Maintaining a utility vehicle is essential for ensuring its longevity and optimal performance. This section aims to provide valuable insights and instructions for proper upkeep, addressing common issues that users may encounter over time.

Understanding the intricacies of your vehicle’s components is crucial for effective troubleshooting. By familiarizing yourself with the mechanical and electrical systems, you can identify potential problems before they escalate, saving time and resources.

Additionally, regular maintenance not only enhances the functionality of your vehicle but also contributes to safety during operation. Following the guidelines provided here will equip you with the knowledge needed to keep your equipment in excellent condition.

This section will provide a comprehensive overview of a versatile utility vehicle designed for various tasks. Its robust design and impressive capabilities make it a popular choice among users who require reliability and performance in diverse environments.

- Introduction to the vehicle’s purpose and applications

- Key features and specifications

- Engine performance and efficiency

- Transmission and drivetrain characteristics

- Suspension and handling capabilities

- Interior and comfort features

- Safety features and compliance

- Common uses in agriculture and landscaping

- Maintenance tips for optimal performance

- Popular accessories and enhancements

- Customer feedback and reviews

Common Issues and Troubleshooting Tips

When operating utility vehicles, users may encounter various challenges that can hinder performance. Understanding these common issues and having strategies for troubleshooting can enhance the overall experience and extend the lifespan of the equipment. This section provides insight into frequent problems and offers practical solutions.

Engine Performance Problems

One of the most reported concerns involves engine performance. Symptoms such as difficulty starting or stalling during operation may indicate underlying issues. Regularly checking fuel levels, filters, and spark plugs is essential. If problems persist, it may be necessary to inspect the ignition system and battery condition.

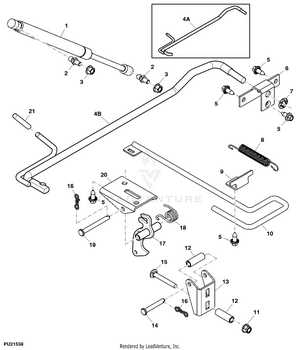

Transmission and Drive Issues

Transmission troubles can manifest as unusual noises or difficulty shifting gears. These symptoms could arise from low fluid levels or contamination. Ensuring the transmission fluid is clean and at the correct level is crucial for smooth operation. Additionally, examining the drive belt for wear can prevent further complications.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle. Adhering to a structured maintenance timetable can prevent unexpected issues and enhance overall functionality.

To achieve optimal performance, consider the following maintenance tasks:

- Daily Checks:

- Inspect fluid levels, including oil and coolant.

- Examine tire pressure and tread condition.

- Ensure all lights and indicators are operational.

- Weekly Maintenance:

- Clean the exterior to prevent corrosion.

- Check battery connections for security and cleanliness.

- Inspect the air filter and replace if necessary.

- Monthly Servicing:

- Change engine oil and replace the oil filter.

- Lubricate moving parts to reduce wear.

- Examine belts and hoses for signs of damage.

- Annual Inspection:

- Conduct a comprehensive system check.

- Replace spark plugs and inspect ignition components.

- Flush the cooling system and replace coolant.

By following this schedule, you can ensure that your vehicle remains in peak condition, ready to tackle any task with reliability and efficiency.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing utility vehicles. Proper tools not only enhance efficiency but also ensure that tasks are completed safely and effectively. A well-equipped workshop allows for smoother operations and minimizes downtime during maintenance activities.

Basic Hand Tools

Start with a comprehensive set of hand tools, including wrenches, pliers, and screwdrivers. These items are essential for various tasks, such as tightening bolts and adjusting components. Investing in high-quality hand tools can make a significant difference in performance and longevity.

Diagnostic Equipment

Incorporating diagnostic tools is vital for identifying issues accurately. Devices such as multimeters and diagnostic scanners provide valuable insights into the vehicle’s performance. Utilizing these instruments can lead to more informed decisions and timely interventions, ensuring optimal functionality.

Step-by-Step Repair Procedures

This section provides a comprehensive overview of the systematic approach to resolving common issues. Each step is designed to guide you through the necessary actions to restore functionality efficiently.

-

Initial Assessment:

- Identify the symptoms and gather relevant information.

- Check for visible damages or unusual noises.

-

Preparation:

- Gather required tools and replacement parts.

- Ensure a clean workspace to facilitate the process.

-

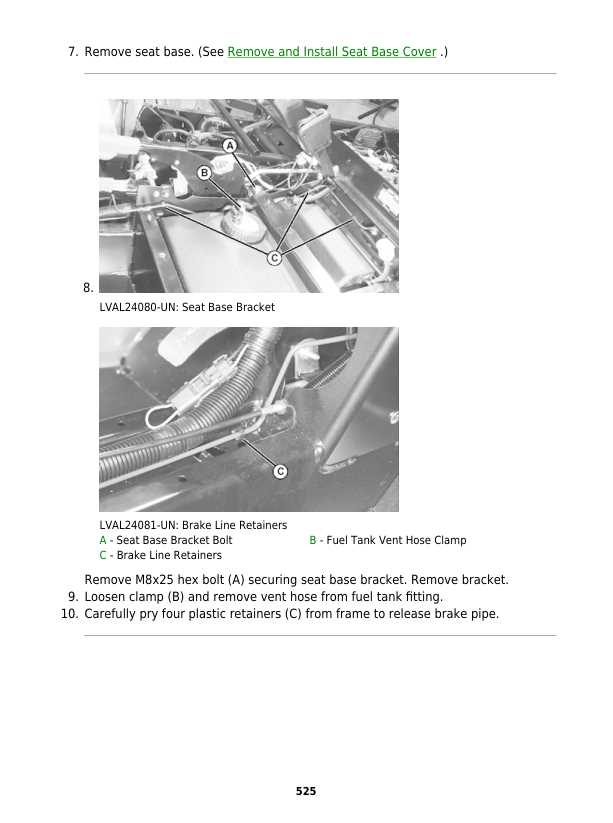

Disassembly:

- Carefully remove any coverings or panels.

- Document the order of disassembly for reassembly.

-

Inspection:

- Examine components for wear and tear.

- Test electrical connections and fluid levels.

-

Replacement:

- Replace any damaged or malfunctioning parts.

- Follow manufacturer specifications for installation.

-

Reassembly:

- Reattach all panels and coverings in reverse order.

- Ensure all fasteners are secured properly.

-

Testing:

- Start the unit and monitor for any irregularities.

- Conduct a thorough test drive to confirm repairs.

By following these detailed steps, you can effectively address and resolve issues, ensuring optimal performance of the equipment.

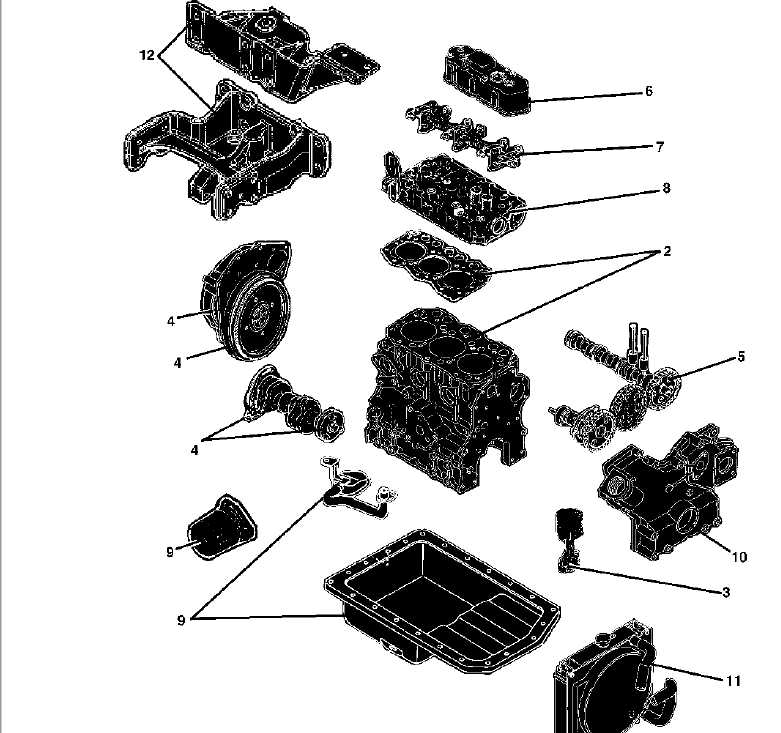

Replacing Engine Components Effectively

When dealing with the maintenance of motorized vehicles, the ability to replace engine parts efficiently is crucial. Understanding the proper techniques and best practices can significantly enhance performance and longevity.

Begin by gathering the necessary tools and components. Ensure that all replacement parts are compatible with the specific engine model to avoid complications. It is also advisable to work in a clean, well-lit environment to facilitate the process.

Next, follow a systematic approach to disassembly. Document the configuration of components before removal, as this will aid in reassembly. Take care to handle all parts with precision to prevent damage.

Once the components are removed, inspect them for wear and tear. Regular maintenance can prevent further issues down the line. Install the new parts by reversing the disassembly steps, ensuring that each component is securely fitted and functioning correctly.

Finally, conduct thorough testing to verify that the engine operates smoothly post-replacement. This step is vital for ensuring that the vehicle remains reliable and efficient in its performance.

Electrical System Diagnostics

The assessment of the electrical system is crucial for maintaining optimal performance in any vehicle. Proper diagnostics ensure that all components function correctly and efficiently. Identifying issues early can prevent further complications and reduce repair costs.

Begin the evaluation by checking the battery condition, as it is the heart of the electrical system. A weak or dead battery can lead to various malfunctions. Use a multimeter to measure voltage levels and confirm they meet specified requirements.

Next, inspect the wiring and connections. Look for signs of wear, corrosion, or loose connections that can disrupt the electrical flow. Ensure all connectors are secure and free of debris.

Additionally, testing individual components, such as fuses and relays, is essential. Replace any faulty parts to maintain system integrity. Document findings to track performance over time and identify recurring issues.

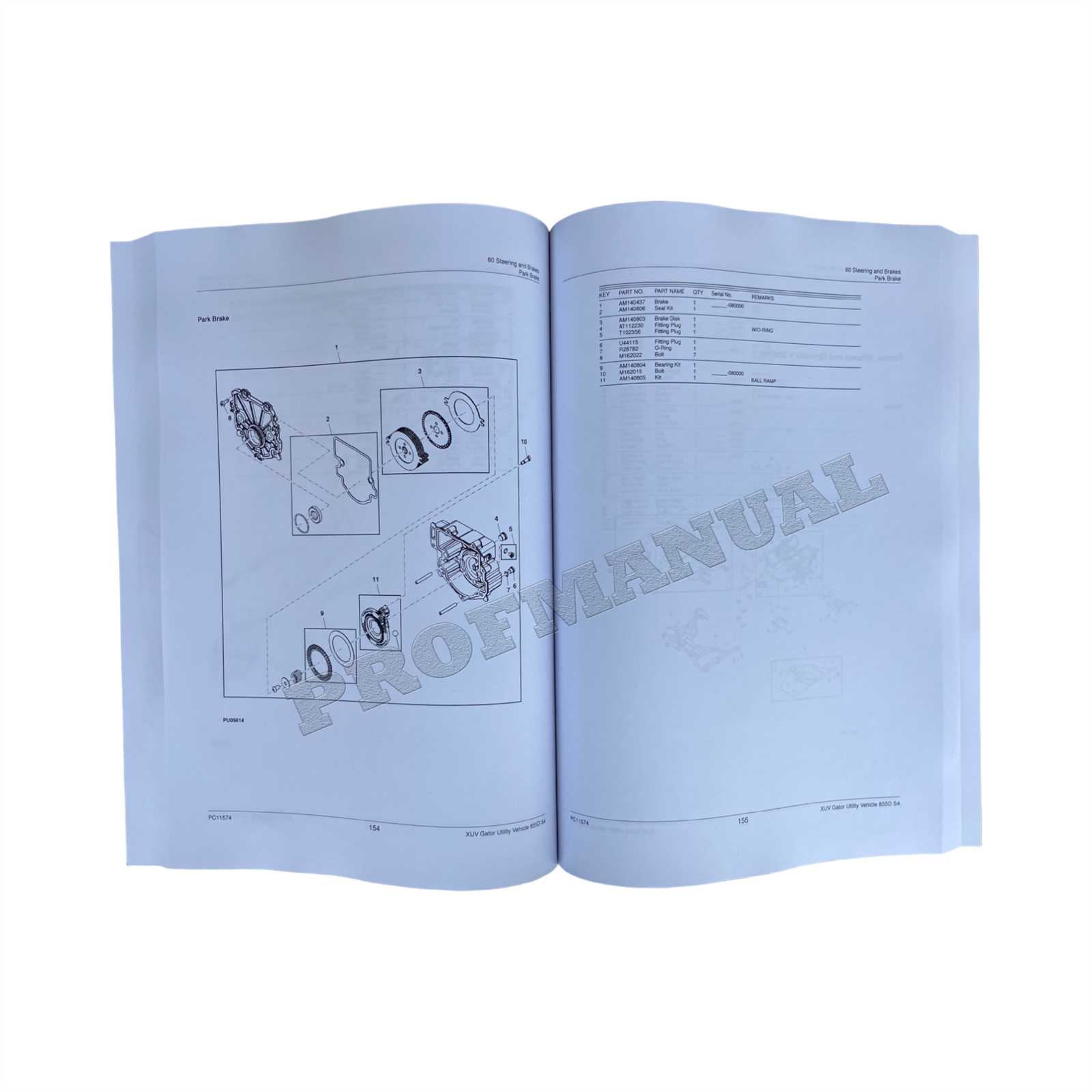

Understanding the Hydraulic System

The hydraulic system plays a crucial role in the operation of various machinery, enabling the transfer of power through fluid movement. This system utilizes incompressible fluids to facilitate the functioning of numerous components, allowing for smooth and efficient movement. Understanding its mechanics is essential for ensuring optimal performance and longevity of the equipment.

Key Components of Hydraulic Systems

Hydraulic systems are composed of several vital components, including pumps, valves, actuators, and reservoirs. Each part serves a specific function, contributing to the overall effectiveness of the system. Pumps generate the necessary pressure to circulate the fluid, while valves control the flow and direction, ensuring that the actuators respond accurately to operational commands.

Maintenance Considerations

Regular maintenance of the hydraulic system is essential to prevent leaks and maintain efficiency. Checking fluid levels, inspecting hoses for wear, and ensuring all connections are secure can significantly enhance system reliability. Addressing issues promptly can prevent more significant problems and extend the lifespan of the equipment.

Upgrading and Modifying Your Gator

Enhancing and personalizing your utility vehicle can significantly improve its performance and functionality. Whether you aim to increase power, boost off-road capabilities, or simply tailor the design to your preferences, various modifications are available to suit your needs.

Before starting any upgrades, it’s essential to research compatible components and their benefits. Here are some popular enhancements:

| Modification Type | Description | Benefits |

|---|---|---|

| Suspension Upgrade | Improving shock absorbers and springs | Enhanced stability and comfort on rough terrain |

| Engine Tuning | Adjusting fuel and air intake settings | Increased horsepower and efficiency |

| Tire Replacement | Installing all-terrain or specialized tires | Better traction and handling |

| Lighting Kit | Adding LED lights or auxiliary lamps | Improved visibility during nighttime operation |

Each modification can significantly affect the vehicle’s overall capabilities, allowing you to adapt it for various tasks or recreational activities. Always ensure that upgrades comply with local regulations and safety standards.

Safety Precautions During Repairs

When conducting maintenance or troubleshooting on machinery, adhering to safety measures is crucial to prevent accidents and ensure a secure working environment. This section outlines essential guidelines that should be followed to mitigate risks and enhance personal safety during the process.

Before starting any work, it’s important to familiarize yourself with the equipment and understand its specific functions. Proper preparation can significantly reduce the likelihood of mishaps. Here are some key safety recommendations:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate safety gear such as gloves, goggles, and hard hats to protect against potential hazards. |

| Work Area Inspection | Ensure the workspace is clean and free from obstructions, which can cause slips or falls. |

| Proper Tools | Use the correct tools for each task, and ensure they are in good condition to avoid malfunctions. |

| Electrical Safety | Before working on electrical components, disconnect the power source to prevent electric shock. |

| Clear Communication | If working in a team, establish clear signals and communication methods to coordinate activities effectively. |

By following these safety precautions, individuals can significantly enhance their protection while performing necessary tasks on machinery, leading to a more efficient and safe working environment.

Finding Genuine Replacement Parts

When maintaining and servicing any utility vehicle, sourcing authentic components is essential for optimal performance and longevity. Using original parts ensures compatibility, reliability, and adherence to manufacturer standards, preventing potential issues caused by inferior alternatives.

Benefits of Authentic Components

- Enhanced Durability: Genuine parts are designed to withstand the demands of rugged use.

- Perfect Fit: Original components guarantee seamless integration into the vehicle.

- Improved Performance: Authentic parts help maintain the efficiency and functionality of the machine.

- Manufacturer Support: Genuine parts often come with warranties and customer service options.

Where to Find Genuine Parts

- Authorized Dealers: Visiting certified dealerships ensures access to a wide range of authentic components.

- Manufacturer Websites: Many manufacturers offer online catalogs and ordering systems for genuine parts.

- Specialized Retailers: Stores focusing on utility vehicles typically stock original components.

- Online Marketplaces: Reputable platforms may offer authentic parts, but verify seller credibility.

Resources for Further Assistance

When dealing with complex machinery, having access to reliable resources is essential for ensuring proper maintenance and troubleshooting. This section outlines various avenues for obtaining support, information, and guidance for optimal performance.

Online Communities

Engaging with online forums and community groups can provide valuable insights from experienced users. These platforms often feature discussions on common issues, modifications, and best practices. Participating in these networks allows you to share knowledge and learn from others’ experiences.

Official Support Channels

Manufacturers often offer official support through their websites, including downloadable resources, troubleshooting guides, and contact information for customer service. Utilizing these channels can help you resolve specific concerns efficiently, ensuring your equipment remains in peak condition.