The world of off-road vehicles offers enthusiasts a unique blend of adventure and engineering. Understanding the intricacies of these robust machines enhances both the ownership experience and the capability to navigate challenging terrains. This section aims to provide essential insights into the maintenance and troubleshooting of these powerful vehicles.

Equipping oneself with the right knowledge is crucial for ensuring longevity and optimal performance. By delving into various aspects of vehicle care, users can identify potential issues before they escalate. This proactive approach not only saves time but also enhances safety during excursions.

From basic upkeep to more complex interventions, a thorough grasp of vehicle functions empowers owners to tackle repairs confidently. Knowledge of specific components and systems can transform any vehicle enthusiast into a skilled caretaker of their prized possession, ready to conquer the wild.

Common Issues in Jeep JL Models

This section discusses frequent challenges encountered in specific off-road vehicles, highlighting their characteristics and performance concerns. Understanding these common issues can aid owners in maintaining their vehicles effectively.

- Electrical Problems: Many users report issues with electrical components, such as malfunctioning sensors and battery drain.

- Transmission Concerns: Some drivers experience shifting difficulties, which can affect overall driving comfort and efficiency.

- Suspension Wear: The suspension system may show signs of wear earlier than expected, impacting ride quality and handling.

Addressing these concerns promptly can enhance the longevity and reliability of the vehicle.

Tools Needed for Maintenance Tasks

Proper upkeep of your vehicle requires a variety of essential instruments. Having the right tools on hand can simplify tasks, enhance efficiency, and ensure safety while performing maintenance duties.

- Basic Hand Tools:

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers

- Specialty Tools:

- Torque wrench

- Oil filter wrench

- Diagnostic scanner

- Cleaning Supplies:

- Shop towels

- Degreaser

- Protective gloves

- Safety Equipment:

- Safety glasses

- Steel-toed boots

- First aid kit

Gathering these tools will help facilitate effective maintenance, ultimately prolonging the lifespan of your vehicle and enhancing performance.

Step-by-Step Engine Repair Guide

This section provides a comprehensive approach to addressing common issues related to engine functionality. Following these structured steps can help ensure effective troubleshooting and restoration, enhancing performance and reliability.

-

Preparation: Gather necessary tools and safety equipment. Ensure you have access to a clean workspace with adequate lighting.

-

Diagnostic Assessment: Begin by inspecting the engine for any visible signs of wear or damage. Listen for unusual noises and check fluid levels.

-

Disassembly: Carefully remove components such as the intake manifold, exhaust system, and other relevant parts. Keep track of screws and small items.

-

Inspection of Parts: Examine each component for cracks, corrosion, or excessive wear. Replace any damaged parts as necessary.

-

Cleaning: Thoroughly clean all parts using appropriate solvents. Ensure that all surfaces are free from debris and residue.

-

Reassembly: Begin reassembling the engine, following the reverse order of disassembly. Pay attention to torque specifications for bolts and connections.

-

Testing: After reassembly, start the engine and monitor for any irregularities. Check for leaks and listen for unusual sounds during operation.

Following this structured process can help ensure a successful restoration of engine functionality, leading to improved overall performance.

Suspension System Troubleshooting Tips

The suspension system is crucial for maintaining vehicle stability and comfort while driving. Issues with this system can manifest in various ways, affecting handling and ride quality. Identifying and addressing these problems early can prevent further damage and enhance overall performance.

Start by observing any unusual noises, such as clunks or squeaks, when navigating bumps or potholes. These sounds may indicate worn components or loose connections. Inspecting the bushings and joints regularly can help catch issues before they escalate.

If you experience excessive bouncing or a rough ride, check the condition of the shock absorbers. Damaged or leaking shocks can significantly impair the vehicle’s ability to absorb impacts. Testing the bounce by pressing down on each corner of the vehicle can reveal potential failures–if the vehicle continues to bounce after releasing, it may be time for replacement.

Another important aspect is the alignment of the suspension. Misalignment can cause uneven tire wear and affect steering response. Regularly examining the alignment can ensure proper handling and improve safety.

Lastly, don’t overlook the importance of regular maintenance. Keeping an eye on all components, including springs and struts, will help maintain optimal performance and extend the life of the suspension system.

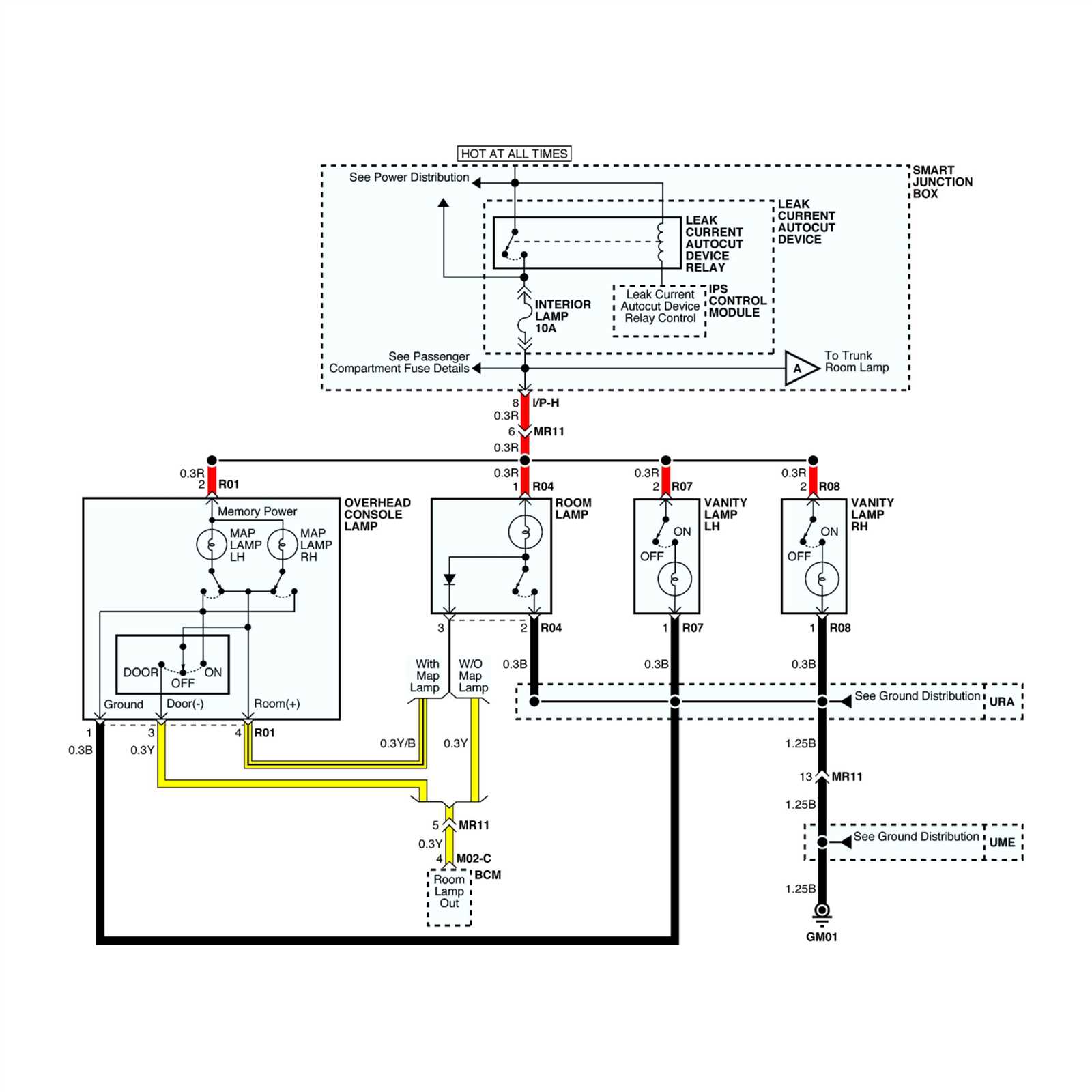

Electrical System Diagnosis Procedures

This section outlines essential methods for evaluating electrical components and their functions within the vehicle. A systematic approach ensures accurate identification of issues and promotes effective troubleshooting.

Begin by conducting a thorough visual inspection of wiring and connectors for signs of damage, corrosion, or loose connections. Utilize a multimeter to measure voltage, current, and resistance, confirming that each component operates within specified parameters.

Follow up by testing specific circuits sequentially. Use a wiring diagram to trace connections and identify potential faults. Pay attention to fuses and relays, as these can often be the source of electrical problems.

For advanced diagnostics, consider employing specialized scanning tools that can communicate with the vehicle’s onboard systems. These tools provide valuable insights and error codes that assist in pinpointing the root cause of electrical malfunctions.

Finally, document all findings and repairs made during the diagnosis process. This record not only aids in future troubleshooting but also serves as a reference for maintenance and repairs.

Braking System Inspection and Repair

The braking system is a critical component of any vehicle, ensuring safety and performance during operation. Regular examination and maintenance of this system are essential to prevent potential failures and ensure optimal functionality. Understanding the key elements involved in this process will help maintain the effectiveness of the braking mechanisms.

Components to Inspect

Begin by checking the brake pads and rotors for wear. Worn pads can lead to decreased stopping power, while damaged rotors may cause vibrations during braking. Additionally, inspect the brake fluid levels and look for any signs of leaks in the hydraulic lines, as these issues can compromise overall braking efficiency.

Maintenance Procedures

Routine maintenance should include cleaning the braking components to remove debris and contaminants. It is also advisable to replace any worn or damaged parts promptly. Timely interventions not only enhance safety but also extend the lifespan of the braking system, ensuring reliable performance under various driving conditions.

Transmission Maintenance Best Practices

Proper upkeep of the transmission system is essential for ensuring optimal performance and longevity of any vehicle. Adopting effective maintenance strategies can help prevent costly repairs and enhance driving experience.

Regular Fluid Checks

- Monitor fluid levels regularly to ensure they are within the recommended range.

- Inspect fluid condition for discoloration or burning smell, which indicates contamination.

- Replace transmission fluid according to manufacturer recommendations to maintain efficiency.

Scheduled Inspections

- Conduct periodic inspections of the transmission system for leaks and wear.

- Check components such as seals and gaskets for any signs of damage.

- Utilize professional services for comprehensive evaluations to identify potential issues early.

DIY Modifications for Enhanced Performance

Enhancing the performance of your off-road vehicle can be an exciting project for enthusiasts. There are various modifications you can undertake to improve handling, power, and overall driving experience. These upgrades not only elevate performance but can also provide a more enjoyable and tailored driving experience.

Suspension Upgrades

Improving the suspension system is one of the most effective ways to enhance performance. Upgrading to quality shock absorbers and springs can significantly increase stability and control, especially on rugged terrains. Consider a lift kit for added ground clearance, allowing for better obstacle navigation and a more commanding presence on the trail.

Engine Enhancements

Boosting engine performance can be achieved through various methods. Installing a high-flow air intake system can improve airflow, while a performance exhaust system can enhance engine efficiency. These modifications not only increase horsepower but also contribute to a more aggressive sound and improved throttle response. Regular tuning and maintenance ensure that your upgrades work harmoniously with the existing engine components.

Seasonal Maintenance Checklist for Jeep JL

Regular upkeep is essential to ensure optimal performance and longevity of your vehicle. Each season brings unique challenges and conditions that can affect various components. A proactive approach to maintenance helps identify potential issues before they escalate, ensuring a smooth driving experience throughout the year.

Spring and Summer Considerations

As temperatures rise, it’s crucial to check the cooling system. Ensure that the coolant levels are adequate and that there are no leaks. Additionally, inspect the air conditioning system for efficient operation, and replace the cabin air filter to maintain air quality. Tires should be examined for wear and proper inflation, as they significantly affect handling and safety.

Fall and Winter Preparations

As colder weather approaches, focus on the battery’s condition, as low temperatures can impact its performance. Inspect the wiper blades and replace them if necessary to ensure clear visibility during rain or snow. Also, verify that the antifreeze levels are sufficient to prevent freezing, and consider switching to winter tires for enhanced traction in slippery conditions.

Finding Replacement Parts Effectively

When it comes to maintaining your vehicle, sourcing suitable components is crucial for ensuring optimal performance and longevity. Whether you’re looking for upgrades or essential parts, understanding how to navigate the market can make all the difference.

Researching Reliable Suppliers

Start by identifying reputable suppliers who specialize in automotive components. Online reviews and community forums can provide insights into their reliability and customer service. Consider visiting local shops as well, as they may offer personalized assistance and immediate availability of parts.

Utilizing Online Resources

Leverage various online platforms to compare prices and availability. Websites dedicated to automotive enthusiasts often feature parts catalogs, forums for discussion, and user feedback that can guide your purchasing decisions. Always ensure the parts meet the specifications required for your model.