Understanding the operational intricacies of various agricultural machinery is crucial for achieving efficiency and longevity in daily fieldwork. These guides provide detailed instructions tailored for those who seek to keep machinery functioning optimally over time. From periodic upkeep to advanced diagnostics, the insights shared offer users practical knowledge and hands-on techniques to handle machinery with confidence.

Designed for Ease of Use, these resources break down complex systems into manageable steps, making the process accessible even for those who may be newer to mechanical maintenance. Users will find invaluable tips on performing regular checks, replacing essential components, and understanding system behaviors.

Whether maintaining older models or newer, high-tech machines, these handbooks support operators in navigating various situations. Through a structured approach to upkeep, users can enhance the productivity of their machinery, ultimately contributing to a more sustain

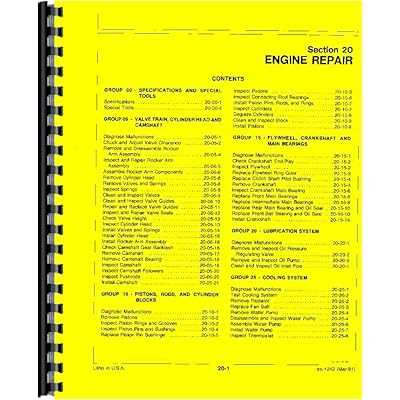

In this section, we explore efficient methods to diagnose and address common engine issues. Understanding core symptoms can help pinpoint underlying problems, leading to quicker solutions and improved performance. This guide covers essential steps for identifying and resolving issues to maintain consistent engine function.

- Inspect the fuel system for blockages or leaks. Consistent fuel flow is critical for engine efficiency.

- Examine the ignition system, including spark plugs and wires, to ensure reliable power delivery.

- Evaluate the cooling system for possible overheating sources. Proper temperature control prevents wear and enhances longevity.

- Listen for unusual sounds during operation, such as knocks or rattles, which may signal component wear or misalignment.

- Check fluid levels

Hydraulic System Service Essentials

Understanding the fundamentals of maintaining a hydraulic system is critical for ensuring efficient and reliable operation of heavy-duty machinery. These systems, which power a variety of mechanical functions, require precise upkeep to prevent costly downtime and extend component lifespan.

Fluid Inspection and Replacement

Regular inspection of hydraulic fluid is essential to ensure the system runs smoothly. Clean, uncontaminated fluid not only enhances performance but also reduces the risk of wear and tear on system components. Check fluid levels frequently, and replace the fluid according to the machinery’s recommended schedule to maintain optimal function.

Checking Seals and Fittings

Inspecting seals and fittings is another vital part of hydraulic system maintenance. Even minor leaks can lead to decreased pressure and compromised performance. Regularly examine all connections, replacing worn or damaged seals immediately to maintain system integrity and prevent further issues.

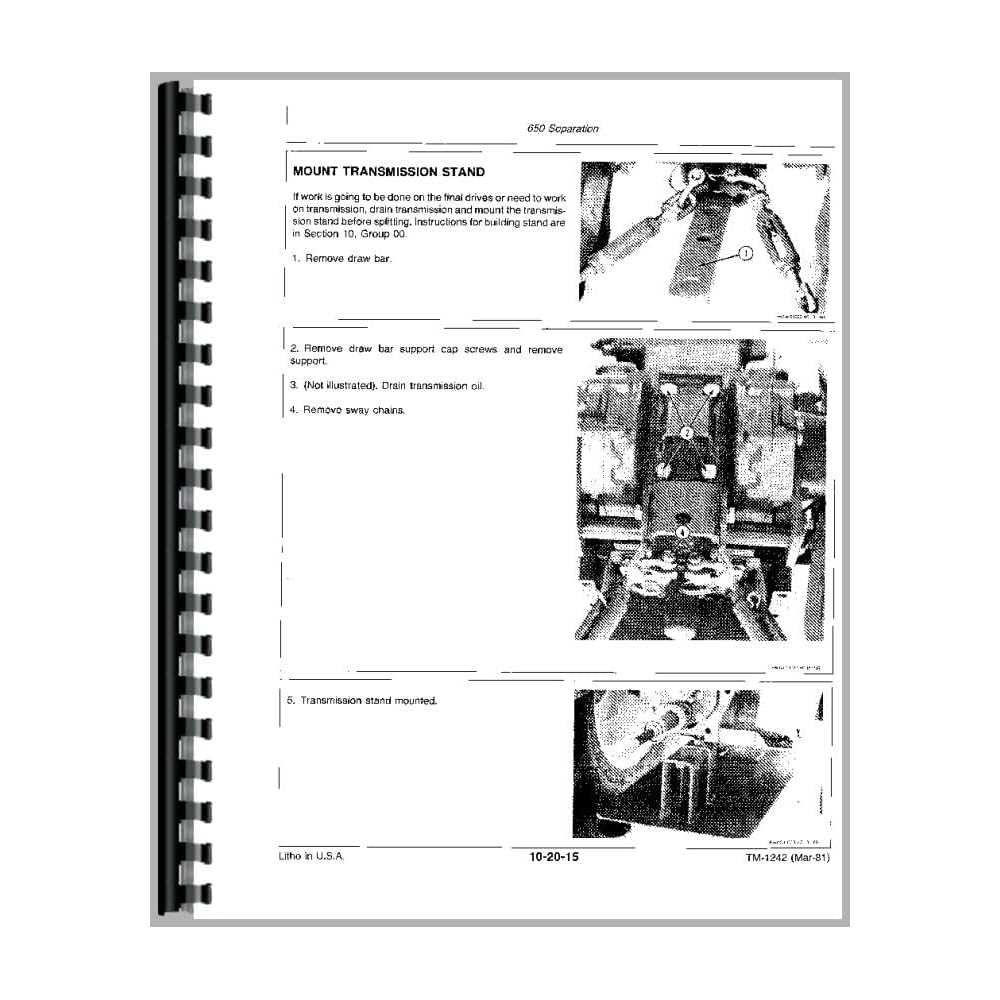

Transmission Repair Instructions

Understanding how to work with the transmission is essential for ensuring a vehicle’s smooth and consistent performance. This section provides detailed guidelines on diagnosing issues, disassembling parts, and maintaining internal components. The instructions will enable you to approach the process with confidence and efficiency.

Step-by-Step Guide

- Preparation: Begin by gathering all necessary tools and ensuring the work area is clean. This will help streamline each step and avoid potential errors.

- Diagnosing Issues: Before disassembly, carefully inspect the transmission for any visible leaks, wear, or unusual sounds.

Electrical System Diagnostics

The analysis of electrical systems is crucial for identifying and addressing potential issues that may arise in machinery. This process involves examining various components and their interactions to ensure optimal functionality. Proper diagnostics can prevent minor problems from escalating into significant malfunctions, saving time and resources in the long run.

Understanding Component Functionality

Each element within the electrical framework plays a vital role in the overall performance. By assessing the operation of circuits, connectors, and batteries, one can pinpoint discrepancies that may affect efficiency. Familiarity with the specific roles of each part enables a more effective diagnostic approach.

Diagnostic Tools and Techniques

Utilizing appropriate tools such as multimeters and oscilloscopes can enhance the diagnostic process. These instruments allow for precise measurements of voltage, current, and resistance, facilitating the identification of faults. Employing systematic testing procedures ensures that no potential issues are overlooked.

Safety Tips for Equipment Repairs

Ensuring a secure environment during maintenance tasks is crucial for preventing accidents and injuries. Adhering to safety guidelines not only protects the individual working on the machinery but also extends the lifespan of the tools involved. Below are essential precautions to consider before engaging in any servicing activities.

Personal Protective Gear

Wearing appropriate personal protective equipment (PPE) is vital. This includes items such as gloves, safety goggles, and helmets, which shield against potential hazards. Each piece of gear serves a specific purpose in safeguarding the worker from various risks associated with handling machinery.

Work Area Organization

A well-organized workspace minimizes the chances of accidents. Keep the area tidy, ensuring that all tools and parts are easily accessible. Proper storage of equipment reduces clutter and allows for safer navigation around the worksite.

Safety Measure Description PPE Usage Always wear gloves, goggles, and helmets when working. Tool Maintenance Regularly inspect tools for wear and tear to prevent malfunctions. Proper Training Ensure all personnel are trained in safe handling and procedures. Emergency Plan Have a clear plan for emergencies, including first aid resources. Upgrading Parts for Enhanced Performance

Enhancing the functionality of machinery can significantly improve efficiency and longevity. By replacing standard components with advanced alternatives, operators can achieve better performance levels and meet specific operational demands. Upgrading parts is not just about immediate results; it also contributes to overall reliability and effectiveness over time.

Investing in high-quality replacements can lead to noticeable improvements in speed, durability, and energy efficiency. For instance, selecting performance-oriented elements can result in smoother operation and reduced wear and tear. Additionally, modern upgrades often incorporate innovative technology, enabling smoother interactions between various systems within the machinery.

Moreover, tailored enhancements can provide advantages in specific applications, whether it be for heavy-duty tasks or precision work. Evaluating the unique requirements of your setup allows for strategic upgrades that align with desired outcomes, ultimately leading to enhanced productivity and operational success.

Resources for Rare Tractor Models

Finding accurate information and support for uncommon machinery can be challenging. Enthusiasts and owners often seek specialized resources to ensure proper maintenance and troubleshooting. This section aims to highlight valuable sources that can aid in the care and operation of less widely recognized agricultural machinery.

Online Forums and Communities

- Participating in dedicated online forums can connect you with other enthusiasts who share insights and experiences.

- Social media groups offer a platform for discussing issues and solutions specific to rare models.

- Online marketplaces sometimes feature user-generated content, including tips and guides.

Specialized Literature

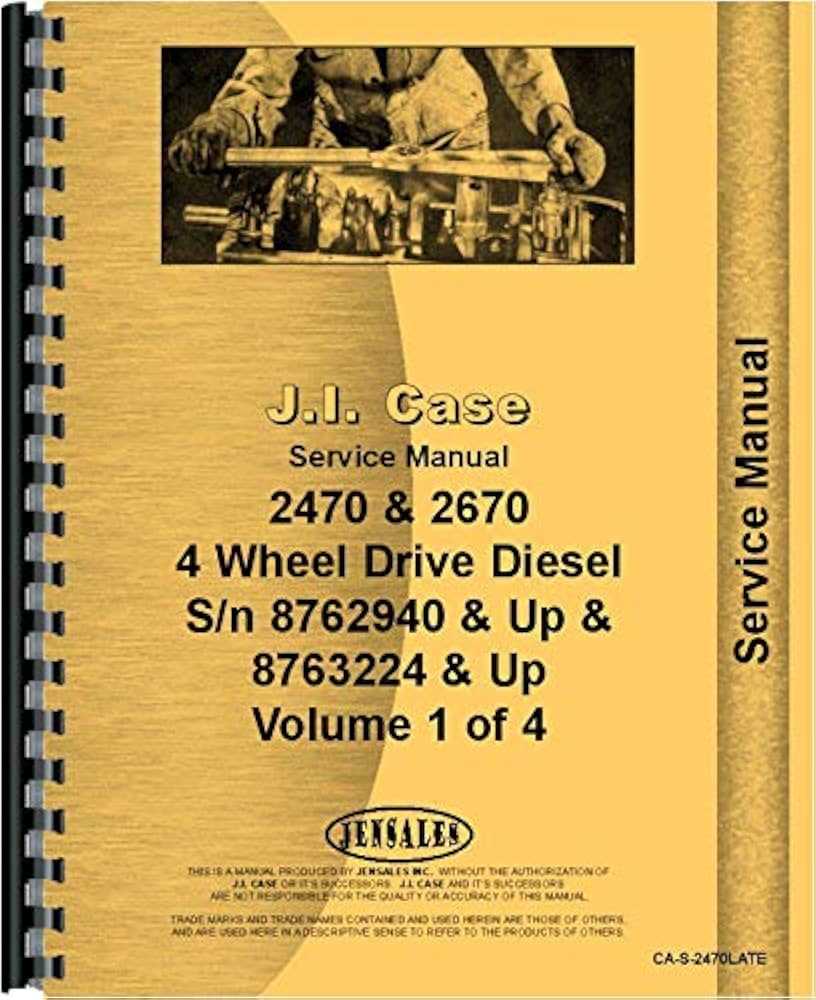

- Look for books and publications focusing on specific machinery types to gain deeper knowledge.

- Vintage magazines often contain useful articles about rare models, including technical tips.

- Manuals created by manufacturers may still be available through various online retailers or auction sites.