When it comes to ensuring the longevity and efficiency of your agricultural machinery, having access to comprehensive guidance is crucial. This section aims to provide essential insights and practical advice for troubleshooting and enhancing the performance of your equipment.

Understanding the core components and functions of your vehicle can significantly improve its operation. By following straightforward procedures and applying maintenance best practices, you can address common issues effectively and keep your machinery running smoothly.

With a focus on hands-on techniques, this guide will help you navigate through various challenges that may arise during use. From regular inspections to addressing unexpected malfunctions, having a reliable reference can empower you to tackle repairs with confidence.

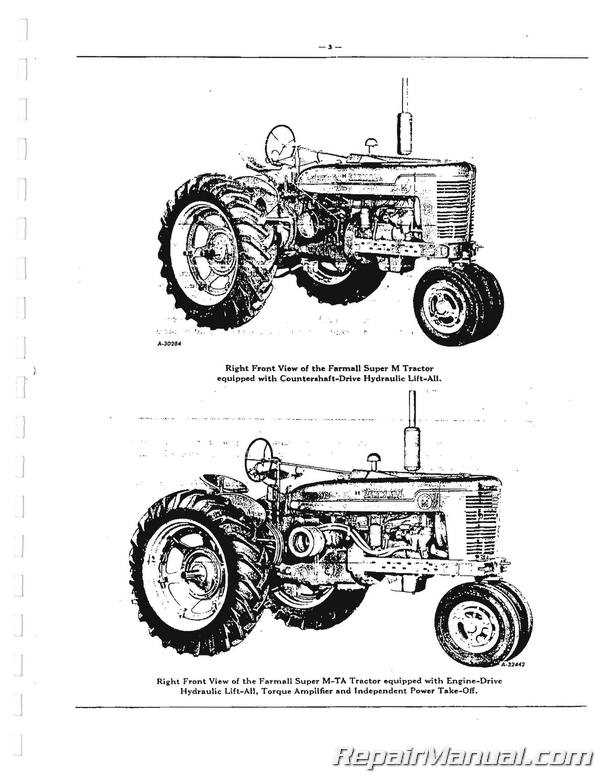

This section focuses on comprehending the intricacies of a specific agricultural machine’s power unit. The engine plays a crucial role in the overall functionality and performance, making it essential to grasp its mechanics and operational principles. By delving into the essential components and their interrelations, users can enhance their understanding and maintenance practices.

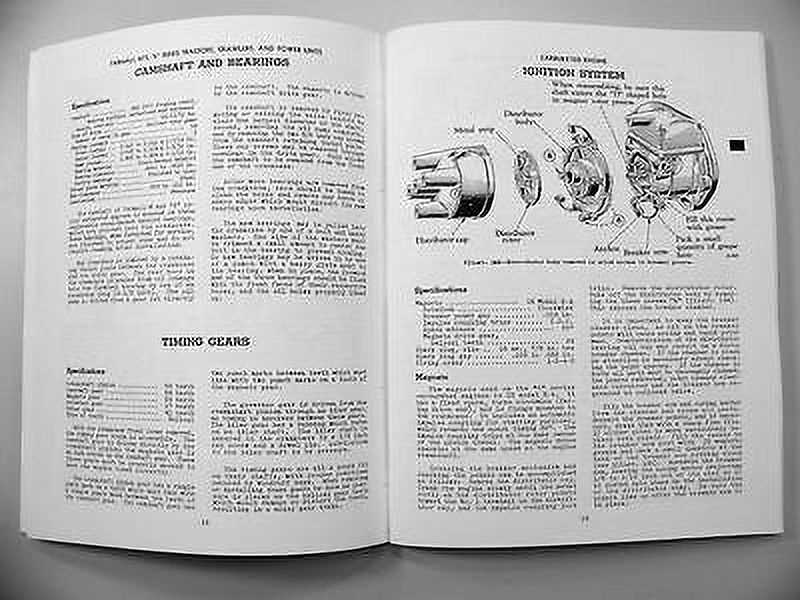

Key Components of the Engine

To effectively engage with the engine, it’s vital to familiarize oneself with its primary elements. Each component contributes uniquely to the machine’s overall functionality. Below is a table summarizing these key parts:

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and supports various components. |

| Piston | Converts fuel energy into mechanical motion. |

| Crankshaft | Transforms linear motion of the pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

Maintenance Tips for Optimal Performance

Regular upkeep is vital for ensuring longevity and efficiency. Familiarity with lubrication schedules and routine inspections can significantly mitigate potential issues. Below are some essential maintenance practices:

- Check oil levels regularly and replace as needed.

- Inspect filters for cleanliness to ensure optimal airflow.

- Monitor coolant levels and temperature to prevent overheating.

Common Mechanical Issues

When dealing with agricultural machinery, it is essential to be aware of frequent mechanical challenges that may arise during operation. These issues can range from minor adjustments to significant component failures, impacting overall efficiency and performance.

Engine Performance: One of the most prevalent concerns is related to engine functionality. Symptoms such as rough idling, stalling, or decreased power output often indicate underlying issues that need addressing. Regular maintenance and timely inspections can help identify these problems early.

Transmission Difficulties: Another common area of concern is the transmission system. Users may experience difficulty shifting gears or unusual noises during operation. These symptoms can be caused by low fluid levels, worn components, or misalignment, necessitating thorough examination and possible intervention.

Hydraulic System Failures: Hydraulic systems are crucial for various operations, and their malfunction can lead to significant downtime. Leaks, reduced pressure, or erratic movements are indicators that the hydraulic system requires attention. Proper upkeep and monitoring of hydraulic fluids are essential for optimal performance.

Electrical Issues: Lastly, electrical problems can arise, affecting various functions, from starting the machine to operating attachments. Faulty wiring, blown fuses, or malfunctioning sensors can disrupt operations. Regular checks and proper troubleshooting techniques can mitigate these challenges.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By following a systematic approach to upkeep, you can enhance performance and extend the lifespan of your machinery.

- Regular Inspections: Conduct routine checks for wear and tear. Look for signs of damage or loose components that may need tightening.

- Fluid Changes: Replace engine oil, coolant, and hydraulic fluids as per the manufacturer’s schedule to keep systems running smoothly.

- Filter Maintenance: Clean or replace air and fuel filters regularly to ensure optimal airflow and fuel efficiency.

- Battery Care: Keep battery terminals clean and ensure connections are secure to prevent electrical issues.

- Tire Management: Monitor tire pressure and tread wear to ensure proper traction and reduce the risk of blowouts.

Implementing these practices can significantly improve reliability and performance, allowing your machinery to serve you effectively for years to come.

Repairing the Fuel System

The functionality of any machinery heavily relies on its power source. Ensuring that the delivery of fuel is seamless is essential for optimal performance. This section addresses the necessary steps and considerations for addressing issues related to the fuel delivery mechanism, emphasizing the importance of proper maintenance and troubleshooting techniques.

Begin by examining the fuel tank for any signs of contamination or blockages. Removing debris and ensuring that the tank is clean will prevent further complications down the line. Following this, inspect the fuel lines for leaks or cracks. Damaged lines can severely affect the flow, leading to performance issues.

Next, evaluate the fuel filter, which plays a crucial role in keeping impurities from entering the engine. A clogged filter can hinder fuel flow, so regular replacement is advised. After replacing the filter, check the fuel pump’s functionality. Ensuring that it operates smoothly will help maintain consistent fuel pressure.

Finally, once all components have been inspected and serviced, perform a test run. Monitor the machinery for any irregularities in operation, paying close attention to the sound and efficiency of the engine. This thorough approach will enhance the longevity and reliability of the equipment.

Electrical System Troubleshooting

Identifying issues within the electrical setup is crucial for maintaining optimal performance and functionality. This section aims to guide you through common problems, their symptoms, and solutions to restore efficient operation.

Begin by considering the following areas that may exhibit faults:

- Battery condition and connections

- Wiring integrity and insulation

- Fuse functionality

- Switch operation

- Electrical component performance

To effectively diagnose issues, follow these steps:

- Inspect the battery for corrosion and ensure secure connections.

- Examine wiring for any signs of wear or damage.

- Test fuses and replace any that are blown.

- Check switches for proper operation and responsiveness.

- Assess components for unusual sounds or failures.

Utilizing a multimeter can aid in measuring voltage and continuity, providing further insights into potential malfunctions. Always ensure safety precautions are followed while conducting any inspections or tests.

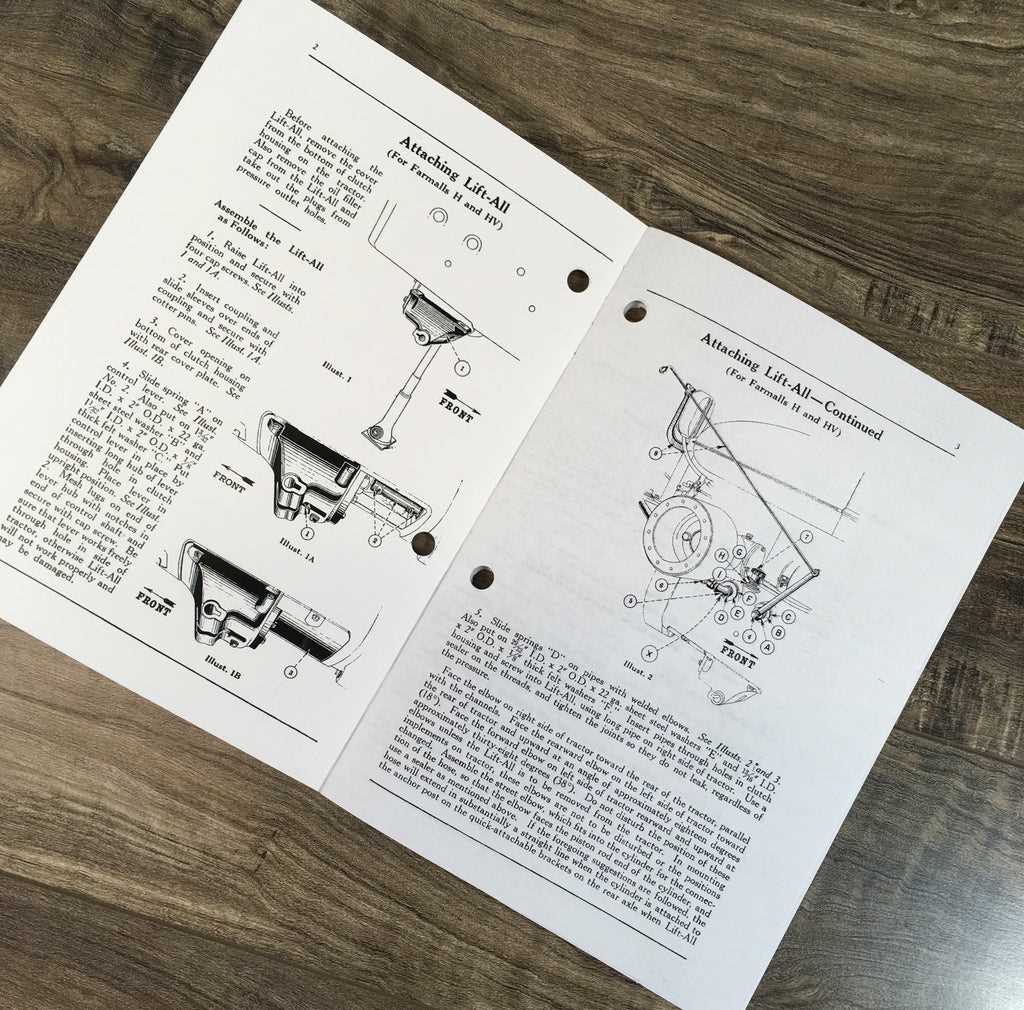

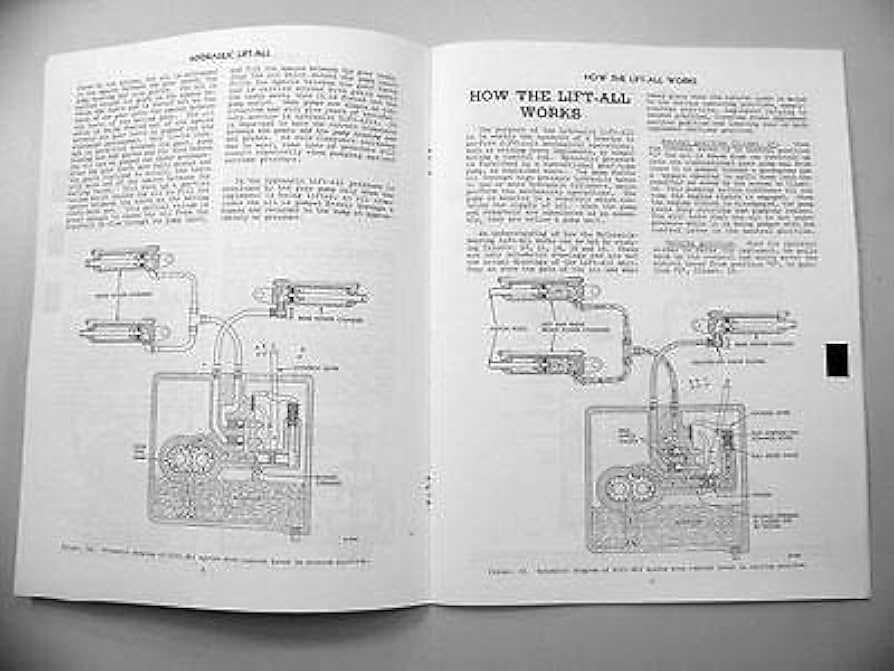

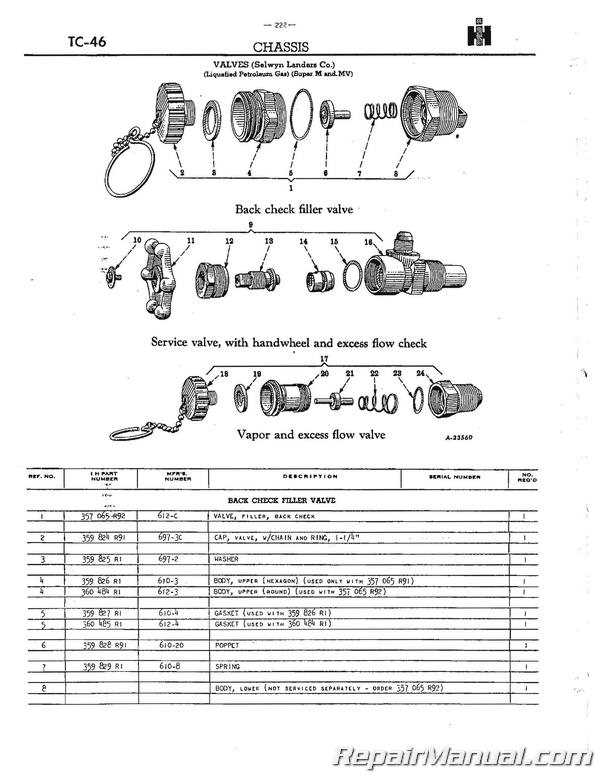

Hydraulic System Overview

The hydraulic system plays a crucial role in enhancing the efficiency and functionality of various machinery. It utilizes fluid power to transmit energy, allowing for the operation of numerous components that require significant force and precision.

Key features of hydraulic systems include:

- Fluid Power: The system relies on incompressible fluid to transmit force, ensuring smooth operation and responsiveness.

- Components: Essential parts consist of pumps, cylinders, hoses, and valves, each contributing to the overall functionality.

- Efficiency: This system offers high power-to-weight ratios, enabling machines to perform heavy tasks with less effort.

Understanding the workings of hydraulic systems is vital for effective maintenance and troubleshooting. Proper care ensures longevity and reliability, allowing for optimal performance in various applications.

Parts Replacement Guide

This section provides essential insights into the process of substituting components in your agricultural machinery. Understanding when and how to replace various parts can significantly enhance the efficiency and longevity of your equipment.

| Component | Signs of Wear | Replacement Procedure |

|---|---|---|

| Engine Oil Filter | Low oil pressure, excessive engine noise | Drain oil, remove the old filter, install a new one, refill oil |

| Fuel Filter | Decreased performance, engine stalling | Locate the filter, detach hoses, replace with a new filter, reconnect |

| Belt | Fraying, cracking, squealing noises | Loosen tension, remove the old belt, position the new belt, adjust tension |

| Hydraulic Fluid | Low fluid level, sluggish operation | Check the reservoir, drain old fluid, add new fluid |

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance or fixing machinery. Adhering to specific guidelines helps prevent accidents and injuries, creating a secure environment for everyone involved.

Essential Guidelines

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes or dust.

- Keep the area organized and free from clutter to minimize hazards.

- Disconnect power sources before beginning any work to prevent accidental activation.

Emergency Preparedness

- Have a first aid kit readily accessible in case of minor injuries.

- Familiarize yourself with emergency shut-off procedures for equipment.

- Know the location of fire extinguishers and how to use them.

- Establish a communication plan to notify others in case of an emergency.