Maintaining the functionality and aesthetics of miniature locomotives and rolling stock is essential for enthusiasts and collectors alike. Proper guidance can significantly enhance the longevity and performance of these intricate models. Whether you are dealing with electrical issues, mechanical malfunctions, or simply seeking to enhance their visual appeal, having a comprehensive resource can be invaluable.

In this segment, we will explore various strategies and techniques for troubleshooting and enhancing your model collection. From basic upkeep to advanced modifications, understanding the inner workings of these small-scale masterpieces can transform your hobby into a rewarding experience. Delving into the specifics can help you tackle common challenges with confidence.

Equipped with the right information, enthusiasts can not only fix issues but also personalize their models to reflect individual preferences and styles. The journey of restoration and enhancement is as rewarding as the end result, fostering a deeper appreciation for the craftsmanship involved in creating these delightful replicas.

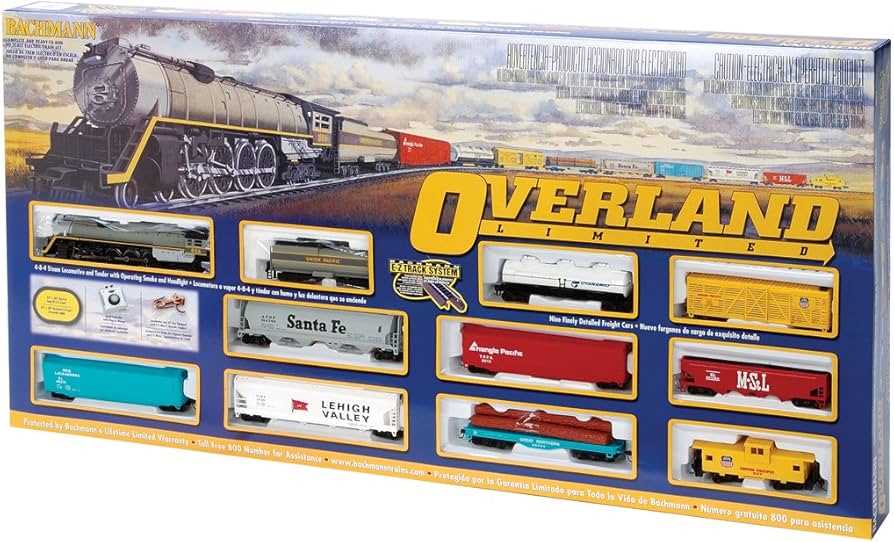

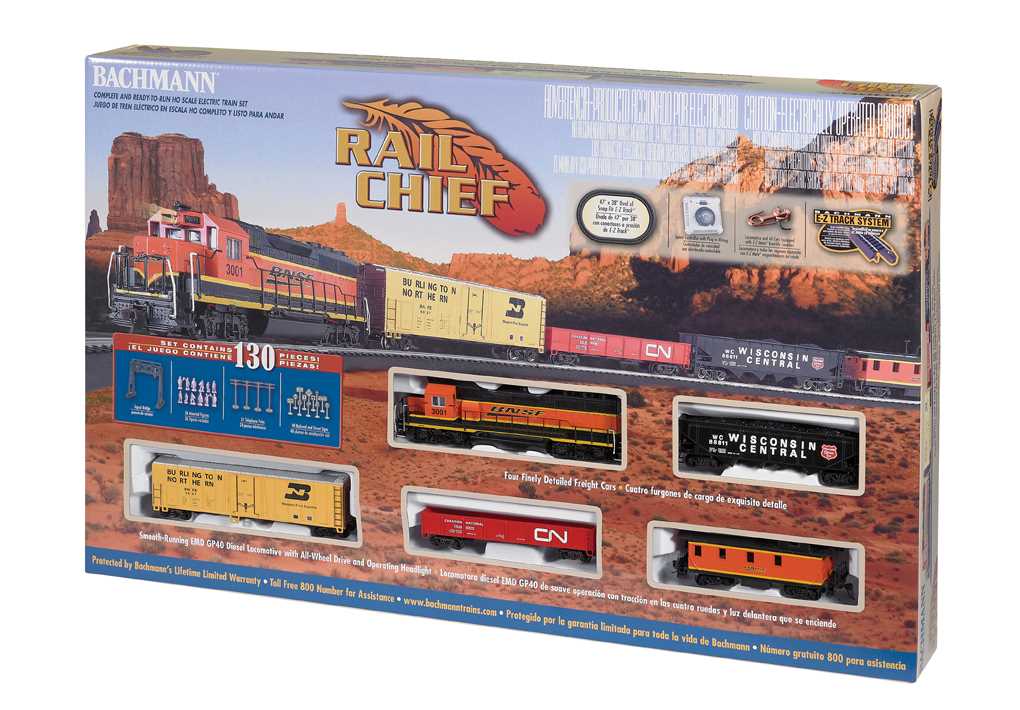

Understanding Bachmann Train Models

The world of model locomotives offers a fascinating blend of artistry and engineering. Each miniature vehicle encapsulates intricate details that reflect real-life counterparts, providing enthusiasts with a unique experience. Familiarity with these creations enhances appreciation and informs effective maintenance strategies.

These scale replicas come in various designs, catering to diverse interests and preferences. From historical representations to contemporary styles, each model showcases specific features that distinguish it from others. Enthusiasts often seek to understand the nuances that set one model apart, including material quality, operational capabilities, and aesthetic appeal.

Moreover, recognizing the significance of compatible components is crucial. Accessories such as tracks, controllers, and scenery elements play a vital role in the overall experience. Understanding how these parts interact with the locomotives can lead to more satisfying operations and creative setups.

In conclusion, a deep comprehension of these miniature vehicles not only enriches the hobby but also empowers collectors and operators to engage more meaningfully with their models. The journey through this captivating realm encourages exploration, creativity, and technical know-how.

Common Issues with Bachmann Trains

When it comes to model locomotives, enthusiasts often encounter various challenges that can affect performance and overall enjoyment. Understanding these common problems is essential for maintaining functionality and enhancing the experience of model railroading.

Electrical Problems

- Power Loss: Models may experience intermittent or complete power failures, often caused by poor connections or faulty wiring.

- Short Circuits: Improperly installed components can lead to shorts, resulting in erratic behavior or damage to the system.

- Lighting Issues: Inconsistent or non-functional lights are frequent issues, often stemming from loose connections or burned-out bulbs.

Mechanical Difficulties

- Wheel Binding: Misaligned wheels or track issues can cause binding, affecting smooth operation.

- Coupler Problems: Incompatibilities or wear in couplers can hinder the ability to connect multiple cars effectively.

- Noise: Unusual sounds during operation may indicate loose parts or the need for lubrication.

Tools Needed for Repairs

Having the right equipment is essential for maintaining and restoring your models. A well-equipped workspace can significantly enhance the efficiency and effectiveness of your maintenance tasks. This section outlines the various implements that can assist you in ensuring your collectibles remain in optimal condition.

First and foremost, a set of precision screwdrivers is crucial for accessing intricate components. Look for a variety that includes different sizes and types to accommodate various fasteners. Additionally, pliers with fine tips are invaluable for gripping and manipulating small parts, especially in tight spaces.

Furthermore, a soldering iron may be necessary for electrical connections, allowing for seamless integration or repair of wiring. Alongside this, a multimeter is essential for diagnosing electrical issues, ensuring that all components function correctly.

Cleaning supplies, such as soft brushes and isopropyl alcohol, are also important. They help maintain the appearance and functionality of the models by removing dust and grime without causing damage. Finally, having a reliable work surface, along with adequate lighting, can make a significant difference in your overall experience during maintenance tasks.

Step-by-Step Repair Process

This section provides a detailed approach to addressing common issues with model locomotives. By following a systematic method, you can effectively troubleshoot and restore functionality, ensuring your collection operates smoothly.

- Identify the Problem:

- Observe the locomotive during operation.

- Note any unusual sounds or behaviors.

- Check for physical damage or disconnections.

- Gather Necessary Tools:

- Screwdriver set

- Multimeter

- Lubricants

- Cleaning supplies

- Disassemble the Unit:

- Carefully remove screws and components.

- Keep track of all parts to ensure easy reassembly.

- Inspect Internal Components:

- Check the motor and gears for wear.

- Examine wiring for frays or breaks.

- Look for debris that may obstruct movement.

- Make Necessary Adjustments:

- Replace damaged parts as needed.

- Realign components for optimal performance.

- Apply lubrication to moving parts.

- Reassemble the Unit:

- Carefully put all components back together.

- Ensure all screws are tightened securely.

- Test Functionality:

- Run the model to check for improvements.

- Monitor for any persistent issues.

Following these steps will help you efficiently resolve issues and keep your models in peak condition. Regular maintenance is key to longevity and performance.

Maintaining Your Bachmann Trains

Proper care and regular upkeep are essential for ensuring the longevity and optimal performance of your miniature locomotives and their accompanying components. By following a few simple guidelines, enthusiasts can keep their collections in excellent condition, enhancing both their functionality and aesthetic appeal.

Routine Cleaning

Keeping your models clean is crucial. Dust and dirt can accumulate over time, affecting both appearance and performance. Use a soft brush or cloth to gently remove debris, and be sure to clean the wheels and track surfaces regularly to ensure smooth operation.

Lubrication and Maintenance

Regular lubrication of moving parts is vital for preventing wear and tear. A small amount of suitable oil applied to the wheels, axles, and gears can help maintain smooth functionality. Always consult product specifications for recommended lubricants to avoid damage.

| Maintenance Task | Frequency |

|---|---|

| Clean wheels and track | Every month |

| Lubricate moving parts | Every 3-6 months |

| Inspect for damage | Every 6 months |

Electrical Troubleshooting Tips

When dealing with issues related to power systems, a systematic approach can help identify and resolve problems effectively. Understanding the basics of electrical components and their functions is essential for diagnosing faults and ensuring smooth operation. Below are several strategies and considerations to guide you through the troubleshooting process.

Common Symptoms and Solutions

| Symptom | Possible Cause | Suggested Action |

|---|---|---|

| No Power | Disconnected power source | Check connections and power supply |

| Intermittent Operation | Loose wiring | Inspect and secure all connections |

| Overheating | Short circuit | Examine for damaged insulation and replace if necessary |

| Erratic Functioning | Faulty components | Test and replace defective parts |

Best Practices

To minimize the risk of electrical issues, regular maintenance and inspection of components are vital. Always ensure that equipment is powered down before performing any checks or replacements. Keeping a well-organized workspace can also prevent accidental damage and facilitate easier troubleshooting. Documenting findings and solutions can serve as a valuable reference for future maintenance efforts.

Upgrading Components for Better Performance

Enhancing the functionality of your model setups can significantly elevate your overall experience. By focusing on critical elements that influence speed, reliability, and aesthetics, enthusiasts can achieve optimal results. This section explores key areas for upgrades, providing insights into which components can offer the most substantial benefits.

Key Areas for Improvement

When considering enhancements, it is essential to identify specific components that contribute to the overall performance. The following table outlines popular upgrades and their advantages:

| Component | Upgrade Type | Benefits |

|---|---|---|

| Motors | High-Torque | Increased power and speed |

| Wheels | Precision-Fit | Improved traction and stability |

| Electronics | Upgraded Control Boards | Smoother operation and enhanced features |

Considerations for Upgrades

Before embarking on any modifications, it is crucial to assess compatibility and installation requirements. Ensure that the selected components align with your existing setup to avoid potential issues. Furthermore, proper maintenance after upgrades will ensure longevity and sustained performance enhancements.

Identifying Parts for Replacement

When maintaining your model collection, recognizing components that require attention is crucial. Proper identification of these elements not only enhances performance but also prolongs the lifespan of the entire assembly. Knowing what to look for can save time and resources, ensuring a smooth experience in the hobby.

Visual Inspection: Start by examining each segment closely. Look for signs of wear, such as cracks, discoloration, or unusual sounds during operation. A thorough check can reveal parts that might need to be replaced.

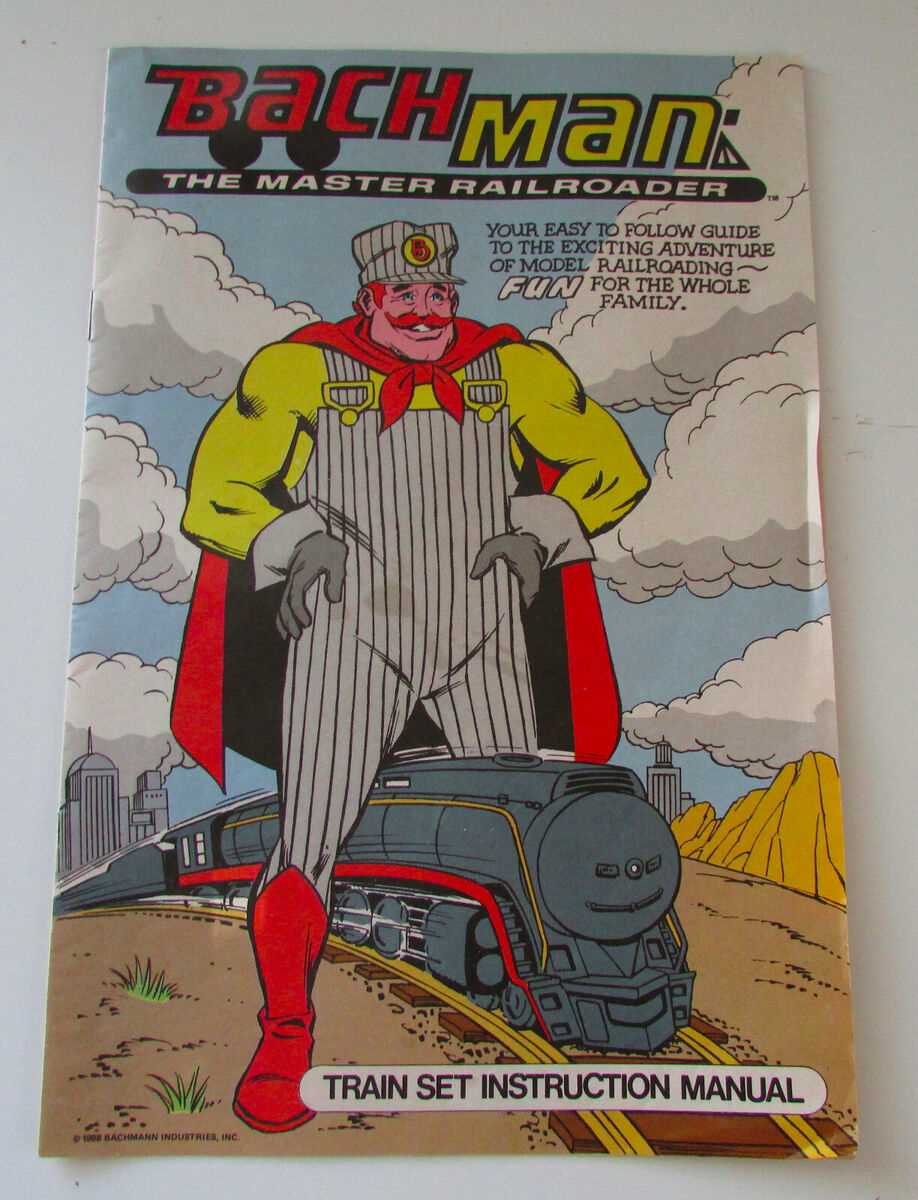

Reference Guides: Utilize diagrams and reference materials to cross-check the components you are inspecting. These resources provide valuable insights into the specific parts and their functions, making it easier to identify any discrepancies.

Compatibility: Ensure that any components you consider for replacement are compatible with your existing setup. Mismatched parts can lead to further issues, so always verify specifications before making a decision.

Feedback from Peers: Engaging with the community can offer additional perspectives. Experienced hobbyists often share tips and advice regarding common issues and effective solutions, making it easier to pinpoint necessary replacements.

By following these steps, you’ll be well-equipped to identify and address any parts that need attention, ensuring your model operates at its best.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a secure environment is crucial. Proper precautions help prevent accidents and injuries, creating a safer workspace for everyone involved. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks.

Always wear appropriate personal protective equipment, such as gloves and safety goggles, to shield yourself from any debris or harmful substances. These items act as barriers against physical and chemical dangers that may arise during the process.

Ensure proper ventilation in your work area. Inadequate airflow can lead to the accumulation of harmful fumes or dust. If you’re working with solvents or any chemicals, utilizing fans or opening windows can help maintain a safe atmosphere.

Be mindful of your workspace. Keep tools and materials organized to avoid tripping hazards. A clutter-free environment not only enhances safety but also improves efficiency, allowing for a more focused approach to tasks.

Regularly inspect tools and equipment before use to identify any defects or wear. Using faulty tools can lead to unexpected accidents, so it’s important to replace or repair them as needed. Safety should always be a priority when selecting and handling equipment.

Finally, stay informed about emergency procedures. Knowing how to respond in case of an accident can make a significant difference. Familiarize yourself with the location of first aid kits and emergency exits to ensure a swift response if necessary.

Resources for Further Assistance

For enthusiasts seeking additional support in maintaining and enhancing their models, a wealth of resources is readily available. These tools and communities offer invaluable guidance, from troubleshooting tips to advanced techniques, ensuring a rewarding experience in this hobby.

Online Communities and Forums

Joining dedicated online forums can provide instant access to a wealth of knowledge shared by fellow hobbyists. Websites such as dedicated discussion boards or social media groups are excellent platforms for asking questions, sharing experiences, and receiving expert advice.

Instructional Videos and Tutorials

Visual learners may find that video content significantly aids their understanding. Numerous platforms host tutorials ranging from basic maintenance to complex modifications. Engaging with these resources can foster confidence and skill development in managing your models.

Remember: Exploring various resources can enhance your skills and deepen your enjoyment of the craft. Don’t hesitate to seek out assistance and connect with others who share your passion!