Maintaining the performance and longevity of a utility vehicle requires a deep understanding of its components and systems. This guide aims to equip owners with essential insights and techniques necessary for effective upkeep. Whether you’re troubleshooting issues or performing routine tasks, having access to detailed information is crucial for successful management.

Understanding the intricacies of your machine is vital for ensuring it operates smoothly and efficiently. From mechanical parts to electrical systems, each element plays a significant role in overall functionality. This resource will provide a structured approach to address common challenges and enhance operational capabilities.

Furthermore, armed with the right knowledge, you can prevent potential problems before they escalate. By following best practices and utilizing appropriate techniques, vehicle owners can ensure optimal performance and minimize downtime. Dive into this essential compilation to discover the tools and strategies that will keep your utility vehicle running at its best.

Overview of John Deere Gator HPX

This section provides a comprehensive look at a versatile utility vehicle designed for various applications. Built for durability and efficiency, this model is ideal for both work and recreational use, combining rugged construction with user-friendly features.

The vehicle is equipped with a powerful engine, ensuring reliable performance in diverse terrains. Its robust frame supports heavy loads, making it suitable for tasks such as hauling equipment or transporting materials.

Safety and comfort are prioritized in the design, with ergonomic seating and easy access to controls. This enhances the overall experience for operators, allowing for extended use without fatigue.

Additionally, the adaptability of this model is a standout feature. With various attachments available, it can be customized to meet specific needs, whether for agriculture, landscaping, or maintenance tasks.

In summary, this utility vehicle is a practical choice for those seeking a dependable and flexible solution for their transportation and work-related requirements.

Common Issues and Troubleshooting Tips

When operating utility vehicles, users may encounter various challenges that can affect performance and functionality. Identifying these issues promptly and applying effective solutions can enhance the longevity and reliability of the equipment. Below are some common problems along with practical advice to resolve them.

Frequent Problems

- Starting Difficulties: Vehicles may fail to start due to battery issues, fuel shortages, or ignition failures.

- Transmission Troubles: Gear shifting problems often arise from low fluid levels or mechanical wear.

- Overheating: Engine overheating can result from coolant leaks or a malfunctioning radiator.

- Electrical Failures: Issues with lights or accessories may be traced to blown fuses or loose connections.

Troubleshooting Strategies

- Check Battery: Ensure the battery is charged and terminals are clean.

- Inspect Fuel Levels: Verify that there is sufficient fuel in the tank.

- Examine Fluid Levels: Regularly check oil and coolant levels to prevent overheating.

- Test Electrical Components: Replace any blown fuses and secure loose wiring connections.

By following these tips and addressing issues early, operators can maintain optimal performance and reduce the risk of costly repairs.

Essential Tools for Repairs

When it comes to maintaining and restoring outdoor utility vehicles, having the right equipment is crucial for efficiency and effectiveness. A well-equipped toolkit can make the difference between a successful job and unnecessary frustration. Understanding the essential implements needed for various tasks will not only save time but also enhance the quality of the work done.

1. Wrenches and Sockets: A set of adjustable wrenches and socket sets is fundamental for loosening and tightening bolts and nuts. Different sizes are necessary to accommodate various components, ensuring a snug fit and preventing damage.

2. Screwdrivers: Both flathead and Phillips screwdrivers are indispensable for accessing panels and securing parts. A magnetic tip can be especially useful for handling small screws in tight spaces.

3. Pliers: Needle-nose and standard pliers provide the grip needed for holding or bending wires and small parts. They are invaluable for manipulating components that are hard to reach.

4. Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening that can lead to breakage or failure of parts.

5. Multimeter: A multimeter is essential for diagnosing electrical issues. It allows users to measure voltage, current, and resistance, helping to pinpoint problems effectively.

6. Safety Gear: Protective eyewear and gloves are crucial for ensuring personal safety while working on mechanical tasks. Safety should always be a priority when handling tools and machinery.

By having these essential implements on hand, users can tackle a wide range of maintenance tasks with confidence and skill, leading to improved performance and longevity of their utility vehicles.

Step-by-Step Maintenance Procedures

Proper upkeep of your utility vehicle is essential for optimal performance and longevity. Following systematic procedures not only enhances functionality but also helps prevent potential issues. Below, you will find a detailed guide to routine maintenance tasks that should be performed regularly to keep your vehicle in excellent condition.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace engine oil and oil filter to ensure smooth operation and reduce wear. |

| Air Filter Inspection | Every 100 hours | Check and clean the air filter to maintain airflow and engine efficiency. |

| Tire Pressure Check | Weekly | Ensure tires are inflated to the recommended pressure for safe driving. |

| Battery Maintenance | Monthly | Inspect battery terminals for corrosion and ensure proper charge levels. |

| Brake System Check | Every 200 hours | Examine brake pads and fluid levels for effective stopping power. |

| Fuel System Inspection | Every 100 hours | Inspect fuel lines and filter for leaks or blockages to maintain fuel efficiency. |

Adhering to these maintenance tasks will significantly contribute to the reliability and safety of your utility vehicle, ensuring it remains ready for any task at hand.

Electrical System Diagnostics

Understanding the intricacies of an electrical system is crucial for effective troubleshooting and maintenance. This section delves into the fundamental aspects of diagnosing electrical issues, focusing on essential components, potential failures, and systematic approaches to resolving problems.

Key Components and Their Functions

Electrical systems comprise various elements that work together to ensure optimal performance. Key components include the battery, wiring harness, fuses, and electrical connectors. Each part plays a vital role in the overall functionality. For instance, the battery provides the necessary power to start the engine, while the wiring harness facilitates the flow of electricity between components. Regular inspection of these elements is essential to identify any signs of wear or damage that could lead to malfunctions.

Diagnostic Procedures

To effectively diagnose electrical issues, a methodical approach is required. Begin with a thorough visual inspection, checking for loose connections, corrosion, or frayed wires. Utilize a multimeter to measure voltage and continuity across various components, confirming that each part operates within its specified range. Additionally, employing diagnostic tools can streamline the process, allowing for more accurate identification of faults. Always consult the specifications and guidelines for each component to ensure precise diagnostics.

In conclusion, mastering the art of electrical system diagnostics is essential for maintaining functionality and prolonging the lifespan of the equipment. Regular checks and systematic troubleshooting can prevent minor issues from escalating into significant problems.

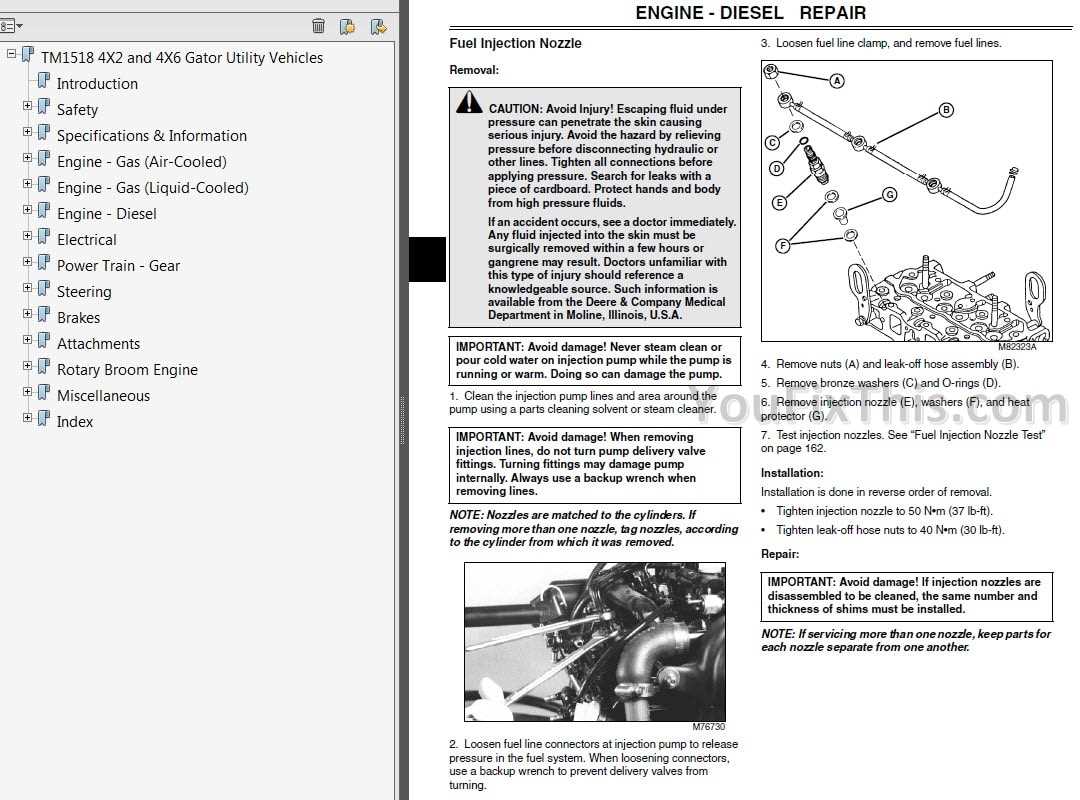

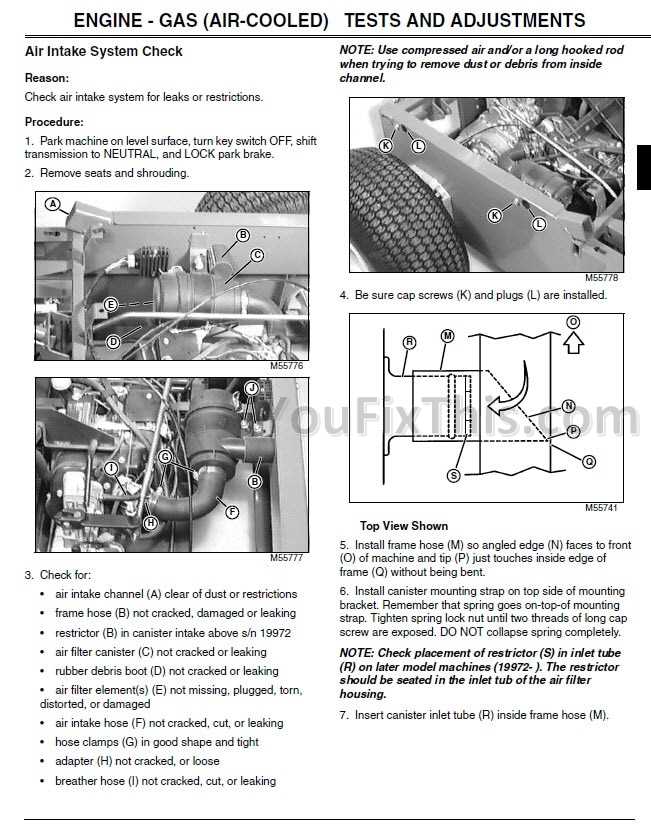

Replacing the Engine Components

Maintaining optimal performance in utility vehicles often requires the careful replacement of engine parts. This process ensures that the machinery operates efficiently and extends its lifespan. Understanding the correct procedures for replacing these components is essential for effective upkeep and reliability.

Identifying Components to Replace

Before starting the replacement process, it is crucial to accurately identify which parts are malfunctioning or have worn out. Common components that may need attention include the piston rings, valves, and gaskets. Regular inspections and diagnostics can help pinpoint issues that, if left unaddressed, could lead to significant operational problems.

Step-by-Step Replacement Process

Once you have determined which parts need replacement, follow a systematic approach. Begin by ensuring the engine is completely cooled and disconnecting the battery for safety. Remove any necessary covers or components that obstruct access to the targeted parts. Proceed to replace the components by following the manufacturer’s specifications closely. After installation, double-check all connections and ensure everything is securely fastened before reassembling the vehicle.

Regular maintenance and timely replacement of engine components will greatly enhance the performance and reliability of your machinery.

Transmission and Drivetrain Insights

This section delves into the intricacies of the transmission and drivetrain systems, essential components that ensure optimal performance and efficiency. Understanding these systems allows for better maintenance and enhances the longevity of the vehicle.

Key aspects to consider include:

- Functionality: The drivetrain transmits power from the engine to the wheels, facilitating movement and control.

- Components: Major elements include the transmission, drive shafts, differential, and axles, each playing a pivotal role in overall functionality.

- Types: Different configurations, such as automatic and manual transmissions, offer varied driving experiences and efficiency levels.

- Maintenance: Regular checks on fluid levels, wear and tear, and proper alignment are vital to prevent costly repairs.

By familiarizing oneself with these systems, operators can enhance their understanding and ultimately improve the performance of their vehicle.

Hydraulic System Maintenance Guide

Proper upkeep of the hydraulic system is essential for ensuring the optimal performance and longevity of your vehicle. Regular maintenance helps prevent failures and enhances efficiency by keeping the components in excellent condition. This section outlines key practices to keep the hydraulic system functioning smoothly.

Routine Inspections

Fluid Replacement

Over time, hydraulic fluid can degrade and become contaminated. It’s crucial to replace the fluid at recommended intervals to maintain system integrity. Always use the manufacturer’s specified type of fluid and ensure the system is properly bled of air after replacement to prevent cavitation and ensure optimal pressure.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with mechanical work. Proper preparation and awareness of potential hazards are key components of a secure working environment.

Before commencing any maintenance work, it is essential to equip yourself with the appropriate personal protective equipment (PPE). This includes items such as gloves, goggles, and sturdy footwear. Additionally, ensuring that your workspace is organized and free from unnecessary obstacles can greatly enhance safety.

| Precaution | Description |

|---|---|

| Use Personal Protective Equipment | Wear gloves, goggles, and sturdy footwear to safeguard against injuries. |

| Organize Workspace | Keep tools and materials neatly arranged to avoid tripping hazards. |

| Disconnect Power Sources | Always ensure that machines are powered down and disconnected before starting work. |

| Read Instructions | Thoroughly review any relevant documentation to understand procedures and risks. |

| Have a First Aid Kit | Keep a well-stocked first aid kit nearby to address any minor injuries immediately. |

Following these guidelines can create a safer atmosphere for maintenance activities. Regularly reviewing and updating safety practices ensures ongoing protection during all mechanical endeavors.

Finding Replacement Parts Effectively

Locating the right components for your vehicle can often be a daunting task, especially when you’re faced with a variety of options and sources. To ensure your equipment remains operational, it’s essential to adopt a systematic approach to sourcing replacements. This guide aims to streamline your search process, allowing you to identify and acquire the necessary parts with minimal hassle.

Utilizing Online Resources

Online platforms serve as a valuable resource for discovering suitable components. Specialized websites and forums dedicated to equipment maintenance can provide insights into availability and compatibility. Searching for parts using specific model numbers or descriptions will yield more accurate results, helping you navigate through numerous listings with ease.

Consulting Local Dealers and Distributors

Engaging with local suppliers can also be beneficial. Establishing a relationship with nearby dealers allows you to access genuine parts while receiving personalized assistance. Additionally, these businesses often have connections to manufacturers, which can expedite the ordering process. Don’t hesitate to inquire about warranties or return policies, ensuring peace of mind with your purchase.

In summary, a strategic approach that combines online searches with local dealer consultations can significantly enhance your chances of finding the correct parts efficiently. By leveraging these resources, you can maintain your equipment’s performance and longevity.

Owner Experiences and Tips

This section aims to share valuable insights and practical advice gathered from users of all-terrain utility vehicles. Understanding the experiences of fellow enthusiasts can greatly enhance your ownership journey and help you navigate challenges effectively.

Common Challenges and Solutions

Many owners encounter similar issues over time, ranging from mechanical hiccups to routine maintenance dilemmas. For instance, a frequent concern is battery longevity. Users recommend regularly checking connections and ensuring the battery is fully charged, especially before long outings. Additionally, keeping an eye on tire pressure can prevent unnecessary wear and improve handling.

Maintenance Tips from Experienced Users

Regular Servicing: Scheduling routine inspections is crucial. Engaging a professional can help identify potential problems early on, saving time and money in the long run.

Cleaning: After each use, owners suggest thoroughly cleaning the vehicle to prevent dirt buildup, particularly in the undercarriage. This not only maintains aesthetics but also protects vital components from corrosion.

Community Engagement: Connecting with other users through online forums or local clubs can provide additional support and knowledge sharing. Owners often report that exchanging tips and experiences enhances their understanding and enjoyment of their vehicles.

Online Resources for Further Assistance

Accessing the right information is crucial for effective maintenance and troubleshooting. Numerous online platforms offer a wealth of resources that can enhance your understanding and aid in resolving issues related to your utility vehicle. These resources include forums, instructional videos, and manufacturer websites that provide valuable insights and support.

| Resource Type | Description | Website/Link |

|---|---|---|

| Forums | Community-driven discussions where users share experiences and solutions. | Example Forum |

| Video Tutorials | Step-by-step guides demonstrating various maintenance tasks and repairs. | YouTube |

| Official Manufacturer Site | Access to technical documents, FAQs, and customer support. | Example Manufacturer |

| Online Retailers | Purchase replacement parts and accessories with specifications and reviews. | Example Parts Store |