Proper upkeep of your espresso maker is essential for achieving optimal performance and longevity. Understanding the key components and common issues can help you maintain a consistent brewing experience.

Regular checks can prevent minor malfunctions from escalating into major problems. Familiarizing yourself with the machine’s parts and their functions will empower you to troubleshoot effectively and keep your equipment running smoothly.

In this section, you will find valuable insights and practical tips to address typical challenges that may arise during use. With the right knowledge, you can ensure that your coffee-making companion remains in excellent condition.

Rancilio Silvia Repair Manual

This section provides essential guidance for maintaining and troubleshooting a specific type of espresso machine. It covers various techniques and insights that can assist users in ensuring optimal performance and longevity of their device. By following these recommendations, users can address common issues effectively.

Regular upkeep is crucial for the smooth operation of your coffee maker. Familiarity with the components and their functions will empower you to identify potential problems early. Whether it’s routine cleaning or addressing more complex malfunctions, understanding the inner workings will greatly enhance your brewing experience.

Additionally, having the right tools and parts on hand can significantly streamline the process. From minor adjustments to more involved fixes, being prepared will save both time and frustration. Consult various resources to gather information on the best practices for maintaining your appliance.

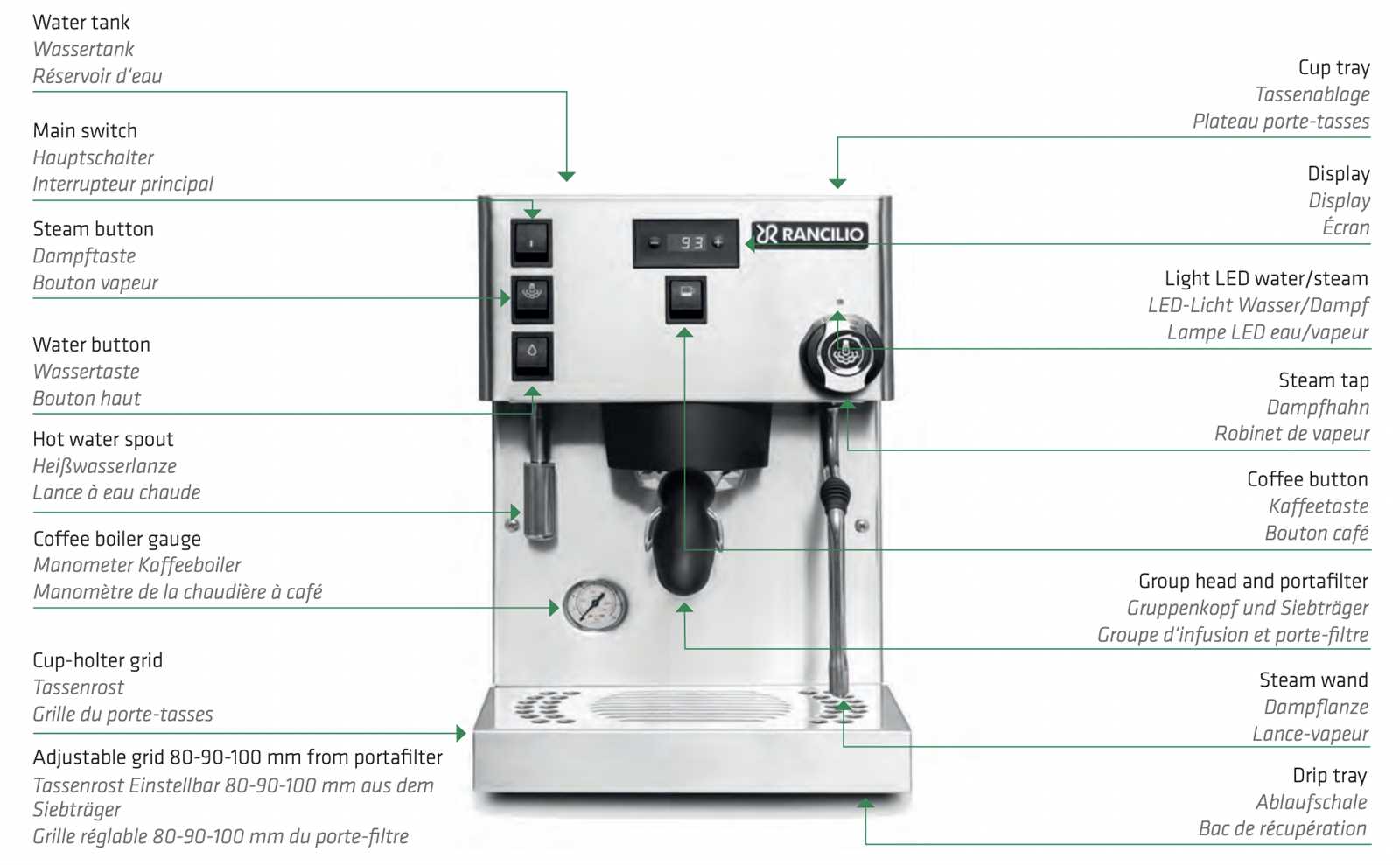

Understanding Rancilio Silvia Components

This section aims to provide an overview of the various elements that make up a specific espresso machine, highlighting their functions and interrelationships. Each component plays a crucial role in the overall performance and user experience of the device, contributing to the rich flavors and aromas that characterize a well-crafted beverage.

Main Elements of the Espresso Machine

- Boiler: This is the core element responsible for heating water to the optimal temperature for brewing.

- Group Head: The part where water is dispensed through the coffee grounds, influencing extraction quality.

- Portafilter: A handle that holds the coffee grounds in place during brewing, essential for achieving the right pressure.

- Steam Wand: Used for frothing milk, allowing for the creation of various coffee beverages.

- Pressure Gauge: A tool that indicates the brewing pressure, helping to monitor the extraction process.

Additional Features

- Water Reservoir: Stores water for brewing and steaming, vital for machine operation.

- PID Controller: Ensures precise temperature regulation, enhancing brewing consistency.

- Drip Tray: Collects excess water and coffee drips, maintaining cleanliness during use.

Understanding these components not only aids in proper usage but also in troubleshooting and maintenance, ensuring a long lifespan for the appliance.

Common Issues and Their Causes

When using coffee machines, users may encounter several frequent problems that can affect performance and beverage quality. Understanding these challenges and their underlying reasons is essential for effective troubleshooting.

- Insufficient Pressure:

This issue often arises from a clogged filter or a malfunctioning pump. Regular maintenance can prevent these problems.

- Inconsistent Temperature:

Temperature fluctuations can be caused by a faulty thermostat or insufficient water flow. Checking these components can help ensure optimal brewing conditions.

- Leaking Water:

Leaks can occur due to worn-out seals or loose connections. Inspecting these areas regularly can help maintain the machine’s integrity.

- Overly Bitter Coffee:

This might result from over-extraction or using coffee grounds that are too fine. Adjusting grind size and extraction time can improve flavor.

- Noise During Operation:

Unusual sounds may indicate mechanical issues, such as a failing motor or loose components. Identifying and addressing these concerns early can prevent further damage.

By recognizing these common issues and their potential causes, users can take proactive steps to enhance the longevity and performance of their coffee-making equipment.

Tools Required for Effective Repairs

To ensure successful maintenance and troubleshooting of your coffee machine, having the right equipment is essential. Proper tools can significantly enhance the efficiency of your tasks, making the process smoother and more effective. Below is a list of necessary instruments to consider when working on your espresso machine.

- Screwdrivers: A set of various sizes, including Phillips and flathead, is crucial for accessing internal components.

- Wrenches: Adjustable and socket wrenches help in loosening or tightening bolts and nuts.

- Pliers: Needle-nose and standard pliers assist in gripping and maneuvering small parts.

- Multimeter: This device is essential for checking electrical connections and diagnosing issues.

- Cleaning Tools: Brushes, cloths, and specialized cleaners maintain hygiene and performance.

Having these tools readily available will not only streamline your work but also extend the lifespan of your machine, ensuring that it operates at peak performance.

Disassembling the Rancilio Silvia Safely

Proper disassembly of espresso machines is crucial for maintenance and troubleshooting. Ensuring safety during this process prevents damage to components and enhances the longevity of the appliance. This section outlines essential steps and precautions to consider when taking apart your equipment.

Before beginning, gather the necessary tools and ensure you have a clean workspace. Follow these guidelines for a successful disassembly:

- Unplug the machine from the power source to avoid electrical hazards.

- Allow the unit to cool down if it has been recently used, preventing burns from hot surfaces.

- Organize your tools, including screwdrivers and wrenches, for easy access.

- Take notes or photos during the process to aid in reassembly later.

Start by removing any detachable parts such as the water tank and drip tray. This will provide better access to internal components. Proceed to unscrew the outer casing, ensuring to keep track of all screws and small pieces.

After removing the exterior, inspect the internal components carefully. If you encounter resistance or feel uncertain, refer to trusted resources or guides for additional guidance.

Once disassembled, handle all parts gently to avoid any unintended damage. Proper care during this process ensures that your espresso machine remains in excellent condition for years to come.

Diagnosing Electrical Problems

Identifying issues within electrical systems can often be a challenging task. Understanding the fundamental aspects of how these systems operate is crucial for effective troubleshooting. This section will guide you through various methods to pinpoint common electrical malfunctions.

Begin by observing the equipment’s performance. Any unusual sounds, inconsistent power supply, or failure to operate correctly may indicate underlying issues. Pay attention to the symptoms displayed during operation.

Next, check the wiring and connections. Loose or damaged wires can lead to interruptions in functionality. Ensuring all connections are secure and intact is a vital step in the diagnostic process.

Utilizing a multimeter can also provide valuable insights. Measuring voltage, resistance, and continuity will help determine whether electrical components are functioning as intended. If readings are outside the normal range, further investigation is required.

Finally, consult the schematic diagrams of the system. These illustrations can help trace the flow of electricity and identify potential fault areas. By following these guidelines, you can systematically approach and resolve electrical issues.

How to Fix Water Flow Issues

Experiencing problems with water flow can be frustrating, especially when it disrupts the brewing process. Various factors can contribute to insufficient or irregular water delivery, but understanding these issues can help in finding effective solutions.

Common Causes of Flow Problems

Several issues may lead to water flow problems in your machine. These can range from clogged components to inadequate pressure. Identifying the root cause is essential for effective troubleshooting. Below are some typical reasons for flow issues:

| Cause | Description |

|---|---|

| Clogged Filter | Debris accumulation can restrict water passage. |

| Scale Buildup | Mineral deposits can impede water flow. |

| Pump Malfunction | Issues with the pump can affect water pressure. |

Steps to Resolve Flow Issues

Once the cause has been identified, follow these steps to restore proper water flow:

- Remove and clean the filter to eliminate clogs.

- Descale the machine using a suitable descaling solution.

- Inspect the pump for any visible damage or blockage.

Regular maintenance can prevent many water flow issues, ensuring your machine operates efficiently for a longer time.

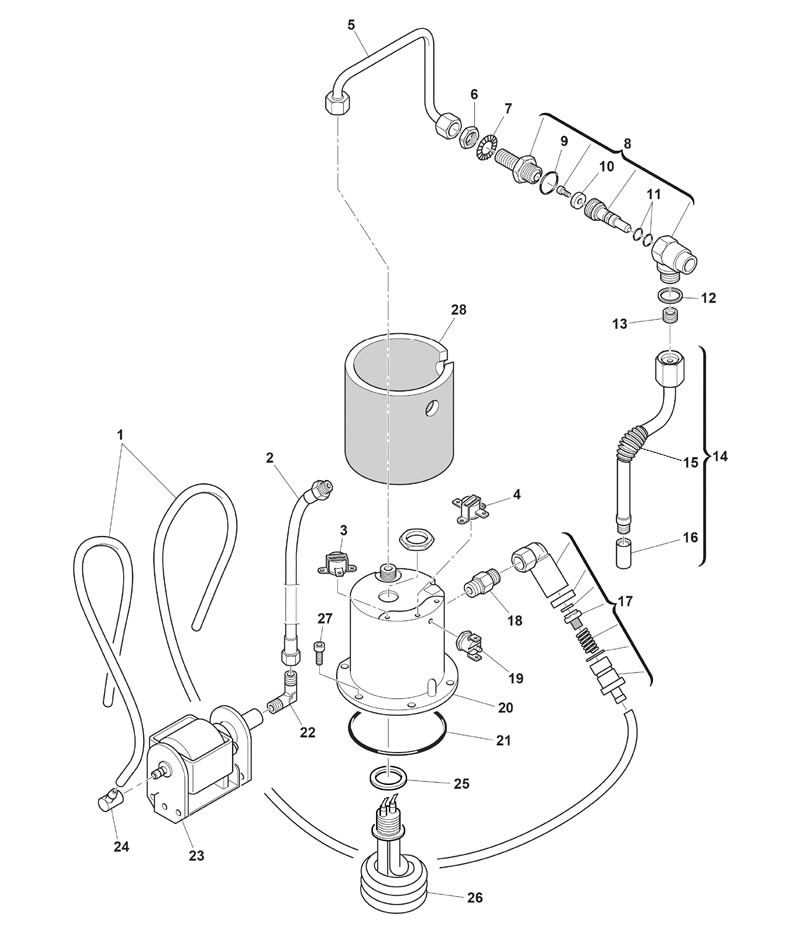

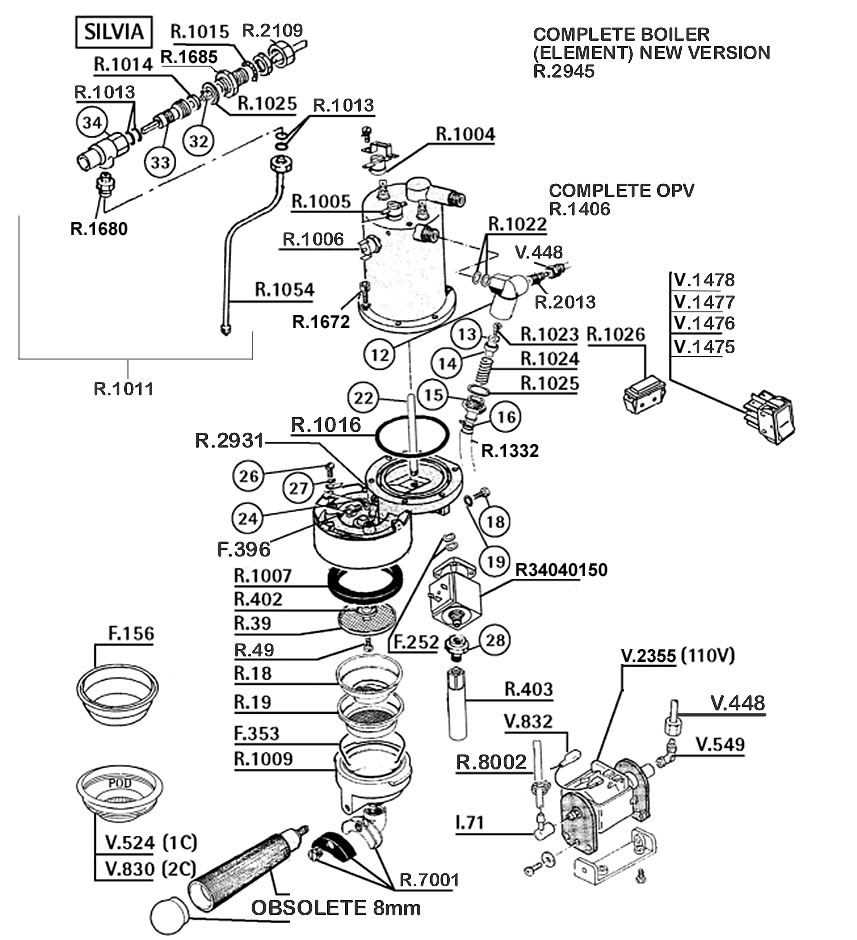

Replacing the Boiler and Heating Element

When facing issues with the heating system of your espresso machine, replacing the boiler and heating element may become necessary. This process involves several key steps to ensure proper installation and functionality of the components, contributing to the machine’s overall performance.

Preparation is crucial before beginning the replacement. Disconnect the appliance from the power source and allow it to cool down completely. Gather the necessary tools, including a screwdriver, wrench, and replacement parts. It is essential to refer to the specific requirements of the components to be installed.

Once prepared, disassemble the machine carefully. Begin by removing the outer casing to access the internal components. Locate the existing boiler and heating element. Carefully detach these parts by loosening any screws or bolts securing them in place.

After removing the old components, install the new boiler and heating element. Align the new parts correctly and secure them using the appropriate fasteners. Ensure all connections are tight to prevent any leaks or malfunctions.

Finally, reassemble the machine by putting the outer casing back in place. Once everything is secured, reconnect the appliance to the power source. It is advisable to test the machine for functionality, checking for any irregularities during operation.

Cleaning and Maintaining Internal Parts

Proper upkeep of internal components is essential for optimal performance and longevity of any espresso machine. Regular maintenance not only ensures a consistent quality of brew but also prevents potential issues that may arise from neglecting these crucial parts. This section focuses on effective techniques for cleaning and maintaining the internal mechanisms to ensure seamless operation.

Recommended Cleaning Procedures

To begin, disassemble the machine carefully, following the manufacturer’s guidelines. Use a soft brush or a cloth to remove any coffee residue or buildup from the internal surfaces. Pay special attention to areas where oils and grounds can accumulate, as these can affect the flavor of the coffee and the machine’s efficiency. For deeper cleaning, consider using a gentle, non-corrosive cleaning solution designed for coffee equipment.

Regular Maintenance Tips

In addition to cleaning, it is important to check the internal parts regularly for any signs of wear or damage. Inspect seals and gaskets for leaks and replace them as necessary. Lubricate moving components according to the manufacturer’s recommendations to ensure smooth operation. Establishing a routine maintenance schedule will help keep your equipment in excellent condition and prolong its lifespan.

Repairing Leaks in the Machine

Addressing fluid leaks within a coffee brewing device is essential for maintaining optimal performance and ensuring longevity. Identifying the source of the leakage can help prevent further damage and enhance the overall brewing experience. This section outlines common causes and practical solutions for managing leaks effectively.

Common Sources of Leaks

- Water Reservoir: Cracks or improper sealing can lead to leaks.

- Group Head: Worn gaskets may cause water to escape.

- Steam Wand: Damage or blockage can result in steam leaks.

- Hoses and Connections: Loose or degraded connections are frequent culprits.

Effective Solutions

- Inspect all seals and gaskets for wear. Replace any that appear damaged.

- Tighten connections to ensure a secure fit.

- Check the water reservoir for cracks. Consider replacing if significant damage is found.

- Test the steam wand by releasing steam. If leaking, disassemble and clean the wand thoroughly.

By regularly monitoring these areas and addressing issues promptly, users can minimize disruptions and enhance the functionality of their brewing equipment.

Restoring Optimal Pressure Levels

Maintaining ideal pressure within a brewing system is crucial for achieving the best flavor extraction. A proper balance ensures that coffee grounds are fully saturated and flavors are adequately released, leading to a richer cup of coffee.

To restore and maintain optimal pressure, consider the following steps:

- Inspect Components: Regularly check valves and seals for wear and tear that could affect pressure retention.

- Calibrate Pressure Settings: Adjust the pressure settings based on the type of coffee being brewed to suit specific flavor profiles.

- Clean the System: Regularly clean all parts to prevent build-up that can restrict flow and alter pressure levels.

- Monitor Water Quality: Ensure that the water used is filtered to avoid mineral build-up that can impact pressure and taste.

By following these steps, you can ensure that the pressure remains within the optimal range, enhancing the overall brewing experience.

When to Replace Gaskets and Seals

Gaskets and seals play a crucial role in maintaining the efficiency and performance of your espresso machine. Over time, these components can wear out, leading to potential leaks and decreased functionality. Recognizing the signs of deterioration is essential for ensuring optimal operation and preventing further damage.

There are several indicators that suggest it may be time to replace these parts:

| Indicator | Action |

|---|---|

| Visible Wear | Inspect gaskets for cracks or deformation. |

| Leaks | Check for water or steam escaping during operation. |

| Decreased Pressure | Monitor pressure readings; if they drop significantly, consider replacement. |

| Unusual Noises | Listen for hissing or popping sounds that indicate air leaks. |

Regular maintenance checks can help identify these issues early, allowing for timely replacements that enhance the longevity and efficiency of your equipment.

Testing and Reassembling the Machine

This section focuses on the procedures for evaluating functionality and putting together the components of the espresso brewing device. Proper testing ensures that all parts operate as intended, while careful reassembly is crucial for maintaining performance and longevity.

Evaluating Functionality

Before reassembling, it’s essential to conduct a thorough assessment of the machine. Follow these steps to ensure everything is functioning correctly:

- Check the power supply to confirm it is operational.

- Inspect the heating element for any signs of damage or corrosion.

- Test the pump by running water through the system.

- Examine the pressure gauge to ensure it reads accurately during operation.

Reassembly Steps

Once testing is complete and any necessary repairs are made, follow these guidelines for reassembling the device:

- Align all components carefully, ensuring no parts are misplaced.

- Secure screws and fasteners tightly to avoid leaks.

- Reconnect electrical connections, taking care to match colors and types.

- Perform a final inspection to confirm everything is in order before the initial use.