Proper upkeep of outdoor machinery is essential for ensuring longevity and optimal performance. Understanding the intricacies of maintenance procedures can significantly enhance the functionality and reliability of your equipment. This section delves into various aspects of care and troubleshooting, providing insights into effective techniques for common challenges.

Maintenance practices not only improve efficiency but also minimize potential breakdowns. By familiarizing yourself with the components and their roles, you can perform routine checks that preemptively address wear and tear. This proactive approach is invaluable for any machinery enthusiast looking to extend the life of their tools.

Common issues can often be resolved with straightforward interventions. This guide aims to equip you with the knowledge necessary to tackle these challenges confidently. With the right information, you can ensure your equipment remains in peak condition, ready to handle any task with ease.

This section aims to highlight frequent challenges faced by users and provide guidance on how to address them effectively. Understanding these common problems can facilitate smoother operation and prolong the lifespan of your equipment.

Frequent Problems

- Difficulty starting the engine

- Inconsistent power output

- Excessive vibration during operation

- Fuel leakage

Troubleshooting Steps

- Check the fuel level and ensure it is fresh and properly mixed.

- Inspect the spark plug for wear and clean or replace it if necessary.

- Examine the air filter and clean or replace it to ensure optimal airflow.

- Look for any visible signs of damage to the fuel lines or connections.

Essential Tools for Repairs

Having the right instruments is crucial for effective maintenance tasks. Proper equipment not only enhances efficiency but also ensures that every job is completed with precision. Below are some fundamental items that every enthusiast should consider for their toolkit.

Basic Hand Tools

Among the first items to acquire are various hand tools. A good selection includes:

- Wrenches: Essential for loosening and tightening bolts.

- Screwdrivers: Necessary for adjusting different screws.

- Pliers: Useful for gripping and bending components.

Safety Gear

Alongside tools, safety should never be overlooked. Proper protection enhances user safety during any project:

- Gloves: Protect hands from cuts and abrasions.

- Goggles: Shield eyes from debris and potential hazards.

Step-by-Step Repair Procedures

This section outlines the systematic approach for addressing issues with the equipment. Following these instructions carefully will ensure effective troubleshooting and restoration of functionality.

-

Initial Assessment

Begin by examining the unit for visible damage or wear. Check the following:

- Housing for cracks or breaks

- Cables and connectors for fraying

- Filters for dirt buildup

-

Disassembly

Carefully dismantle the components to access the interior mechanisms. Use appropriate tools to avoid damaging screws and parts:

- Remove the outer casing

- Take out the power unit

- Disconnect any wiring as needed

-

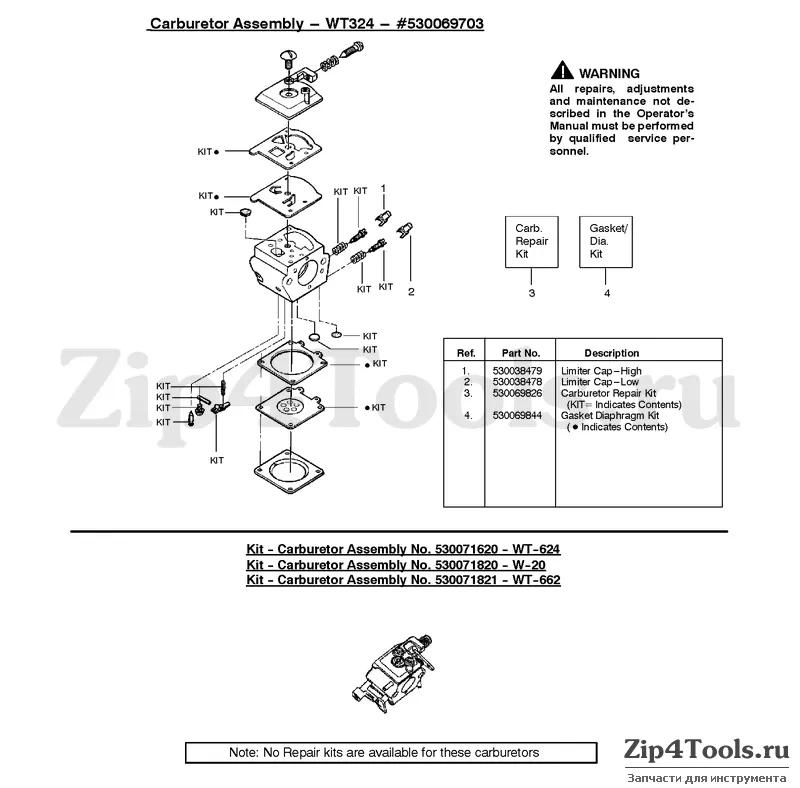

Component Inspection

Inspect each part for signs of wear or failure. Pay special attention to:

- Gaskets and seals for leaks

- Moving parts for smooth operation

- Electrical connections for corrosion

-

Replacement and Repair

Replace any faulty components with new parts. Ensure all replacements match specifications:

- Install new gaskets where necessary

- Replace worn or damaged cables

- Reattach any connectors firmly

-

Reassembly

Once repairs are completed, reassemble the unit in reverse order of disassembly:

- Reconnect the wiring

- Reattach the power unit

- Secure the outer casing

-

Final Testing

Conduct a thorough test to ensure everything functions as expected. Check for:

- Proper operation under load

- No unusual noises

- All safety features engaging correctly

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. Regular attention to various components can significantly enhance performance and reduce the likelihood of breakdowns. Here are some essential practices to consider.

Routine Inspections

Frequent checks of the essential parts can help identify any wear and tear early on. Look for signs of damage or buildup that might hinder functionality. Keeping everything clean and well-lubricated ensures smooth operation.

Proper Storage

Storing your equipment in a dry, sheltered location protects it from harsh weather conditions. Avoiding exposure to extreme temperatures can prevent material degradation. Additionally, using a protective cover can further enhance its longevity.

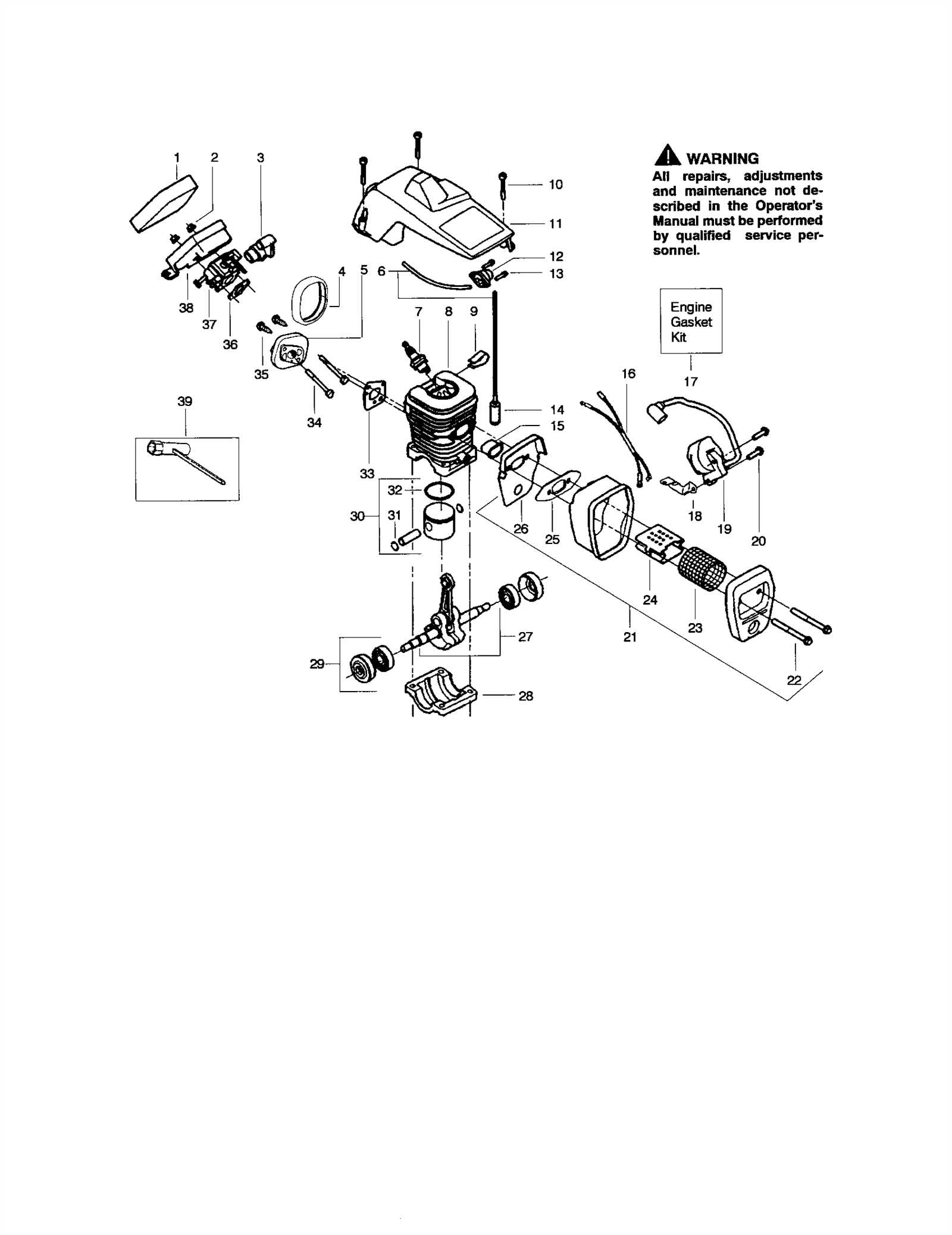

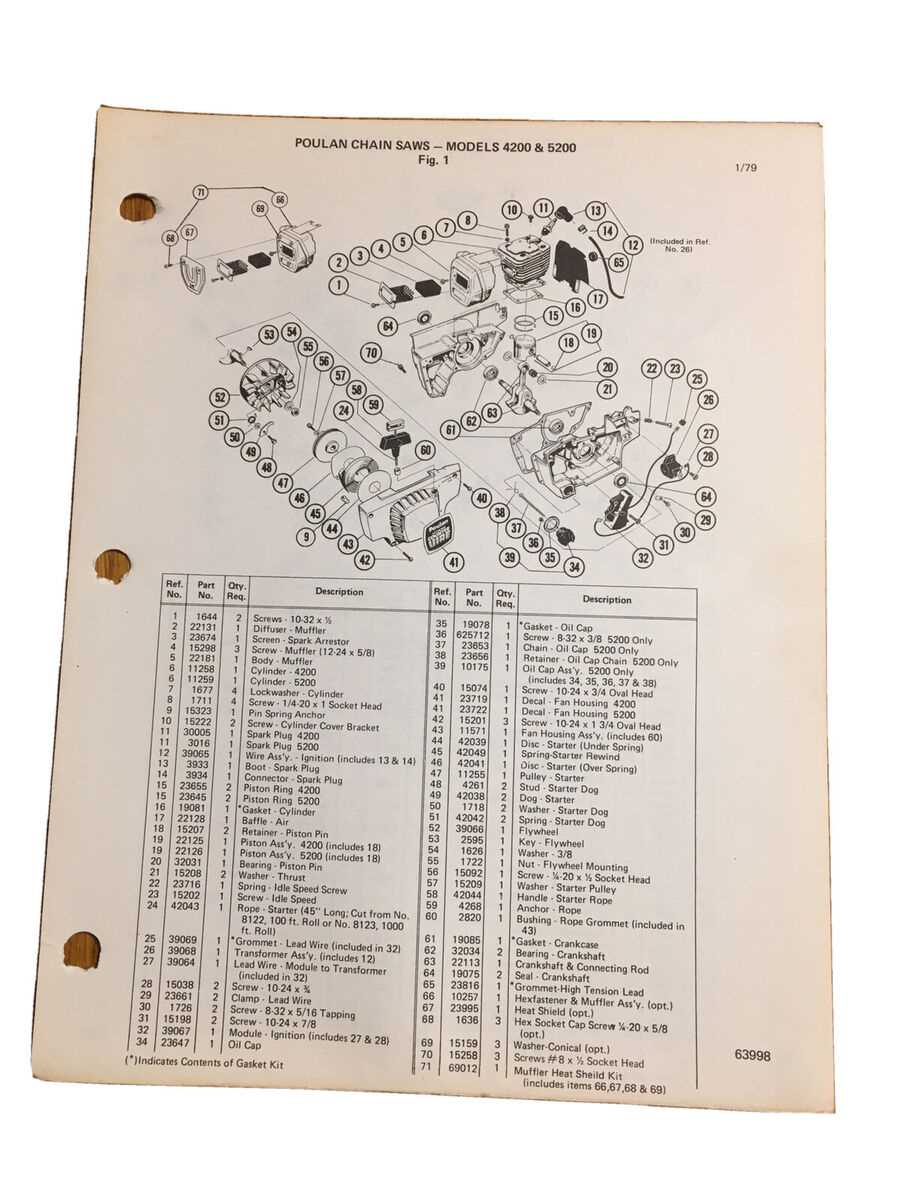

Understanding the Engine Components

Grasping the fundamental parts of a small engine is essential for effective maintenance and troubleshooting. Each component plays a vital role in the overall performance, and understanding their functions can significantly enhance the longevity and efficiency of the machine.

- Cylinder: The core area where combustion occurs, converting fuel into mechanical energy.

- Piston: A crucial part that moves within the cylinder, transferring force from combustion to the crankshaft.

- Crankshaft: This component converts the linear motion of the piston into rotational motion, driving the output.

- Ignition System: Responsible for initiating the combustion process, ensuring that the engine starts and runs smoothly.

- Fuel System: Delivers the necessary fuel-air mixture to the combustion chamber for optimal engine performance.

- Exhaust System: Manages the expulsion of gases resulting from combustion, playing a crucial role in engine efficiency and emissions.

Understanding these key elements allows for better insights into how the engine operates and facilitates more informed maintenance practices.

Replacing the Fuel System Parts

Maintaining the efficiency of your equipment often involves addressing issues within the fuel system. Ensuring that all components function properly is essential for optimal performance. This section outlines the steps necessary for replacing critical parts to keep your device running smoothly.

Start by assessing the condition of the fuel lines, filters, and other related components. If any part shows signs of wear or blockage, it’s crucial to replace it. Begin the process by disconnecting the fuel lines carefully to avoid spills.

Next, install the new fuel filter to ensure clean fuel flow. Make sure all connections are secure and check for any leaks after reassembly. Finally, prime the system and start the equipment to verify everything operates correctly.

Chain and Bar Maintenance

Proper upkeep of the cutting mechanism is essential for optimal performance and longevity. Regular attention to the chain and guide bar can prevent unnecessary wear and enhance the efficiency of the equipment.

Start by ensuring that the chain is adequately lubricated. A well-oiled chain reduces friction and heat, minimizing the risk of damage. Check the oil reservoir frequently and refill as needed, especially during prolonged use.

Inspect the chain for any signs of wear or damage, such as dullness or missing links. A sharp chain ensures clean cuts and reduces strain on the motor. If necessary, sharpen the chain using an appropriate tool or replace it if it’s excessively worn.

The guide bar should also be checked for straightness and any signs of wear. Ensure that it is clean and free from debris, as buildup can affect cutting performance. Rotate the bar periodically to promote even wear and extend its life.

Finally, always follow the manufacturer’s recommendations for maintenance intervals and procedures to ensure safe and efficient operation.

Electrical System Diagnostics

The assessment of an electrical system is crucial for ensuring optimal performance and identifying potential issues. This section focuses on methods to evaluate the functionality of various components, helping to detect anomalies and prevent failures in the system.

Identifying Common Issues

Understanding typical problems that may arise within the electrical setup can facilitate quicker diagnostics. Look for signs such as irregular operation, inconsistent power supply, or unusual sounds when the system is engaged.

Testing Procedures

Employ appropriate testing tools to measure voltage, current, and resistance in different parts of the system. These measurements can indicate whether components are functioning within their designed specifications or require further attention.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also preserve the equipment involved. Understanding these measures is essential for a successful and secure experience.

Personal Protective Equipment

Wearing appropriate personal protective gear is vital. This includes gloves to protect hands from sharp edges, goggles to shield eyes from debris, and sturdy footwear to prevent slips and falls. These items create a barrier between the user and potential hazards.

Work Environment Considerations

Maintaining a clean and organized workspace is equally important. Ensuring adequate lighting and removing clutter can significantly reduce the risk of accidents. Additionally, having all necessary tools within reach minimizes the need to move around excessively, further enhancing safety.

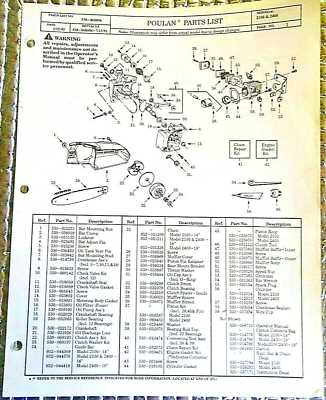

Finding Replacement Parts

When it comes to maintaining and enhancing the functionality of your equipment, sourcing suitable components is essential. Having access to the right parts ensures that your device operates efficiently and reliably over time. This section will guide you on how to locate the necessary items effectively.

Start by checking local suppliers. Many hardware stores and specialty shops stock a variety of components that may fit your needs. Building a relationship with local vendors can also provide insights into specific items that may not be readily available online.

Online resources are invaluable for tracking down specific components. Numerous websites specialize in parts for various devices, offering detailed catalogs that make searching simpler. Ensure you have the model specifications on hand to avoid any mix-ups.

Another useful approach is to join online forums or communities focused on equipment maintenance. Members often share their experiences and can recommend trusted sources for replacement parts, as well as provide tips for installation and usage.

Lastly, consider contacting the manufacturer directly. They can often provide the most accurate information regarding compatible parts and may even offer the items you need for purchase.

Service Manual Resources

This section provides valuable information on obtaining support documents essential for maintenance and troubleshooting. These resources can guide users in understanding the functionalities and addressing issues effectively.

Types of Available Resources

Various types of support documents are accessible, including instructional guides, troubleshooting tips, and parts lists. These materials serve to enhance the user experience by providing detailed information tailored to specific needs.

Where to Find Them

| Resource Type | Description | Access Method |

|---|---|---|

| Instructional Guides | Detailed instructions for operation and care. | Manufacturer’s website |

| Troubleshooting Tips | Common issues and their solutions. | Online forums |

| Parts Lists | Catalog of replacement components. | Authorized dealers |

Customer Support and Warranty Information

Understanding the available assistance and warranty details is crucial for ensuring optimal performance and longevity of your equipment. This section provides essential insights into the support options and guarantees that accompany your product.

Available Support Channels

Customers can access various support channels for inquiries and issues. Whether through online resources, phone assistance, or local service centers, help is readily available to address concerns and provide solutions. Utilizing these resources can enhance your experience and ensure your device functions smoothly.

Warranty Coverage

The warranty provides customers with peace of mind regarding potential defects and operational issues. It outlines the duration of coverage and the specific conditions under which support is provided. It is important to review these terms to understand what is included and how to take advantage of the benefits offered.