Understanding the intricacies of high-performance engines is crucial for enthusiasts and professionals alike. This section delves into the essential aspects of upkeep and troubleshooting for advanced diesel power systems. Whether you’re seeking to enhance performance or address specific issues, having a solid foundation is vital.

Effective maintenance involves more than just regular checks; it requires a thorough grasp of the components and their functions. By familiarizing yourself with the operational principles, you can ensure longevity and reliability. This guide aims to provide insights that empower you to tackle various challenges with confidence.

In this comprehensive resource, you will discover step-by-step instructions and valuable tips designed to assist you in achieving optimal performance. Each section is crafted to address specific needs, making it easier to navigate through the complexities of engine management. Prepare to elevate your understanding and skills as you delve into this informative journey.

Understanding the 6.7 Powerstroke Engine

This section provides insights into a robust diesel engine renowned for its performance and reliability in heavy-duty vehicles. It combines advanced technology with engineering excellence, ensuring efficient power delivery and durability under various driving conditions.

Key Features and Innovations

The engine incorporates several innovations that enhance its operational efficiency. Turbocharging plays a crucial role, significantly increasing air intake and power output while maintaining fuel efficiency. Additionally, a state-of-the-art fuel injection system optimizes combustion, contributing to lower emissions and improved torque.

Maintenance Considerations

Regular upkeep is essential to sustain optimal functionality. Routine inspections and timely fluid changes are vital for preventing wear and tear. Understanding the unique components and their roles can help in identifying potential issues early, ensuring longevity and reliable performance.

Common Issues and Solutions

When it comes to high-performance diesel engines, various challenges can arise over time. Understanding these potential problems and their remedies is essential for maintaining optimal performance and longevity. Below are some frequently encountered difficulties along with effective solutions.

Fuel Delivery Problems

Inconsistent fuel delivery can lead to reduced engine efficiency and power loss. This issue is often caused by clogged fuel filters or malfunctioning injectors. Regularly replacing the fuel filter and ensuring that injectors are clean can help prevent these problems. Additionally, using high-quality fuel can enhance overall performance.

Cooling System Failures

Overheating can be a serious concern for diesel engines. This may result from a failing thermostat, leaking hoses, or a malfunctioning water pump. Regular inspection of the cooling system components and timely replacement of any worn parts are vital. Ensuring proper coolant levels and using the correct type of coolant can also help maintain the system’s efficiency.

Essential Tools for Repairs

When it comes to performing maintenance on your vehicle, having the right equipment can make a significant difference. Whether tackling minor adjustments or major overhauls, a well-equipped workshop enhances efficiency and safety. Below is an overview of crucial tools that every enthusiast should consider having on hand for effective servicing.

Basic Hand Tools

A solid set of hand tools is fundamental for any mechanical work. These versatile instruments allow you to tackle various tasks, from tightening bolts to making adjustments. Key components include:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening fasteners |

| Wrenches | Essential for various bolt sizes |

| Screwdrivers | Necessary for assembling and disassembling parts |

Specialized Equipment

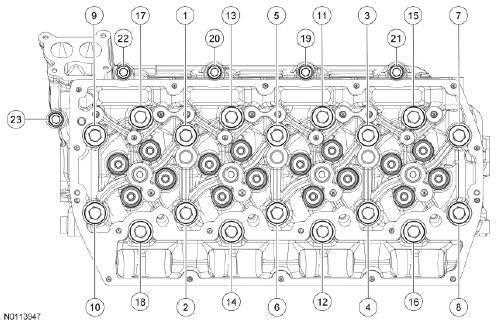

In addition to basic tools, specialized equipment is often required for more complex tasks. Investing in these items can facilitate intricate repairs and enhance overall performance:

| Tool | Purpose |

|---|---|

| Diagnostic Scanner | For reading error codes and diagnosing issues |

| Torque Wrench | Ensures bolts are tightened to the correct specifications |

| Jack and Stands | For safely lifting and securing the vehicle |

Step-by-Step Maintenance Guide

This section provides a comprehensive overview of essential upkeep procedures to ensure optimal performance and longevity of your vehicle. Regular maintenance is crucial for preventing issues and enhancing efficiency.

Routine Inspections

- Check fluid levels regularly, including oil, coolant, and transmission fluid.

- Inspect belts and hoses for signs of wear or damage.

- Examine the battery connections and clean any corrosion.

Scheduled Services

- Change the oil and replace the filter every 5,000 miles or as recommended.

- Rotate tires to ensure even wear, typically every 6,000 miles.

- Flush and replace the coolant system fluid as per the manufacturer’s schedule.

Performance Upgrades for Your Engine

Enhancing the capabilities of your vehicle’s engine can significantly improve its performance and efficiency. By implementing specific modifications, you can achieve better power delivery, increased fuel efficiency, and an overall more responsive driving experience. This section explores various upgrade options to help you unlock the full potential of your engine.

Intake and Exhaust Systems

Upgrading the intake and exhaust systems can lead to substantial gains in airflow. A high-performance air intake allows for better air circulation, while a more efficient exhaust system facilitates quicker expulsion of gases. This combination can result in improved horsepower and torque, enhancing your vehicle’s responsiveness and acceleration.

Tuning and Engine Management

Optimizing your engine’s parameters through tuning can yield impressive results. Advanced engine management systems allow for precise adjustments to fuel maps, ignition timing, and boost levels, maximizing power output and efficiency. Regular updates and custom tuning sessions can ensure that your engine operates at its best, adapting to any modifications made.

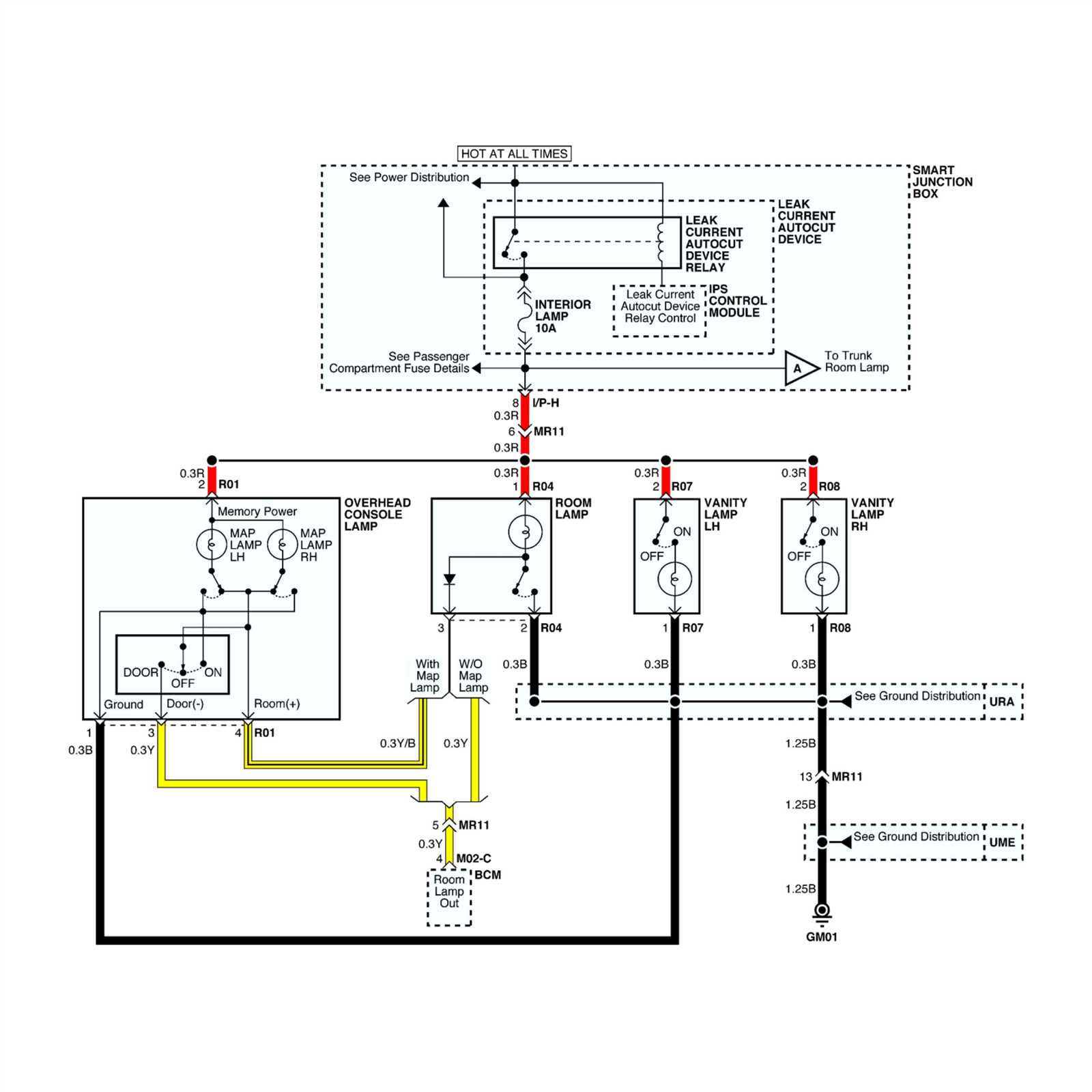

Diagnosing Electrical Problems

Identifying issues within the electrical system of a vehicle can be a complex process that requires a systematic approach. Effective troubleshooting involves understanding the various components and how they interact, allowing for the isolation of faults and efficient rectification.

Begin by observing the symptoms. Any irregularities, such as flickering lights or starting difficulties, can provide crucial clues. It’s important to gather as much information as possible about when the problems occur, as this can significantly aid in pinpointing the source of the malfunction.

Utilize diagnostic tools to assess the electrical components accurately. Multimeters and scanners can measure voltage levels and read error codes, facilitating a deeper understanding of the system’s condition. Always ensure that connections are secure and free from corrosion, as these factors can greatly influence performance.

Consult the wiring diagrams for your specific vehicle model. These diagrams offer invaluable insight into the layout and connections within the electrical system, making it easier to trace faults. Focus on the circuits related to the identified issues, as this will streamline the diagnostic process.

Finally, test components individually when necessary. Isolating each part can help confirm whether it is functioning correctly or if it needs replacement. By following these steps, you can effectively address electrical challenges and restore your vehicle’s performance.

Fluid Change Recommendations

Regularly replacing essential fluids is crucial for maintaining the optimal performance and longevity of your vehicle. Proper fluid management ensures that all systems function efficiently and helps prevent potential issues that may arise from neglect.

Key Fluids to Monitor

- Engine Oil

- Transmission Fluid

- Coolant

- Brake Fluid

- Power Steering Fluid

Change Intervals

- Engine Oil: Replace every 5,000 to 7,500 miles, depending on driving conditions and oil type.

- Transmission Fluid: Check every 30,000 to 60,000 miles, with replacement as needed.

- Coolant: Recommended change every 50,000 to 100,000 miles, or as indicated by your vehicle’s maintenance schedule.

- Brake Fluid: Flush every 2 years to maintain braking efficiency.

- Power Steering Fluid: Inspect regularly and replace every 50,000 miles or as required.

Adhering to these recommendations will help ensure that your vehicle remains reliable and performs at its best for years to come.

Turbocharger Maintenance Tips

Ensuring the longevity and efficiency of your turbocharger is crucial for optimal engine performance. Regular upkeep can prevent potential issues and enhance overall functionality. Here are some essential practices to keep your turbocharger in prime condition.

Regular Inspections

Frequent checks of the turbocharger can help identify any developing problems before they escalate. Look for signs of oil leaks, unusual noises, or performance drops. Addressing these symptoms promptly can save time and resources in the long run.

Proper Lubrication

Maintaining adequate lubrication is vital for the smooth operation of a turbocharger. Ensure that the oil used is of high quality and suitable for your engine type. Regularly change the oil as per the manufacturer’s recommendations to prevent excessive wear and tear.

| Maintenance Task | Frequency |

|---|---|

| Inspect for leaks and noises | Every 3,000 miles |

| Change engine oil | Every 5,000 miles |

| Check air filters | Every 10,000 miles |

| Inspect exhaust system | Annually |

By following these maintenance tips, you can significantly improve the reliability and efficiency of your turbocharger, ensuring it performs at its best for years to come.

Cooling System Checkpoints

The cooling mechanism is crucial for maintaining optimal engine performance. Regular inspections help to ensure the system operates effectively, preventing overheating and potential damage. Below are key aspects to monitor during your assessment.

Key Components to Inspect

When evaluating the cooling system, focus on several critical parts that play a vital role in heat management:

| Component | Inspection Details |

|---|---|

| Radiator | Check for leaks and blockages; ensure the fins are clear of debris. |

| Thermostat | Test for proper operation; replace if it fails to open or close correctly. |

| Hoses | Inspect for cracks, bulges, or signs of wear; ensure connections are secure. |

| Water Pump | Listen for unusual noises; check for coolant leaks around the pump. |

Fluid Quality and Levels

Regularly check the coolant levels and quality. Using a hydrometer can help assess the freezing and boiling points of the fluid, ensuring it is adequate for temperature extremes.

Common Mistakes During Repairs

When working on vehicles, especially complex diesel engines, it’s crucial to avoid certain pitfalls that can lead to more significant issues down the line. Many enthusiasts and technicians may overlook essential procedures or misinterpret instructions, resulting in unnecessary complications. Recognizing these frequent errors can help ensure smoother maintenance processes and enhance overall performance.

Inadequate Preparation

One of the most prevalent oversights is insufficient preparation before starting the work. Failing to gather the necessary tools and parts can lead to interruptions and frustration. Additionally, not reviewing the specifications or guidelines thoroughly may result in incorrect installations or adjustments.

Ignoring Manufacturer Recommendations

Another common mistake is disregarding the manufacturer’s suggestions. Each engine has specific requirements for components, lubricants, and procedures that are crucial for optimal functionality. Ignoring these recommendations can lead to subpar performance and may even void warranties.

| Mistake | Consequence |

|---|---|

| Inadequate preparation | Increased downtime and potential damage |

| Ignoring manufacturer recommendations | Decreased efficiency and warranty issues |

| Poor documentation | Confusion during reassembly |

| Rushing the process | Higher likelihood of errors |

Safety Precautions While Working

Ensuring a safe environment is paramount when engaging in any mechanical maintenance or servicing. Awareness of potential hazards and adherence to safety protocols can significantly reduce the risk of accidents and injuries.

Before commencing any tasks, familiarize yourself with the tools and equipment. Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots. Proper attire is essential to safeguard against unexpected situations.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment | Always wear gloves, goggles, and other protective gear to minimize injury risks. |

| Work Environment | Keep the workspace clean and organized to prevent tripping hazards and ensure efficient operation. |

| Tool Inspection | Regularly check tools for damage or wear. Replace or repair any faulty equipment immediately. |

| Emergency Procedures | Be aware of emergency exits and procedures. Have a first aid kit readily available. |

| Proper Lifting Techniques | Use your legs to lift heavy items, keeping your back straight to avoid strain or injury. |

By following these guidelines and being vigilant, you can help create a safe and effective working environment that fosters productivity and reduces the likelihood of incidents.

Warranty and Service Information

This section provides essential details regarding the guarantees and maintenance support associated with your engine system. Understanding these aspects is crucial for ensuring optimal performance and longevity of your vehicle. Proper service and adherence to warranty guidelines can significantly enhance your experience and protect your investment.

Warranty Coverage

The warranty typically includes provisions for parts and workmanship, safeguarding against manufacturing defects. Coverage duration may vary based on specific agreements, and it is advisable to keep documentation accessible for reference. Regular maintenance performed by certified professionals is often a requirement to uphold warranty validity.

Service Recommendations

To maintain the efficiency of your engine, follow the manufacturer’s service schedule meticulously. Regular inspections and timely repairs can prevent potential issues from escalating. It is recommended to consult authorized service centers for repairs to ensure compliance with warranty conditions and to utilize genuine replacement components.