For automotive enthusiasts and professionals alike, understanding the intricacies of a particular power unit is essential for optimal performance and longevity. This guide delves into the complexities of one specific model, providing invaluable insights into disassembly, diagnostics, and reassembly techniques. The goal is to empower individuals with the knowledge necessary to tackle various challenges encountered during maintenance.

With an emphasis on practicality, this document outlines step-by-step procedures, equipping readers with the skills needed to address common issues effectively. From identifying problematic components to implementing best practices, every detail is designed to enhance both efficiency and efficacy. The approach not only facilitates a thorough understanding but also fosters confidence in handling repairs.

In addition, this resource highlights essential tools and equipment, ensuring that users are well-prepared for each phase of the process. By laying a strong foundation of knowledge, the guide aims to transform daunting tasks into manageable projects, making the journey of restoration both enjoyable and rewarding.

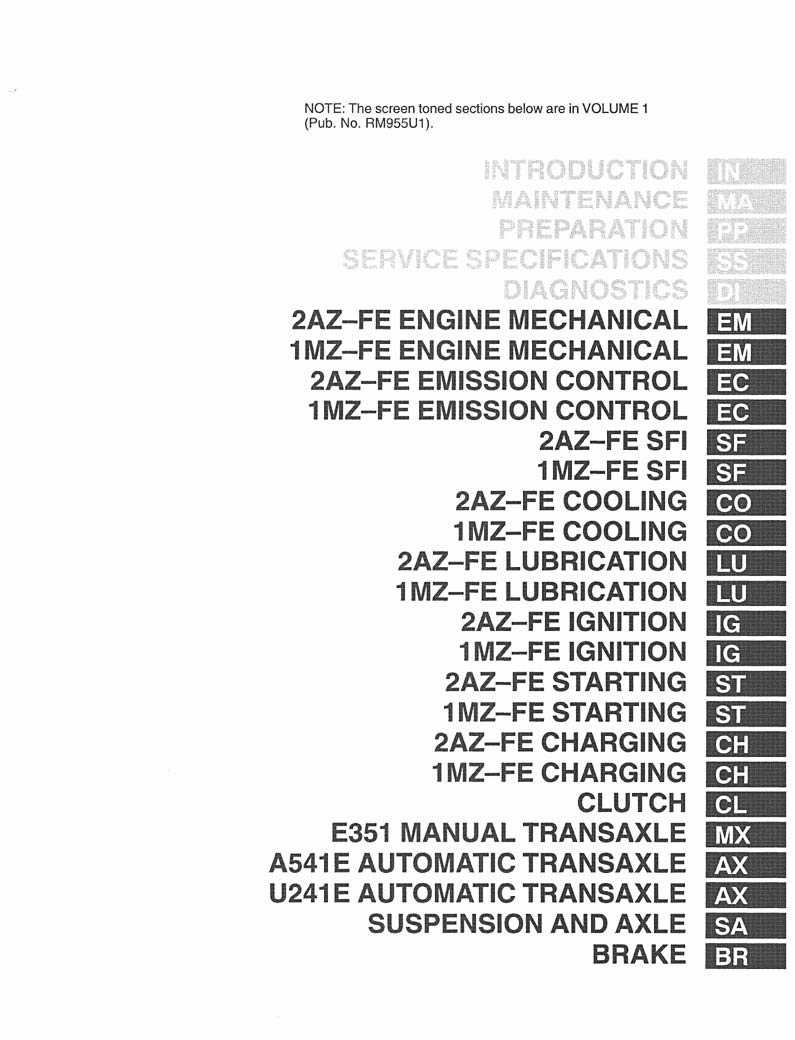

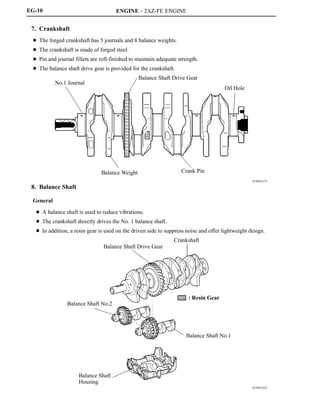

Toyota 2AZ-FE Engine Overview

This section provides an in-depth look at a popular power unit known for its reliability and performance. It serves a variety of vehicles, showcasing a balance between efficiency and power output. Designed with modern engineering techniques, it incorporates advanced features that enhance its functionality.

The architecture includes a lightweight design that contributes to overall fuel efficiency. Its configuration allows for smooth operation, making it suitable for both daily commutes and longer journeys. Additionally, the unit is equipped with a robust intake and exhaust system that optimizes airflow, leading to improved responsiveness.

Maintenance aspects are crucial for longevity, with various components that can be easily accessed for servicing. Regular upkeep ensures that performance remains at an optimal level. The design also includes features aimed at reducing emissions, aligning with environmental standards.

This power unit exemplifies a commitment to engineering excellence, providing a dependable choice for enthusiasts and everyday drivers alike. Its versatility and adaptability make it a staple in many automotive applications.

Common Issues with the 2AZ-FE

This section highlights frequent complications encountered with a specific type of power unit. Understanding these common problems can assist in preventive measures and timely interventions, ultimately prolonging the lifespan and performance of the vehicle.

Frequent Complications

- Oil Leaks: Many owners report issues with leaks, often stemming from gaskets and seals deteriorating over time.

- Overheating: This can occur due to coolant leaks or a malfunctioning thermostat, leading to severe damage if not addressed promptly.

- Excessive Oil Consumption: Some vehicles may exhibit a tendency to consume more oil than normal, potentially indicating worn piston rings or valve seals.

- Misfires: These can be caused by faulty ignition components, leading to a rough running condition.

Preventive Measures

- Regularly inspect and maintain fluid levels to prevent leaks.

- Monitor the cooling system for signs of wear and replace components as necessary.

- Conduct periodic checks on ignition systems to ensure all parts are functioning correctly.

- Keep an eye on oil consumption and address any unusual increases immediately.

Essential Tools for Repair

Having the right set of instruments is crucial for any maintenance task. Proper tools not only enhance efficiency but also ensure safety and accuracy while working on various components. Below is a list of essential items that every enthusiast should consider for successful disassembly and assembly processes.

- Socket Set: A comprehensive socket set is vital for loosening and tightening bolts and nuts.

- Wrenches: Both adjustable and fixed wrenches are necessary for gripping and turning fasteners.

- Screwdrivers: A variety of screwdrivers, including Phillips and flathead, are essential for tackling screws in different sizes.

- Pliers: These are useful for gripping, bending, and cutting wire or small components.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specified torque settings.

In addition to the basic tools, certain specialized items can be beneficial:

- Oil Filter Wrench: Simplifies the removal and installation of oil filters.

- Jack and Jack Stands: Essential for safely lifting and supporting the vehicle.

- Multimeter: Useful for diagnosing electrical issues and measuring voltage, current, and resistance.

- Shop Vacuum: Helps in keeping the workspace clean by removing debris and spills.

Investing in high-quality tools not only improves the outcome of any task but also prolongs the life of the instruments themselves. A well-equipped toolkit can make all the difference in achieving optimal performance and reliability.

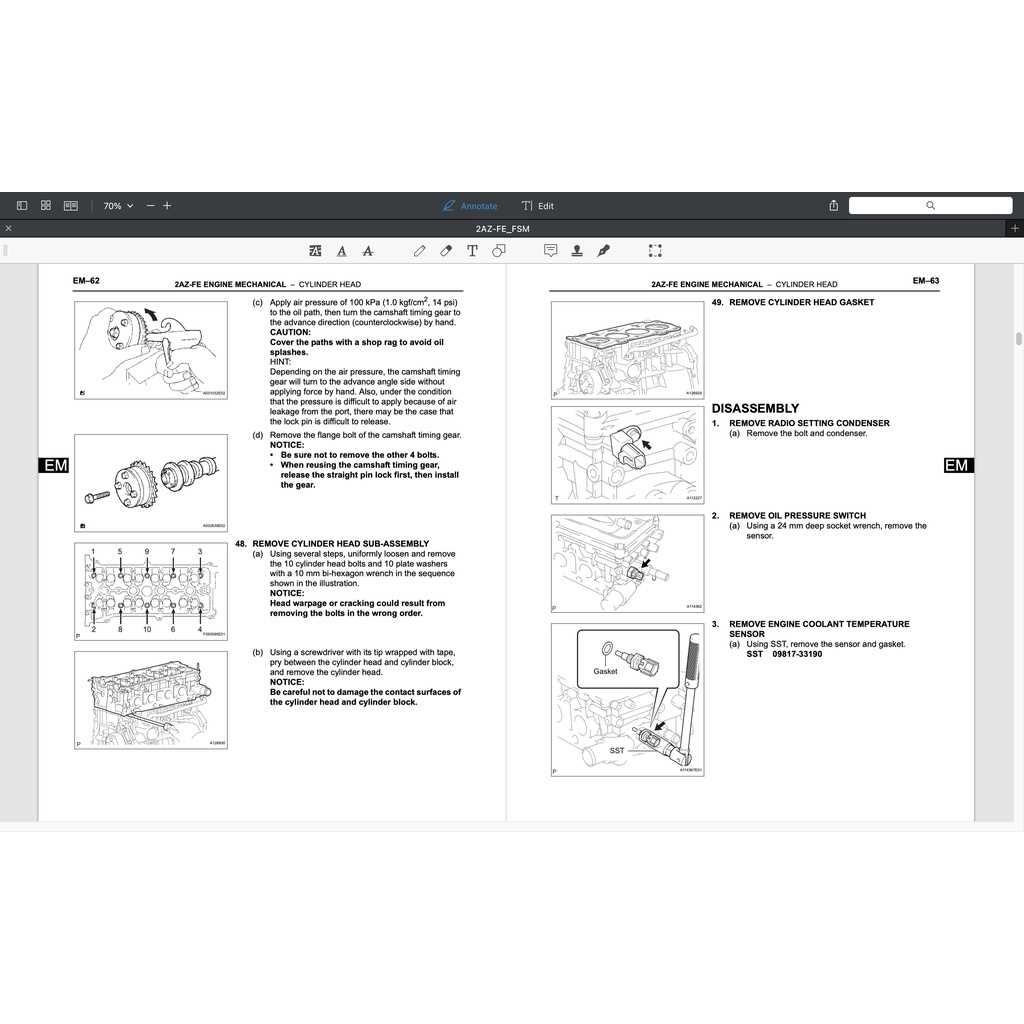

Step-by-Step Disassembly Process

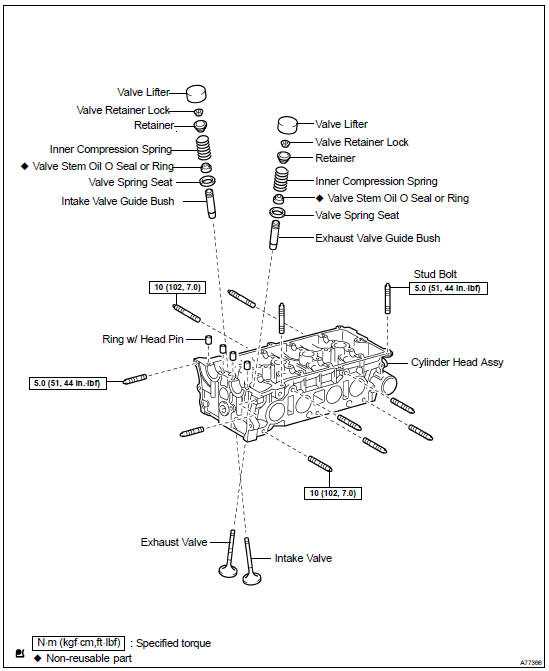

The disassembly of a mechanical unit is a critical procedure that requires careful attention to detail and adherence to systematic steps. Properly executing this process ensures that all components are preserved and can be reassembled without issues. This guide outlines the essential stages to effectively take apart the assembly, allowing for thorough inspection and maintenance.

Begin by preparing your workspace. Ensure it is clean, well-lit, and organized. Gather all necessary tools, including sockets, wrenches, and a torque wrench, to facilitate a smooth disassembly. It’s advisable to have a designated area for parts to avoid confusion later.

Next, disconnect all electrical connections and remove any hoses or ancillary components that may obstruct access to the main assembly. Document the locations of wires and connections for easy reconnection during reassembly. Labeling parts and fasteners can greatly simplify the process.

Proceed by removing the outer casing or covers, taking care to note any specific torque specifications for bolts and screws. Use a torque wrench to avoid damaging threads. As you continue, pay close attention to the order of disassembly; following a logical sequence helps maintain organization and ensures that no components are overlooked.

Once the outer sections are removed, gradually work your way inward. Detach internal components methodically, taking photographs or notes at each stage. This documentation can serve as a valuable reference during reassembly. Be cautious with delicate parts, as they may require gentle handling to prevent damage.

After all parts are separated, conduct a thorough inspection of each component. Look for signs of wear or damage that may require attention. Properly cleaning and categorizing parts will prepare them for reinstallation, ensuring optimal functionality upon reassembly.

Inspecting Engine Components

Evaluating the various parts of a power unit is essential for maintaining optimal performance and longevity. Regular examinations can identify potential issues before they escalate into significant problems, ensuring a smooth operation. This section outlines the critical aspects to focus on during inspections, including visual checks and functional assessments.

Key Components to Inspect

- Cylinders: Look for signs of wear, scoring, or cracks that could affect compression and efficiency.

- Pistons: Examine for any damage or unusual deposits that might indicate overheating or oil consumption issues.

- Valves: Ensure that they open and close correctly, checking for warping or leakage.

- Timing Belt: Inspect for fraying, cracks, or signs of wear, as a malfunctioning belt can lead to severe damage.

- Oil Pump: Verify proper operation and check for any leaks or irregular noises during functionality tests.

Inspection Process

- Start with a thorough visual inspection to identify any obvious damage or wear.

- Use appropriate tools to measure clearances and tolerances for critical parts.

- Conduct functional tests where necessary to ensure all components operate as intended.

- Document findings meticulously to track any changes over time and plan maintenance accordingly.

Reassembling the 2AZ-FE Engine

This section focuses on the crucial process of putting components back together after disassembly. Proper reassembly ensures optimal performance and longevity of the unit, highlighting the importance of meticulous attention to detail at every stage. Following a systematic approach not only enhances efficiency but also minimizes the risk of errors that could lead to malfunction.

Before beginning, it is essential to gather all necessary tools and components. Each part should be inspected for wear and cleanliness to ensure a smooth assembly process. Below is a summarized checklist to assist in the reassembly:

| Component | Action | Notes |

|---|---|---|

| Block | Clean and inspect | Check for cracks or wear |

| Pistons | Install with proper orientation | Ensure rings are seated correctly |

| Crankshaft | Align with main bearings | Lubricate before installation |

| Cylinder Head | Torque bolts in sequence | Follow manufacturer specifications |

| Timing Chain | Align marks accurately | Verify tensioner is set |

Following these steps will contribute to a successful assembly. Always refer to specific guidelines for torque settings and procedures to ensure everything functions as intended. Patience and precision are key in this phase to achieve reliable results.

Recommended Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s power unit. Adopting a consistent maintenance routine helps identify potential issues early and contributes to overall efficiency.

Essential Maintenance Tasks

- Frequent fluid checks and changes, including oil, coolant, and transmission fluids.

- Regular inspections of belts and hoses for signs of wear or damage.

- Periodic replacement of filters to maintain clean airflow and fluid integrity.

- Timely spark plug replacements to ensure proper ignition and fuel efficiency.

Best Practices for Longevity

- Follow the manufacturer’s recommended service intervals for routine maintenance.

- Monitor dashboard warning lights and address them immediately.

- Use high-quality parts and fluids to enhance performance.

- Keep the engine bay clean to prevent debris buildup and overheating.

Upgrades for Enhanced Performance

Improving the efficiency and power of your vehicle can transform your driving experience. By incorporating specific modifications, you can achieve significant gains in both speed and handling. This section explores various enhancements that can elevate the overall performance of your automotive setup.

Popular Modifications

There are several well-regarded modifications that enthusiasts often consider. These upgrades not only boost power but also improve responsiveness and efficiency.

| Modification | Benefits |

|---|---|

| Cold Air Intake | Increases airflow and improves combustion efficiency. |

| Performance Exhaust System | Enhances exhaust flow, resulting in increased horsepower. |

| ECU Tune | Optimizes fuel maps for better performance and throttle response. |

| Upgraded Suspension | Improves handling and stability, especially during cornering. |

Considerations Before Upgrading

Before making modifications, it’s essential to assess your vehicle’s current state and determine compatibility with the planned enhancements. Additionally, consider the balance between performance and reliability to ensure that upgrades enhance your driving experience without compromising safety or longevity.

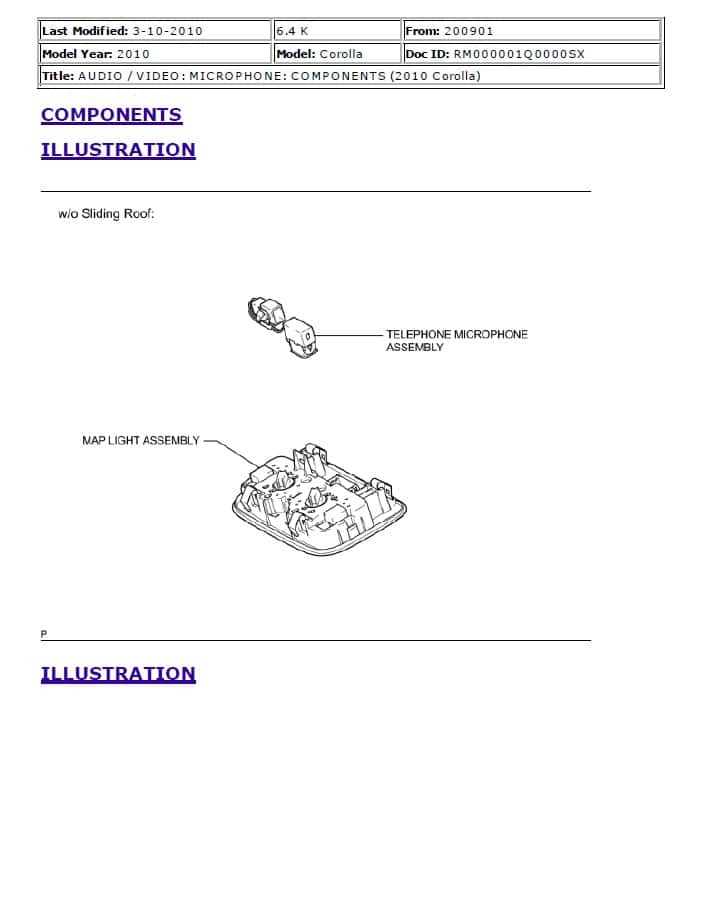

Troubleshooting Electrical Systems

When dealing with issues in automotive electrical systems, a systematic approach is essential. Identifying problems can save time and prevent further damage. This section outlines effective strategies for diagnosing electrical malfunctions.

Begin by assessing the symptoms. Common issues may include:

- Inconsistent power supply

- Flickering lights

- Non-responsive components

- Unusual noises when operating

Next, follow these steps for a thorough examination:

- Visual Inspection: Check for damaged wires, loose connections, or burnt fuses. Look for signs of corrosion or wear.

- Use a Multimeter: Measure voltage, current, and resistance across various components to determine functionality.

- Check Ground Connections: Ensure that all ground points are clean and secure to maintain proper circuit function.

- Inspect Relays and Switches: Test these elements for continuity and functionality, as they are often points of failure.

- Consult Schematics: Reference wiring diagrams for your specific system to trace circuits and pinpoint issues.

Document findings throughout the process, as this can help identify patterns or recurring problems. By maintaining a methodical approach, resolving electrical complications becomes more manageable and efficient.

Understanding Engine Specifications

Comprehending the particulars of a power unit is essential for ensuring optimal performance and longevity. These characteristics provide insight into the capabilities, efficiency, and maintenance needs of the unit, helping enthusiasts and technicians make informed decisions.

Key Specifications

- Displacement: This indicates the total volume of all cylinders combined, typically measured in liters or cubic centimeters. It affects power output and fuel efficiency.

- Compression Ratio: This ratio is the relationship between the maximum and minimum volume in the combustion chamber. A higher ratio often translates to more power but may require higher-octane fuel.

- Power Output: Measured in horsepower or kilowatts, this reflects the maximum power generated, influencing the overall performance of the vehicle.

- Torque: The twisting force produced by the unit, usually measured in pound-feet or Newton-meters, determines the vehicle’s ability to accelerate and pull loads.

Importance of Specifications

Understanding these details is crucial for various reasons:

- They help in selecting the right components for upgrades and replacements.

- Knowledge of these figures aids in diagnosing performance issues.

- They inform choices regarding fuel types and maintenance schedules.

By mastering these specifications, one can enhance both the performance and reliability of the machinery in question.

Diagnosing Oil Leaks

Identifying the source of lubricant leaks is essential for maintaining optimal performance and longevity of your vehicle. Leaks can lead to serious issues if not addressed promptly, making it crucial to understand the signs and methods for locating them effectively. This section outlines the common indicators and systematic approaches to diagnose where the fluid is escaping.

Start by inspecting the exterior surfaces of the machinery for any visible signs of wetness or oil residue. Common areas to examine include seals, gaskets, and connections where components meet. Pay attention to drips or stains on the ground beneath the vehicle, as these can provide clues about the leak’s origin.

Next, consider the color and consistency of the fluid. Different fluids have distinct characteristics; for example, motor lubricant typically has a dark, viscous appearance, while transmission fluid is usually red or brown and thinner. Utilizing these visual cues can aid in pinpointing the source of the leak.

Another effective method involves a thorough inspection of the surrounding components. Utilizing a clean rag or cloth to wipe down areas near potential leak points can help identify fresh lubricant. By comparing the clean surface to areas that appear contaminated, you can better isolate the leak’s location.

Finally, if the source remains elusive, conducting a pressure test can be beneficial. This method involves using specialized equipment to apply pressure to the system, allowing for the detection of leaks that may not be visible under normal conditions. By following these steps, you can efficiently diagnose and address lubricant leaks, ensuring the continued reliability of your vehicle.

Fuel System Repairs Explained

The functionality of a vehicle’s fuel system is critical for optimal performance and efficiency. This section delves into various aspects of addressing issues that may arise within this vital system. Understanding the components and processes involved can lead to effective solutions and a smoother driving experience.

Common Issues and Diagnosis

Identifying problems within the fuel delivery system is essential. Symptoms such as rough idling, decreased acceleration, or unexpected stalling may indicate underlying faults. Conducting a thorough inspection of elements like fuel pumps, injectors, and filters is crucial for accurate diagnosis. Utilizing diagnostic tools can help pinpoint specific malfunctions, ensuring that the right approach is taken to rectify the situation.

Repair Techniques and Best Practices

Once issues have been identified, several techniques can be employed to restore functionality. Replacing clogged filters or faulty pumps often resolves flow-related concerns. For injectors, cleaning or replacement may be necessary, depending on the extent of the buildup. It’s essential to follow manufacturer specifications and utilize high-quality components during any maintenance task. Regular checks and preventative measures can greatly extend the lifespan of the fuel system.

Importance of Regular Servicing

| Benefits | Description |

|---|---|

| Increased Longevity | Routine care extends the lifespan of critical components. |

| Improved Efficiency | Regular upkeep ensures optimal fuel consumption and performance. |

| Safety Assurance | Consistent checks help detect potential hazards, enhancing safety. |

| Cost Savings | Preventive measures can lead to reduced repair costs over time. |