In the realm of agricultural equipment, ensuring optimal performance is paramount for efficiency and longevity. Proper upkeep not only enhances functionality but also significantly extends the lifespan of these essential tools. This section delves into the various aspects of maintenance and troubleshooting, providing valuable insights for operators and enthusiasts alike.

Understanding the intricacies of your machinery can seem daunting, yet having access to detailed guidance simplifies the process. By familiarizing yourself with the various components and their functions, you can proactively address potential issues before they escalate. This resource aims to equip you with the knowledge needed to keep your equipment in peak condition.

From basic adjustments to more complex repairs, mastering the art of maintenance will empower you to take control of your agricultural endeavors. The following sections will offer step-by-step instructions, tips, and best practices to ensure that your machinery remains a reliable ally in the field.

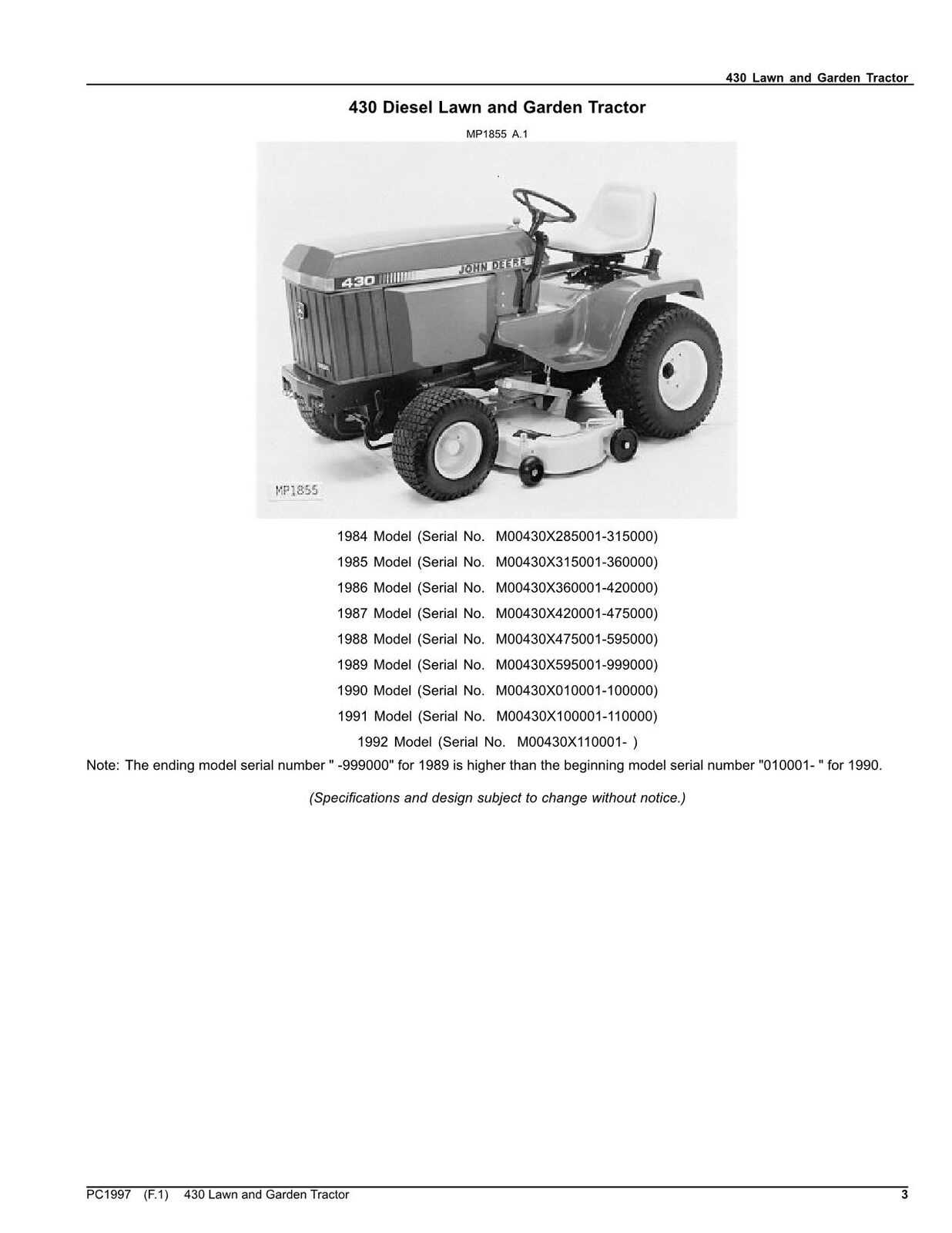

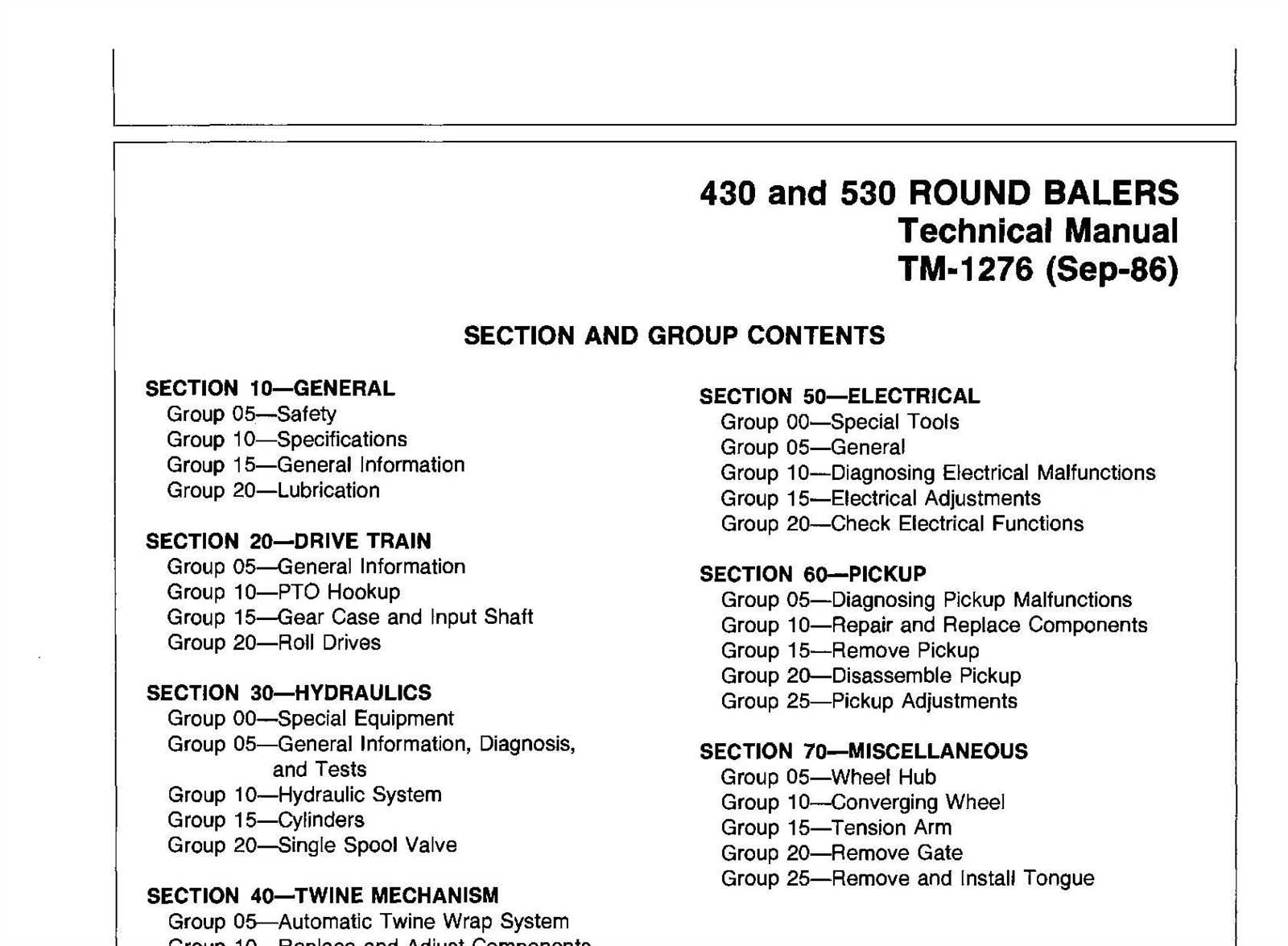

Overview of John Deere 430

This section provides a comprehensive look at a notable model in the agricultural machinery sector. Renowned for its versatility and durability, this equipment is a favored choice among both professionals and enthusiasts in farming and landscaping. Its design emphasizes ease of use and maintenance, making it accessible to a wide range of operators.

Key Features

- Robust engine performance for various tasks

- Compact design ideal for tight spaces

- User-friendly controls for improved handling

- Adaptability with a range of attachments

Common Applications

- Farming and tillage

- Landscaping and gardening

- Snow removal and winter maintenance

- Transporting materials and goods

Importance of Repair Manuals

Having access to detailed guides is crucial for anyone working with complex machinery. These resources provide essential information that helps users troubleshoot issues, perform maintenance, and execute repairs effectively. By following these comprehensive instructions, operators can ensure that their equipment functions smoothly and efficiently.

Moreover, these guides not only enhance the understanding of the machinery’s components but also promote safety during operation. When users are well-informed about the inner workings and potential problems, they can take preventative measures to avoid accidents or malfunctions. This leads to increased longevity of the equipment and reduced downtime.

In addition, such documents can save both time and money. With step-by-step directions, individuals can often handle repairs themselves instead of relying on professional services, which can be costly. This empowers users, fostering confidence in their ability to maintain their machines effectively.

Overall, access to thorough instructional resources is indispensable for maximizing operational efficiency and ensuring the safety and durability of machinery.

Common Issues with John Deere 430

Various challenges can arise with this agricultural machine, often affecting its performance and efficiency. Understanding these frequent problems can assist users in maintaining optimal functionality and extending the lifespan of the equipment.

Typical Mechanical Problems

- Engine Starting Difficulties: Many operators report issues with ignition, leading to delays in operation.

- Overheating: This can stem from insufficient coolant levels or a malfunctioning radiator.

- Transmission Issues: Difficulties in shifting gears may indicate low fluid levels or internal wear.

Electrical Failures

- Battery Problems: A common occurrence is battery drainage, often due to old age or parasitic draws.

- Wiring Issues: Frayed or damaged wires can lead to inconsistent performance of electrical components.

- Faulty Sensors: Malfunctioning sensors may cause incorrect readings, impacting operational efficiency.

Essential Tools for Repairs

Having the right set of instruments is crucial for effectively addressing maintenance tasks and ensuring optimal performance of machinery. A well-equipped toolkit not only streamlines the repair process but also enhances safety and precision during work. This section highlights key items that every technician should consider having at their disposal.

First and foremost, a comprehensive assortment of hand tools is indispensable. Wrenches, pliers, and screwdrivers in various sizes allow for tackling a wide range of fasteners. Additionally, a quality socket set can significantly ease the process of loosening or tightening bolts in hard-to-reach areas.

Moreover, measuring instruments such as calipers and tape measures are vital for accurate assessments and adjustments. These tools ensure that all components fit together perfectly, which is essential for maintaining the integrity of the equipment.

Safety equipment should never be overlooked. Protective eyewear, gloves, and sturdy footwear are necessary to prevent injuries while working on machinery. Investing in reliable safety gear ensures a secure working environment and promotes responsible practices.

Lastly, having diagnostic tools like multimeters and pressure gauges can greatly assist in identifying issues promptly. These instruments provide valuable insights into the functionality of various systems, enabling quick and efficient troubleshooting.

Step-by-Step Repair Processes

This section provides a comprehensive guide to efficiently address maintenance tasks and troubleshooting procedures for your machinery. Following a structured approach will ensure that each issue is tackled methodically, leading to optimal performance and longevity.

-

Identify the Issue:

- Conduct a visual inspection.

- Listen for unusual sounds during operation.

- Check for warning lights or error messages.

-

Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches and socket sets

- Multimeter for electrical checks

-

Consult Reference Material:

- Locate the appropriate technical documentation.

- Review diagrams and part lists.

- Understand recommended procedures and specifications.

-

Perform the Repair:

- Follow safety protocols.

- Carefully disassemble the affected components.

- Replace or repair parts as needed.

-

Reassemble and Test:

- Reinstall all components in reverse order.

- Double-check connections and fittings.

- Run a test to ensure functionality.

Adhering to these steps will help you systematically address challenges, ensuring that your equipment remains in peak condition.

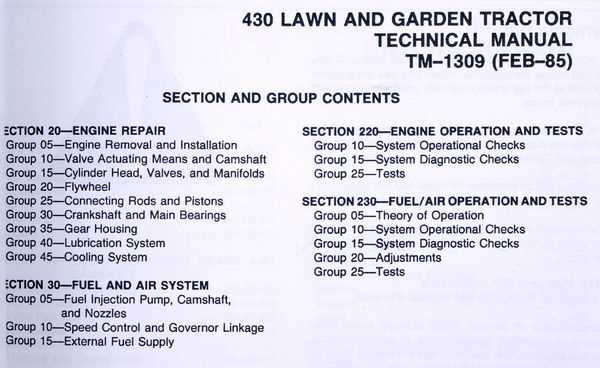

Understanding the Engine Components

In any machinery, the engine serves as the heart, powering the entire system and enabling it to function efficiently. Recognizing the various parts that make up the engine is crucial for proper maintenance and optimal performance. Each component plays a distinct role, contributing to the overall operation and longevity of the machine.

Fuel System: The fuel system is responsible for delivering the necessary fuel to the engine. It includes components such as the fuel tank, pump, and injectors, which work together to ensure a steady supply of fuel for combustion.

Air Intake System: This system facilitates the entry of air into the engine, which is essential for the combustion process. Key elements include the air filter and intake manifold, both of which help maintain optimal airflow and filter out contaminants.

Ignition System: The ignition system ignites the fuel-air mixture within the engine’s cylinders. It consists of components like spark plugs, ignition coils, and wiring, all of which are vital for starting and running the engine efficiently.

Cooling System: To prevent overheating, the cooling system circulates coolant through the engine. Important parts include the radiator, water pump, and thermostat, all of which work together to regulate temperature and maintain engine health.

Exhaust System: The exhaust system expels combustion gases from the engine. It typically includes the exhaust manifold, catalytic converter, and muffler, which not only improve performance but also reduce emissions.

Understanding these fundamental components allows operators to diagnose issues, perform regular checks, and ensure the machinery runs smoothly for years to come.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of machinery is crucial for optimal performance. A systematic approach can help identify problems that may affect functionality, efficiency, or safety. This section outlines effective strategies for troubleshooting electrical components and systems.

Common Issues and Symptoms

When dealing with electrical malfunctions, it’s important to recognize the typical signs that indicate a problem. Here are some common issues:

- Inconsistent power supply

- Burnt fuses or tripped breakers

- Corroded connectors

- Dim or flickering lights

- Unresponsive controls

Troubleshooting Steps

Follow these steps to systematically address electrical concerns:

- Visual Inspection: Check for obvious signs of wear, damage, or loose connections.

- Check Power Sources: Ensure that batteries or power supplies are fully charged and functioning correctly.

- Test Continuity: Use a multimeter to verify that circuits are complete and free from breaks.

- Examine Components: Inspect switches, relays, and wiring for faults.

- Consult Wiring Diagrams: Refer to schematic representations to trace and verify connections.

By following these guidelines, operators can effectively identify and address electrical issues, ensuring the machinery operates smoothly and safely.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves a series of best practices that focus on regular upkeep and preventive measures. By following these guidelines, you can enhance performance, reduce wear and tear, and minimize unexpected breakdowns.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil to improve engine performance. |

| Filter Replacement | Every 100 hours | Replace air and fuel filters to maintain efficiency. |

| Tire Inspection | Monthly | Check for wear and proper inflation to ensure safety. |

| Battery Check | Every 6 months | Clean terminals and check for corrosion. |

| Grease Moving Parts | Every 10 hours | Regular lubrication reduces friction and extends component life. |

By adhering to these maintenance tips, you can ensure that your machinery operates smoothly and efficiently for many years to come. Regular attention to detail will pay off in reliability and performance.

Parts Replacement Guide

Maintaining the efficiency of your equipment is crucial for optimal performance. When components wear out or fail, timely replacement can significantly extend the lifespan of the machine and improve its functionality. This guide provides essential insights into identifying parts that require replacement and offers a systematic approach to ensure proper installation and compatibility.

Identifying Worn Components

Regular inspections are key to recognizing when parts need to be changed. Look for signs such as unusual noises, decreased performance, or visible damage. Common indicators include excessive vibration, leaking fluids, and irregular movements. Keeping a detailed log of maintenance checks will help you track component conditions over time.

Replacement Procedure

Once you’ve identified a component that requires attention, follow these steps for replacement: 1. Gather the necessary tools and replacement parts. 2. Ensure the equipment is turned off and secure. 3. Carefully remove the damaged part, taking note of the installation process. 4. Install the new component, ensuring all connections are secure. 5. Test the equipment to verify proper operation. Following these steps will help ensure that replacements are done safely and effectively, contributing to the overall reliability of your machinery.

DIY vs. Professional Repairs

When it comes to fixing machinery, individuals often face the choice between tackling issues themselves or hiring experts. Each approach has its advantages and drawbacks, making it essential to consider factors such as cost, expertise, and time commitment.

| Aspect | DIY | Professional |

|---|---|---|

| Cost | Generally lower, as labor fees are avoided. | Higher, due to labor and service charges. |

| Time | Can be time-consuming, especially without experience. | Typically faster, as professionals have the skills. |

| Expertise | Varies; may lack specialized knowledge. | Highly skilled; often offers warranties. |

| Satisfaction | Can be rewarding to complete a task independently. | Less personal involvement but guarantees quality. |

Ultimately, the decision depends on individual circumstances, skills, and preferences. Weighing these aspects can help determine the most suitable approach for maintenance and upkeep.

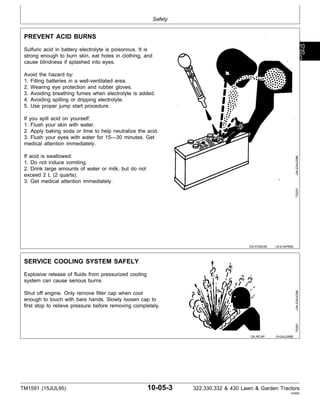

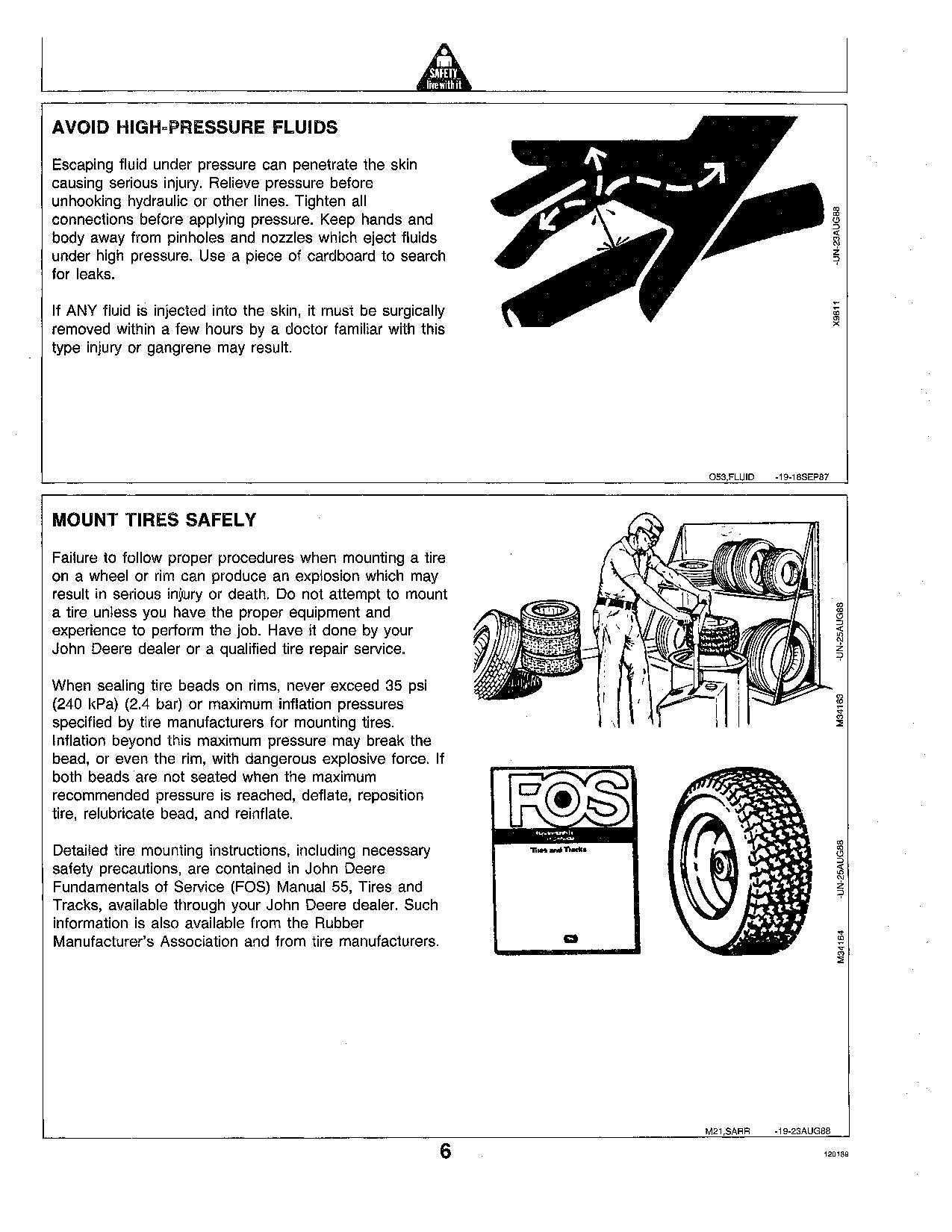

Safety Precautions When Repairing

Ensuring a safe working environment is crucial when undertaking maintenance tasks on machinery. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Understanding potential hazards and preparing adequately can lead to a smoother, safer process.

Personal Protective Equipment (PPE)

Always wear the appropriate protective gear to minimize risks. Essential items include:

- Safety glasses to protect your eyes from debris.

- Gloves to guard against cuts and abrasions.

- Steel-toed boots to shield your feet from heavy objects.

- Ear protection if working with loud machinery.

- Dust masks or respirators when dealing with harmful fumes or dust.

Workspace Safety

Maintaining a clean and organized workspace is vital. Follow these practices:

- Ensure the area is well-lit to avoid mishaps.

- Keep tools and equipment neatly arranged to prevent tripping hazards.

- Store flammable materials away from work areas.

- Make sure emergency exits are clear and accessible.

- Use appropriate lifting techniques to avoid strains.

By prioritizing safety, you can effectively minimize risks and create a productive environment while working on machinery.

Where to Find Genuine Parts

Finding authentic components for your machinery is essential for maintaining optimal performance and longevity. Utilizing high-quality parts not only ensures compatibility but also enhances the overall efficiency of the equipment.

One of the most reliable sources for genuine components is the official dealership network. These authorized retailers often carry a comprehensive inventory of original parts, providing the assurance of quality and compatibility. Additionally, their staff is well-versed in the specific requirements of your machinery, offering valuable assistance in selecting the right items.

Another excellent option is the manufacturer’s website. Many brands feature online catalogs that allow you to search for and order the exact parts you need. This method often includes detailed specifications and diagrams, making it easier to identify the correct components.

Online marketplaces can also be a viable option, but it’s crucial to ensure that the seller is reputable. Look for reviews and ratings to gauge the reliability of the parts being offered. Always verify that the components are authentic and suitable for your machinery.

Local agricultural supply stores may stock genuine parts or be able to order them for you. Building a relationship with these local businesses can be beneficial, as they often have knowledgeable staff who understand the specific needs of equipment used in your area.

Finally, consider joining online forums or community groups dedicated to your machinery. Members often share their experiences and can recommend trustworthy sources for genuine components, ensuring you make informed purchasing decisions.