This section provides an extensive overview of essential procedures for maintaining and servicing agricultural machinery. The focus lies on ensuring optimal functionality and longevity of your equipment through regular upkeep and prompt resolution of issues.

Understanding the intricacies of your machinery is vital for effective operation. Familiarity with the various components and their interactions allows for efficient identification of potential challenges. By following systematic approaches, users can enhance performance and reduce the likelihood of unexpected breakdowns.

Equipping yourself with the right knowledge and techniques is crucial for achieving desired outcomes. This guide serves as a valuable resource, offering insights into troubleshooting common problems and executing routine checks. Mastering these skills empowers users to take control of their equipment’s health and efficiency.

Overview of John Deere 5510

This section provides a comprehensive insight into a specific agricultural machine renowned for its versatility and efficiency. Designed to meet the demands of modern farming, this model embodies robust engineering and innovative features that cater to various agricultural tasks.

Key Features

- Powerful engine for enhanced performance

- Advanced hydraulic systems for improved operation

- Ergonomic design for operator comfort

- Durable construction to withstand rigorous use

Applications

This machine is suitable for a wide range of farming activities, including:

- Plowing and tilling

- Crop planting and harvesting

- Transportation of materials

- Land management and maintenance

Common Issues and Solutions

When operating agricultural machinery, various challenges may arise that can affect performance and efficiency. Understanding these common problems and their solutions is essential for maintaining optimal functionality and ensuring longevity.

Frequent Challenges

- Poor Engine Performance

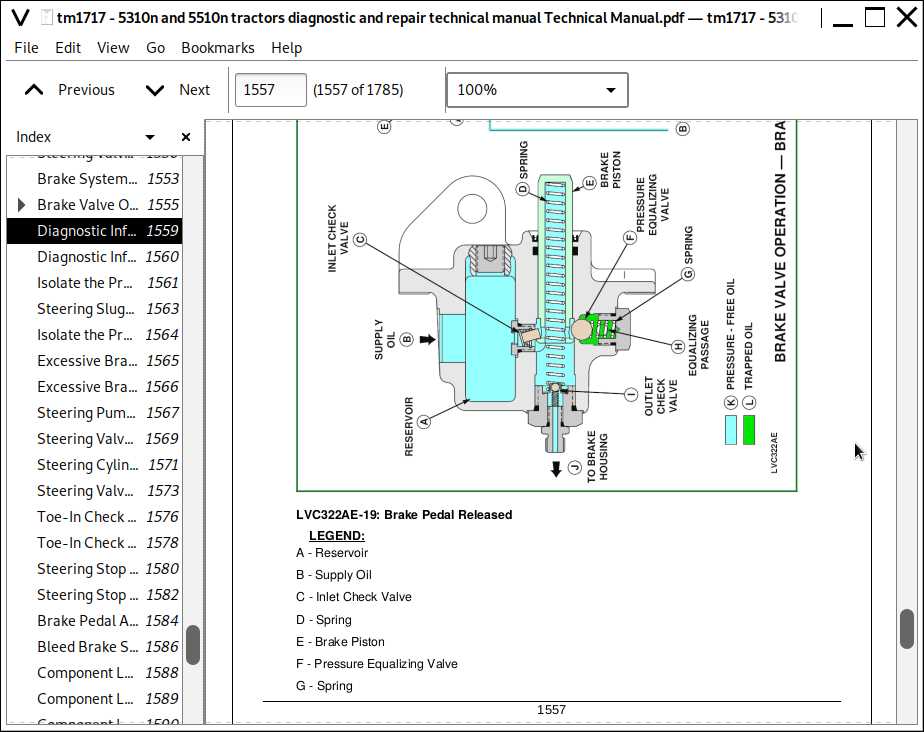

- Hydraulic System Failures

- Electrical System Malfunctions

- Transmission Issues

Solutions and Recommendations

-

Poor Engine Performance:

- Regularly check and replace air filters to ensure proper airflow.

- Inspect fuel quality and replace contaminated fuel.

-

Hydraulic System Failures:

- Monitor hydraulic fluid levels and replace fluids as needed.

- Inspect hoses and connections for leaks or wear.

-

Electrical System Malfunctions:

- Examine battery connections and clean terminals to ensure good contact.

- Test fuses and replace any that are blown.

-

Transmission Issues:

- Check fluid levels and change transmission fluid at regular intervals.

- Inspect the clutch for wear and replace if necessary.

Maintenance Procedures for Optimal Performance

To ensure the best functionality of agricultural machinery, regular upkeep is essential. Implementing systematic care routines can significantly enhance the longevity and efficiency of equipment, reducing the likelihood of unexpected failures. Adopting a proactive approach in maintenance can lead to improved productivity and operational reliability.

Routine Inspections: Frequent evaluations of essential components are crucial. Check fluid levels, filter conditions, and tire pressures to prevent potential issues. Regularly inspect belts and hoses for wear or damage, addressing any signs of deterioration immediately.

Lubrication: Proper lubrication of moving parts minimizes friction and wear. Follow the manufacturer’s recommendations for lubrication intervals and types of grease or oil. Ensure all joints, bearings, and pivot points receive adequate lubrication to maintain smooth operation.

Cleaning: Keeping the machinery clean is vital for optimal performance. Remove dirt, debris, and residues from critical areas, especially around cooling systems and engine compartments. A clean machine not only performs better but also allows for easier identification of any emerging problems.

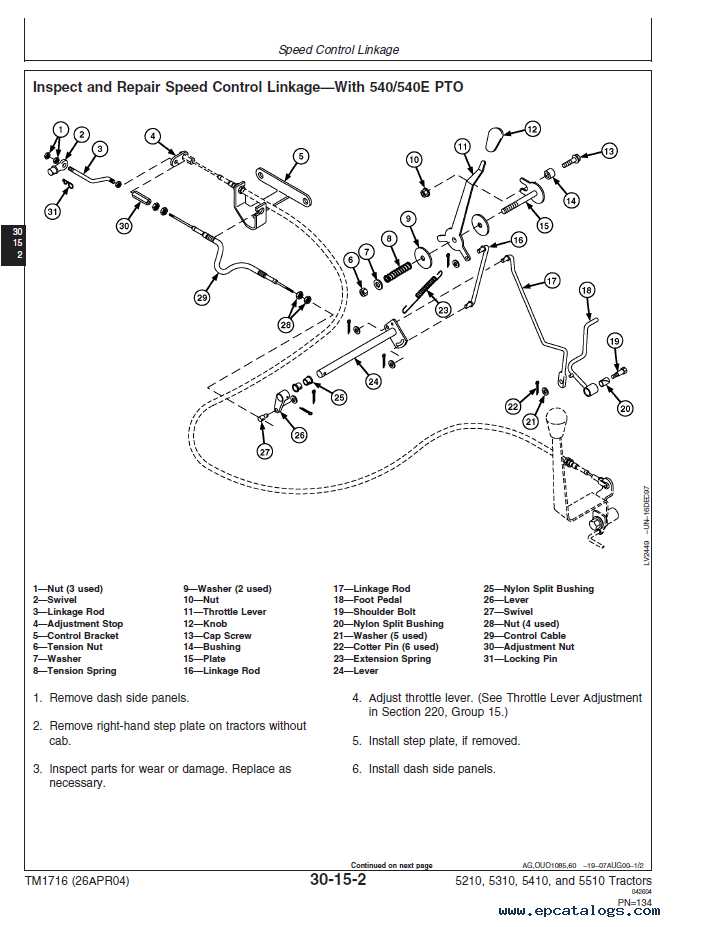

Calibration and Adjustments: Regularly calibrate equipment settings according to specific operational needs. Adjustments may be required for various components to ensure they function within optimal parameters. This practice helps in achieving accurate performance and efficient fuel usage.

Seasonal Preparation: Before seasonal changes, perform a thorough check-up. Winterizing equipment, for instance, involves draining fluids and ensuring proper storage. Likewise, pre-season checks can identify any necessary repairs or adjustments to prepare for peak operational periods.

By following these maintenance protocols diligently, users can maximize the performance and reliability of their agricultural equipment, ensuring it operates efficiently for years to come.

Tools Required for Repairs

When it comes to maintaining agricultural machinery, having the right equipment is crucial for effective and efficient service. Proper tools not only facilitate the repair process but also ensure safety and precision. Below is a comprehensive list of essential instruments needed for successful maintenance tasks.

Essential Hand Tools

- Wrenches: Various sizes are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are important for accessing different fasteners.

- Pliers: Useful for gripping, bending, and cutting wires or other materials.

- Socket Set: A complete set will make it easier to work with different nut and bolt sizes.

- Hammer: A reliable tool for driving fasteners or for light demolition tasks.

Specialized Equipment

- Diagnostic Tools: These are essential for troubleshooting electronic systems and identifying faults.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Lift Equipment: Essential for safely raising machinery to access undercarriages or perform maintenance.

- Grease Gun: Necessary for lubricating various moving parts to maintain performance.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to assist in troubleshooting and maintaining agricultural machinery effectively. Following a systematic approach can help identify issues and ensure optimal performance.

- Preparation:

- Gather necessary tools and replacement parts.

- Ensure a clean and organized workspace to facilitate repairs.

- Review safety guidelines to prevent accidents during the process.

- Diagnosis:

- Inspect the machinery thoroughly for visible signs of wear or damage.

- Listen for unusual noises during operation that may indicate underlying issues.

- Check fluid levels and assess for leaks or contamination.

- Disassembly:

- Carefully remove any covers or panels to access internal components.

- Label parts as they are removed to facilitate reassembly.

- Take photographs if necessary to document the configuration.

- Repair or Replacement:

- Replace worn or damaged parts with high-quality alternatives.

- Follow specific instructions for reconditioning components when applicable.

- Ensure all connections are secure and properly aligned before moving forward.

- Reassembly:

- Carefully put all parts back in place, following the labeling system used during disassembly.

- Double-check that all fasteners are tightened to the recommended torque specifications.

- Reconnect any electrical components ensuring proper function.

- Final Checks:

- Perform a thorough inspection to confirm that everything is in order.

- Run the machinery in a controlled environment to test for proper operation.

- Monitor for any leaks or irregular noises during initial operation.

Following these detailed steps can help ensure the longevity and efficiency of agricultural equipment, making maintenance straightforward and manageable.

Electrical System Troubleshooting Guide

This section provides a comprehensive overview of diagnosing issues within electrical systems commonly found in agricultural machinery. Understanding the intricacies of these systems is essential for effective problem-solving and maintenance.

Follow these steps to systematically identify and resolve electrical problems:

- Visual Inspection:

- Check for damaged wires or connectors.

- Inspect fuses for continuity.

- Look for signs of corrosion on terminals.

- Power Supply Verification:

- Ensure the battery is fully charged.

- Test the voltage output from the alternator.

- Confirm that all switches are functioning correctly.

- Component Testing:

- Use a multimeter to test key components.

- Check relays for proper operation.

- Assess sensors for accurate readings.

- Wiring Diagram Reference:

- Utilize wiring diagrams to trace circuits.

- Identify potential short circuits or open circuits.

- Cross-check with manufacturer specifications.

- Consultation of Resources:

- Review technical bulletins or service guides.

- Engage with forums or communities for shared experiences.

- Seek assistance from trained professionals when necessary.

Implementing these strategies will enhance the troubleshooting process and facilitate effective repairs, ensuring optimal performance of the equipment.

Hydraulic System Maintenance Tips

Proper upkeep of hydraulic systems is essential for ensuring optimal performance and longevity of machinery. Regular maintenance helps prevent costly repairs and enhances the efficiency of the equipment.

Here are some key practices to follow for maintaining hydraulic systems:

- Regular Fluid Checks: Frequently inspect the hydraulic fluid levels. Low fluid can lead to overheating and component wear.

- Filter Replacement: Change hydraulic filters according to the manufacturer’s recommendations to prevent contaminants from damaging the system.

- Leak Inspection: Routinely check hoses and connections for leaks. Addressing any leaks promptly can save fluid and maintain pressure levels.

- System Flush: Periodically flush the hydraulic system to remove any accumulated debris and contaminants.

- Temperature Monitoring: Keep an eye on the operating temperature. Elevated temperatures can indicate issues within the system.

Implementing these maintenance tips will help in prolonging the life of the hydraulic system and improving overall machinery performance.

Replacing Engine Components

Maintaining optimal performance of machinery often involves the careful replacement of various engine parts. This process ensures that the equipment functions efficiently and reliably, minimizing the risk of breakdowns. Understanding the steps involved in this task can significantly enhance the longevity of the engine.

Essential Tools and Equipment

Before initiating the component replacement, it is crucial to gather the necessary tools. Having the right equipment at hand not only simplifies the process but also ensures safety and precision.

| Tool | Purpose |

|---|---|

| Socket Set | For removing and securing bolts |

| Screwdriver | For adjusting various fittings |

| Torque Wrench | For applying precise torque settings |

| Engine Hoist | For lifting heavy components safely |

Steps for Component Replacement

Once the tools are ready, follow a systematic approach for replacing the components. Begin by disconnecting the power supply and draining any fluids. Next, remove the old parts, taking care to note their arrangement for proper installation of new components. Finally, install the new parts, ensuring all connections are secure and fluids are replaced before restarting the engine.

Wheel and Tire Care Practices

Proper maintenance of wheels and tires is essential for ensuring optimal performance and longevity of any vehicle. Regular attention to these components not only enhances safety but also contributes to improved fuel efficiency and a smoother ride. Implementing best practices in care can prevent premature wear and costly replacements.

Inspection and Cleaning: Regularly examining wheels and tires for signs of damage, such as cracks, bulges, or irregular wear patterns, is crucial. Cleaning tires to remove dirt, debris, and other contaminants helps maintain their integrity and appearance. A gentle brush and mild detergent can be effective for this purpose.

Pressure Maintenance: Keeping tires inflated to the recommended pressure is vital. Under-inflation can lead to increased wear, reduced fuel efficiency, and compromised handling. Utilize a reliable gauge to check tire pressure regularly, especially before long journeys.

Alignment and Balancing: Ensuring proper wheel alignment and balancing is necessary for even tire wear and vehicle stability. Misalignment can result in excessive wear on specific areas of the tire, while unbalanced wheels can cause vibrations that affect driving comfort.

Seasonal Considerations: Adapting tire choices according to seasonal changes is important. Using all-season or specialized tires suited for specific weather conditions enhances traction and performance. Additionally, regular rotation of tires helps to ensure even wear across all tires.

By adhering to these maintenance practices, vehicle owners can extend the lifespan of their wheels and tires, promoting safety and efficiency on the road.

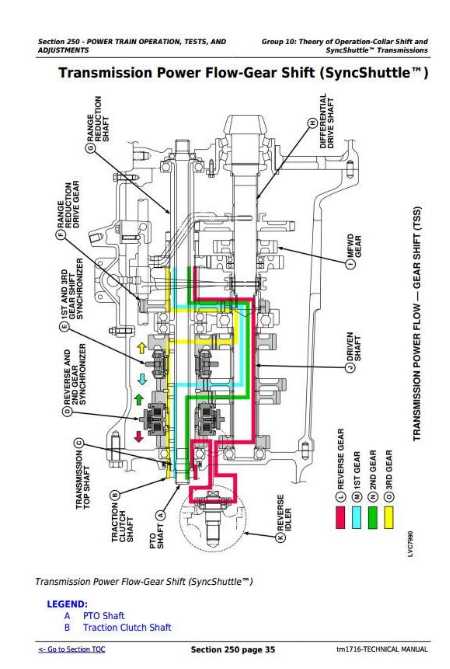

Transmission Troubleshooting Techniques

Tackling issues related to transmission systems requires a systematic approach to identify and resolve potential malfunctions. By employing effective diagnostic strategies, operators can enhance the performance and reliability of their machinery. This section outlines essential techniques to diagnose common transmission problems, facilitating timely repairs and maintenance.

Start by observing the operation of the transmission during various tasks. Pay close attention to unusual noises, shifts, or responses that may indicate underlying issues. Documentation of symptoms is crucial for diagnosing the problem accurately.

| Symptom | Possible Causes | Recommended Actions |

|---|---|---|

| Slipping gears | Low fluid level, worn clutches | Check fluid level and top up; inspect and replace clutches if necessary. |

| Unresponsive shifting | Faulty linkage, damaged shift cable | Examine linkage for obstructions; replace any damaged cables. |

| Overheating | Contaminated fluid, blocked cooler | Replace transmission fluid; clean or replace the cooler. |

| Fluid leaks | Worn seals, loose connections | Inspect seals and tighten connections; replace any damaged seals. |

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks associated with working on machinery. It is essential to prioritize personal well-being and that of others in the vicinity.

First and foremost, always wear appropriate protective gear. This includes safety goggles, gloves, and sturdy footwear to shield against potential hazards. In addition, utilizing ear protection can help guard against excessive noise, which is common in mechanical environments.

Furthermore, it is important to work in a well-ventilated area. Proper airflow helps minimize exposure to harmful fumes and ensures a safer workspace. Before commencing any task, familiarize yourself with the equipment’s specific safety features and instructions, as this knowledge can be vital in emergencies.

Lastly, maintain a clean and organized workspace. A clutter-free environment allows for better movement and reduces the chance of mishaps. By implementing these safety measures, individuals can effectively mitigate risks and contribute to a safer working atmosphere.

Parts Replacement and Upgrades

Maintaining machinery in optimal condition often involves the timely replacement of components and implementing enhancements. Upgrading various parts not only improves performance but also extends the lifespan of the equipment. This section outlines the key considerations and procedures for effectively replacing and upgrading crucial components.

Identifying Worn Components

Regular inspections are essential for identifying parts that require replacement. Look for signs of wear, such as unusual noises, reduced efficiency, or visible damage. Components such as filters, belts, and hoses are particularly susceptible to wear and should be monitored closely. Keeping a detailed log of inspections can help in forecasting replacement needs.

Upgrading for Enhanced Performance

In addition to replacing worn components, upgrading specific parts can lead to significant performance improvements. Consider enhancements like more efficient filters or performance-optimized hydraulic systems. Always consult the manufacturer’s recommendations to ensure compatibility and maintain the integrity of the machinery.

Resources for Further Assistance

When faced with challenges in maintaining and troubleshooting your agricultural machinery, accessing the right resources can significantly enhance your understanding and resolution of issues. A variety of tools, guides, and communities are available to provide support, ensuring that you can achieve optimal performance from your equipment.

Online Forums and Communities

Participating in dedicated online forums can be invaluable for obtaining advice from experienced users. These platforms allow you to share experiences, ask questions, and learn from others who have faced similar challenges. Engaging with fellow enthusiasts can help you uncover tips and techniques that may not be covered in traditional guides.

Manufacturer Support and Documentation

Utilizing official support channels from the manufacturer can provide access to a wealth of documentation and technical assistance. Websites often feature downloadable resources, including troubleshooting guides and service bulletins, which can offer insights into common problems and solutions. Reaching out directly to customer service can also yield personalized support tailored to your specific needs.