Understanding the intricacies of agricultural machinery is essential for ensuring optimal performance and longevity. This section delves into the comprehensive strategies for troubleshooting and enhancing the functionality of your essential farming tools. With the right knowledge and resources, you can effectively tackle various challenges that arise during operation.

Having a well-structured resource at your fingertips can significantly simplify the process of addressing common issues. From basic adjustments to more complex repairs, being equipped with detailed information allows for timely and efficient resolutions. This guide aims to empower operators with the skills and insights necessary to maintain their equipment in peak condition.

Proper upkeep not only extends the life of machinery but also enhances productivity on the field. By familiarizing yourself with the specific components and mechanisms involved, you can prevent potential setbacks and ensure that your operations run smoothly. With a focus on practical advice and hands-on techniques, this section provides valuable support for anyone looking to master the care of their farming apparatus.

Understanding the John Deere 5320

This section aims to provide an in-depth look at a particular model known for its versatility and reliability in agricultural settings. Understanding its features and operational capabilities is essential for maximizing its performance and ensuring longevity. The following details will highlight key aspects that users should consider for effective utilization.

Key Features

| Feature | Description |

|---|---|

| Engine Power | A robust engine that delivers exceptional power for various tasks. |

| Transmission | Advanced transmission system allowing smooth gear shifts and enhanced control. |

| Hydraulics | Efficient hydraulic system designed for superior lifting capacity and responsiveness. |

Operational Considerations

When utilizing this model, operators should be aware of maintenance schedules and common troubleshooting practices. Regular checks and timely interventions can prevent minor issues from escalating, ensuring consistent performance and safety during operation.

Common Issues with John Deere 5320

Farm machinery often encounters a range of problems that can hinder performance and efficiency. Identifying and addressing these frequent challenges is essential for maintaining optimal functionality and ensuring longevity.

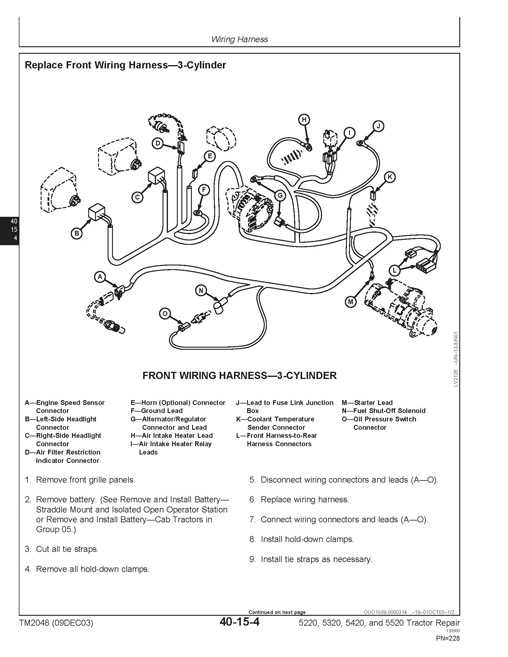

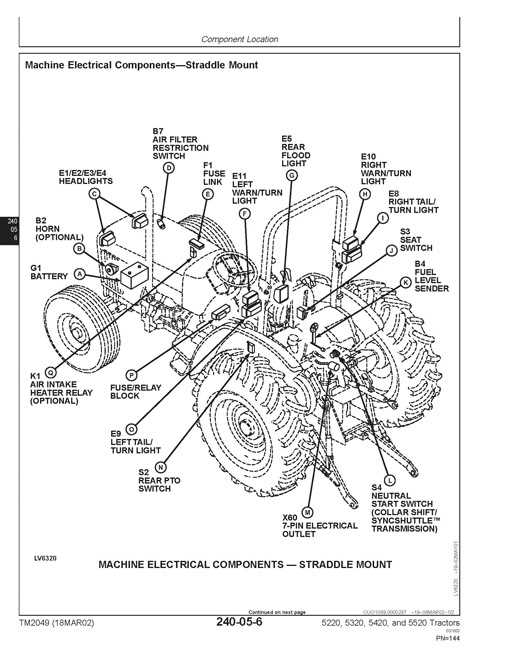

One common concern involves electrical malfunctions, which can lead to starting issues or erratic behavior of components. Regular inspections of wiring and connections can mitigate these problems.

Another frequent issue pertains to hydraulic system failures. Leaks or pressure drops can significantly impact operation, making it crucial to monitor fluid levels and check for signs of wear.

Additionally, engine performance may decline due to fuel system complications or air intake restrictions. Routine maintenance, including fuel filter replacements, can enhance reliability and power output.

Lastly, drivetrain concerns, such as unusual noises or slipping, often arise from wear and tear. Conducting timely inspections and addressing worn parts can prevent further damage and improve overall performance.

Tools Needed for Repairs

When tackling maintenance tasks on agricultural machinery, having the right equipment is crucial for achieving effective results. A well-organized toolkit not only enhances efficiency but also ensures safety during the process. Below is a list of essential implements that will aid in servicing and troubleshooting.

Basic Hand Tools: A selection of wrenches, pliers, and screwdrivers is fundamental. These tools are necessary for loosening and tightening various components, making adjustments, or replacing parts. A sturdy socket set can also prove invaluable for accessing hard-to-reach fasteners.

Diagnostic Equipment: Utilizing diagnostic tools can streamline the identification of issues. Multimeters and diagnostic scanners help in assessing electrical systems and detecting faults, ensuring that problems are addressed promptly.

Specialized Tools: Depending on the specific tasks, certain specialized tools may be required. Items such as torque wrenches, pullers, and alignment tools assist in performing precise adjustments and replacements, ensuring machinery operates at optimal performance.

Safety Gear: Personal protective equipment, including gloves, goggles, and sturdy footwear, is essential to safeguard against potential hazards during maintenance work. Ensuring safety should always be a top priority.

Equipping yourself with these essential tools and safety gear will enable you to conduct maintenance and troubleshooting tasks efficiently and effectively.

Step-by-Step Maintenance Guide

Proper upkeep of your machinery is essential for optimal performance and longevity. This section offers a comprehensive approach to maintaining your equipment, ensuring that it operates efficiently and reliably. Regular checks and procedures can prevent costly breakdowns and enhance productivity.

Routine Inspections

Begin by conducting frequent inspections to identify potential issues before they escalate. Check fluid levels, including oil and coolant, and look for any signs of leaks. Ensure that filters are clean and replace them as necessary. Additionally, examine belts and hoses for wear and tear, and replace any components that show signs of damage.

Lubrication and Cleaning

Regular lubrication is crucial for reducing friction and wear on moving parts. Use appropriate lubricants for different components as specified in the guidelines. Moreover, maintaining cleanliness is vital; remove dirt and debris from the exterior and interior parts of the equipment to prevent buildup that could affect performance. Pay special attention to the air intake and exhaust systems to ensure proper airflow.

By following these steps, you can significantly enhance the efficiency and lifespan of your equipment. Consistent maintenance practices will lead to a smoother operation and reduce the likelihood of unexpected repairs.

Engine Troubleshooting Tips

Maintaining optimal performance in machinery is crucial for efficient operation. When facing issues with the power unit, a systematic approach to diagnosing and addressing problems can save time and resources. Below are some helpful strategies to identify and resolve common engine complications.

- Check Fluid Levels: Ensure that oil, coolant, and fuel levels are adequate. Low levels can lead to overheating or insufficient lubrication.

- Inspect for Leaks: Examine the engine compartment for any signs of leaking fluids. This could indicate faulty seals or gaskets.

- Listen for Unusual Noises: Pay attention to any abnormal sounds during operation. Knocking or grinding noises may suggest internal issues.

- Review Engine Codes: Use diagnostic tools to check for error codes. These can provide insights into specific malfunctions.

- Examine Filters: Regularly inspect and replace air and fuel filters as needed. Clogged filters can restrict airflow and fuel delivery.

By following these guidelines, operators can effectively troubleshoot engine issues, ensuring reliable performance and longevity of their equipment.

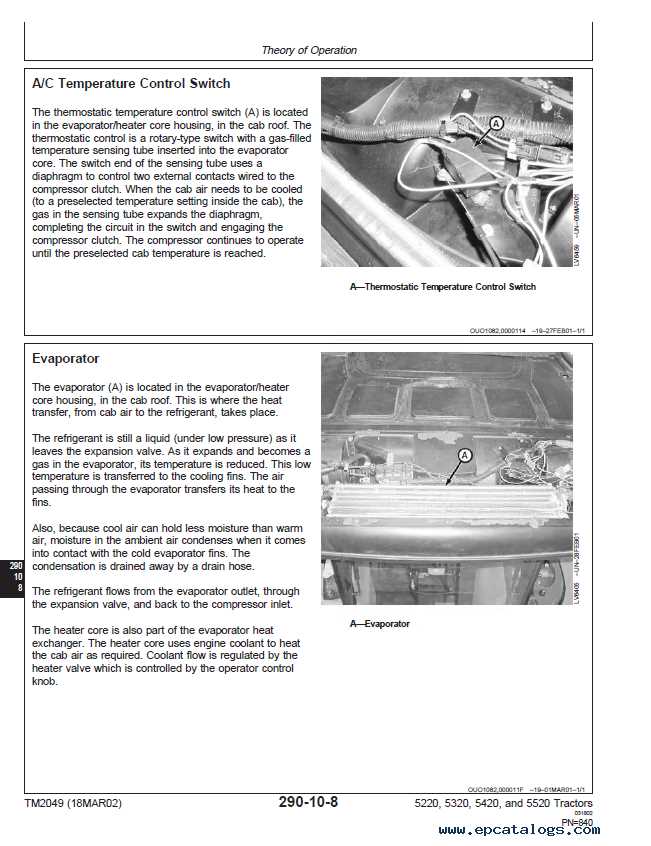

Hydraulic System Overview

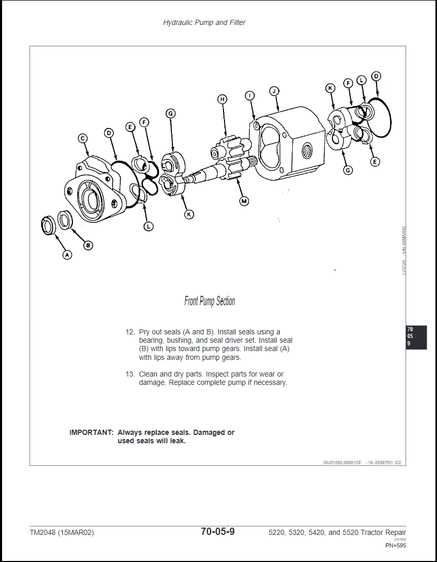

The hydraulic system plays a crucial role in the functionality of agricultural machinery, facilitating efficient operation and enhancing productivity. This system utilizes fluid power to generate motion and force, enabling various attachments and components to perform tasks with precision and ease.

At its core, the hydraulic system consists of several key components, including pumps, cylinders, valves, and hoses. Each of these elements works together to convert mechanical energy into hydraulic energy, which is then used to drive different operations such as lifting, pushing, and steering. Understanding the intricacies of this system is essential for optimal performance and maintenance.

Regular inspection and maintenance of hydraulic components are vital to ensure longevity and efficiency. Common issues can arise from leaks, contamination, or wear, which can adversely affect performance. By staying informed about the hydraulic system’s operation and upkeep, operators can minimize downtime and enhance the reliability of their equipment.

Electrical Problems and Solutions

Electrical issues can significantly affect the performance of machinery, leading to operational disruptions. Identifying and resolving these problems promptly is essential for maintaining efficiency and preventing further complications. This section will explore common electrical challenges and their corresponding solutions to ensure smooth operation.

Common Electrical Issues

| Problem | Possible Causes | Solutions |

|---|---|---|

| Poor Battery Performance | Corrosion, old age, loose connections | Clean terminals, replace battery, tighten connections |

| Faulty Wiring | Wear and tear, rodent damage | Inspect and replace damaged wires |

| Inoperative Lights | Burned-out bulbs, faulty switches | Replace bulbs, test and replace switches |

Troubleshooting Tips

Regular inspections and maintenance can help prevent electrical issues. Always ensure that connections are secure and free from corrosion. When troubleshooting, use a multimeter to check for continuity and voltage at various points in the electrical system. This approach can help pinpoint the source of the problem effectively.

Replacing Belts and Hoses

Maintaining optimal performance of machinery often involves routine checks and replacements of essential components such as belts and hoses. These parts play a critical role in ensuring the efficient operation of the equipment, as they are responsible for transmitting power and facilitating fluid movement.

Inspection of belts and hoses should be a regular part of maintenance. Look for signs of wear, such as cracks, fraying, or glazing on belts, and check hoses for leaks, bulges, or stiffness. Any irregularities can lead to reduced efficiency or even failure of the system.

When replacing these components, ensure you select the correct size and type specified by the manufacturer. Follow a systematic approach: start by disconnecting the power source, then remove any covers or guards that may obstruct access. Carefully detach the old parts, noting their orientation for easier installation of the new ones.

Once the new belts and hoses are in place, double-check all connections and ensure everything is secured properly. Finally, run the equipment briefly to confirm that all components are functioning smoothly without any unusual noises or leaks.

Transmission Maintenance Best Practices

Ensuring optimal performance and longevity of a transmission system requires diligent maintenance practices. Regular attention to key components and fluid conditions can prevent costly failures and enhance operational efficiency. Adopting a proactive approach is essential for any operator aiming to extend the lifespan of their equipment.

One of the foremost practices involves regular fluid checks and changes. Transmission fluid acts as both a lubricant and a coolant, making its quality vital. Monitoring for contaminants and ensuring the fluid is at the appropriate level can help maintain smooth operation. Additionally, replacing the fluid at manufacturer-recommended intervals is crucial to avoid degradation that can lead to mechanical issues.

Moreover, inspecting filters is equally important. Clogged or dirty filters can restrict fluid flow, which compromises the entire system’s functionality. Regular replacement of filters helps ensure that only clean fluid circulates through the transmission, reducing wear on internal components.

It is also advisable to keep an eye on operational temperatures. Overheating can lead to premature wear and failure. Installing temperature gauges or monitoring existing ones allows for timely interventions if the system operates outside of optimal ranges.

Lastly, periodic assessments of the transmission’s physical components–such as seals, gaskets, and linkages–can identify potential leaks or wear before they escalate into serious problems. A comprehensive inspection routine, combined with prompt repairs, contributes significantly to the reliable performance of the transmission system.

Fuel System Diagnostics

The proper functioning of the fuel system is crucial for optimal performance in agricultural machinery. Diagnosing issues within this system involves identifying potential problems that can affect fuel delivery, efficiency, and overall engine operation. This section outlines the key steps and considerations for effective troubleshooting.

Start by inspecting the fuel lines for any signs of leaks or blockages. A thorough examination can reveal cracks, corrosion, or kinks that may hinder fuel flow. Additionally, checking the fuel filter for clogs is essential, as a dirty filter can restrict fuel supply and lead to performance issues.

Next, evaluate the fuel pump’s operation. Listen for unusual sounds and ensure it is maintaining the correct pressure. Any irregularities in sound or pressure can indicate a malfunction that requires attention.

Don’t forget to assess the injectors as well. Cleanliness and proper functioning of these components are vital for ensuring that fuel is atomized correctly for combustion. A simple test can help determine if they are delivering the right amount of fuel.

Finally, it’s beneficial to monitor engine performance under different conditions. Variations in power output or efficiency can provide clues about potential fuel system problems, guiding further diagnostics and corrective measures.

Wheel and Tire Care

Maintaining optimal performance and longevity of your vehicle’s wheels and tires is crucial for safety and efficiency. Proper care not only enhances the driving experience but also minimizes potential repairs and replacements. Regular attention to these components can prevent issues and ensure smooth operation on various terrains.

Regular Inspection

Routine checks of both wheels and tires are essential. Look for signs of wear, such as uneven tread depth or cracks in the sidewalls. Inflation levels should be monitored frequently, as proper air pressure significantly affects handling and fuel efficiency. Make it a habit to inspect for debris or stones lodged in the tread, as these can impact performance.

Cleaning and Maintenance

Cleaning wheels and tires helps to prevent corrosion and maintain aesthetics. Use a gentle cleaner specifically designed for tires and wheels to avoid damage. Applying tire protectants can enhance their appearance and provide a layer of protection against UV rays. Additionally, consider rotating tires regularly to promote even wear and extend their lifespan.

Safety Measures During Repairs

Ensuring a secure environment while conducting maintenance is paramount. Adhering to appropriate precautions can significantly reduce risks and enhance efficiency during service tasks. This section outlines essential practices to follow for a safe working atmosphere.

Essential Precautions

- Always wear protective gear, including gloves, goggles, and sturdy footwear.

- Keep the workspace clean and organized to avoid accidents.

- Ensure that tools and equipment are in good condition before use.

Operational Safety

- Disconnect the power source to prevent unintended operation.

- Use appropriate lifting techniques or equipment when handling heavy components.

- Follow manufacturer guidelines and protocols for specific tasks.

Implementing these measures contributes to a safer and more productive environment, minimizing potential hazards associated with maintenance activities.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a crucial task to ensure optimal performance and longevity. Whether you’re undertaking maintenance or addressing a breakdown, knowing where to source quality parts is essential for efficient operation.

Authorized Dealers

One of the most reliable sources for acquiring replacement components is through authorized dealers. These outlets often provide genuine parts that meet manufacturer specifications, ensuring compatibility and performance. Additionally, they typically offer expert advice and support, which can be invaluable during your search.

Online Retailers

The internet presents a plethora of options for finding necessary components. Various online platforms specialize in equipment parts, allowing you to compare prices and availability easily. Always check for customer reviews and ratings to gauge the reliability of the seller before making a purchase.