In the realm of automotive maintenance, having access to detailed documentation is essential for ensuring the longevity and functionality of large vehicles. Such resources provide vital insights into the various components, systems, and procedures that are critical for efficient operation. By utilizing these guides, individuals can enhance their understanding and skills related to vehicle care and troubleshooting.

These resources serve as valuable tools for both professionals and enthusiasts alike. They encompass a wide range of topics, from basic maintenance to complex system diagnostics. With the right information at hand, users can confidently tackle issues, perform necessary adjustments, and uphold the performance standards required for demanding environments.

Moreover, the availability of well-structured documentation facilitates a deeper comprehension of technical concepts. This understanding not only aids in immediate problem-solving but also fosters a proactive approach to vehicle upkeep. By engaging with these informative materials, users are better equipped to maintain their vehicles effectively, ensuring optimal performance over time.

Heavy Duty Truck Repair Manuals

This section explores essential resources for maintaining and fixing large vehicles used in transportation and construction. These guides provide comprehensive instructions, enabling users to effectively address various mechanical issues that may arise.

- Detailed procedures for diagnostics

- Step-by-step instructions for maintenance tasks

- Tips for troubleshooting common problems

Access to reliable information can significantly enhance the efficiency and longevity of these robust vehicles. Whether it’s routine upkeep or addressing specific malfunctions, having the right resources is crucial for operators and technicians alike.

- Understanding system components

- Learning safety protocols

- Implementing best practices for performance improvement

In conclusion, utilizing well-structured guidance ensures that those involved in the care of these significant machines can perform their tasks with confidence and accuracy.

Importance of Comprehensive Repair Guides

Having access to detailed instructional materials is crucial for maintaining and restoring large vehicles. These resources serve as vital references for technicians, enabling them to perform their tasks efficiently and effectively. A well-structured guide not only enhances understanding but also reduces the likelihood of errors during maintenance procedures.

Enhancing Technical Knowledge

Thorough instructional materials provide valuable insights into various components and systems. This understanding is essential for:

- Improving diagnostic skills

- Facilitating troubleshooting processes

- Understanding the intricacies of different models

Ensuring Safety and Compliance

Comprehensive resources also play a significant role in safety and regulatory compliance. They help ensure that:

- Proper safety protocols are followed

- Maintenance tasks meet industry standards

- Technicians are aware of the latest regulations

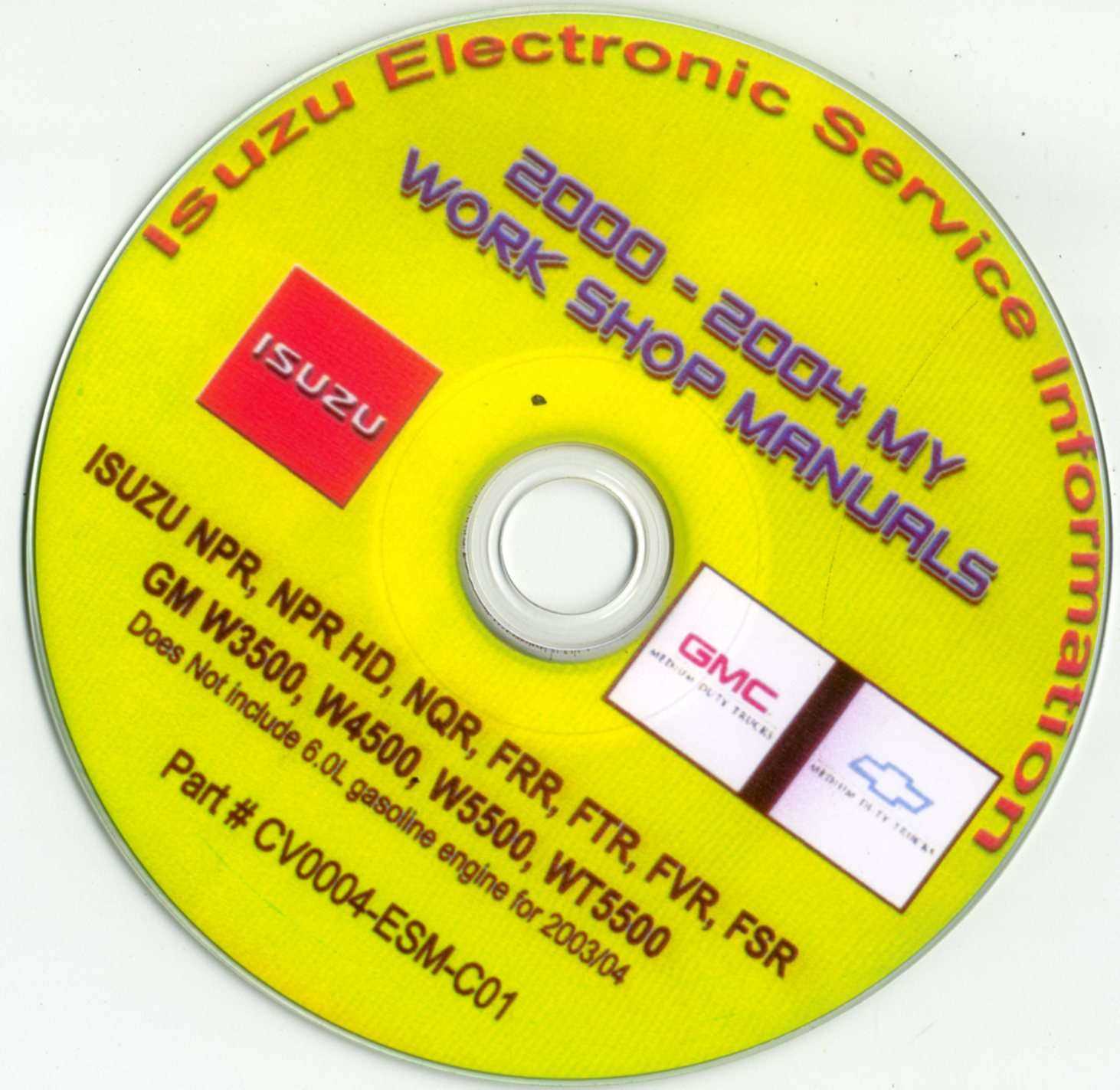

Types of Manuals for Truck Maintenance

Effective upkeep of large vehicles relies on various guides that provide essential information for proper functioning. These resources cover a wide range of topics, ensuring that operators and technicians have the necessary knowledge to maintain and troubleshoot their vehicles effectively.

Common Categories of Guides

- Owner’s Guides: These documents are designed for vehicle owners, offering insights into basic maintenance practices and operational tips.

- Service Publications: Focused on more technical information, these publications provide detailed procedures for servicing and maintaining specific components.

- Diagnostic Resources: Essential for troubleshooting, these guides outline common issues and provide step-by-step solutions.

- Parts Catalogs: These catalogs list all the components available for a particular vehicle, helping users identify and order the necessary parts.

Purpose of Each Type

Each category serves a distinct function:

- Owner’s Guides empower users with knowledge about regular care.

- Service Publications are crucial for professionals needing in-depth technical procedures.

- Diagnostic Resources assist in quickly identifying and resolving issues.

- Parts Catalogs simplify the ordering process by providing comprehensive lists.

Understanding Technical Specifications and Standards

Technical specifications and standards play a crucial role in ensuring that vehicles operate safely and efficiently. These guidelines establish parameters for performance, safety, and quality, enabling manufacturers, mechanics, and users to maintain a consistent level of excellence. Understanding these specifications is essential for anyone involved in the maintenance and operation of large vehicles.

Importance of Adhering to Standards

Adhering to established standards guarantees that every component functions as intended, reducing the risk of failures that could lead to costly repairs or accidents. Additionally, compliance with these specifications helps in maintaining the vehicle’s value and reliability over time.

Key Specifications to Consider

When examining the technical aspects of a vehicle, several key specifications should be taken into account. These include weight limits, engine performance metrics, and safety regulations. Below is a table outlining some of the essential specifications:

| Specification | Description |

|---|---|

| Weight Capacity | Maximum load a vehicle can safely carry. |

| Engine Power | Output measured in horsepower or kilowatts. |

| Braking Distance | Distance required to bring the vehicle to a stop. |

| Emission Standards | Regulations governing the permissible levels of pollutants. |

Diagnostic Procedures for Common Issues

Identifying problems in large vehicles requires a systematic approach. Proper techniques help in accurately diagnosing faults, ensuring efficient solutions. This section outlines essential procedures to effectively pinpoint and address typical complications.

First, it is crucial to conduct a thorough visual inspection. Look for obvious signs of wear, leaks, or damage that could indicate underlying issues. Checking fluid levels and connections can reveal abnormalities that might affect performance.

Next, utilize electronic diagnostic tools. These devices can communicate with onboard systems, providing valuable data on error codes and performance metrics. Understanding these readings is key to determining the nature of the problem.

In addition to electronic methods, road testing offers insights into the vehicle’s behavior under various conditions. Observing how it performs can help isolate symptoms and lead to more accurate conclusions.

Finally, always refer to the specific guidelines provided for similar models. Familiarity with common issues and their solutions enhances troubleshooting efficiency and contributes to successful resolution.

Step-by-Step Repair Instructions

Following a systematic approach is essential when addressing mechanical issues. A well-structured guide can greatly assist in understanding the necessary procedures, ensuring that each task is completed efficiently and effectively. This section outlines a clear framework for tackling various maintenance tasks.

- Identify the Problem: Start by diagnosing the issue. Observing symptoms can provide crucial insights into the malfunction.

- Gather Required Tools: Ensure you have all necessary tools and components on hand to avoid interruptions during the process.

- Follow Safety Protocols: Prioritize safety by using protective gear and following standard safety guidelines.

Once the preliminary steps are completed, proceed with the following stages:

- Remove any obstructive parts to gain access to the area needing attention.

- Carefully execute the required adjustments or replacements as indicated in the guidelines.

- Reassemble all components methodically, ensuring everything is secured properly.

- Conduct a thorough test to verify that the issue has been resolved.

Adhering to these structured instructions will lead to successful outcomes and prolong the lifespan of the machinery.

Safety Protocols During Repairs

Ensuring a secure working environment is paramount when performing maintenance tasks. Implementing effective safety measures protects both the personnel involved and the equipment being serviced. Adhering to these protocols minimizes the risk of accidents and enhances overall efficiency in the workspace.

Personal Protective Equipment

- Always wear appropriate gear, such as gloves and safety glasses.

- Use steel-toed boots to safeguard against heavy objects.

- Ensure high-visibility clothing is worn in areas with low visibility.

Workplace Organization

- Keep tools and equipment organized to prevent tripping hazards.

- Designate specific areas for equipment and hazardous materials.

- Regularly inspect workspaces for any potential dangers or clutter.

Tools and Equipment for Heavy Repairs

Maintaining and restoring large vehicles requires a variety of specialized instruments and devices that ensure efficiency and safety during the process. These resources not only facilitate tasks but also enhance the overall quality of work performed. Understanding the essential tools is crucial for achieving optimal results in challenging maintenance situations.

Essential Instruments

Among the primary items needed are wrenches, sockets, and screwdrivers, which form the backbone of any mechanical toolkit. High-torque wrenches are particularly important for tightening components to manufacturer specifications. Ratchet sets allow for quick adjustments, minimizing time spent on each task.

Supportive Devices

In addition to basic tools, various supportive devices play a significant role. Hydraulic lifts are indispensable for elevating large structures, providing access to undercarriages and other hard-to-reach areas. Diagnostic equipment is also critical, as it helps identify issues that may not be immediately visible, streamlining the troubleshooting process.

Cost-Effectiveness of DIY Repairs

Engaging in self-conducted maintenance can lead to significant financial benefits for vehicle owners. By handling tasks personally, individuals often save on labor expenses, which can accumulate over time. This section explores the economic advantages of performing maintenance independently, as well as the factors to consider when evaluating this approach.

Financial Savings

One of the primary reasons for opting for personal maintenance is the reduction in overall costs. Professional services can be quite pricey, and many simple tasks can be performed without specialized knowledge. By utilizing available resources and tools, owners can complete these jobs effectively.

Factors to Consider

While the potential for savings is appealing, it’s essential to assess several elements before deciding on self-service. These include:

| Factor | Impact |

|---|---|

| Skill Level | Higher skills can lead to better outcomes. |

| Time Investment | More time may be needed compared to professionals. |

| Access to Tools | Required tools can incur additional costs. |

| Risk of Errors | Mistakes can lead to higher long-term costs. |

Choosing the Right Manual for Your Truck

Selecting the appropriate guide for your vehicle is crucial for effective maintenance and troubleshooting. A well-chosen resource can provide detailed insights, facilitating both routine checks and complex fixes. Understanding the specific needs of your vehicle type will help you identify the most suitable documentation available.

Assessing Your Vehicle’s Requirements

Before making a decision, consider the unique specifications of your vehicle. Different models and configurations may require tailored information. Look for guides that address your specific engine type, transmission, and features to ensure comprehensive coverage.

Evaluating Content and Usability

Not all resources are created equal. Seek materials that present information clearly and are easy to navigate. Features such as illustrations, step-by-step instructions, and troubleshooting tips enhance usability. Ensure the guide includes updates to stay relevant with any modifications in design or technology.

Ultimately, investing time in selecting the right guide will empower you to maintain your vehicle efficiently and effectively.

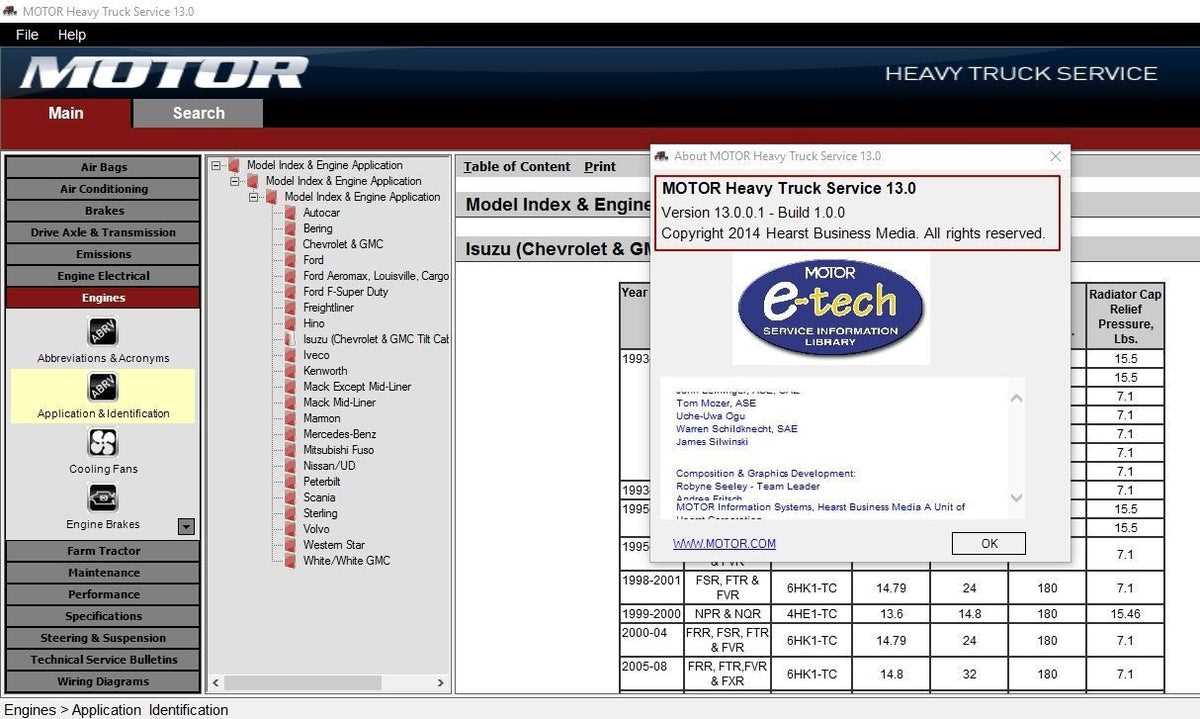

Online Resources and Digital Manuals

In the modern era, the availability of online platforms and electronic documentation has transformed how individuals access information regarding vehicle maintenance. These resources provide a convenient alternative to traditional print formats, enabling users to obtain guidance anytime and anywhere.

Several key advantages highlight the importance of these digital platforms:

- Accessibility: Users can reach these resources from various devices, such as smartphones, tablets, and computers.

- Up-to-Date Information: Online platforms often provide the latest updates, ensuring that users have access to current knowledge.

- Cost-Effectiveness: Many digital resources are available for free or at a lower cost compared to printed versions.

- Interactive Features: Some platforms include videos, diagrams, and forums for user discussions, enhancing the learning experience.

Among the most popular types of online resources are:

- Manufacturer Websites: Official sites often feature comprehensive guides and resources tailored to specific vehicle models.

- Online Forums: Communities where enthusiasts and professionals share tips, experiences, and advice related to maintenance and troubleshooting.

- Digital Libraries: Platforms that compile a wide array of documentation, offering searchable databases for efficient information retrieval.

Utilizing these online tools can significantly aid individuals in their vehicle maintenance efforts, providing them with the knowledge and confidence needed to address various challenges.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for large vehicles. Understanding the nuances of servicing these machines can enhance efficiency and prolong their lifespan.

What are the most common issues encountered during maintenance?

Common challenges often include electrical failures, engine performance problems, and fluid leaks. Recognizing these signs early can prevent more serious complications.

How often should inspections be conducted?

Regular check-ups are recommended based on usage and manufacturer guidelines, typically ranging from every few months to annually, ensuring optimal functioning.

What resources are available for troubleshooting?

Various tools, guides, and online forums provide insights and solutions, enabling users to tackle issues independently or consult professionals when needed.

Can I perform maintenance myself, or should I seek professional assistance?

While some tasks can be managed independently with the right knowledge and tools, complex repairs often require specialized expertise to ensure safety and reliability.