This section provides essential insights into the maintenance and restoration of compact combustion systems, designed for various applications. Whether you’re a novice or an experienced technician, understanding the intricacies of these systems is vital for optimal performance and longevity.

Through detailed examinations and step-by-step instructions, this guide aims to empower users to tackle common challenges effectively. By delving into each component’s functionality and potential issues, individuals will be equipped to enhance their operational knowledge and skills.

Furthermore, this resource emphasizes preventative measures, ensuring that users can minimize wear and tear while maximizing efficiency. Engaging with the nuances of these units not only fosters a deeper appreciation for their mechanics but also aids in achieving the ultimate goal of seamless functionality.

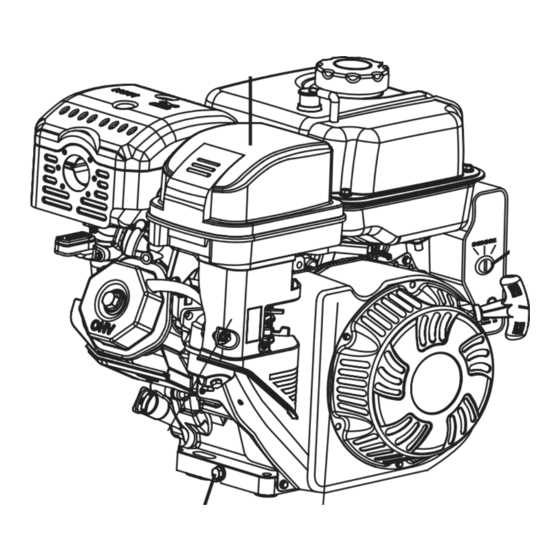

Understanding the Predator 420cc Engine

This section delves into the intricacies of a popular power unit often used in various applications. Gaining insights into its construction, features, and performance can enhance the user experience and ensure optimal functionality.

Key Features

- Compact design for versatile usage.

- Robust construction for durability and reliability.

- High torque output for effective power delivery.

- Easy accessibility for maintenance tasks.

Applications

- Garden equipment such as lawn mowers and tillers.

- Generator systems for emergency power supply.

- Go-karts and other recreational vehicles.

- Utility tasks requiring portable power solutions.

Common Issues and Symptoms

Understanding frequent problems that can arise with small combustion systems is essential for effective troubleshooting. Recognizing these challenges early can save time and enhance the overall performance of the unit.

Starting Difficulties

One of the most prevalent concerns is difficulty in initiating the system. This can manifest as a lack of response when the starter is engaged or unusual sounds indicating a malfunction. Factors such as fuel delivery issues, air blockage, or spark plug problems may contribute to this symptom.

Unusual Noises

Operators may notice unexpected sounds during operation, which often signal underlying issues. Knocking or tapping noises might indicate wear on internal components or insufficient lubrication. Regular maintenance and timely inspections can help mitigate these risks and prolong the lifespan of the unit.

Tools Needed for Repair

When undertaking maintenance tasks, having the right instruments is crucial for achieving optimal results. The appropriate tools not only facilitate the process but also ensure safety and efficiency. This section outlines essential equipment that will aid in troubleshooting and fixing various components.

Wrenches are indispensable for loosening and tightening bolts and nuts. A variety of sizes will be necessary to accommodate different fasteners. Additionally, screwdrivers with both flat and Phillips heads will be required for removing covers and accessing internal parts.

Socket sets can greatly enhance the efficiency of working with various fittings, allowing for quick adjustments. A spark plug wrench is specifically designed for easy removal and installation of spark plugs, ensuring proper ignition performance.

For more intricate tasks, consider having a torque wrench to apply the correct amount of force, preventing damage to sensitive components. A multimeter can be invaluable for diagnosing electrical issues, while pliers will assist in gripping and manipulating small parts.

Lastly, a comprehensive toolbox will help keep everything organized, making it easier to locate instruments as needed. Being well-equipped will lead to a smoother and more successful undertaking.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully taking apart the unit for thorough inspection and maintenance. Following these steps will ensure each component is removed systematically, allowing for efficient troubleshooting and replacement of parts as needed.

Preparation

Before commencing the disassembly, gather all necessary tools such as wrenches, screwdrivers, and pliers. Ensure the workspace is clean and well-lit to facilitate visibility and accessibility. It is advisable to have a container for small parts to prevent loss during the process.

Disassembly Steps

Start by disconnecting the fuel supply and removing the cover to access the inner components. Proceed to detach any attached elements, such as the carburetor and exhaust, by loosening their respective bolts. Continue working methodically, documenting each step to assist with reassembly. Pay special attention to the orientation and placement of each part, ensuring they are stored safely for later installation.

Inspecting Internal Components

Regular examination of the internal parts is crucial for maintaining optimal performance and longevity of the unit. Understanding how to assess these components can help identify potential issues before they escalate, ensuring efficient operation.

Key Components to Examine

- Cylinder head

- Piston and rings

- Crankshaft

- Connecting rod

- Valves and springs

Inspection Steps

- Remove the outer casing to gain access to internal parts.

- Carefully check for wear and damage on each component.

- Measure clearances using appropriate tools.

- Look for signs of carbon buildup or corrosion.

- Document findings for future reference and necessary actions.

Reassembling the Engine Correctly

Properly putting components back together is crucial for optimal performance and longevity. Each part must be aligned accurately to ensure seamless operation. Following a systematic approach helps prevent issues that may arise from improper assembly.

Begin by gathering all necessary components and tools. Ensure that each piece is clean and free of debris. Carefully refer to documentation for specific torque specifications and alignment guidelines. Utilizing new gaskets and seals is essential to avoid leaks and ensure a tight fit.

During reassembly, pay attention to the sequence of operations. Start with the lower assembly, progressively adding components while checking for any signs of wear or damage. Confirm that all fasteners are securely tightened but avoid over-tightening, which can lead to breakage.

Finally, once everything is back in place, conduct a thorough inspection. Verify that all systems are functional and that there are no residual issues from previous disassembly. Following these steps will enhance reliability and performance, providing peace of mind for future use.

Fuel System Troubleshooting Tips

Maintaining optimal performance of the fuel delivery system is crucial for ensuring smooth operation. Various issues can arise that may affect efficiency and functionality. Here are some helpful strategies to diagnose and resolve common problems.

- Inspect Fuel Quality: Ensure that the fuel is clean and free from contaminants. Old or stale fuel can lead to poor combustion.

- Check Fuel Lines: Examine all lines for leaks, cracks, or blockages. Damaged lines can disrupt flow and cause performance issues.

- Examine Filters: Regularly inspect and replace fuel filters as needed. Clogged filters can restrict flow and impact performance.

- Evaluate the Carburetor: Clean or adjust the carburetor to ensure proper fuel-air mixture. Issues here can lead to starting difficulties or rough idling.

- Test Fuel Pump: Ensure that the pump is functioning correctly. Listen for unusual noises or vibrations that may indicate failure.

By systematically addressing these areas, one can effectively troubleshoot and resolve issues related to the fuel delivery system.

Ignition System Maintenance Procedures

Regular upkeep of the ignition mechanism is crucial for optimal performance and longevity. This section outlines essential tasks to ensure the system operates smoothly, enhancing reliability and efficiency.

Key maintenance steps include:

- Inspecting the ignition components for wear and damage.

- Replacing faulty spark plugs to maintain strong combustion.

- Cleaning the ignition coil terminals to ensure proper electrical connection.

- Checking and adjusting the ignition timing as needed.

Follow these procedures regularly to avoid issues and ensure your machinery runs at peak performance.

Lubrication Guidelines for Longevity

Proper maintenance of internal components is crucial for enhancing the lifespan and performance of your machinery. Regular application of suitable lubricants reduces friction, minimizes wear, and ensures optimal functionality over time.

Here are essential guidelines to follow:

- Select the Right Lubricant: Choose a high-quality lubricant that meets the specifications recommended for your system.

- Maintain Proper Levels: Regularly check and maintain lubricant levels to avoid dry running conditions.

- Regular Changes: Change the lubricant at recommended intervals to remove contaminants and prevent sludge buildup.

- Clean Surfaces: Before applying new lubricant, ensure that all surfaces are clean to promote effective adhesion.

Adhering to these guidelines will contribute significantly to the efficiency and durability of your machinery, ultimately leading to fewer repairs and extended service life.

Cleaning the Air Filter Efficiently

Maintaining optimal airflow is essential for ensuring the smooth operation of small machinery. A clean air filtration component plays a vital role in enhancing performance and prolonging the lifespan of the equipment. Regular cleaning is necessary to prevent debris accumulation, which can lead to inefficiencies and potential damage.

Step-by-Step Cleaning Process

Begin by removing the filtration element from its housing. Inspect it for any visible dirt or obstructions. If the component is foam-based, rinse it gently under lukewarm water. For paper filters, use a soft brush to eliminate dust. Avoid using harsh chemicals, as they may deteriorate the material.

Drying and Reinstallation

After cleaning, ensure the filtration component is thoroughly dried. This step is crucial, as moisture can lead to mold growth. Once dry, reinsert the filter back into its original position, ensuring a snug fit. Regular maintenance not only improves performance but also contributes to fuel efficiency and reliability.

Performance Upgrades for Enhanced Power

Enhancing the output of your small combustion system can significantly improve its efficiency and overall performance. Various modifications can be implemented to increase horsepower and torque, resulting in a more responsive and robust unit.

Here are some effective upgrades to consider:

- High-Performance Air Filter: Replacing the stock air filter with a high-flow variant allows for better airflow, enhancing combustion and power delivery.

- Exhaust System Upgrade: Installing a performance exhaust system reduces back pressure, improving exhaust flow and enabling the unit to breathe more freely.

- Carburetor Tuning: Adjusting the carburetor settings can optimize fuel-air mixture, resulting in improved acceleration and efficiency.

- Camshaft Replacement: Upgrading to a performance camshaft can significantly alter valve timing, allowing for increased airflow and enhanced performance characteristics.

- Ignition System Enhancement: An upgraded ignition system provides a stronger spark, improving combustion efficiency and responsiveness.

Implementing these upgrades can lead to a noticeable improvement in performance, making your small engine more powerful and enjoyable to operate.

Safety Precautions During Repairs

When working on machinery, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Adhering to basic guidelines can significantly reduce the risk of injury and equipment damage.

Before beginning any task, ensure you are equipped with the appropriate protective gear. This includes gloves, goggles, and sturdy footwear. Such precautions will protect against potential hazards like flying debris or sharp components.

Always work in a well-ventilated area. Proper airflow minimizes the accumulation of harmful fumes and reduces the risk of fire. If necessary, use fans or open windows to enhance circulation.

Disconnect all power sources before initiating any maintenance. This simple step is crucial in avoiding electric shocks and unintentional activation of the equipment during work.

Familiarize yourself with the specific components you are handling. Understanding how different parts interact can help identify potential issues and streamline the process. If unsure, consult relevant documentation or seek expert advice.

Finally, maintain a clean workspace. Clutter can lead to accidents, so ensure all tools and materials are organized and within reach. This practice not only enhances safety but also improves efficiency.