The intricate world of automotive machinery often demands a detailed understanding of its vital components. This section delves into the complexities of rejuvenating a specific type of power unit, ensuring that enthusiasts and professionals alike can navigate the challenges of maintenance and restoration with confidence.

In any mechanical system, a solid foundation is crucial for optimal performance. Here, we explore the essential techniques and methodologies that will aid in addressing common issues and enhancing the longevity of the unit. From disassembly to reassembly, each step is designed to empower you with the knowledge needed to tackle both minor and major tasks effectively.

Whether you are an experienced technician or a novice looking to expand your skill set, this resource provides invaluable insights into troubleshooting, component replacement, and best practices. With a focus on precision and thoroughness, this guide serves as a valuable companion for anyone committed to achieving excellence in automotive care.

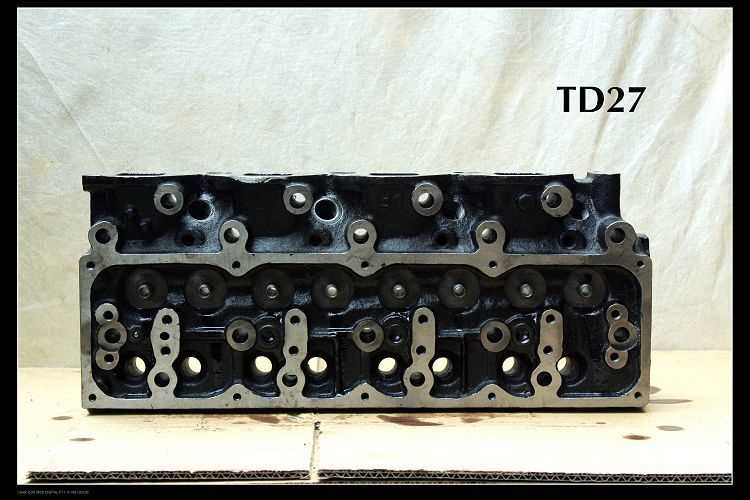

Nissan TD27 Engine Overview

This section provides a comprehensive understanding of a robust power unit commonly found in various vehicles. Renowned for its durability and reliability, this unit has garnered a loyal following among automotive enthusiasts and professionals alike. The following details will shed light on its specifications, features, and general performance attributes.

Key Features

This power unit is characterized by its four-cylinder design, which contributes to its efficiency and compactness. With a displacement of approximately 2.7 liters, it offers a balanced blend of power and fuel economy. Turbocharging enhances performance, providing an extra boost when needed while maintaining low-end torque. Its iron block construction ensures longevity and resistance to wear under various operating conditions.

Performance and Applications

Known for its adaptability, this unit has been employed in a range of applications, from light-duty trucks to recreational vehicles. The consistent output and reliability make it a preferred choice for those seeking dependable performance in diverse environments. Furthermore, the straightforward design facilitates maintenance, allowing users to perform routine checks and repairs with relative ease. Overall, this power unit stands out for its combination of strength and efficiency, making it a valuable asset in the automotive landscape.

Common Issues with TD27 Engines

Understanding typical problems associated with this power unit can help owners maintain optimal performance and longevity. Various challenges can arise due to wear, environmental factors, and maintenance practices, leading to a range of operational inefficiencies.

Overheating Problems

One frequent concern is overheating, which can result from a faulty cooling system. Issues such as a malfunctioning thermostat or a clogged radiator can impede proper heat dissipation, potentially causing severe damage if not addressed promptly. Regular checks of the cooling components are essential to prevent these scenarios.

Oil Consumption and Leaks

Excessive oil consumption and leaks are also common in this type of unit. Gaskets and seals may deteriorate over time, leading to fluid loss and reduced lubrication. It is vital to monitor oil levels and inspect for any visible leaks to ensure the internal mechanisms remain adequately lubricated and functioning efficiently.

Essential Tools for Engine Repair

Having the right instruments is crucial for any mechanical work, ensuring efficiency and accuracy during the process. A well-equipped workspace can significantly enhance the outcome of your tasks, leading to better performance and longevity of the components being serviced.

Basic Hand Tools

- Wrenches: A variety of sizes, including both standard and metric, to tackle different fasteners.

- Screwdrivers: Flathead and Phillips options for various screws.

- Socket Set: Useful for loosening and tightening bolts quickly and effectively.

- Pliers: Needle-nose and adjustable types to grip and manipulate small parts.

Specialized Instruments

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Compression Tester: Evaluates the condition of the cylinders.

- Vacuum Gauge: Helps diagnose vacuum leaks and assess performance issues.

- Feeler Gauge: Measures gap widths accurately for precise adjustments.

Investing in quality tools not only simplifies tasks but also minimizes the risk of damage, ensuring that all components function optimally after servicing. A thorough selection can make all the difference in achieving professional results in your mechanical endeavors.

Step-by-Step Disassembly Guide

This section provides a detailed procedure for carefully taking apart the mechanical unit, ensuring each component is handled with precision. Following these steps will help prevent damage and facilitate easier reassembly later on.

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and safety equipment before beginning the disassembly process. |

| 2 | Disconnect the battery and remove any electrical connections to ensure safety. |

| 3 | Drain all fluids to prevent spills and make the disassembly cleaner. |

| 4 | Begin by removing the outer covers and protective shields, keeping track of all fasteners. |

| 5 | Carefully detach the main components, such as the intake and exhaust sections, documenting their arrangement. |

| 6 | Remove the connecting elements, ensuring to label each piece to facilitate reassembly. |

| 7 | Once all parts are removed, inspect each component for wear or damage, noting any necessary replacements. |

Reassembly Tips and Best Practices

Reassembling mechanical components requires careful attention to detail and a methodical approach. Following specific guidelines not only ensures the longevity of the unit but also enhances overall performance. This section provides essential tips to streamline the process and mitigate common pitfalls.

Start by organizing all parts and fasteners in a clean workspace. Labeling components can save time during reassembly, allowing for a smoother workflow. Use trays or magnetic bowls to prevent small items from getting lost.

Before putting everything back together, inspect each piece for wear or damage. Replace any worn gaskets or seals to prevent future leaks. It’s also beneficial to consult any available diagrams or documentation to ensure all components are reinstalled correctly.

When tightening fasteners, follow the manufacturer’s specifications for torque settings. A torque wrench is essential to apply the correct pressure without overtightening, which could lead to damage. Work systematically, tightening bolts in the recommended sequence to maintain even pressure across the assembly.

Finally, take the time to double-check all connections and ensure everything is properly aligned before starting the unit. A careful approach during reassembly can significantly enhance reliability and performance, reducing the likelihood of issues down the line.

Maintenance Routines for Longevity

To ensure the enduring performance of your vehicle’s power unit, consistent upkeep is essential. Regular care not only enhances reliability but also maximizes efficiency, ultimately extending its lifespan.

Essential Maintenance Tasks

- Check and replace oil regularly to prevent wear.

- Monitor coolant levels and replace as needed.

- Inspect belts and hoses for signs of wear or damage.

- Clean air filters to maintain optimal airflow.

- Examine fuel systems to avoid blockages.

Seasonal Considerations

- Perform a thorough inspection before winter to address cold weather issues.

- Adjust maintenance schedules based on driving conditions, such as off-road usage.

- Ensure that battery terminals are clean and connections are secure, particularly before summer heat.

Performance Upgrades for TD27

Enhancing the capabilities of your vehicle’s power unit can significantly improve overall driving experience and efficiency. By implementing various modifications, you can achieve better acceleration, improved fuel economy, and increased torque. Below are several effective ways to elevate the performance of your unit.

- Air Intake System:

Upgrading the air intake allows for better airflow, which can enhance combustion efficiency. Consider installing a high-performance air filter or a cold air intake system.

- Exhaust System:

Improving the exhaust system can reduce back pressure, leading to more power. Look for aftermarket headers and performance exhaust systems that optimize exhaust flow.

- Fuel Delivery:

Enhancing the fuel system ensures optimal fuel flow and combustion. Upgrading the fuel pump and injectors can provide the necessary support for increased performance.

- Tuning:

Reprogramming the electronic control unit (ECU) can unlock the full potential of your setup. Custom tuning can adjust fuel maps and ignition timing for improved power delivery.

- Intercooler Upgrade:

For turbocharged variants, a larger intercooler can reduce intake temperatures, increasing density and performance. This upgrade helps maintain optimal operating conditions under load.

By carefully selecting and implementing these modifications, you can experience a noticeable enhancement in your vehicle’s performance, ensuring a more exhilarating driving experience.

Fuel Efficiency Improvement Techniques

Enhancing fuel efficiency is crucial for reducing operational costs and minimizing environmental impact. By implementing a variety of strategies, individuals can optimize their vehicle’s performance and achieve better mileage. This section explores effective methods to boost fuel economy, ensuring a smoother and more economical driving experience.

Regular Maintenance is fundamental for maximizing efficiency. Routine checks of essential components, such as air filters and spark plugs, can prevent performance issues that lead to excessive fuel consumption. Keeping tires properly inflated also plays a significant role in maintaining optimal traction and reducing drag.

Driving Habits greatly influence fuel usage. Adopting a smoother driving style, avoiding rapid acceleration and heavy braking, can significantly improve consumption. Additionally, maintaining a steady speed on highways and utilizing cruise control when appropriate helps in minimizing fuel wastage.

Weight Reduction is another effective technique. Removing unnecessary items from the vehicle can lead to a lighter load, which, in turn, enhances efficiency. Every extra pound requires additional energy to propel the vehicle, so decluttering is beneficial.

Use of Quality Fuel can also contribute to better performance. Choosing fuels with additives that clean the fuel system can improve combustion efficiency, ultimately leading to improved mileage. Regularly switching to higher-quality fuel types can make a noticeable difference over time.

Smart Route Planning helps in avoiding traffic jams and unnecessary idling. Utilizing navigation tools to find the most efficient paths not only saves time but also conserves fuel, leading to more economical driving.

By adopting these techniques, vehicle owners can effectively enhance fuel efficiency, reduce costs, and contribute to a more sustainable driving environment.

Troubleshooting Electrical Problems

Addressing issues related to the electrical system is crucial for optimal performance and safety. Identifying the root cause of these problems can prevent further complications and ensure reliability. Below are key steps and considerations for diagnosing electrical faults.

- Check Battery Condition:

- Inspect for corrosion on terminals.

- Verify voltage with a multimeter.

- Ensure connections are tight and secure.

- Inspect Fuses and Relays:

- Identify blown fuses by visual inspection.

- Test relays for functionality using a multimeter.

- Replace any defective components promptly.

- Examine Wiring and Connectors:

- Look for frayed or damaged wires.

- Ensure connectors are free of dirt and corrosion.

- Use dielectric grease to prevent moisture buildup.

- Test Electrical Components:

- Use a multimeter to check continuity.

- Evaluate sensors for proper operation.

- Inspect switches and actuators for wear and functionality.

Following these steps systematically can lead to effective identification and resolution of electrical issues, ensuring a smooth operation.

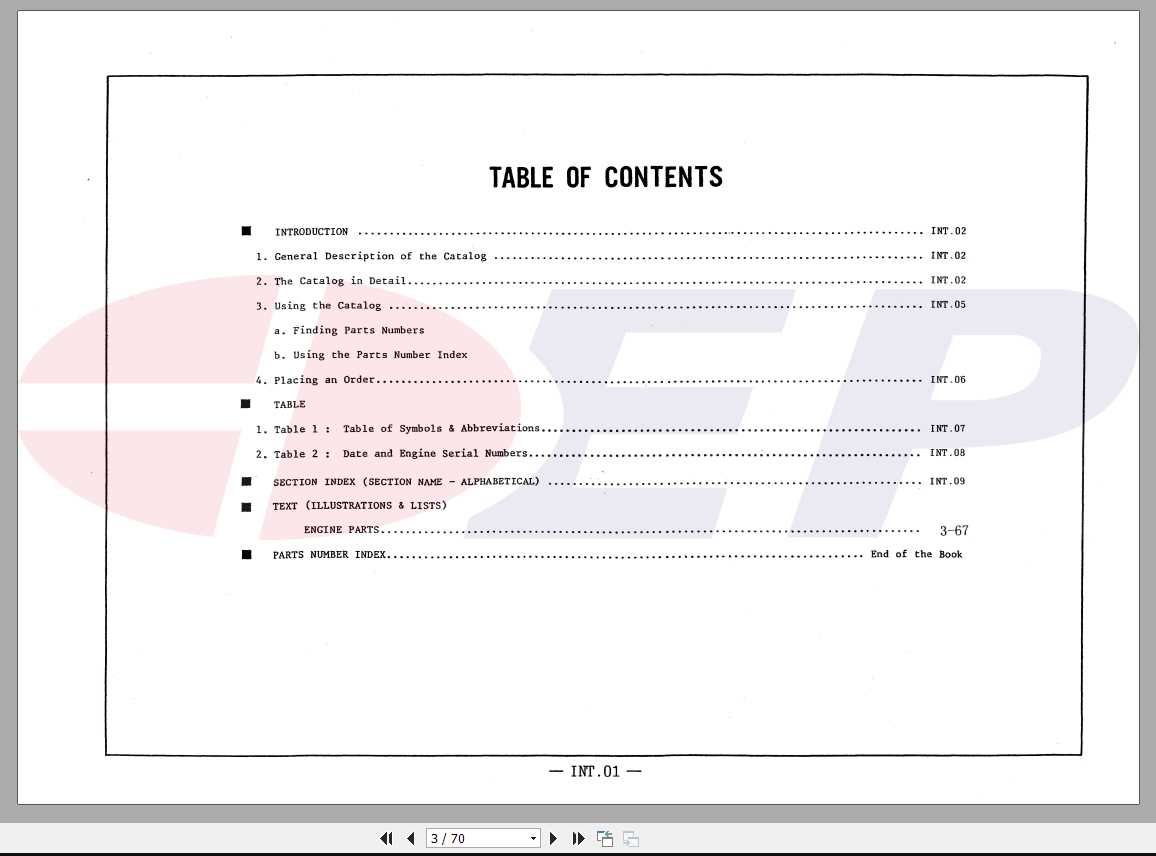

Finding Replacement Parts Efficiently

Locating suitable components for your vehicle can often be a daunting task. However, with the right approach, you can streamline the process and ensure you obtain high-quality items at reasonable prices. Understanding where to search and how to evaluate options will save both time and resources, allowing for a more efficient restoration experience.

Utilizing Online Resources

The internet serves as a vast repository for automotive parts. Websites dedicated to vehicle components often provide extensive catalogs and detailed specifications. Online marketplaces are excellent for comparing prices, while forums and social media groups can offer invaluable insights from fellow enthusiasts. Leverage these platforms to gather information about reliability and best practices when sourcing parts.

Local Suppliers and Salvage Yards

Don’t overlook the potential of local shops and salvage yards. These venues often carry a variety of components that may not be readily available online. Visiting in person allows you to inspect parts closely, ensuring they meet your quality standards. Additionally, building a rapport with local suppliers can lead to discounts and insider knowledge about new arrivals or hard-to-find pieces.