In the realm of aquatic activities, maintaining the integrity of essential gear is crucial for ensuring optimal performance and safety. This section delves into the best practices for utilizing an effective bonding solution designed for restoring functionality to your equipment. With proper application techniques, you can extend the life of your gear and enhance your overall experience in the water.

Understanding the Importance of Proper Adhesive Use is fundamental to achieving a successful outcome. By familiarizing yourself with the characteristics of the adhesive, as well as the surfaces it will be applied to, you can ensure a secure and lasting bond. Whether you are addressing minor imperfections or more significant issues, mastering these techniques will yield satisfying results.

Preparation and Application Steps are essential components in this process. From surface cleaning to curing times, each stage plays a vital role in the effectiveness of the bonding procedure. This guide will provide you with detailed instructions to navigate through these steps confidently, empowering you to maintain your gear with ease.

Seac Wetsuit Repair Glue Overview

This section provides an insight into a versatile adhesive designed specifically for aquatic apparel. Ideal for enhancing the longevity of your gear, this product is essential for those who frequently engage in water sports or activities.

Featuring a robust formula, it effectively bonds various materials commonly used in water-related clothing, ensuring durability and resistance against the elements. Whether facing small tears or larger damage, this adhesive is a reliable solution to restore functionality.

| Feature | Description |

|---|---|

| Type of Adhesive | Flexible and waterproof formula |

| Application | Easy to apply, suitable for diverse materials |

| Drying Time | Quick setting for immediate use |

| Packaging | Available in various sizes for convenience |

Application Methods for Repair Adhesive

When it comes to fixing various materials, utilizing the right bonding agent effectively can make all the difference. This section outlines effective techniques for applying the adhesive to ensure a strong, lasting hold.

Surface Preparation is essential for optimal adhesion. Start by cleaning the surfaces thoroughly to remove any dirt, grease, or moisture. This can be done with a suitable cleaner or solvent, followed by drying the area completely.

Next, application techniques vary depending on the type of bonding required. For precise control, using a small brush or applicator can help apply a thin, even layer of the compound. Alternatively, a squeeze tube can provide more substantial coverage for larger areas.

After applying the agent, pressure application is crucial. Gently pressing the surfaces together ensures that the adhesive spreads evenly and forms a solid bond. Holding the pieces in place for the recommended time will enhance the overall strength of the connection.

Finally, allow the bond to cure completely as per the manufacturer’s instructions. This step is vital for achieving the best results and ensuring longevity in the repaired area. Proper adherence to these methods will lead to successful outcomes in your projects.

Surface Preparation Tips for Best Results

Achieving optimal bonding performance begins with proper surface preparation. Ensuring that the areas to be joined are clean, dry, and free of contaminants is crucial for long-lasting results. Follow these guidelines to enhance the effectiveness of your adhesion process.

Cleaning the Surface

- Use a mild detergent mixed with water to remove dirt and grime.

- Rinse thoroughly with clean water to eliminate any soap residue.

- Dry the surfaces completely with a lint-free cloth to prevent moisture from interfering with adhesion.

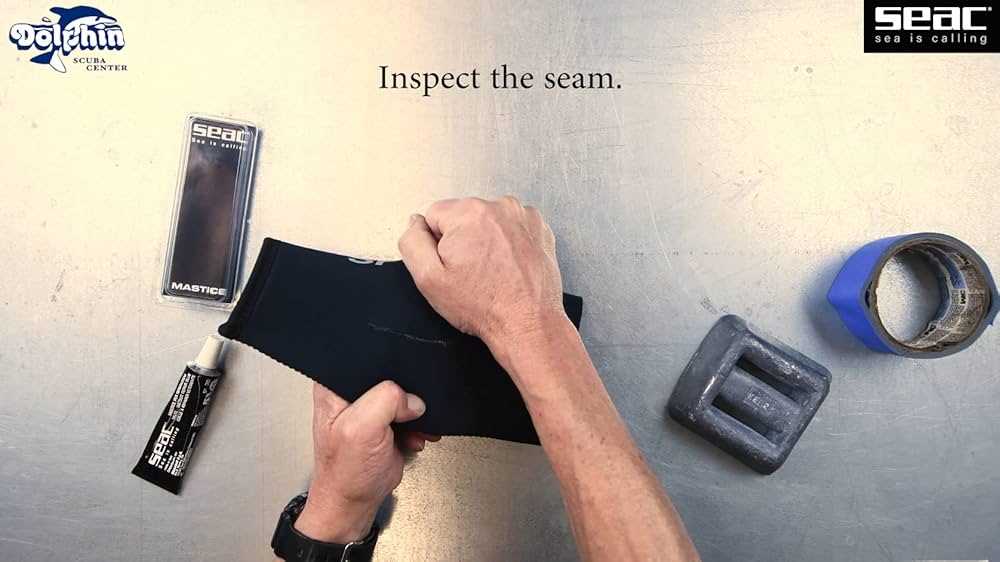

Checking for Damage

- Inspect the material for any tears, cuts, or abrasions.

- Trim any jagged edges to create a smooth, even surface.

- If necessary, lightly sand the area to promote better adhesion.

By following these preparation steps, you can ensure that the materials bond effectively, leading to a durable and reliable outcome.

Common Issues and Solutions in Repairing

When dealing with the restoration of aquatic apparel, various challenges may arise. Understanding these common problems and their corresponding remedies can significantly enhance the effectiveness of the process. This section outlines prevalent issues and provides practical solutions to ensure optimal performance and longevity of the gear.

Frequent Challenges

Several typical complications can occur during the mending process, including inadequate adhesion, surface irregularities, and environmental influences. Each of these factors can hinder the overall success of the task.

Effective Solutions

To address these challenges, consider the following approaches:

| Issue | Solution |

|---|---|

| Poor adhesion | Ensure surfaces are clean and dry before application, and apply adequate pressure during curing. |

| Surface irregularities | Use a filler material to smooth out rough areas before applying the adhesive. |

| Environmental factors | Work in a controlled environment to avoid temperature extremes that could affect curing. |

Storage Recommendations for Adhesive Longevity

To ensure optimal performance and longevity of bonding agents, proper storage practices are essential. By adhering to specific guidelines, users can extend the shelf life and maintain the effectiveness of their adhesive products.

Temperature and Environment

Maintaining a suitable environment is crucial for preserving the quality of adhesives. Here are key considerations:

- Store in a cool, dry place away from direct sunlight.

- Avoid exposure to extreme temperatures; ideal conditions are between 15°C to 25°C (59°F to 77°F).

- Keep containers tightly sealed to prevent moisture ingress.

Organizational Practices

Proper organization can also play a significant role in maintaining the integrity of bonding substances:

- Label containers clearly with expiration dates for easy reference.

- Avoid stacking heavy items on top of adhesive containers to prevent damage.

- Regularly check stock levels and rotate products to use older items first.

Safety Precautions During Application

When applying adhesive materials, it is essential to prioritize safety to ensure a successful outcome and protect your health. Proper handling and awareness of the environment can significantly reduce potential risks associated with the process.

Ventilation is crucial when using any bonding agent. Ensure that the area is well-ventilated to minimize inhalation of fumes. Open windows and use fans to promote airflow.

Always wear protective gear, including gloves and safety goggles, to shield your skin and eyes from any contact with the substance. This precaution helps prevent irritation or allergic reactions.

Keep the workspace clean and organized to avoid accidents. Remove any unnecessary items and ensure that surfaces are free from clutter. This practice can prevent spills and mishaps during the application process.

Additionally, it’s important to follow manufacturer instructions carefully. Adhering to guidelines regarding application techniques and drying times will enhance both safety and effectiveness.

Finally, be aware of your surroundings. Keep children and pets away from the workspace to prevent unintended exposure to hazardous materials.

Tools Needed for Effective Repairs

To achieve successful fixes on diving gear, it’s essential to gather the right equipment. The proper tools will not only enhance the efficiency of the task but also ensure long-lasting results. This section outlines the necessary items that can streamline the process and yield satisfactory outcomes.

Essential Tools

- Cutting Tool: A sharp blade or scissors to trim damaged areas.

- Surface Cleaner: A mild detergent or specialized cleaner for preparing the area.

- Applicator: A brush or spatula for even distribution of the adhesive.

- Measuring Tool: A ruler or tape measure to ensure accurate sizes.

- Clamps or Weights: To hold materials in place while setting.

Additional Supplies

- Sandpaper: For smoothing rough edges before application.

- Protective Gear: Gloves and masks to safeguard during the process.

- Storage Containers: To keep tools organized and accessible.

- Cleaning Rags: For wiping excess material and maintaining a tidy workspace.

Steps for Effective Adhesive Bonding

Achieving a strong connection between surfaces requires careful preparation and execution. Following systematic procedures can significantly enhance the bonding process, ensuring durability and reliability.

Preparation of Surfaces

- Clean the surfaces thoroughly to remove dirt, oils, and moisture.

- Roughen the surfaces slightly to increase adhesion by providing more area for the bonding agent to grip.

- Ensure both surfaces are dry before applying any bonding material.

Application Techniques

- Apply the bonding agent evenly across one surface for consistent coverage.

- Use the appropriate amount as per the manufacturer’s recommendations to avoid excess that could compromise the bond.

- Press the two surfaces together firmly, ensuring they align properly to avoid gaps.

- Secure the bond if necessary, using clamps or weights until the adhesive sets completely.

Following these steps can lead to a successful and enduring connection between materials, enhancing performance and extending the lifespan of the bonded item.

Frequently Asked Questions About Usage

This section addresses common inquiries regarding the application and effectiveness of the adhesive designed for underwater gear maintenance. Users often seek clarification on best practices and tips for optimal results.

How do I prepare the surface before application?

Prior to using the adhesive, ensure that the area is clean and dry. Remove any dirt, salt, or residues by rinsing with fresh water and wiping with a soft cloth. A clean surface promotes better adhesion.

Can I use this adhesive on different materials?

This bonding agent is versatile and suitable for various types of materials commonly found in aquatic apparel. Always conduct a small test on an inconspicuous area to confirm compatibility.

For best results, follow the manufacturer’s recommendations on curing times and application methods. Proper usage ensures longevity and reliability of your gear.

Maintenance of Wetsuits After Repair

Proper care following any restoration work is essential to extend the lifespan of your diving attire. Regular attention ensures that the fabric remains durable and that any enhancements remain effective. Here are key practices to follow for optimal upkeep.

Regular Cleaning

- Rinse with fresh water after each use to remove salt, sand, and chlorine.

- Use a mild detergent specifically designed for neoprene or similar materials.

- Air dry away from direct sunlight to prevent material degradation.

Storage Tips

- Store in a cool, dry place, avoiding extreme temperatures and humidity.

- Hang on a wide hanger to maintain shape, or lay flat if space allows.

- Avoid folding, as creases can weaken the fabric over time.

Following these guidelines will help maintain the integrity and performance of your gear, ensuring enjoyable and safe experiences in the water.

Environmental Considerations for Disposal

When it comes to disposing of products used in aquatic activities, it is crucial to consider their environmental impact. Proper disposal methods can significantly reduce harm to ecosystems and promote sustainability.

Importance of Responsible Disposal

Responsible disposal practices are essential for maintaining the health of our environment. Incorrect disposal can lead to pollution and harm wildlife. Here are some key points to consider:

- Minimize waste by reusing or recycling materials whenever possible.

- Follow local regulations regarding disposal of specific products.

- Avoid disposing of materials in landfills if alternative options are available.

Best Practices for Disposal

Implementing best practices can ensure a minimal ecological footprint. Consider the following methods:

- Check if the product can be returned to the manufacturer for proper disposal.

- Research local recycling programs that accept specific materials.

- Use designated hazardous waste collection sites for proper disposal of materials that cannot be recycled.

Comparison with Other Repair Products

This section explores how a specific adhesive solution stands out against alternative bonding agents available in the market. Understanding the strengths and weaknesses of different options can guide users in making informed decisions for their maintenance needs.

Performance and Durability

When evaluating various bonding agents, performance and longevity are crucial factors. Some alternatives may offer quick adhesion but lack the durability required for prolonged use, especially in demanding conditions. In contrast, this adhesive is designed to withstand extreme environments, ensuring a long-lasting bond that remains reliable over time.

Application Ease

Another important aspect is the ease of application. Many products require extensive preparation or complicated procedures, which can be frustrating for users. This particular solution boasts a straightforward application process, allowing for quick and efficient use without the need for specialized tools or skills.

Customer Testimonials and Experiences

This section highlights the feedback and insights from individuals who have utilized a specific adhesive solution for underwater gear. Their personal accounts reflect a variety of encounters and results, showcasing the product’s effectiveness in real-world applications.

Many users express satisfaction with the ease of application, noting that the process was straightforward and efficient. One customer mentioned how simple it was to fix minor damages, allowing them to extend the lifespan of their gear without the need for professional services. Another shared that they appreciated the quick drying time, which enabled them to get back to their aquatic adventures promptly.

Moreover, several testimonials emphasize the durability of the bond created by the product. Users have reported that their repaired items have withstood rigorous conditions, including prolonged exposure to saltwater and extreme temperatures. This durability has encouraged many to confidently recommend the solution to fellow enthusiasts.

Overall, the collective experiences underline a sense of reliability and performance, making it a favored choice among those looking to maintain their essential equipment.