Proper upkeep of your snow management device is essential for optimal performance and longevity. Understanding the intricacies of its components can help users troubleshoot common issues effectively. This section aims to provide comprehensive insights into maintaining and restoring your equipment, ensuring it remains reliable during harsh weather conditions.

Identifying Potential Issues is the first step toward successful management. Regular inspections can reveal wear and tear that might hinder efficiency. By recognizing symptoms early, you can prevent more significant problems from arising and save on costly repairs.

Maintenance Practices are crucial for enhancing the lifespan of your machine. Following a structured approach to cleaning, lubricating, and replacing parts as needed ensures that your equipment performs at its best. This guide offers detailed instructions to help you navigate through various upkeep tasks with confidence.

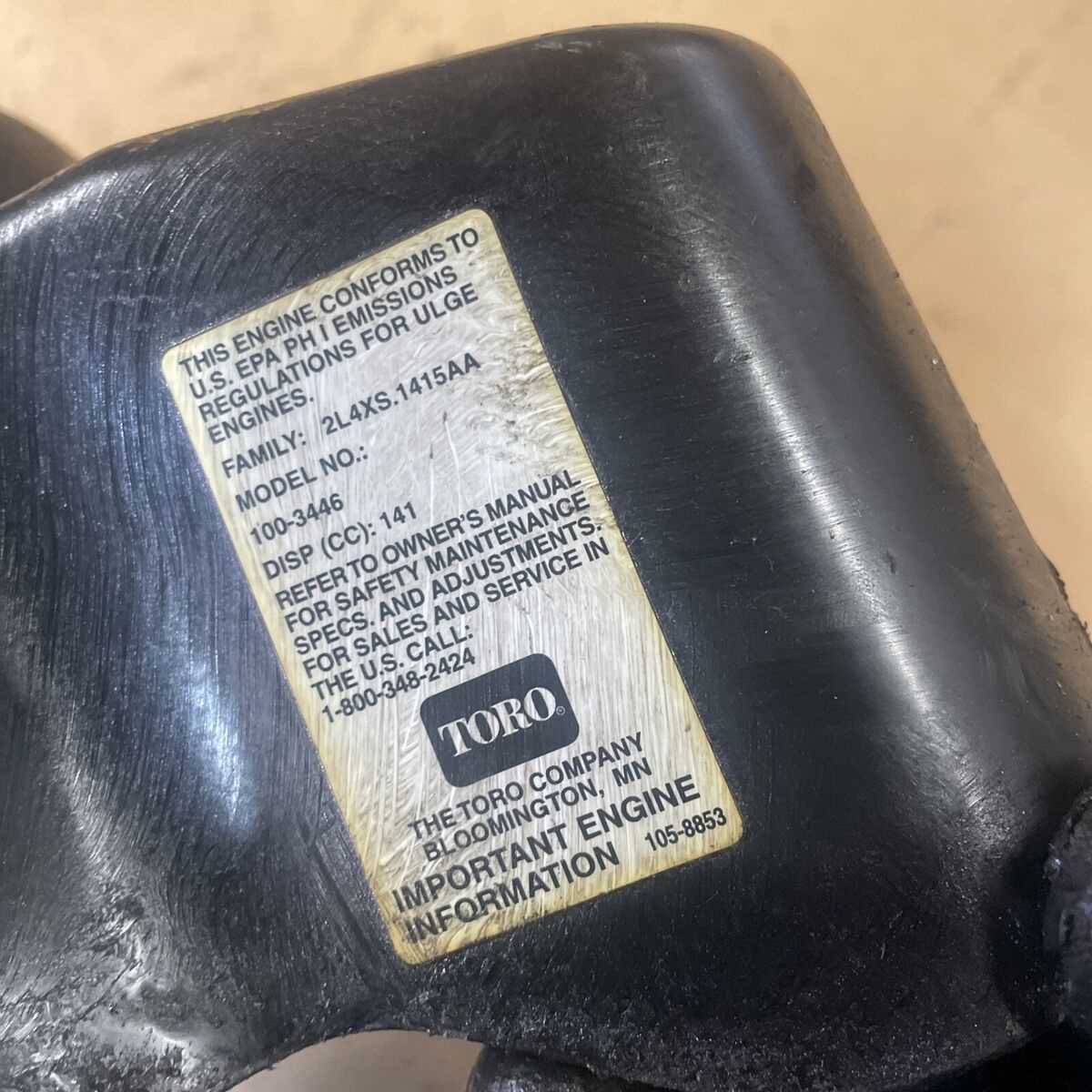

Toro CCR 3650 Overview

This section provides a comprehensive look at a well-regarded snow clearing device, highlighting its features, benefits, and overall functionality. Designed for efficiency, this machine is tailored to tackle winter weather challenges with ease, making it a valuable asset for homeowners and professionals alike.

Key Features: This snow removal tool is equipped with a powerful engine that ensures reliable performance, even in heavy snow conditions. Its compact design allows for easy maneuverability, making it ideal for both small driveways and larger areas. The user-friendly controls simplify operation, ensuring that anyone can use it effectively.

Benefits: One of the primary advantages of this equipment is its ability to clear snow quickly and thoroughly, reducing the time and effort needed for winter maintenance. Additionally, its durable construction ensures longevity, allowing users to rely on it season after season. The efficiency of this machine not only saves time but also enhances safety by keeping pathways clear.

In summary, this snow clearing solution stands out due to its blend of power, efficiency, and ease of use, making it a top choice for those facing the challenges of winter weather.

Common Issues with Toro Snowblowers

Snow-clearing machines are essential tools for managing winter weather, but like any equipment, they can experience problems. Understanding these common challenges can help users maintain their machines and ensure smooth operation during the snowy season.

- Starting Difficulties: Many users report issues with starting their machines. This can often be attributed to fuel problems, battery issues, or spark plug malfunctions.

- Stalling: Machines may stall unexpectedly during operation. This could be due to clogged fuel lines, insufficient fuel supply, or mechanical failures.

- Auger Problems: The auger, responsible for moving snow, may encounter blockages or fail to engage properly, leading to ineffective snow removal.

Addressing these concerns promptly can enhance performance and prolong the lifespan of the equipment.

- Fuel Quality: Always use fresh fuel and check for contamination to avoid starting and stalling issues.

- Regular Maintenance: Schedule routine inspections to identify potential problems before they escalate.

- Proper Storage: Store the machine in a dry place to prevent rust and damage to sensitive components.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and restoring outdoor machinery. A well-equipped toolkit not only simplifies the process but also enhances efficiency, allowing for precise and effective actions. Understanding the various instruments needed will help ensure that you are prepared for any task that arises.

Basic Hand Tools

Start with fundamental hand tools that are essential for any maintenance project. A sturdy screwdriver set is vital for loosening and tightening screws of various sizes. Additionally, a reliable wrench set allows you to tackle nuts and bolts effectively. Don’t forget a pair of pliers for gripping and twisting tasks, as well as a hammer for driving components into place.

Specialized Equipment

For more complex issues, specialized tools become necessary. A multimeter can help diagnose electrical problems by measuring voltage and current, while a spark plug socket is essential for accessing and replacing spark plugs. Keeping a mechanic’s creeper on hand can also provide comfort and ease when working underneath machinery. Investing in these tools will significantly enhance your ability to address various challenges.

Step-by-Step Repair Procedures

This section provides a detailed approach to troubleshooting and fixing common issues encountered with your equipment. By following a systematic method, you can effectively address malfunctions and ensure optimal performance.

Identification of Issues

Begin by thoroughly examining the unit for visible signs of wear or damage. Listen for unusual sounds during operation, which may indicate underlying problems. It’s essential to pinpoint specific symptoms, as this will guide your subsequent actions.

Disassembly and Inspection

Once you have identified the issues, carefully disassemble the components, taking note of each part’s placement. Use appropriate tools to avoid causing additional harm. After disassembly, inspect each component for wear, cracks, or other forms of damage. Replace any faulty parts as necessary, ensuring compatibility with the existing system.

Following these guidelines will help restore functionality and prolong the life of your machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular upkeep and attention to detail. By implementing a few key practices, you can extend the lifespan of your machinery and keep it running smoothly throughout its use.

Regular Inspections

Conducting routine checks is essential for identifying potential issues before they escalate. Focus on the following:

- Inspect for any signs of wear or damage.

- Check all fluid levels and replenish as needed.

- Examine belts and hoses for cracks or fraying.

Proper Cleaning

Keeping your equipment clean is vital for optimal performance. Consider these steps:

- Remove dirt and debris from all surfaces.

- Clean air filters regularly to ensure proper airflow.

- Use appropriate cleaning agents to avoid damage to components.

Adopting these practices will help maintain the integrity of your machinery, leading to better performance and a longer operational life.

How to Troubleshoot Engine Problems

When facing issues with an engine, it’s essential to systematically identify the underlying causes. Various symptoms can indicate a range of problems, and knowing how to approach these issues can save time and ensure effective resolution. This guide provides a structured method for diagnosing engine malfunctions, allowing you to pinpoint and address concerns efficiently.

| Symptom | Possible Causes | Suggested Actions |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty ignition, fuel blockage | Check battery charge, inspect ignition system, verify fuel supply |

| Excessive Smoke | Oil leakage, fuel mixture issues | Examine oil levels, check carburetor settings |

| Unusual Noises | Worn components, loose parts | Inspect for loose screws, examine belts and pulleys |

| Overheating | Coolant leaks, blocked airflow | Check coolant levels, clean air filters |

| Loss of Power | Clogged filters, fuel delivery issues | Replace air and fuel filters, assess fuel lines |

By following these steps and referencing the associated symptoms, you can methodically troubleshoot engine issues. Always ensure safety precautions are observed during inspections, and consult a professional if problems persist.

Replacing Blades: A Guide

Keeping your outdoor equipment in top condition is essential for optimal performance. One crucial maintenance task is the replacement of cutting edges. Over time, these components can become dull or damaged, affecting the efficiency and effectiveness of your machine. This guide will provide you with the necessary steps to safely and effectively replace the blades, ensuring that your equipment operates smoothly.

Preparation

Before beginning the replacement process, ensure that you have the appropriate tools on hand. You will typically need a wrench, a socket set, and safety gloves. It’s important to disconnect the power source to avoid any accidental starts during the procedure. Additionally, inspect the new blades for any defects before installation.

Removing Old Blades

Once prepared, carefully tilt or position your equipment to access the cutting components. Use your wrench to loosen the bolts securing the old blades. Remember to keep track of any washers or spacers, as these will need to be reused. Once the bolts are removed, gently detach the blades and set them aside.

Installing New Blades

Position the new cutting edges in place, ensuring they are aligned correctly with any guides. Replace the washers and bolts, tightening them securely but avoiding overtightening, which can cause damage. Double-check the installation to confirm everything is properly aligned and secure.

Final Checks

After installation, reconnect the power source and perform a test run. Observe the operation to ensure everything functions smoothly. Regular maintenance and timely replacement of cutting edges will not only prolong the life of your equipment but also enhance its performance.

Winter Preparation Checklist

As the colder months approach, it is essential to ensure your equipment is ready to face the challenges of winter. Proper preparation can enhance performance, extend the lifespan of your tools, and ensure safety during use. Below is a checklist to help you get everything in order for the upcoming season.

| Task | Description | Status |

|---|---|---|

| Inspect Fuel System | Check for old fuel and replace it with fresh fuel to prevent engine issues. | Completed / Pending |

| Clean Air Filter | Remove and clean the air filter to ensure optimal airflow and performance. | Completed / Pending |

| Check Spark Plug | Inspect the spark plug for wear and replace it if necessary for efficient ignition. | Completed / Pending |

| Inspect Blades | Sharpen or replace blades to ensure effective operation during snow removal. | Completed / Pending |

| Test Electrical Components | Verify the functionality of lights, batteries, and other electrical parts. | Completed / Pending |

| Check Tires | Inspect tire condition and ensure they are properly inflated for better traction. | Completed / Pending |

| Store Properly | Ensure the equipment is stored in a dry and sheltered place to prevent damage. | Completed / Pending |

Where to Find Replacement Parts

Finding suitable components for maintenance and repair can be essential for ensuring your equipment runs smoothly. There are various sources where you can locate high-quality replacements, ranging from authorized dealers to online marketplaces. Understanding where to search can save you time and help you make informed choices.

Authorized Dealers

One of the most reliable places to obtain parts is through authorized retailers. These vendors typically offer original components that match the specifications of your machine. They often have knowledgeable staff who can assist with compatibility questions and help you find the exact item you need.

Online Marketplaces

Another option is to explore online platforms that specialize in machinery components. Websites like e-commerce giants provide a vast selection of parts, often at competitive prices. When purchasing online, ensure that you check seller ratings and reviews to confirm the quality of the items being offered.

User Experiences and Tips

This section aims to provide insights from users who have worked with snow removal equipment. Their experiences highlight common challenges, effective solutions, and practical advice to enhance the performance and longevity of your machine.

Common Challenges

- Starting issues during cold weather.

- Loss of power or inefficient snow clearing.

- Clogged chute from wet snow or ice.

Practical Solutions

- Ensure proper maintenance: Regularly check the oil and replace it as needed.

- Use a fuel stabilizer to keep the engine running smoothly in colder temperatures.

- Clear the chute and auger frequently to avoid blockages.

By implementing these tips, users have reported improved functionality and reliability of their snow removal machines, making winter operations much more efficient.