Maintaining the functionality of compact power units is essential for ensuring their longevity and performance. This guide provides valuable insights into the intricacies of upkeep, offering practical solutions for common challenges faced by users. Understanding the core principles of operation and care can significantly enhance the user experience and extend the lifespan of these vital machines.

Effective maintenance encompasses a range of practices that not only address minor issues but also prevent major failures. By delving into specific components and their functions, individuals can better appreciate the engineering behind these power sources. This knowledge empowers users to perform basic troubleshooting and adjustments, fostering a sense of confidence and competence in handling their equipment.

Moreover, a proactive approach to upkeep involves recognizing the signs of wear and tear early on. Through careful observation and routine checks, operators can identify potential problems before they escalate, thus saving time and resources in the long run. The following sections will outline essential techniques and tips that can transform any novice into a capable custodian of their machinery.

Kohler Small Engine Overview

This section provides a comprehensive understanding of the compact power units designed for various applications. These robust machines are known for their reliability and efficiency, making them a popular choice among users in diverse industries. They play a crucial role in enhancing productivity and ensuring smooth operation in numerous settings.

Featuring advanced technology, these units are engineered to deliver exceptional performance while minimizing environmental impact. Their versatile design accommodates a range of tasks, from landscaping to construction, showcasing their adaptability. Maintenance and servicing are essential for ensuring longevity and optimal function, as regular attention can prevent potential issues.

Key attributes include ease of operation, fuel efficiency, and user-friendly features. Understanding the fundamental components, such as ignition systems and fuel delivery, is vital for effective usage and troubleshooting. Knowledge of these elements empowers users to maximize the potential of their equipment while addressing any concerns that may arise during operation.

Common Issues with Kohler Engines

When working with compact power units, several recurring challenges may arise that can affect performance and reliability. Understanding these common problems can help users diagnose issues more effectively and implement solutions swiftly.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hard Starting | Difficulty in ignition, prolonged cranking | Check spark plug, fuel supply, and battery condition |

| Overheating | Excessive heat, engine shutdown | Inspect coolant levels, clean cooling fins, and check oil levels |

| Rough Idling | Inconsistent running, vibrations | Clean or replace air filter, adjust carburetor settings |

| Excessive Smoke | Visible exhaust smoke, foul odor | Inspect oil levels, check for worn piston rings or valve seals |

| Fuel Leaks | Puddles under unit, fuel odor | Inspect fuel lines, connections, and seals for damage |

Essential Tools for Engine Repair

When it comes to maintaining and fixing machinery, having the right instruments is crucial for effective work. These tools not only facilitate the process but also ensure that tasks are completed safely and accurately. Below is a list of indispensable items that every technician should have in their toolkit.

- Socket Set: A comprehensive socket set allows for easy access to various fasteners, ensuring efficient assembly and disassembly.

- Wrenches: Both adjustable and fixed wrenches are essential for gripping and turning nuts and bolts.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for handling screws of different types.

- Pliers: Needle-nose pliers and locking pliers provide excellent grip and leverage for manipulating small components.

- Torque Wrench: This tool is vital for applying the correct amount of force when tightening fasteners, preventing damage from over-tightening.

- Multimeter: A multimeter helps in diagnosing electrical issues by measuring voltage, current, and resistance.

- Cleaning Supplies: Brushes, rags, and degreasers are important for maintaining cleanliness and preventing contamination during work.

- Safety Gear: Gloves, goggles, and masks protect the technician from potential hazards encountered during tasks.

Equipping yourself with these fundamental tools enhances your ability to tackle various challenges effectively, ensuring that your projects are completed with precision and care.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues with your machinery. By following a systematic procedure, you can identify and resolve common problems efficiently. Each step is designed to help you understand the potential causes and solutions, ensuring optimal performance.

Common Issues and Their Solutions

| Problem | Possible Cause | Recommended Action |

|---|---|---|

| Won’t start | Insufficient fuel or clogged filter | Check fuel level and replace filter if needed |

| Excessive noise | Loose components | Tighten all bolts and screws |

| Overheating | Blocked air intake | Clean air intake and check cooling fins |

| Poor performance | Dirty spark plug | Clean or replace the spark plug |

Step-by-Step Diagnostic Process

To effectively troubleshoot, follow these outlined steps:

- Identify the symptoms of the issue.

- Refer to the table for potential causes and solutions.

- Test each possible solution sequentially.

- Document the outcomes to track which methods were effective.

By adhering to this guide, you will enhance your understanding and ability to maintain your equipment with confidence.

Maintaining Your Kohler Small Engine

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Implementing a consistent maintenance routine can prevent potential issues and enhance the efficiency of your power equipment.

Essential Maintenance Tasks

Focus on the following key areas to keep your apparatus in peak condition:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace the oil to ensure smooth operation and reduce wear. |

| Air Filter Cleaning | Every 25 hours | Clean or replace the air filter to maintain airflow and performance. |

| Spark Plug Inspection | Every 100 hours | Check and replace spark plugs to ensure reliable starting and efficient combustion. |

| Fuel System Check | Before use | Inspect the fuel lines and filter for any clogs or leaks. |

Storage and Winterization

Proper storage practices are vital to prevent deterioration during off-seasons. Drain fuel, clean components, and store in a dry, sheltered location to protect your investment.

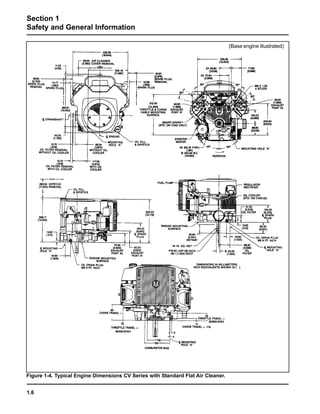

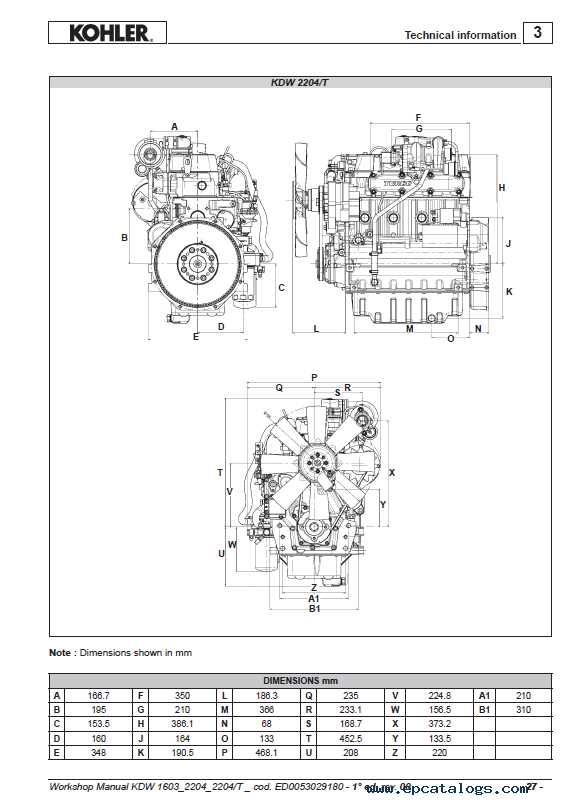

Understanding Engine Components and Parts

Grasping the fundamental elements and their functions is crucial for anyone working with mechanical power sources. Each segment plays a pivotal role in ensuring optimal performance and efficiency. Familiarity with these components not only aids in diagnostics but also enhances overall comprehension of the machinery.

Power Unit: The heart of the system, responsible for converting fuel into mechanical energy. Its design affects the overall output and efficiency.

Fuel Delivery System: This assembly manages the flow of fuel to the combustion chamber. It includes parts like the carburetor or fuel injector, which atomize the fuel for proper combustion.

Ignition System: This setup initiates the combustion process. It typically involves spark plugs or ignition coils, ensuring a reliable start and consistent operation.

Cooling Mechanism: Essential for maintaining optimal operating temperatures, this system prevents overheating. It may include fans, radiators, or liquid cooling systems, depending on the design.

Exhaust System: Responsible for directing harmful gases away from the operational area, this assembly also affects performance. Proper maintenance ensures efficient expulsion of exhaust fumes.

Lubrication System: Vital for reducing friction between moving parts, this system distributes oil to ensure smooth operation and longevity of the components.

Understanding these key parts enhances troubleshooting abilities and fosters a deeper appreciation for mechanical systems, leading to improved maintenance practices and performance optimization.

Fuel System Diagnostics and Repairs

The fuel system is a crucial component for optimal performance, and understanding its intricacies can significantly enhance functionality. Proper diagnostics and maintenance of this system can prevent issues that may arise from improper fuel delivery, contamination, or mechanical failures.

Identifying Common Issues: Various symptoms indicate potential problems within the fuel delivery mechanism. These may include hard starting, poor acceleration, or stalling. Diagnosing these issues requires careful observation and testing to pinpoint the source of the malfunction.

Inspection Steps: Begin by examining the fuel lines for any leaks, cracks, or blockages. Ensure that filters are clean and free from debris. Additionally, checking the fuel pump’s operation is essential, as it must generate adequate pressure for proper function. If necessary, utilize a pressure gauge to confirm the pump’s performance.

Repair Techniques: For minor leaks, replacement of damaged hoses or connections may suffice. If the filter is clogged, replacing it will often resolve flow issues. In cases of pump failure, it may require complete replacement to restore efficiency. Always consult the specifications for proper parts and procedures.

Preventative Maintenance: Regularly scheduled inspections and cleaning can help maintain system integrity. Using high-quality fuel and ensuring the tank is free from contaminants can greatly extend the lifespan of the components involved. By taking these proactive measures, the likelihood of encountering significant issues can be minimized.

Electrical System Troubleshooting Techniques

Diagnosing electrical issues in machinery requires a systematic approach to identify the root cause of malfunctions. Understanding the basic components and their interactions is essential for effective problem-solving. This section outlines key methods to troubleshoot electrical systems, ensuring efficient operation and reliability.

Begin by checking the power supply to confirm that all connections are secure and functioning properly. Inspect fuses and circuit breakers for any signs of damage or malfunction. If power appears to be flowing correctly, proceed to examine wiring for frays, corrosion, or loose terminals that could disrupt the circuit.

Utilize a multimeter to measure voltage, resistance, and continuity throughout the system. This tool can help pinpoint specific areas of concern, such as faulty switches or defective components. Be sure to test each part systematically, starting from the power source and working your way through to the load.

If issues persist after these checks, consider the role of relays and solenoids. Testing these components separately can reveal whether they are operating as intended. Additionally, pay attention to grounding; poor connections can lead to erratic behavior or complete failure.

Finally, consult schematics for the electrical layout of the system, as these diagrams can provide valuable insights into how components interact and may highlight areas that require further investigation. By following these techniques, users can effectively address and resolve electrical challenges, ensuring optimal performance.

Oil Change Procedures for Longevity

Regular maintenance of lubricants is essential for ensuring optimal performance and extending the lifespan of mechanical systems. Properly executed oil changes not only enhance functionality but also prevent premature wear and tear, ultimately saving time and resources.

Benefits of Regular Oil Changes

- Improved Efficiency: Clean oil reduces friction, allowing components to work more smoothly.

- Enhanced Protection: Fresh lubricant helps to protect against corrosion and deposits.

- Extended Life Span: Consistent maintenance significantly increases the durability of mechanical parts.

Steps for Effective Oil Changes

- Gather Necessary Tools: Ensure you have the right tools, including a wrench, oil filter wrench, and a suitable container for used oil.

- Warm Up the System: Running the system briefly warms the oil, making it easier to drain.

- Drain the Old Oil: Locate the drain plug, remove it, and allow the used oil to flow completely into the container.

- Replace the Oil Filter: Remove the old filter and install a new one to ensure optimal filtration.

- Add New Oil: Refill with the appropriate lubricant, checking the level with the dipstick to avoid overfilling.

- Dispose of Used Oil Properly: Take the used lubricant to a recycling center to protect the environment.

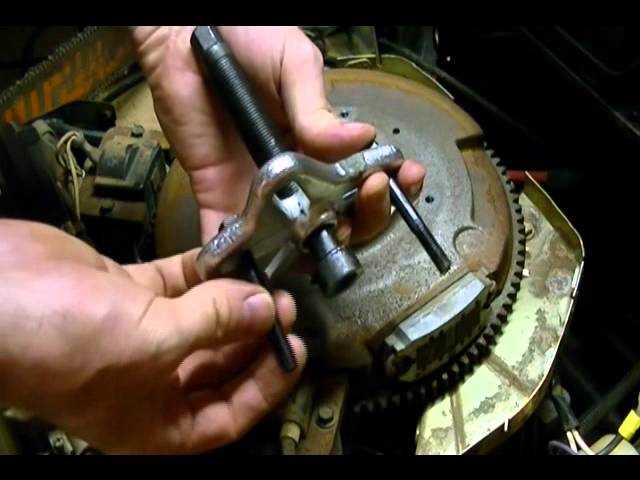

Rebuilding Kohler Engines: Key Steps

Revitalizing a power unit can be a rewarding endeavor, bringing new life to a machine that has seen better days. This process involves several essential phases to ensure optimal performance and longevity. Understanding these stages is crucial for achieving a successful overhaul.

- Preparation:

- Gather all necessary tools and parts.

- Create a clean and organized workspace.

- Review the specifications and guidelines relevant to your model.

- Disassembly:

- Carefully remove external components.

- Label parts to facilitate reassembly.

- Take notes or photos to remember configurations.

- Inspection:

- Examine all components for wear and damage.

- Check seals and gaskets for integrity.

- Assess the condition of internal parts such as pistons and crankshafts.

- Cleaning:

- Thoroughly clean all parts to remove dirt and debris.

- Use appropriate solvents for stubborn deposits.

- Ensure all passages are clear of obstructions.

- Reassembly:

- Replace any worn or damaged components with new parts.

- Follow the original assembly sequence closely.

- Use fresh lubricants where needed to prevent friction.

- Testing:

- Run the unit to check for smooth operation.

- Listen for unusual noises that may indicate issues.

- Monitor for leaks and ensure proper function.

By adhering to these fundamental steps, one can effectively breathe new life into a weary machine, ensuring it operates efficiently for years to come.

Safety Tips for Engine Repairs

Ensuring a safe working environment is crucial when performing maintenance on machinery. Adopting proper precautions can prevent accidents and injuries, allowing for a smoother and more efficient process. Here are essential guidelines to follow while handling mechanical tasks.

Preparation Before Starting

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure your workspace is well-ventilated and free from clutter to reduce hazards.

- Gather all necessary tools and materials beforehand to minimize distractions.

During the Work Process

- Disconnect any power sources before beginning work to prevent accidental starts.

- Keep flammable materials away from your workspace to avoid fire risks.

- Stay focused and avoid multitasking to maintain attention on the task at hand.

- Use tools and equipment as intended to prevent damage and injury.

By adhering to these guidelines, you can create a safer environment that promotes efficient work and minimizes risks. Prioritize safety to protect yourself and those around you.

When to Seek Professional Help

Understanding when to call in an expert can significantly impact the longevity and functionality of your machinery. While many tasks can be tackled independently, certain situations demand specialized knowledge and skills that only a trained technician can provide. Recognizing the signs that indicate a need for professional intervention is crucial for ensuring optimal performance and preventing further issues.

Signs Indicating a Need for Expertise

If you encounter persistent problems that do not resolve with basic troubleshooting, it’s time to consider enlisting professional assistance. This includes unusual noises, leaks, or performance inconsistencies that remain unaddressed after following standard guidelines. Moreover, if you lack the necessary tools or confidence to perform intricate tasks, seeking help is a wise choice.

Complex Issues and Safety Concerns

Certain complications, especially those involving electrical components or intricate mechanical systems, require an expert’s touch. Furthermore, safety should always be a priority. If there’s a risk of injury or damage to the unit, consulting a professional can prevent dangerous situations and costly repairs. Trusting an experienced technician ensures that the work is done correctly and safely.