This section aims to provide valuable insights into the upkeep and restoration of a specific line of agricultural machinery. Understanding the intricacies of these machines is essential for optimal performance and longevity.

Throughout this guide, readers will discover detailed instructions and helpful tips that facilitate the process of ensuring these machines operate smoothly. By familiarizing oneself with the core components and functionalities, operators can enhance their troubleshooting skills and perform necessary adjustments effectively.

Whether you are a seasoned expert or a newcomer, this resource serves as a practical reference for addressing common issues, conducting routine inspections, and implementing effective solutions. Embracing a proactive approach to maintenance not only extends the life of the equipment but also maximizes productivity in the field.

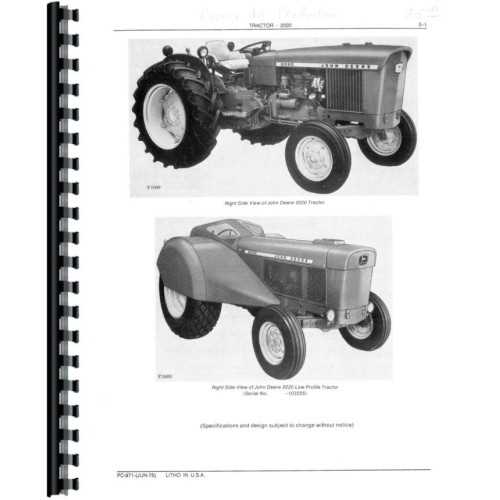

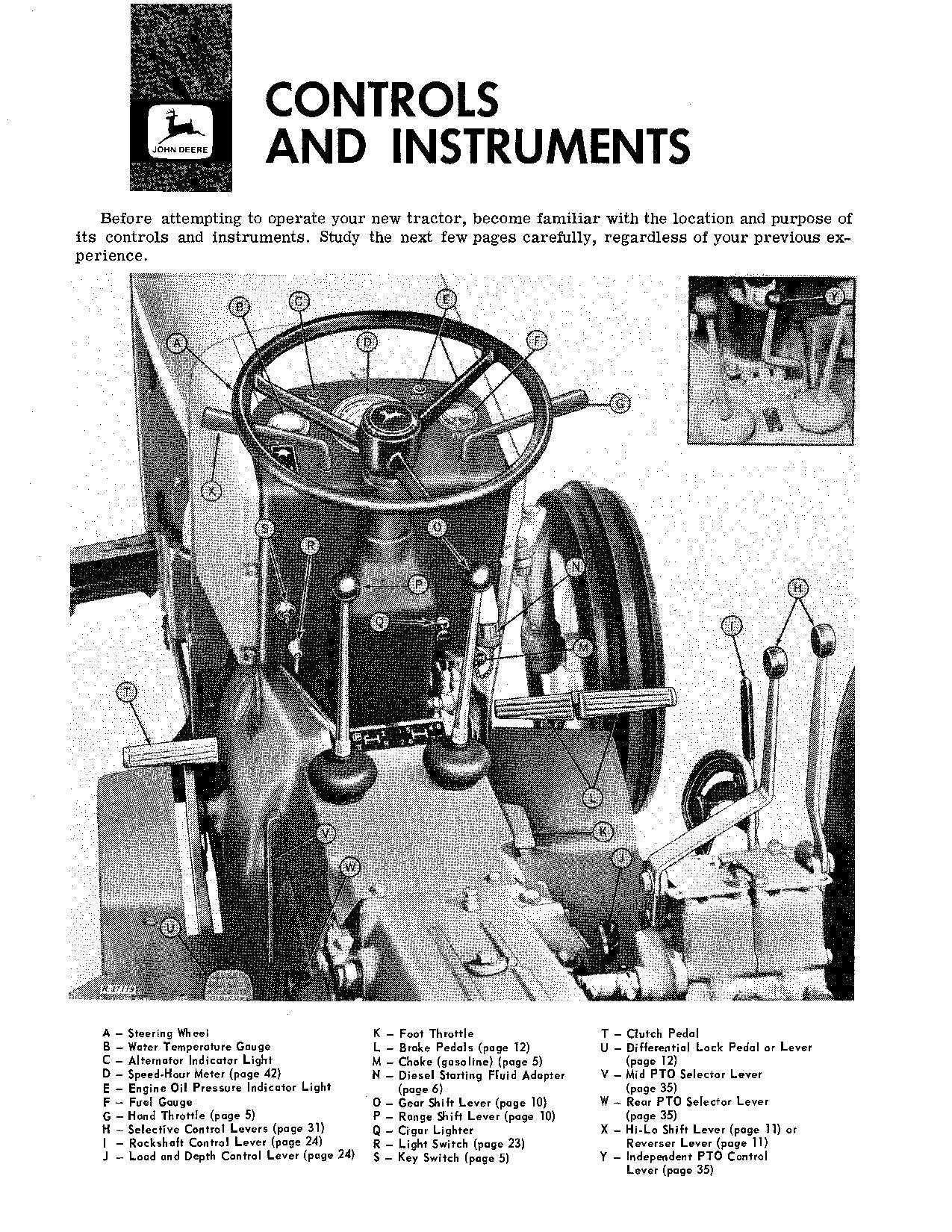

Overview of John Deere 2020

This section provides an insight into a renowned agricultural machine known for its reliability and efficiency in various farming tasks. It has gained popularity among operators for its performance and user-friendly design, making it a staple in modern agriculture.

Key Features

The machine is equipped with advanced technology that enhances its capabilities. Its robust engine ensures optimal power delivery, allowing it to handle demanding workloads with ease. Additionally, the intuitive controls facilitate seamless operation, making it accessible for both seasoned professionals and newcomers.

Maintenance Considerations

Regular upkeep is essential to maintain the efficiency and longevity of this equipment. Operators should adhere to recommended service intervals and perform routine checks to ensure all components are functioning correctly. Understanding the maintenance needs can significantly contribute to the machine’s overall performance and reliability.

Common Issues Faced by Owners

Many individuals who own agricultural machinery encounter a range of challenges during operation and maintenance. Understanding these common difficulties can help in preventing more serious complications and ensure smooth functionality. Below are some frequently reported concerns that users experience.

Engine Performance Problems

One of the most prevalent issues is related to engine performance. Owners often report difficulties with starting, stalling, or reduced power output. These symptoms may be caused by various factors, including fuel delivery issues, air filter blockages, or ignition system malfunctions. Regular inspections and timely replacements of worn components can mitigate these concerns.

Hydraulic System Failures

The hydraulic system is crucial for the operation of various implements. Users frequently face problems such as leaks, unresponsive controls, or inadequate lifting capacity. These issues may arise from worn seals, damaged hoses, or low fluid levels. Addressing hydraulic system maintenance proactively can enhance overall efficiency and longevity.

Essential Tools for Repairs

For any maintenance task, having the right equipment is crucial to ensure efficiency and effectiveness. This section outlines the fundamental instruments that facilitate the upkeep of various machinery, enhancing performance and longevity.

Basic Hand Tools

Starting with hand tools, a good selection includes wrenches, screwdrivers, and pliers. These items are indispensable for tightening, loosening, and adjusting components. Opt for high-quality materials to ensure durability and reliability during use.

Diagnostic Instruments

Next, consider diagnostic tools that assist in identifying issues accurately. Multimeters, pressure gauges, and scan tools can provide valuable insights into the condition of machinery. Using these devices enables users to pinpoint problems and make informed decisions about necessary actions.

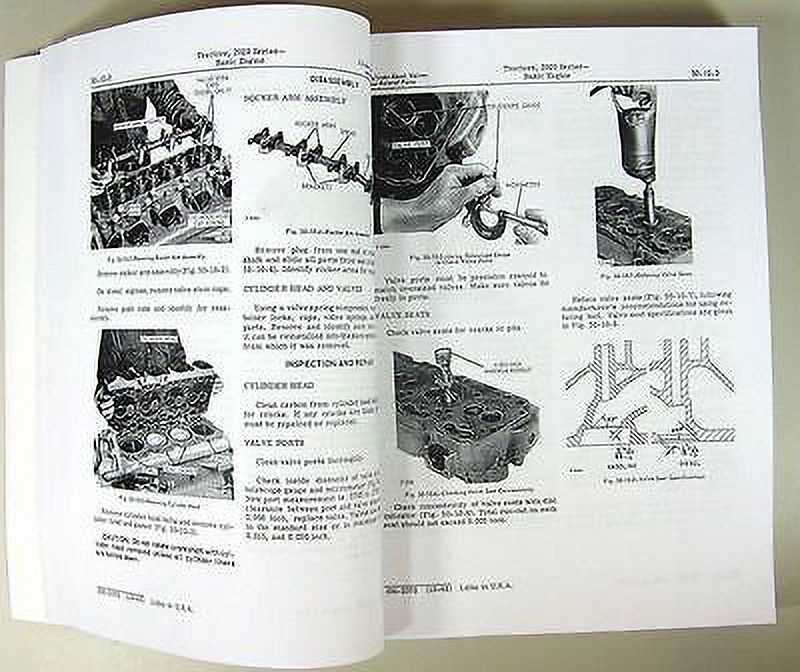

Step-by-Step Maintenance Procedures

Proper upkeep is essential for optimal performance and longevity of your equipment. Following systematic protocols ensures that all components function effectively and helps prevent future issues. This section outlines essential steps to maintain your machinery, promoting efficiency and reliability.

1. Routine Cleaning: Begin by removing dirt and debris from the exterior and engine components. Use a soft brush or compressed air to clear away any buildup, ensuring that ventilation areas remain unobstructed.

2. Fluid Checks: Regularly inspect all fluid levels, including engine oil, coolant, and hydraulic fluids. Topping up or replacing fluids as needed is crucial for smooth operation and preventing overheating.

3. Filter Replacement: Schedule the replacement of air and oil filters at recommended intervals. Clean filters enhance air quality and lubrication, contributing to overall efficiency.

4. Inspect Belts and Hoses: Examine all belts and hoses for signs of wear, cracking, or fraying. Replace any components that show significant wear to prevent unexpected breakdowns.

5. Battery Maintenance: Check battery connections for corrosion and ensure that terminals are secure. Cleaning and maintaining the battery extends its life and improves starting performance.

6. Tire Inspection: Regularly assess tire pressure and tread depth. Properly inflated tires contribute to better traction and fuel efficiency.

7. Lubrication: Apply grease to moving parts and pivot points as specified in the guidelines. Regular lubrication minimizes wear and ensures smooth operation.

Following these maintenance steps will enhance the reliability of your equipment, helping to avoid costly repairs and extend its operational life.

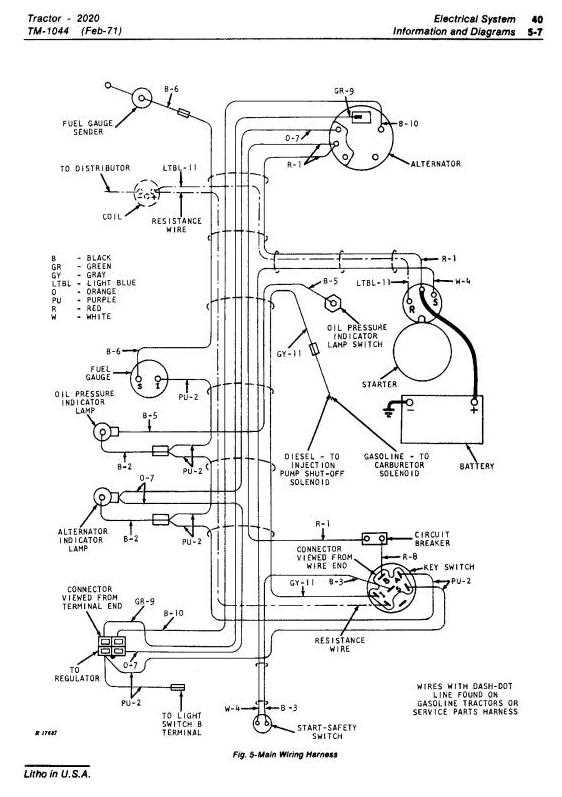

Electrical System Troubleshooting

This section focuses on diagnosing and resolving issues within the electrical framework of agricultural machinery. Understanding common problems and their potential solutions can enhance performance and prevent downtime.

Symptoms of Electrical Issues

Several signs may indicate faults within the system, such as inconsistent power supply, malfunctioning lights, or unresponsive components. Identifying these symptoms early can save time and resources.

Basic Troubleshooting Steps

Start by inspecting connections for corrosion or damage. Check fuses and relays to ensure they are functioning correctly. Utilizing a multimeter can assist in verifying voltage levels and continuity across circuits.

Common Problems and Solutions

Wiring faults are a frequent cause of electrical malfunctions. Repairing or replacing damaged wires can often resolve these issues. Additionally, ensure that all connectors are secure and free of debris.

In cases of persistent problems, consult the electrical schematics specific to your equipment. These diagrams provide essential insights into the layout and function of the system, facilitating more effective troubleshooting.

Engine Performance Enhancements

Improving the efficiency and power of an engine can significantly enhance overall functionality and longevity. Various modifications and upgrades can lead to improved fuel economy, increased torque, and enhanced responsiveness, making the machine more effective for various tasks.

One key method to boost performance involves optimizing the air intake system. Upgrading to a high-flow air filter can enhance airflow, allowing the engine to breathe better. Additionally, installing a performance intake manifold can further increase air delivery, promoting more efficient combustion.

Another effective approach is to examine the exhaust system. Upgrading to a less restrictive exhaust can reduce back pressure, facilitating quicker expulsion of exhaust gases. This improvement can lead to better engine performance and a more aggressive sound.

Tuning the engine’s control module can also yield substantial gains. Custom tuning can adjust fuel maps and ignition timing, optimizing performance based on specific conditions and requirements. This process ensures that the engine operates at its peak efficiency.

Finally, regular maintenance and monitoring are essential to sustain performance improvements. Keeping the fuel system clean, replacing spark plugs, and ensuring proper lubrication can all contribute to a more robust and responsive engine.

Hydraulic System Maintenance Tips

Regular upkeep of hydraulic systems is essential for ensuring optimal performance and longevity. By following a few key practices, operators can significantly reduce the risk of unexpected failures and enhance the efficiency of their machinery.

Check Fluid Levels

Maintaining appropriate fluid levels is crucial for the proper functioning of hydraulic systems. Regularly inspect the reservoir and top up with the recommended hydraulic fluid as needed. Neglecting this step can lead to inadequate lubrication and overheating.

Inspect Hoses and Fittings

Frequent examination of hoses and fittings is vital. Look for signs of wear, such as cracks or leaks, which can compromise the system’s integrity. Replacing damaged components promptly will prevent larger issues and maintain system efficiency. Additionally, ensure all connections are tight to avoid fluid loss.

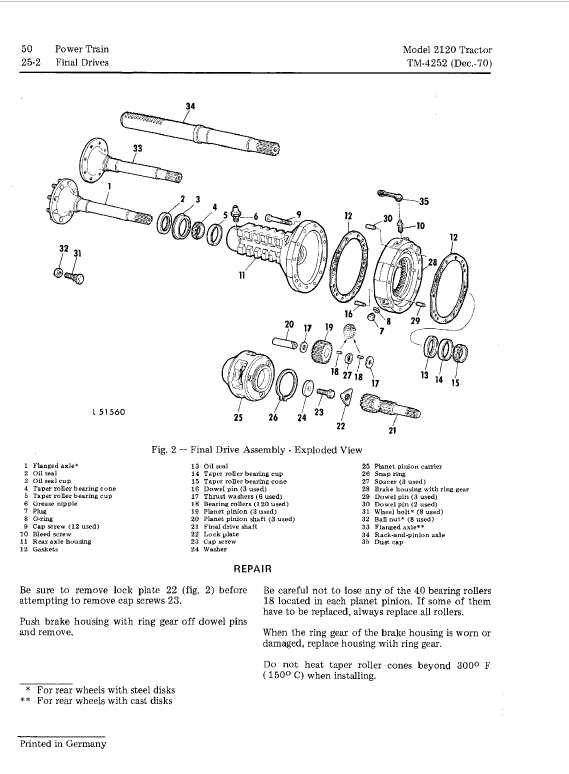

Parts Replacement Guide

This section provides essential information for replacing components in your equipment. Understanding the process and identifying the correct parts are crucial for maintaining optimal performance and longevity. Proper installation and timely replacements can prevent further issues and ensure smooth operation.

When considering part swaps, begin by consulting the specifications for compatibility. It’s important to source genuine or high-quality aftermarket parts to maintain reliability. Review the manual for detailed diagrams and instructions, which will assist in the correct assembly and disassembly of components.

Before starting the replacement process, ensure you have all necessary tools on hand. Safety should always be a priority, so wear appropriate gear and follow safety guidelines. If you’re unfamiliar with the replacement procedure, consider seeking assistance from a professional or referencing detailed guides.

Regular maintenance checks will help identify parts that require attention. Keeping a log of replacements can also provide insight into the performance and health of the machine, helping to forecast future needs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount for both efficiency and well-being. Proper measures can prevent accidents and facilitate a smoother working environment. It is crucial to follow guidelines that enhance protection against potential hazards.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-ventilated and free from clutter to minimize risks.

- Disconnect the power source before starting any work to prevent accidental activation.

- Keep tools organized and within reach to avoid unnecessary movements and distractions.

Emergency Preparedness

- Familiarize yourself with the location of first aid kits and fire extinguishers.

- Know how to respond in case of emergencies, including reporting procedures and evacuation routes.

- Maintain communication devices within reach to call for help if needed.

By adhering to these precautions, individuals can significantly reduce the likelihood of incidents and ensure a safe working atmosphere while conducting maintenance tasks.

Understanding the Operator’s Manual

The operator’s guide serves as an essential resource for anyone looking to effectively utilize and maintain their machinery. It encompasses vital information regarding functionality, safety protocols, and maintenance routines, ensuring optimal performance and longevity of the equipment. Familiarizing oneself with this document is crucial for both novice and experienced operators.

Key components of the guide include detailed explanations of the controls, operational procedures, and troubleshooting tips. This knowledge empowers users to handle various situations confidently, enhancing their overall experience and efficiency.

| Section | Description |

|---|---|

| Introduction | An overview of the equipment and its intended uses. |

| Safety Guidelines | Important precautions to prevent accidents and injuries. |

| Operational Instructions | Step-by-step guidance on how to operate the machinery effectively. |

| Maintenance Tips | Routine checks and procedures to ensure proper upkeep. |

| Troubleshooting | Common issues and their respective solutions for quick resolution. |

Tips for Seasonal Maintenance

Proper upkeep of machinery is essential for optimal performance throughout the year. Regular attention to seasonal tasks can prevent issues and prolong the lifespan of your equipment. Here are some effective strategies to consider during seasonal transitions.

Start by checking fluid levels, including oil and coolant, ensuring they are at recommended levels. Clean or replace filters as necessary to maintain airflow and efficiency. Inspect belts and hoses for wear, addressing any signs of damage promptly to avoid potential breakdowns.

Additionally, take time to examine tires for proper inflation and tread wear, which can impact traction and fuel efficiency. Lubricate moving parts according to the manufacturer’s guidelines, enhancing functionality and reducing friction. Finally, store equipment in a sheltered area during extreme weather conditions to protect it from the elements.

Resources for Parts and Service

Finding the right components and support for maintenance is essential for optimal performance. Accessing reliable sources can significantly enhance the longevity and efficiency of your equipment.

Online Resources

- Manufacturer’s Official Website

- Online Retailers Specializing in Agricultural Equipment

- Parts Catalogs and Databases

Local Options

- Authorized Dealers and Distributors

- Local Repair Shops

- Farm Equipment Auctions and Sales

Utilizing these avenues can help ensure you have the necessary resources for effective upkeep and timely repairs.