When it comes to ensuring the longevity and performance of your vehicle’s power source, having a thorough understanding of its components and functions is essential. This section delves into crucial aspects of upkeep, offering insights that cater to both novice and experienced enthusiasts alike.

Maintaining the integrity of your engine is not just about routine checks; it’s about fostering a deep connection with the machinery that drives you. By exploring various techniques and troubleshooting methods, you will empower yourself to tackle challenges effectively and confidently.

In this exploration, practical knowledge is your greatest ally. You will find detailed descriptions and systematic approaches that simplify complex processes, making the journey of understanding your engine not only informative but also enjoyable.

Understanding 6.2 Diesel Engine Basics

This section aims to explore the fundamental principles and characteristics of a specific type of internal combustion engine, known for its robust performance and durability. Understanding these basics is crucial for anyone involved in maintenance or troubleshooting of such power units.

The following key aspects define the operation and efficiency of this engine type:

- Fuel System: The engine relies on a specific type of fuel injection system, ensuring precise delivery and atomization for optimal combustion.

- Ignition Process: Unlike gasoline engines, the ignition process involves compression, which plays a vital role in generating the necessary heat for fuel combustion.

- Cooling Mechanisms: Effective cooling systems are essential to maintain operational temperatures and prevent overheating during prolonged use.

- Lubrication Requirements: Proper lubrication is critical for reducing friction and wear, ensuring long-lasting performance.

Familiarizing oneself with these components can enhance understanding and facilitate effective maintenance practices. Whether for professional use or personal projects, knowledge of these fundamental principles is invaluable.

Common Issues in 6.2 Diesel Engines

Engines of this type are known for their robust performance, yet they can experience several recurring challenges that may affect their efficiency and longevity. Understanding these common problems can help in identifying early signs of wear and ensuring proper maintenance.

Fuel Delivery Problems: One frequent issue is related to the fuel system. Clogged filters or malfunctioning injectors can lead to inadequate fuel supply, resulting in poor performance or difficulty starting.

Overheating: Another prevalent concern is overheating, often caused by insufficient coolant flow, a malfunctioning thermostat, or a failing water pump. Monitoring the cooling system is crucial to prevent serious damage.

Electrical Failures: Electrical components, such as glow plugs and batteries, may also experience issues. Worn-out glow plugs can affect starting in colder conditions, while battery problems can lead to starting difficulties.

Oil Leaks: Seals and gaskets can degrade over time, leading to oil leaks. Regular checks can help in identifying and addressing these leaks before they result in significant oil loss.

Excessive Smoke: Finally, excessive exhaust smoke can indicate various underlying issues, including fuel mixture problems or worn piston rings. Proper diagnostics are essential to pinpoint the root cause and implement effective solutions.

Essential Tools for Diesel Repairs

Maintaining and servicing heavy machinery requires a specialized set of instruments to ensure efficiency and reliability. Understanding which tools are vital for effective troubleshooting can greatly enhance the overall performance of the equipment.

Wrenches and Sockets: A comprehensive assortment of wrenches and socket sets is fundamental. These instruments allow for precise tightening and loosening of various fasteners, ensuring that components are securely attached.

Diagnostic Equipment: Utilizing advanced diagnostic tools is crucial for identifying issues within complex systems. These devices provide valuable insights into engine performance, enabling technicians to pinpoint malfunctions quickly.

Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage caused by over-tightening or insufficient fastening.

Fluid Handling Tools: Equipment for draining and refilling fluids is necessary. This includes pumps, funnels, and containers designed to manage different types of fluids safely and efficiently.

Inspection Tools: Items like flashlights, mirrors, and borescopes are invaluable for examining hard-to-reach areas. They aid in visual inspections and help identify wear or damage that might not be immediately visible.

Hand Tools: A reliable set of hand tools, including pliers, screwdrivers, and hammers, is essential for everyday tasks and minor adjustments, ensuring that technicians are prepared for any situation.

Equipping oneself with these fundamental instruments is vital for achieving successful outcomes in maintenance tasks. By investing in quality tools, practitioners can enhance their capabilities and ensure long-term reliability of the machinery.

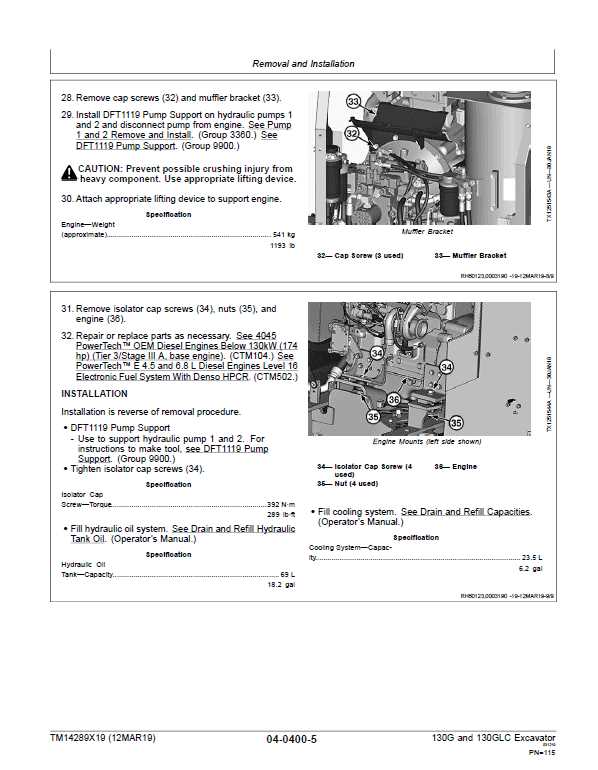

Step-by-Step Maintenance Procedures

Proper upkeep of your vehicle is essential for optimal performance and longevity. This section outlines systematic approaches to ensure each component operates efficiently, minimizing the risk of unexpected issues.

The following guidelines provide a structured process for conducting maintenance tasks:

-

Preparation:

- Gather necessary tools and equipment.

- Ensure the work area is clean and well-lit.

- Review the vehicle’s specifications and guidelines.

-

Fluid Checks:

- Inspect engine oil levels and quality.

- Examine coolant and transmission fluid levels.

- Top off any low fluids and replace if necessary.

-

Filter Replacement:

- Identify air and fuel filters needing replacement.

- Follow proper removal procedures to prevent contamination.

- Install new filters and ensure secure fittings.

-

Inspection of Belts and Hoses:

- Check for signs of wear or damage on belts.

- Examine hoses for leaks or brittleness.

- Replace any compromised components to prevent failures.

-

Battery Maintenance:

- Clean terminals and ensure secure connections.

- Test battery charge levels and replace if necessary.

- Inspect for corrosion and address any issues promptly.

-

Final Inspection:

- Verify all components are reassembled correctly.

- Start the vehicle and listen for unusual noises.

- Take a short test drive to assess performance.

By following these comprehensive steps, you can maintain the vehicle in prime condition, enhancing its reliability and efficiency for years to come.

Identifying Fuel System Problems

Understanding issues within the fuel delivery mechanism is crucial for ensuring optimal engine performance. Symptoms may range from poor acceleration to complete engine failure, necessitating a thorough examination of various components involved in fuel circulation.

Common Symptoms of Fuel System Malfunctions

- Difficulty starting the engine

- Unusual engine noises during operation

- Decreased power output

- Increased exhaust emissions

- Fuel leaks or noticeable odors

Key Components to Inspect

- Fuel Pump: Check for proper operation and pressure levels.

- Fuel Filter: Inspect for blockages that could restrict flow.

- Injectors: Evaluate for clogs or leaks that may affect fuel atomization.

- Lines and Hoses: Look for cracks or wear that might lead to leaks.

- Pressure Regulator: Ensure it maintains the correct pressure in the system.

Regular monitoring and timely diagnostics of these areas can prevent further complications and extend the lifespan of the engine.

Electrical Diagnostics for Diesel Engines

Effective troubleshooting of engine electrical systems is crucial for ensuring optimal performance and reliability. Understanding the various components and their interactions allows for a systematic approach to identifying issues that may arise within the system.

Common electrical problems can include faulty wiring, malfunctioning sensors, and inadequate power supply. Utilizing a combination of diagnostic tools and techniques enables technicians to pinpoint the source of the malfunction efficiently.

| Component | Common Issues | Diagnostic Tool |

|---|---|---|

| Batteries | Weak charge, corrosion | Multimeter |

| Alternators | Overcharging, undercharging | Voltage tester |

| Starter Motors | Clicking sound, no response | Test light |

| Sensors | Incorrect readings, failure | OBD-II scanner |

By systematically examining these components, technicians can effectively diagnose electrical faults and implement the necessary corrective measures to restore functionality.

Overhauling the Engine: A Guide

When it comes to enhancing performance and longevity, overhauling an internal combustion unit is a crucial process. This undertaking involves disassembling the engine, inspecting its components, and making necessary repairs or replacements to restore optimal functionality. Whether for routine maintenance or addressing specific issues, a thorough overhaul can lead to significant improvements in efficiency and reliability.

Preparation and Assessment

Before diving into the disassembly, it’s essential to prepare adequately. Begin by gathering the necessary tools and supplies, such as wrenches, gaskets, and lubricants. Next, perform a comprehensive assessment of the unit to identify any visible signs of wear or damage. This preliminary inspection will guide your focus during the overhaul process, ensuring you address all critical areas.

Disassembly and Inspection

With everything in place, carefully disassemble the engine. Document each step to aid reassembly. As you remove components, examine them for any signs of excessive wear, cracks, or deformities. Special attention should be given to the pistons, cylinder walls, and crankshaft. Any irregularities discovered during this stage may necessitate further intervention, such as machining or replacing parts to ensure a seamless operation once reassembled.

By following these steps, you can achieve a successful overhaul that breathes new life into your power unit.

Cooling System Maintenance Techniques

Maintaining the efficiency of the cooling system is crucial for optimal engine performance. Proper care not only prolongs the lifespan of components but also ensures effective temperature regulation, preventing overheating. Regular inspection and timely interventions are key to achieving these goals.

Here are essential techniques for maintaining the cooling system:

| Technique | Description |

|---|---|

| Fluid Checks | Regularly inspect coolant levels and quality. Replace any fluid that appears dirty or contaminated. |

| Thermostat Inspection | Ensure the thermostat operates correctly to maintain the optimal operating temperature. |

| Radiator Maintenance | Clean the radiator fins to enhance airflow and prevent blockage. Check for leaks or damage. |

| Hose Condition | Examine hoses for cracks, wear, or swelling. Replace any compromised hoses to avoid leaks. |

| System Flush | Perform a coolant flush periodically to remove sediment and debris, ensuring efficient heat transfer. |

Exhaust and Emission Troubleshooting

Identifying issues related to exhaust systems and emissions is crucial for maintaining optimal performance and compliance with environmental standards. This section aims to provide a comprehensive approach to diagnosing and resolving common problems associated with these systems.

Common Symptoms: Recognizing the signs of exhaust and emission issues is the first step in troubleshooting. Typical symptoms include unusual noises, a decrease in engine efficiency, and the presence of warning lights on the dashboard. Additionally, noticeable smoke from the tailpipe or a strong smell of fuel can indicate underlying problems.

Diagnosis: Begin by inspecting the exhaust system for visible damage or leaks. A thorough examination of components such as the catalytic converter, muffler, and exhaust pipes is essential. Use a diagnostic scanner to check for any error codes that may point to specific emission-related faults. Pay close attention to the condition of sensors that monitor exhaust gases, as these can significantly affect performance.

Potential Solutions: Depending on the findings, solutions may vary from replacing damaged parts to cleaning or recalibrating sensors. If a leak is detected, sealing it promptly can prevent further complications. In cases where the catalytic converter is malfunctioning, replacement may be necessary to restore proper function. Regular maintenance, including timely oil changes and filter replacements, can also help mitigate future issues.

Final Considerations: Staying proactive in exhaust and emission management not only enhances vehicle longevity but also contributes to a healthier environment. Regular inspections and adhering to service intervals can ensure that the system operates efficiently and within regulatory limits.

Transmission and Drivetrain Insights

This section delves into the complexities of power transfer systems in vehicles, emphasizing their critical role in delivering performance and reliability. Understanding the intricacies of these components is essential for maintaining optimal functionality and enhancing overall driving experience.

Components Overview

The transmission system is a vital element that manages the distribution of engine power to the wheels. It consists of various parts, including gears, shafts, and clutches, which work in harmony to ensure smooth operation. An effective drivetrain not only influences acceleration but also impacts fuel efficiency and vehicle longevity.

Common Issues and Solutions

Frequent challenges with these systems include fluid leaks, unusual noises, and shifting difficulties. Regular maintenance, such as fluid changes and inspections, can mitigate these issues. Addressing problems promptly can prevent further damage and enhance the lifespan of the vehicle’s performance systems.

Best Practices for Preventive Maintenance

Effective upkeep is essential for ensuring optimal performance and longevity of machinery. By adopting a proactive approach, operators can minimize the risk of unexpected breakdowns and costly repairs. This section outlines key strategies that promote the efficient functioning of equipment.

Regular Inspections: Conducting systematic evaluations helps identify potential issues before they escalate. Schedule routine checks to assess all components, ensuring that everything operates within specified parameters.

Fluid Management: Maintaining proper fluid levels is crucial for performance. Regularly check and replace oils, coolants, and other vital fluids according to the manufacturer’s guidelines to ensure optimal operation.

Filter Replacement: Clogged filters can lead to inefficiencies and damage. Establish a schedule for replacing air, fuel, and oil filters to maintain clean and efficient system performance.

Lubrication: Proper lubrication of moving parts reduces friction and wear. Utilize recommended lubricants and follow a consistent lubrication schedule to extend the lifespan of components.

Documentation: Keeping thorough records of maintenance activities aids in tracking performance trends and identifying recurring issues. Utilize a maintenance log to document inspections, repairs, and parts replacements.

Implementing these best practices fosters a culture of care and responsibility, ultimately enhancing reliability and efficiency in operations.

Resources for Further Learning

Expanding your knowledge in the field of automotive systems can be greatly beneficial for both enthusiasts and professionals. A variety of resources are available to enhance your understanding, from books and online courses to forums and community groups. These platforms provide valuable insights and practical skills that are essential for effective troubleshooting and maintenance.

Books and Publications

Numerous publications offer in-depth information on engine systems and their components. Consider exploring comprehensive guides that focus on operational principles, diagnostics, and troubleshooting techniques. Additionally, specialized magazines often feature articles written by industry experts, which can provide updates on the latest advancements and techniques.

Online Communities and Courses

Engaging with online communities can foster collaboration and knowledge sharing. Many forums allow you to ask questions and receive guidance from experienced individuals. Furthermore, various educational platforms offer courses tailored to different skill levels, covering topics from basic concepts to advanced practices, ensuring that learners have access to a wealth of information.