. Familiarizing yourself with the components and functionalities of your tractor will enable you to identify potential problems early. Whether it’s addressing minor adjustments or executing significant repairs, knowledge is your best ally.

Additionally, knowing the right tools and resources to utilize can make a substantial difference. Accessing detailed instructions and specifications tailored to your model ensures you are well-prepared for any task. This guide aims to equip you with the information needed to keep your lawn tractor running smoothly.

Understanding the John Deere GX345

This section delves into a popular model known for its robust performance and versatility in outdoor tasks. Recognized by many enthusiasts, this machine combines power and efficiency, making it suitable for various applications in lawn care and landscaping.

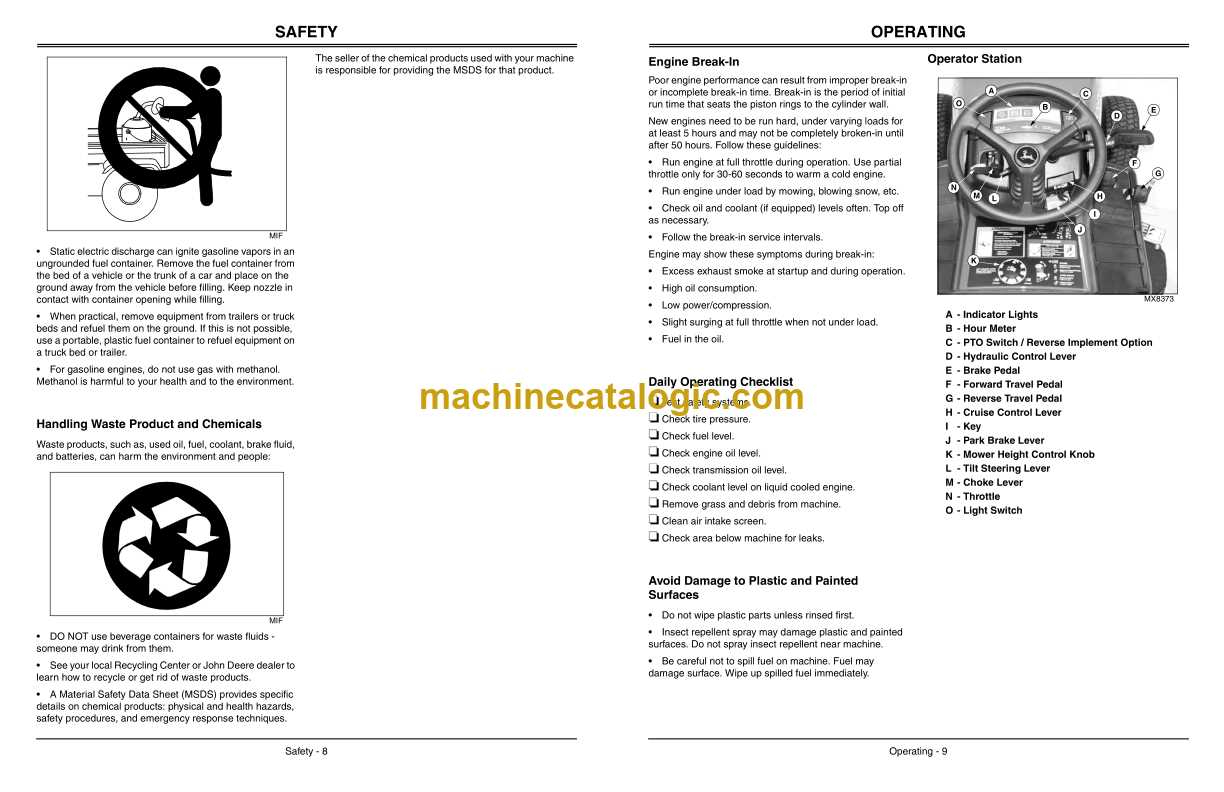

Equipped with a reliable engine, this unit delivers impressive torque and a smooth operation, ensuring that users can tackle even the toughest terrains with ease. The thoughtful design includes features that enhance usability, such as an ergonomic seating arrangement and intuitive controls, promoting a comfortable experience for operators.

Maintenance plays a crucial role in prolonging the lifespan of this equipment. Regular checks and timely servicing are essential for optimal functionality, enabling users to maximize productivity while minimizing downtime. Understanding the components and systems involved will empower owners to keep their machinery in peak condition.

In summary, familiarity with this outdoor tool not only enhances operational efficiency but also encourages a proactive approach to upkeep, ensuring that it remains a reliable asset for years to come.

Common Issues with GX345 Tractors

Tractors in this category often encounter a variety of challenges that can affect their performance and efficiency. Understanding these frequent problems can help owners address them promptly and maintain optimal functionality.

| Issue | Description | Potential Solution |

|---|---|---|

| Engine Starting Problems | Difficulty in starting the engine, which may be caused by fuel delivery issues or battery failures. | Check the battery charge and fuel levels; inspect the ignition system. |

| Overheating | Engine overheating can lead to significant damage and is often due to coolant leaks or blocked radiators. | Ensure proper coolant levels and clean any debris from the radiator. |

| Poor Cutting Performance | Inconsistent or uneven cutting can arise from dull blades or improper height settings. | Sharpen the blades and adjust the cutting height as needed. |

| Transmission Issues | Shifting problems may occur, hindering the operator’s ability to change speeds smoothly. | Inspect the transmission fluid and ensure the linkage is properly adjusted. |

| Electrical Failures | Malfunctions in the electrical system can lead to various operational issues, often due to corroded connections. | Examine and clean all electrical connections, and replace any damaged wires. |

Essential Tools for GX345 Repairs

Proper maintenance of your outdoor equipment requires a set of specific implements to ensure effective servicing. Having the right tools not only streamlines the process but also enhances safety and efficiency. This section will highlight the indispensable tools you should consider for handling various tasks.

Basic Tool Set

A foundational toolkit is essential for performing routine maintenance and minor fixes. The following table outlines the necessary items you should include:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For tightening and loosening bolts and nuts. |

| Flathead and Phillips Screwdrivers | For various screw types in assemblies. |

| Adjustable Wrench | For gripping and turning nuts and bolts of different sizes. |

| Pliers | For gripping, twisting, and cutting wires or small components. |

| Torque Wrench | To ensure bolts are tightened to the specified settings. |

Specialized Equipment

In addition to basic tools, specialized instruments may be necessary for more complex procedures. Consider the following:

| Tool | Purpose |

|---|---|

| Diagnostic Scanner | To read error codes and diagnose issues electronically. |

| Oil Filter Wrench | For easy removal and installation of oil filters. |

| Fuel Line Pliers | To assist in removing and replacing fuel lines safely. |

| Grease Gun | For lubricating joints and moving parts efficiently. |

| Multimeter | For checking electrical components and connections. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This comprehensive guide provides detailed instructions to help you maintain your machine effectively. By following these steps, you can prevent potential issues and enhance the overall efficiency of your machinery.

1. Check the Oil Level: Begin by examining the oil level using the dipstick. If it’s below the recommended mark, add the appropriate type of oil to keep the engine running smoothly.

2. Inspect the Air Filter: Remove the air filter and check for dirt and debris. A clean filter allows for better airflow, improving performance. Replace it if it’s excessively dirty.

3. Sharpen the Blades: Dull blades can lead to uneven cuts. Regularly inspect and sharpen them to ensure clean and efficient operation. Be cautious while handling sharp edges.

4. Clean the Deck: Remove grass clippings and debris from the underside of the cutting deck. This prevents rust and promotes better cutting efficiency.

5. Check Tire Pressure: Ensure that the tires are inflated to the recommended pressure. Properly inflated tires provide better traction and stability.

6. Examine the Battery: Inspect the battery terminals for corrosion and ensure a secure connection. Clean any buildup to maintain electrical efficiency.

7. Grease Moving Parts: Lubricate all moving components as specified in your guidelines. This reduces friction and wear, prolonging the life of the machine.

8. Inspect Belts and Cables: Regularly check for wear and tear on belts and cables. Replace any frayed or damaged parts to prevent operational issues.

9. Store Properly: After maintenance, store the equipment in a dry, sheltered location. This helps prevent weather-related damage and prolongs its lifespan.

By adhering to these maintenance steps, you can ensure that your equipment remains in peak condition, ready to perform whenever you need it.

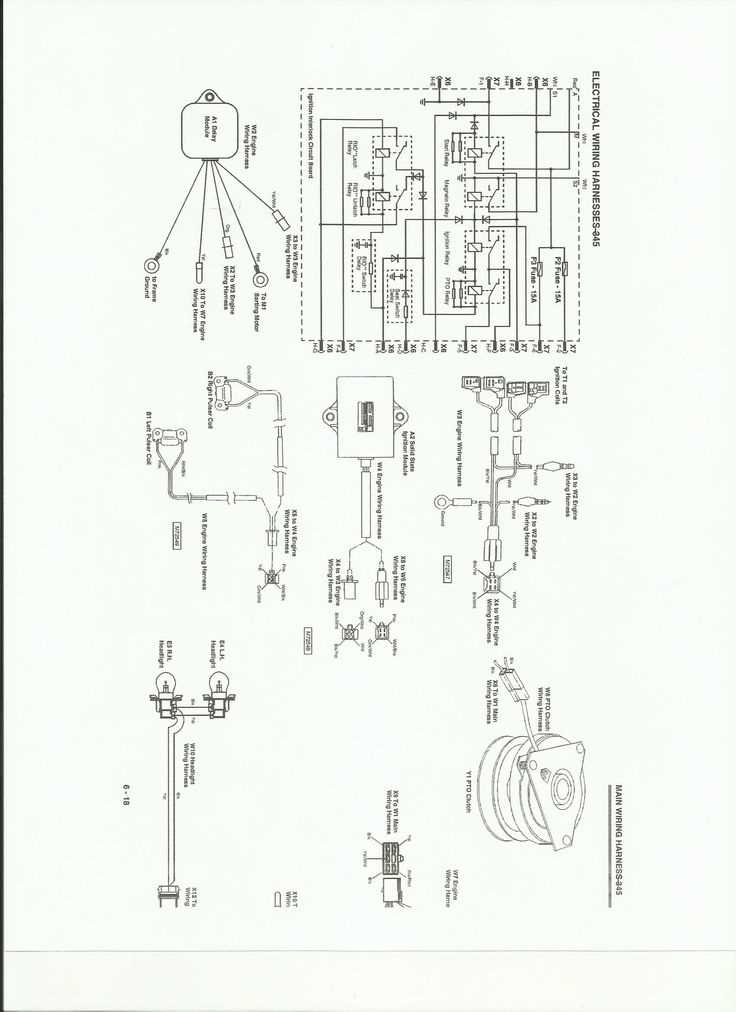

Diagnosing Electrical Problems

Identifying issues within the electrical system of your equipment can often be a complex task. It requires a systematic approach to pinpoint the source of the malfunction. By following a series of logical steps, you can effectively troubleshoot and resolve these complications, ensuring optimal performance and reliability.

Start by gathering basic information about the symptoms. Is there a complete power failure, or are certain components not functioning as intended? Observing any warning lights or unusual sounds can provide critical clues. Once you have an understanding of the symptoms, inspect the battery and connections. Corrosion or loose terminals can often lead to inadequate power supply.

Next, utilize a multimeter to test the voltage across different components. This tool is essential for verifying whether the electrical pathways are intact and if the proper voltage is reaching the necessary parts. Pay close attention to fuses; a blown fuse can be a simple fix that restores functionality.

If initial checks do not yield results, examine the wiring harness for any signs of damage, such as fraying or breaks. Additionally, consider checking the switches and relays, as these can often be overlooked yet play a vital role in the system’s operation. Document your findings, as keeping track of tests performed can aid in identifying patterns or recurring issues.

Finally, if the problem persists despite thorough inspection, consulting with a professional or referencing detailed guides may be necessary to delve deeper into complex circuitry or component failures. Proper diagnosis is key to ensuring your equipment remains in peak condition.

Engine Overhaul Procedures Explained

Overhauling an engine is a meticulous process aimed at restoring its performance and extending its lifespan. This task involves various steps that ensure each component functions optimally. Understanding these procedures is essential for effective maintenance and troubleshooting.

Preparation Steps

Before diving into the overhaul, proper preparation is crucial. Follow these steps:

- Gather necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review technical specifications and guidelines.

- Inspect the engine for visible damage or wear.

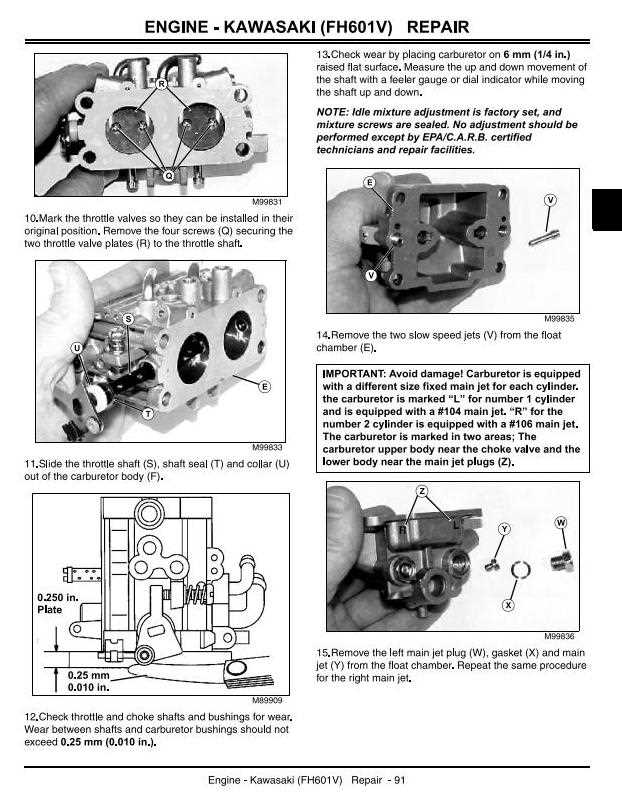

Disassembly and Inspection

Once preparations are complete, proceed with disassembly and inspection:

- Carefully remove the engine from its mount.

- Detach components such as the cylinder head, pistons, and crankshaft.

- Inspect each part for signs of wear, cracks, or other damage.

- Document findings to assist in the reassembly process.

Following these steps will lay the groundwork for a successful overhaul, ensuring that the engine operates at peak efficiency once reassembled.

Transmission Troubleshooting Tips

Maintaining optimal performance in your vehicle’s power transfer system is crucial for efficient operation. Identifying and resolving issues early can prevent costly repairs and extend the lifespan of your machinery. Below are some helpful guidelines to diagnose and address common transmission problems.

- Check Fluid Levels: Low or contaminated fluid can lead to poor performance. Regularly inspect the fluid levels and quality.

- Listen for Unusual Noises: Grinding, whining, or clunking sounds may indicate internal issues. Pay attention to these indicators when the system is engaged.

- Inspect for Leaks: Look for any signs of fluid leakage around the transmission. Puddles or damp areas can signal a problem that needs immediate attention.

- Test Shifting Mechanism: Ensure that shifting is smooth and responsive. Difficulty in changing gears may suggest a problem with linkage or internal components.

Taking proactive measures and performing regular checks can significantly improve the reliability of your vehicle’s transmission. Should you encounter persistent issues, consulting a professional for further diagnostics may be necessary.

- Verify Electrical Connections: Inspect wiring and connectors for damage or corrosion that could disrupt the transmission’s electronic components.

- Evaluate Temperature: Overheating can lead to transmission failure. Make sure the cooling system is functioning properly.

- Look for Warning Lights: Dashboard indicators can provide vital information about the system’s health. Address any alerts promptly.

Replacing the Cutting Deck

Maintaining optimal performance of your lawn equipment often requires attention to the cutting mechanism. Over time, wear and tear can necessitate a replacement to ensure efficient operation and a clean cut. This guide will walk you through the steps involved in swapping out the cutting deck.

Before you begin, gather the necessary tools and materials:

- Wrench set

- Screwdriver

- Replacement cutting deck

- Safety gloves

- Owner’s manual for reference

Follow these steps to successfully replace the cutting deck:

- Prepare the Equipment: Ensure the engine is off and the spark plug is disconnected to prevent accidental starts.

- Lift the Unit: Use a jack or raise the mower to access the underside easily.

- Remove the Old Deck: Detach any bolts or screws securing the cutting deck. Carefully slide it out from under the mower body.

- Install the New Deck: Position the replacement deck under the mower, aligning it with the mounting points.

- Secure the Deck: Reattach the bolts or screws firmly, ensuring everything is tightly fastened.

- Reconnect the Spark Plug: After the installation, reconnect the spark plug and lower the mower back to the ground.

After completing these steps, your equipment should be ready for optimal cutting performance. Regular checks and maintenance will help prolong the life of the new deck.

Seasonal Care and Storage Advice

Proper maintenance and storage of your outdoor equipment are crucial for its longevity and optimal performance. Understanding the seasonal requirements can help ensure that your machinery remains in top condition throughout the year. This section offers essential tips for caring for your equipment as seasons change.

Spring Maintenance

As the warm weather approaches, it’s important to prepare your equipment for use. Begin by inspecting the machinery for any signs of wear or damage that may have occurred during the winter months. Changing the oil and filters is essential to promote efficiency. Additionally, clean the air filters and check the spark plugs, replacing them if necessary. Sharpening the blades will enhance performance, making your tasks easier and more efficient.

Winter Storage

When the cold season arrives, proper storage becomes paramount. Clean your equipment thoroughly to prevent rust and corrosion. Drain any fuel to avoid complications with the engine during hibernation. Cover the machinery with a breathable tarp to protect it from moisture while allowing airflow. Consider placing it in a sheltered area to mitigate exposure to harsh weather conditions. Following these guidelines will ensure that your equipment is ready to perform when the new season begins.

Safety Tips for DIY Repairs

Engaging in home maintenance and vehicle servicing can be rewarding, but it’s essential to prioritize safety throughout the process. Proper precautions not only protect you from accidents but also ensure that the equipment remains in optimal condition. Below are essential guidelines to follow when undertaking your own fixes.

Preparation and Personal Protection

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and sturdy footwear.

- Ensure your workspace is clean and well-lit to avoid tripping hazards and enhance visibility.

- Gather all necessary tools and parts before starting to minimize distractions during the task.

Tools and Equipment Safety

- Inspect all tools before use to ensure they are in good condition and free from defects.

- Follow the manufacturer’s instructions when using power tools, including correct handling and storage procedures.

- Disconnect power sources or batteries when working on machinery to prevent accidental starts.

By adhering to these safety practices, you can significantly reduce the risk of injuries and ensure a smoother, more efficient maintenance experience.

Where to Find Replacement Parts

Finding suitable components for your equipment is essential for maintaining optimal performance. Numerous sources can provide the necessary items, ensuring that your machinery remains in top condition. This guide outlines various options available for sourcing quality parts.

Authorized Dealers

One of the most reliable sources for obtaining parts is through authorized dealers. These retailers specialize in genuine components and typically have extensive inventories. Additionally, they can offer expert advice and support to help you identify the right parts for your needs.

Online Marketplaces

The internet offers a wide array of platforms where you can purchase replacement items. Online marketplaces often feature both new and refurbished options, allowing for cost-effective solutions. Be sure to check reviews and seller ratings to ensure quality.

| Source | Type of Parts | Pros | Cons |

|---|---|---|---|

| Authorized Dealers | Genuine Parts | Reliable quality, expert support | Higher prices |

| Online Marketplaces | New/Refurbished Parts | Cost-effective, wide selection | Variable quality |

| Local Salvage Yards | Used Parts | Budget-friendly, unique finds | Limited availability, no warranty |