Maintaining outdoor machinery is essential for ensuring optimal performance and longevity. This section provides valuable insights into the upkeep of specific types of grass-cutting equipment, focusing on common issues and effective solutions. Understanding the intricacies of these machines can greatly enhance their functionality and efficiency.

From troubleshooting minor problems to addressing more complex challenges, having a comprehensive resource at hand is crucial. This guide aims to equip users with the knowledge necessary to tackle various maintenance tasks, empowering them to handle their equipment with confidence. A proactive approach to care not only saves time and money but also maximizes the enjoyment of working with these tools.

Whether you are a seasoned operator or a newcomer, familiarizing yourself with essential practices will make a significant difference. By exploring techniques and methods to maintain your equipment, you can ensure that it remains in peak condition throughout its lifespan. Embrace the opportunity to enhance your skills and keep your machinery running smoothly.

Cub Cadet Mower Overview

This section provides a comprehensive look at a popular brand of lawn care equipment designed for efficiency and ease of use. These machines are engineered to handle various landscaping tasks, making them a favorite among homeowners and professionals alike.

With a range of models available, each unit offers unique features that cater to different needs. Understanding these options can enhance your experience and maintenance practices.

| Model | Engine Power | Cutting Width | Fuel Type |

|---|---|---|---|

| Model A | 18 HP | 42 inches | Gasoline |

| Model B | 20 HP | 50 inches | Gasoline |

| Model C | 22 HP | 54 inches | Gasoline |

By familiarizing yourself with the specifications and capabilities, you can better assess which unit meets your requirements and ensures optimal performance.

Common Issues with Cub Cadet Mowers

When it comes to maintaining outdoor equipment, several challenges may arise, impacting performance and efficiency. Understanding these common problems can help in diagnosing and resolving issues promptly.

- Engine Difficulties:

- Starting troubles due to fuel or spark plug issues.

- Overheating caused by inadequate cooling or oil levels.

- Cutting Problems:

- Uneven trimming, often due to dull blades or improper height settings.

- Clumping of grass that may result from wet conditions or clogged discharge areas.

- Drive System Issues:

- Sluggish movement caused by worn belts or low fluid levels.

- Difficulty in steering due to malfunctioning control systems.

- Electrical Failures:

- Battery drainage leading to starting failures or weak performance.

- Faulty wiring connections causing intermittent operation.

By being aware of these prevalent challenges, users can take proactive steps to ensure their equipment remains in optimal condition.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the lasting performance of your equipment. By implementing a few simple practices, you can significantly extend its lifespan and enhance efficiency. These guidelines will help you maintain optimal functionality and prevent common issues.

Routine Inspections

Conduct frequent evaluations to identify potential problems early. Check for any signs of wear or damage, such as frayed belts or loose connections. Addressing minor concerns promptly can prevent more significant repairs down the line.

Proper Cleaning

Keeping the machinery clean is vital for maintaining performance. Remove any debris, grass clippings, or dirt that may accumulate during use. This practice not only promotes efficient operation but also helps prevent corrosion and rust, which can lead to more severe damage over time.

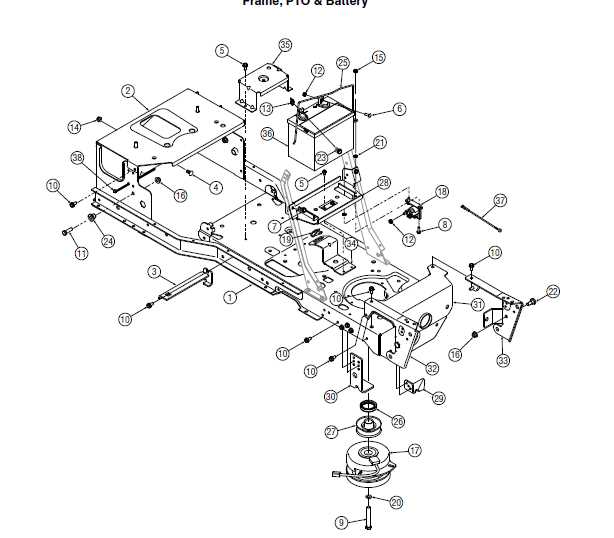

Essential Tools for Repairs

Having the right instruments is crucial for efficient maintenance and troubleshooting. This section outlines the necessary equipment that can enhance your ability to work effectively and tackle various tasks with confidence.

Basic Tool Set

- Wrenches: Ideal for loosening and tightening bolts and nuts.

- Screwdrivers: Essential for removing and securing screws of different types.

- Socket Set: Offers versatility for various fasteners and provides better torque.

- Hammer: Useful for tapping and adjusting components without causing damage.

Specialized Instruments

- Multimeter: Helps in diagnosing electrical issues by measuring voltage and resistance.

- Torque Wrench: Ensures proper tightness of bolts, preventing damage from over-tightening.

- Fuel Line Clamp: Useful for managing fuel flow during maintenance tasks.

- Cleaning Brushes: Essential for removing dirt and debris from hard-to-reach areas.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues with your equipment. Following these structured steps can simplify the process, ensuring that you effectively troubleshoot and resolve problems while maintaining the machine’s optimal performance.

Preparation and Safety

Before beginning any maintenance task, it is essential to gather the necessary tools and materials. Additionally, ensure your workspace is safe and organized. Always wear appropriate safety gear to protect yourself during the process.

Troubleshooting Steps

Start by identifying the symptoms your equipment is displaying. Follow a methodical procedure to diagnose the issue, checking each component systematically. Document your findings for future reference.

| Step | Action |

|---|---|

| 1 | Inspect the power source and connections. |

| 2 | Check fluid levels and condition. |

| 3 | Examine mechanical parts for wear or damage. |

| 4 | Replace or repair faulty components as needed. |

| 5 | Test the machine to ensure functionality. |

Electrical System Troubleshooting

Addressing issues within the electrical framework of your equipment is essential for ensuring optimal performance. Understanding the common problems and their potential solutions can help you quickly diagnose and rectify faults, leading to a smoother operation.

Common Electrical Issues

Electrical malfunctions can manifest in various ways, including starting difficulties, dimming lights, or intermittent functionality. Identifying these symptoms can guide you towards the underlying cause.

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| Engine won’t start | Dead battery | Charge or replace the battery |

| Lights are dim | Faulty alternator | Test and replace the alternator if needed |

| Intermittent power | Loose connections | Inspect and secure all wiring connections |

Steps for Effective Troubleshooting

Begin by conducting a visual inspection of the wiring and components. Look for signs of wear, damage, or corrosion. Use a multimeter to test voltage levels and continuity to pinpoint the issue accurately. By following these steps, you can effectively address electrical concerns and maintain the reliability of your equipment.

Engine Maintenance Guidelines

Regular upkeep of your power unit is essential for optimal performance and longevity. By following a structured maintenance routine, you can ensure that the engine operates smoothly and efficiently, minimizing the risk of breakdowns and enhancing overall functionality.

Essential Maintenance Tasks

Conducting periodic inspections and servicing is crucial. Key tasks include checking oil levels, replacing filters, and cleaning components to prevent buildup. Each of these actions contributes significantly to the health of the engine.

Maintenance Schedule

Adhering to a scheduled maintenance plan can greatly improve reliability. Below is a recommended timeline for essential upkeep:

| Task | Frequency |

|---|---|

| Oil Change | Every 50 hours of operation |

| Filter Replacement | Every 100 hours of operation |

| Spark Plug Inspection | Every 200 hours of operation |

| Air Filter Cleaning | Every 25 hours of operation |

Blades: Sharpening and Replacement

Maintaining cutting edges is essential for optimal performance and longevity of your equipment. Regular attention to these components ensures a clean and efficient cut, promoting healthy growth in the surrounding landscape. This section will guide you through the processes of honing and swapping out these vital parts.

Here are key steps for sharpening:

- Gather necessary tools such as a file, sharpening stone, or grinder.

- Ensure safety by disconnecting the power source before beginning work.

- Examine the edges for wear or damage; focus on dull spots.

- Gradually sharpen the edges at the manufacturer’s recommended angle.

- Clean the blades after sharpening to remove any metal shavings.

When it comes to replacement, consider the following:

- Identify the specific model to ensure compatibility with new blades.

- Use appropriate tools to remove the old blades, typically requiring wrenches or sockets.

- Install the new blades securely, ensuring they are aligned correctly.

- After installation, perform a thorough check before use to ensure safety.

By adhering to these guidelines, you can maintain the effectiveness of your equipment and extend its lifespan.

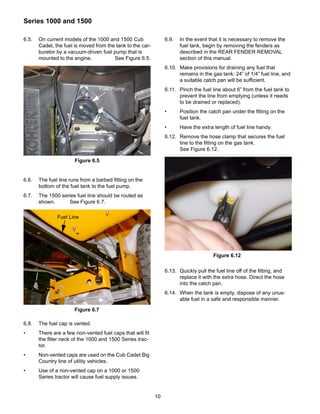

Fuel System Care

Maintaining the fuel delivery system is essential for optimal performance and longevity of your equipment. Proper attention to this area can prevent issues such as poor starting, stalling, and decreased efficiency. This section will guide you through the best practices to ensure your fuel system operates smoothly.

Regular Inspection

Conducting regular inspections of the fuel components is vital. Check for leaks, cracks, or any signs of wear. Pay close attention to fuel lines and connections, as even small issues can lead to significant problems. Replace any damaged parts promptly to avoid further complications.

Fuel Quality Maintenance

Using clean, high-quality fuel is crucial for the health of your engine. Always store fuel in a clean, sealed container and avoid using fuel that has been sitting for an extended period. Consider adding a fuel stabilizer if you anticipate long storage times. Regularly replace the fuel filter to ensure that impurities do not reach the engine.

Winterizing Your Mower

Preparing your outdoor equipment for the colder months is essential to ensure longevity and optimal performance when the season changes. Taking the right steps to safeguard your machine can prevent costly damages and make the transition to spring much smoother.

Essential Steps for Winter Preparation

Begin by thoroughly cleaning the exterior and undercarriage to remove any dirt, grass, and debris. A clean surface helps prevent rust and other forms of corrosion. Next, inspect all components, including the blades and belts, for wear and replace any that show significant signs of damage.

Fuel and Oil Maintenance

Draining or stabilizing the fuel is crucial. If you choose to drain, make sure to run the engine until it consumes the remaining fuel. Alternatively, adding a fuel stabilizer can help preserve the gasoline over the winter. Don’t forget to change the oil to keep the engine lubricated and free from contaminants.

Finally, store the unit in a dry, sheltered location. Covering it with a breathable tarp can offer additional protection against dust and moisture. By following these guidelines, you can ensure that your outdoor equipment remains in prime condition for the next growing season.

Finding Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Whether you are facing wear and tear or require upgrades, understanding where to source these items is crucial for effective maintenance.

Online Retailers: Numerous websites specialize in providing a wide array of components tailored to various models. These platforms often feature search filters that allow you to identify the exact part you need based on specifications and compatibility.

Local Suppliers: Visiting nearby stores can also be beneficial. Many local distributors maintain stocks of essential parts and can offer guidance on the best options for your specific equipment.

Community Forums: Engaging with online communities can provide valuable insights. Enthusiasts and experienced users often share their recommendations for reliable sources and even specific part numbers that ensure proper fit and function.

By exploring these avenues, you can streamline the process of obtaining the necessary components, ensuring your equipment remains in optimal condition.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance on outdoor machinery is essential for both personal safety and the longevity of the equipment. By following proper guidelines, you can minimize the risk of accidents and enhance the effectiveness of your work.

Firstly, always wear appropriate protective gear. This includes gloves, safety goggles, and sturdy footwear to shield against potential hazards. Additionally, keep hair tied back and avoid loose clothing that might get caught in moving parts.

Secondly, before starting any task, disconnect the power source. This precaution prevents accidental activation and safeguards you from electric shocks. Moreover, ensure the area is well-lit and free from clutter to maintain a clear workspace.

Lastly, familiarize yourself with the machinery’s specifications and safety features. Understanding how different components function can prevent mishaps and aid in troubleshooting. By adhering to these guidelines, you can effectively ensure a safer and more efficient working process.