Understanding how to effectively maintain and troubleshoot your portable energy source is essential for ensuring its longevity and optimal performance. This section will provide you with valuable insights into common issues that may arise and the necessary steps to address them. A well-maintained unit can serve you reliably for years, providing the power you need when you need it most.

In this guide, you will discover various techniques for diagnosing malfunctions and performing essential upkeep. By familiarizing yourself with the operational aspects of your device, you can enhance its efficiency and prevent potential problems. Regular maintenance not only extends the life of your equipment but also ensures that it operates at peak performance, delivering consistent energy supply.

Whether you are a seasoned user or a newcomer to portable power solutions, this comprehensive overview will equip you with the knowledge to manage your unit effectively. Understanding the intricacies of your equipment will empower you to tackle any challenges that arise confidently.

This section aims to provide a comprehensive overview of a portable power device that is popular among outdoor enthusiasts and for emergency use. Understanding its components and functionality is crucial for effective troubleshooting and maintenance.

Key Components and Features

Familiarity with the essential parts of the device can help users effectively address any issues. This knowledge enables a deeper understanding of how each component contributes to overall performance.

| Component | Description |

|---|---|

| Engine | Powers the unit, converting fuel into mechanical energy. |

| Fuel Tank | Holds the fuel necessary for operation, impacting run time. |

| Control Panel | Displays power output and allows for easy operation adjustments. |

| Outlet Ports | Provide connections for electrical devices, enabling power delivery. |

Importance of Regular Maintenance

Regular upkeep is vital to ensure long-lasting performance. Users should adopt a routine maintenance schedule to identify and rectify potential issues before they escalate.

Common Issues with Ryobi Generators

When dealing with portable power units, various challenges may arise that hinder their performance. Understanding these frequent complications can help users maintain their devices more effectively and ensure reliable operation.

| Issue | Description |

|---|---|

| Starting Problems | Units may fail to start due to fuel issues, spark plug defects, or battery failures. |

| Noisy Operation | Excessive noise can be a result of mechanical wear or loose components. |

| Power Fluctuations | Inconsistent voltage may occur due to load mismatches or internal faults. |

| Overheating | Units may overheat due to inadequate ventilation or low oil levels. |

| Fuel Leaks | Leaks can stem from damaged fuel lines or seals, posing safety risks. |

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance and troubleshooting of equipment. Proper tools not only make the process easier but also ensure safety and efficiency during the task.

Here are some fundamental instruments you will need:

- Screwdrivers: A set of various sizes is essential for loosening and tightening screws.

- Wrenches: Adjustable and fixed wrenches help in gripping nuts and bolts securely.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Multimeter: An essential device for checking voltage, current, and resistance in electrical circuits.

- Socket set: Provides versatility for different sizes of nuts and bolts.

- Hammer: Handy for driving nails or for forceful adjustments.

- Flashlight: Necessary for illuminating dark areas during inspections or repairs.

These tools create a solid foundation for any maintenance project, allowing for thorough examination and effective resolution of issues.

Step-by-Step Troubleshooting Guide

This guide provides a structured approach to identifying and resolving common issues encountered with portable power units. Following these steps will help you efficiently pinpoint the source of the problem and implement the necessary solutions.

Identifying the Problem

- Check if the device is receiving power.

- Inspect the fuel level and quality.

- Examine the oil levels and condition.

- Listen for unusual sounds during operation.

Troubleshooting Steps

- Ensure all connections are secure and clean.

- Replace any damaged or worn components.

- Test the ignition system for faults.

- Consult the specifications for proper settings.

- Run diagnostics if available to uncover hidden issues.

By following this systematic troubleshooting approach, you can effectively restore functionality and ensure reliable performance from your unit.

Replacing the Spark Plug

Replacing the spark plug is a crucial maintenance task that ensures optimal performance of your power unit. A worn or damaged spark plug can lead to poor ignition and decreased efficiency, making it essential to address this component regularly.

Steps to Follow

Begin by disconnecting the ignition source to prevent accidental starts. Locate the spark plug, which is typically found near the engine. Use a spark plug socket and ratchet to unscrew the old plug carefully. Inspect it for wear and damage, which can indicate underlying issues.

Installing the New Spark Plug

Before installing the new plug, check the gap specifications recommended by the manufacturer. Adjust the gap if necessary using a feeler gauge. Once prepared, insert the new spark plug into the socket and tighten it securely, but avoid over-torquing. Reconnect the ignition source and perform a test run to ensure everything is functioning smoothly.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is crucial for ensuring optimal performance and longevity of your power equipment. Regular maintenance helps prevent issues such as clogging and fuel degradation, which can lead to inefficient operation or even failure.

Regularly Inspect Fuel Lines

Check the fuel lines for any signs of wear, cracks, or leaks. Damaged lines can lead to fuel loss and potentially hazardous situations. Replace any compromised components promptly to maintain system integrity.

Use Fresh Fuel

Always utilize fresh fuel to prevent problems associated with stale gasoline, such as varnishing and sediment buildup. If the equipment is not used frequently, consider adding a fuel stabilizer to extend shelf life and maintain fuel quality.

Tip: Storing fuel in a cool, dark place can also help preserve its quality and effectiveness.

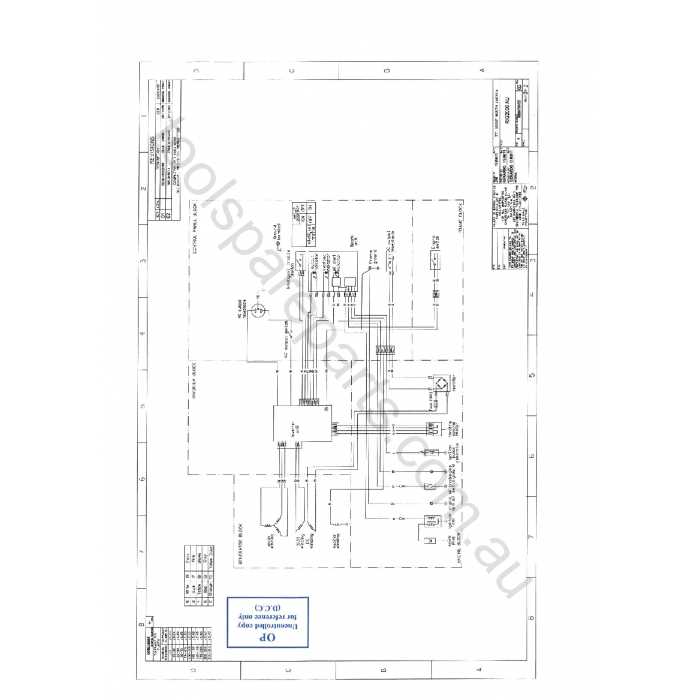

Electrical Components Overview

This section provides an insight into the essential electrical components that play a critical role in ensuring optimal functionality and performance. Understanding these parts is crucial for effective troubleshooting and maintenance.

Main Electrical Parts

- Power Switch: The primary control element that allows the user to turn the device on or off.

- Voltage Regulator: Maintains a consistent output voltage to prevent fluctuations that could damage connected devices.

- Starter Motor: Initiates the operation of the machine, providing the necessary force to start the engine.

- Battery: Supplies electrical energy required for ignition and powering accessories.

- Fuse: Protects the circuit from overload by breaking the connection if the current exceeds a safe level.

Common Issues

- Failure to start due to issues with the starter motor or battery.

- Voltage irregularities that can affect the performance of connected devices.

- Overheating caused by a malfunctioning voltage regulator.

- Burnt fuses indicating a potential short circuit or overload in the electrical system.

Inspecting the Battery Connections

Ensuring proper electrical connections is crucial for optimal performance and longevity of portable power sources. Regularly checking these connections can prevent issues and maintain efficient operation.

Start by disconnecting the power source to avoid any risk of electrical shock. Inspect the terminals for signs of corrosion or dirt, which can impede the flow of electricity. If corrosion is present, gently clean the terminals using a wire brush or a mixture of baking soda and water.

Next, verify that the connections are tight and secure. Loose connections can lead to voltage drops and unreliable performance. If you notice any wear on the cables or connectors, consider replacing them to ensure a solid connection. After cleaning and tightening, reconnect the terminals and ensure that they are positioned correctly.

Finally, perform a voltage test with a multimeter to confirm that the battery is supplying the correct voltage. This step will help identify any underlying issues that may need to be addressed for optimal functionality.

How to Change the Oil

Regular maintenance of your equipment is essential for optimal performance and longevity. One of the most important tasks is changing the lubricant, which ensures smooth operation and protects internal components.

Follow these steps to effectively replace the oil:

- Gather Your Supplies:

- New lubricant

- Oil pan

- Funnel

- Wrench

- Cloth or paper towels

- Prepare the Equipment:

Ensure that the unit is turned off and has cooled down. Place it on a flat surface to prevent spills.

- Drain the Old Oil:

Locate the drain plug and use the wrench to loosen it. Allow the old lubricant to flow into the oil pan until completely drained.

- Replace the Drain Plug:

Once the oil has fully drained, reattach the drain plug securely.

- Add New Oil:

Using the funnel, pour the new lubricant into the designated fill area. Refer to your specifications for the correct amount.

- Check the Oil Level:

After adding the oil, use the dipstick to ensure the level is adequate. Adjust if necessary.

- Clean Up:

Dispose of the old lubricant responsibly and clean any spills.

Following these steps will help maintain the efficiency and lifespan of your machine.

Understanding Generator Load Capacity

Comprehending the load capacity of power-producing units is essential for efficient operation and optimal performance. It involves recognizing how much electrical demand can be met without overloading the system, ensuring longevity and reliability.

Load capacity is typically expressed in watts, which indicates the total amount of electricity that can be safely supplied. It is crucial to consider both starting and running wattage, as many appliances require more power to start than to operate continuously. This understanding helps in making informed decisions regarding the selection and usage of electrical devices.

| Type of Appliance | Starting Watts | Running Watts |

|---|---|---|

| Refrigerator | 1200 | 800 |

| Television | 400 | 200 |

| Power Tools | 1500 | 1000 |

| Microwave | 1500 | 1000 |

| Computer | 600 | 300 |

By assessing the total load requirements of all connected devices, users can determine the necessary power supply needed for seamless functionality. Proper management of load capacity not only enhances performance but also safeguards against potential damages caused by overload situations.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Proper precautions not only protect the individual performing the work but also prevent potential damage to the equipment. Adhering to safety guidelines creates a secure environment for troubleshooting and servicing machinery.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, goggles, and hearing protection. This equipment safeguards against hazards that may arise during the servicing process, such as sharp edges or loud noises. Make sure to inspect your gear before starting any task.

Work Environment Safety

Maintain a clean and organized workspace to minimize the risk of accidents. Ensure adequate lighting and ventilation, and keep flammable materials away from the area. Additionally, familiarize yourself with the location of safety equipment, such as fire extinguishers and first aid kits, to be prepared for any emergencies.

When to Seek Professional Help

There are instances when tackling mechanical issues independently may not be the best approach. Recognizing the signs that indicate the need for expert assistance can save time, prevent further complications, and ensure safety. Here are some situations when professional support is advisable:

- If you encounter persistent problems that you cannot diagnose.

- When unusual noises or smells arise that signal potential hazards.

- If the equipment fails to operate despite following troubleshooting steps.

- When repairs involve complex electrical components that require specialized knowledge.

- If the device has been damaged due to improper use or maintenance.

Understanding these scenarios can help you make informed decisions about when to reach out to a skilled technician.